Stainless steel surface scale removal method and pickling solution adopted by same

A surface oxidation and stainless steel technology, which is applied in the fields of pickling solution and stainless steel surface scale removal, can solve the problems of fluorine-containing compounds environmental pollution, poor effect, water pollution, etc., achieve smooth stainless steel surface, prevent over-corrosion, and simplify processing The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0024] The stainless steel surface scale removal method of the present embodiment is as follows:

[0025] Put the stainless steel parts into the pickling solution at room temperature (15-25 °C, the same below) for 30 minutes to remove the scale on the stainless steel surface, then take out the stainless steel parts and put them in deionized water for ultrasonic cleaning for 15 minutes, and finally Stainless steel parts can be taken out and dried with hot air.

[0026] The pickling liquid of the present embodiment is the aqueous solution that is made up of the component of following concentration: dilute sulfuric acid 200mL / L, oxalic acid 3g / L, coconut oil fatty acid 3g / L, sodium hexametaphosphate 3g / L, urotropine 3g / L. The concentration of dilute sulfuric acid is 30wt%.

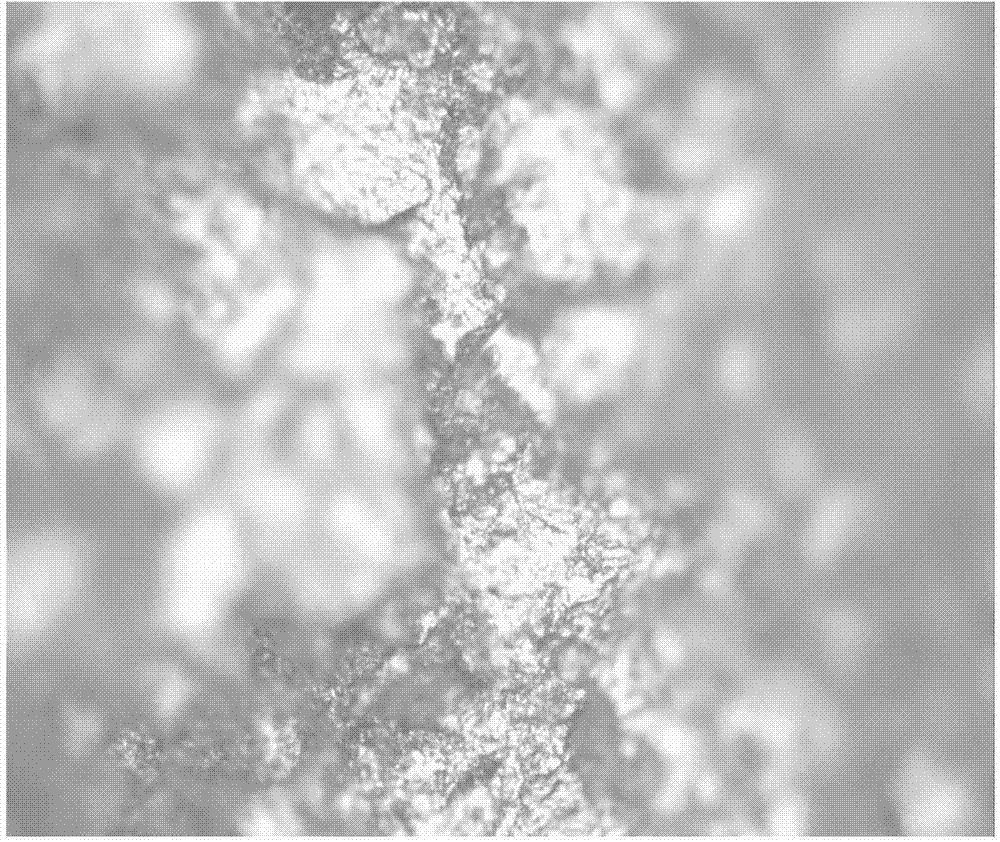

[0027] The metallographic microscope photograph of the stainless steel surface after the present embodiment is processed sees figure 1 .

Embodiment 2~ Embodiment 3)

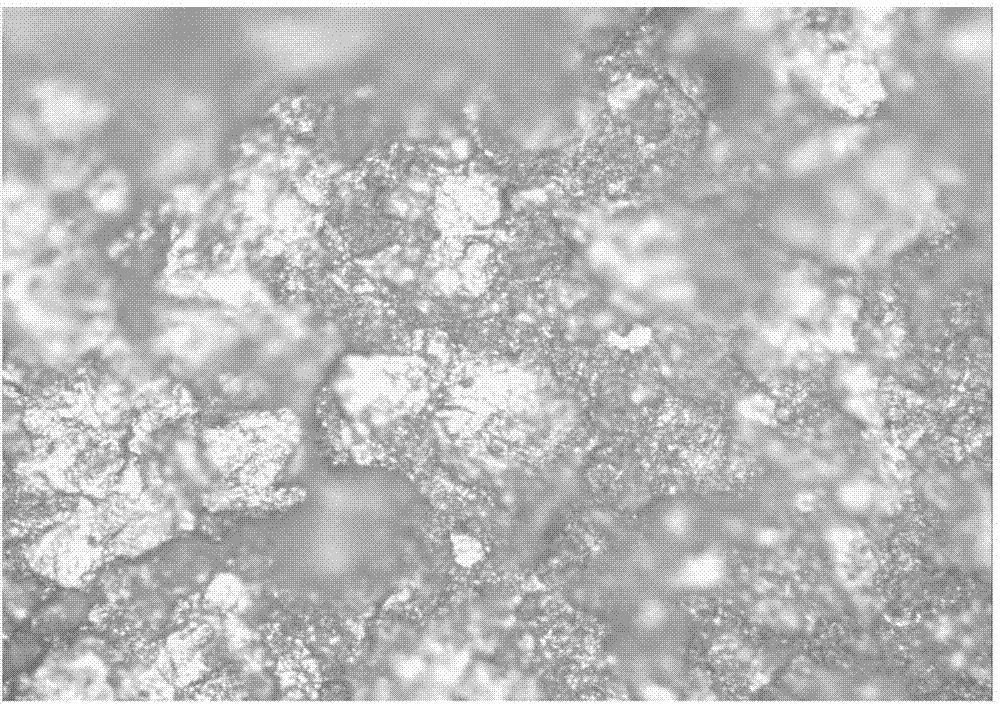

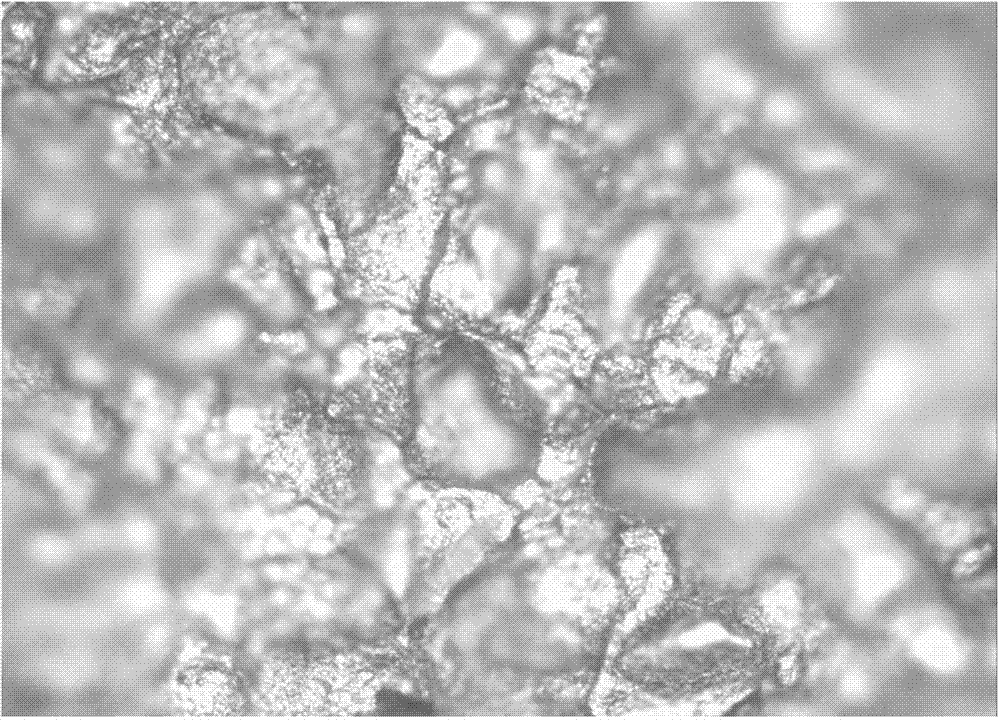

[0029] Each embodiment is basically the same as Embodiment 1, and the differences are shown in Table 1. The metallographic microscope photographs of the stainless steel surface after each embodiment process are shown in respectively figure 2 and image 3 .

[0030] auxiliary acid Surfactant Example 1 3g / L oxalic acid 3g / L coconut oil fatty acid Example 2 3g / L citric acid 3g / L nonylphenol polyoxyethylene ether Example 3 3g / L phytic acid 1.5g / L coconut oil fatty acid + 1.5g / L nonylphenol polyoxyethylene ether

[0031] Depend on Figure 1 ~ Figure 3 It can be seen that the surface effect of the stainless steel treated by the method of Example 3 is the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com