Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "No acid mist" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cleaning agent and cleaning method for air conditioner

InactiveCN101475878AImprove heating efficiencyImprove cooling efficiencyNon-ionic surface-active compoundsFlush cleaningStrong acidsHigh pressure water

The invention discloses a detergent and a cleaning method for a complete air-conditioner, which not only can uniformly and completely remove dirt but also cannot strongly corrupt components and parts such as aluminum, copper and stainless steel, are time-saving and labor saving, safe and reliable, and pollution-free, and have low cost. Raw materials of the detergent are at least two compositions of citric acid, inorganic weak acid and inorganic strong acid; a non-ionic surfactant or a non-ionic surfactant is mixed with an anionic surfactant; and the detergent comprises an oxygen solvent, an acid corrosion inhibitor, and the balance being water. The cleaning method comprises: disassembling a motor and a fan, and taking off the motor and the fan for independent cleaning; preparing the detergent into an aqueous solution according to the proportion of between 10 and 15 percent, hanging the complete air-conditioner after disassembly of the motor and the fan into a cleaning tank, soaking the complete air-conditioner for 30 minutes at normal temperature, and starting ultrasonic waves to clean for 10 to 30 minutes; placing the complete air-conditioner into a washing tank, and using a high-pressure water gun to spray the surface and the inside of the air-conditioner; and using hot blast to dry the air-conditioner at a temperature of 80 DEG C.

Owner:DALIAN SANDAAOKE CHEM

Pickling and passivating treatment process for stainless steel pipes

InactiveCN102220591AImprove surface qualityImprove efficiencyMetallic material coating processesGramPotassium dichromate

The invention discloses a pickling and passivating treatment process for stainless steel pipes, which comprises the steps of pretreatment, liquid preparation and pickling and passivating treatment, wherein the pickling and passivating liquid consists of 20 to 22 percent of nitric acid (with specific gravity of 1.42), 30 to 50 grams per liter of potassium dichromate, 30 to 50 grams per liter of additive and the balance of water. In the pickling and passivating treatment process, pickling and passivating are accomplished in one step to form silvery white bright beautiful surfaces of the stainless steel pipes and form high-quality passivated films, so that the surface quality of the treated metal pipes is improved and the treated metal pipes have high corrosion resistance; the descaling speed and the descaling efficiency are high; the corrosion of the metal substrates is small and the corrosion inhibition rate is high; and acid mist in a cleaning operation process is avoided, and the long-existing NOx and HF serious pollution problem of stainless steel continuous pickling and passivating is solved.

Owner:扬州华宇管件有限公司

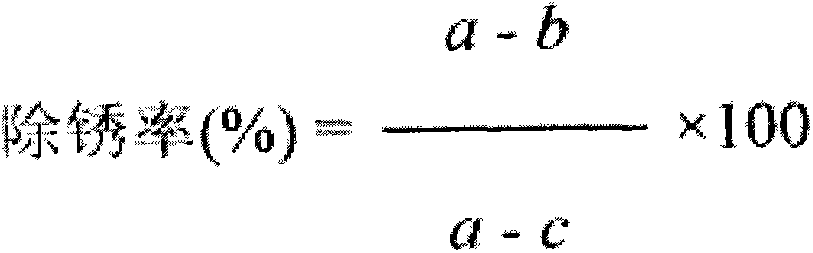

Brightening rust removing agent

The present invention relates to a substance which removes rustiness on the surface of steel and iron, in particular to brightening rust remover, which solves the problem that the steel and the iron have gloomy surfaces after the rust removing in the prior art. The brightening rust remover is composed of materials in the following weight ratio: chlorhydric acid is 30-50 percent, hexamethylene tetramine is 1-5 percent, sodium lauryl sulphate is 2-8 percent, peregal OS-15 is 5-10 percent, and the residual is water. The present invention has the characteristics that rustiness can be removed quickly, the steel and the iron are brighter than the original state after the rustiness is removed, no over corrosion and hydrogen brittleness phenomenon exist, no pollution exists, and the cost is low, etc. Since the difference of the degrees of corrosion, the rustiness removing time is generally within 1-5 minutes.

Owner:山西银河镀锌有限公司

High tin bronze plating solution for chemical plating of surface of tempered bead wire, and its chemical dip plating method

InactiveCN103924225AEasy to operateEasy to controlLiquid/solution decomposition chemical coatingChemical platingTurbidity

The invention discloses a high tin bronze plating solution for chemical plating of the surface of a tempered bead wire, and its chemical dip plating method. The plating solution comprises a main salt, a stabilizer with the concentration of 15-65g / L, a complexing agent with the concentration of 0.01-10g / L, and a solvent. The chemical dip plating solution is prepared by using the above components according to the proportions of the components, and after the tempered bead wire is plated through the chemical dip plating method, the method allows the thickness of a chemical plated high tin bronze layer of the tempered bead wire to be controlled in a range of 1.2-2.5mum, a mass ratio of the plated layer to the tempered bead wire to be stably controlled in a range of 0.15-0.80g / kg and the tin content of the plated layer to reach 8-12%. The method has the advantages of no electoplating, simple operation, easy control and low cost, and the plating solution has the advantages of certain oxidation resistance, unlikely turbidity, no acid mist, reduction of the maintenance cost, and good plating effect.

Owner:JIANGSU XINGDA STEEL TYPE CORD

Steel rust removing liquid

The invention provides a steel rust removing liquid which comprises the following components of oxalic acid, triethanolamine, phosphoric acid, hydrochloric acid, fatty alcohol-polyoxyethylene ether, hexamethylenetetramine and water. A buffering agent and an acid fog inhibiting agent are also added into the steel rust removing liquid provided by the invention besides using a few amount of organic acid. The steel rust removing liquid not only can well remove metal oxides, but also has the characteristics of retarding steel corrosion and inhibiting acid fog volatilization and the like.

Owner:陈瑜

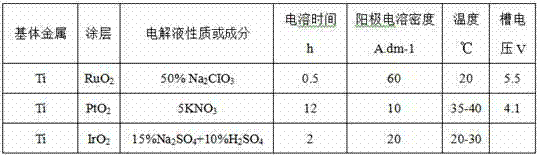

Method for recovering noble metal from waste titanium anodes with noble metal coatings

ActiveCN104775036AWide applicabilitySeparation and purification process cycle shortenedProcess efficiency improvementTitaniumPrecious metal

The invention provides a method for recovering noble metal from waste titanium anodes with noble metal coatings, and belongs to the technical field of metal sorting. After a stripping agent is heated, the waste titanium anodes, with the noble metal coatings, to be treated are immersed into the stripping agent to be soaked for several minutes so that the noble metal coatings can be stripped into the stripping agent, and then the remaining titanium anodes are taken out; in this way, the stripping agent is repeatedly used, solid-liquid separation is performed on the stripping agent to obtain filter residues and filter liquid, and a common noble metal separation and purification technology is performed on the filter residues, so that the pure noble metal is obtained; a common titanium recovery technology is performed on the filter liquid to recover titanium. The stripping recovery rate of the noble metal and the titanium-base anodes reaches up to 99%, and the purity of the noble metal can be larger than or equal to 99.95%; the loss of the titanium-base anodes is low and is smaller than or equal to 0.5%. The method is wide in application range and short in technology period, the maximum recovery rate of the noble metal is larger than or equal to 98%, and because the titanium-base anodes after the noble metal is stripped can be reused through repairing, the production cost is lowered. According to the method, operation is easy, heating temperature is low, no caking exists in a system, consumption of raw materials is low, no acid mist is generated, and the effects of energy saving and environmental friendliness are achieved.

Owner:KUNMING GUIYI METAL MATERIAL

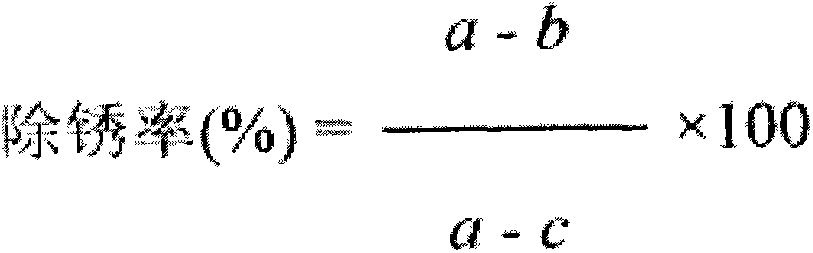

Rust remover and preparation method thereof

The invention discloses a rust remover and a preparation method thereof. The rust remover is prepared from the following components in percentage by mass: 60 to 80 percent of organic acid, 19 to 39 percent of inorganic acid and 0.8 to 3 percent of corrosion inhibitor, wherein the organic acid is one or more than two kinds of tartaric acid, citric acid, oxalic acid and trichloroacetic acid; the inorganic acid is one or more than two kinds of sulfamic acid, phosphorous acid and ammonium acid fluoride; and the corrosion inhibitor is benzotrizaole or / and sodium dihydrogen phosphate. According to the rust remover disclosed by the invention, the use of hydrochloric acid or sulfuric acid is completely avoided; no acid mist during rust removal is generated, the corrosion to equipment in a workshop is avoided and the labor environment is improved; meanwhile, the corrosion inhibitor is weaker in acidity, the over corrosion to workpieces is avoided and the condition that the skin of an operator is severely corroded is prevented; in addition, after a certain amount of workpieces are treated, the rust removing efficiency is reduced; and by continuously adding the rust remover disclosed by the invention, the rust removing efficiency can be restored, i.e., a rust removing bath solution disclosed by the invention can be conveniently and repeatedly used.

Owner:ZHONGSHAN HUAGUANG CHEM

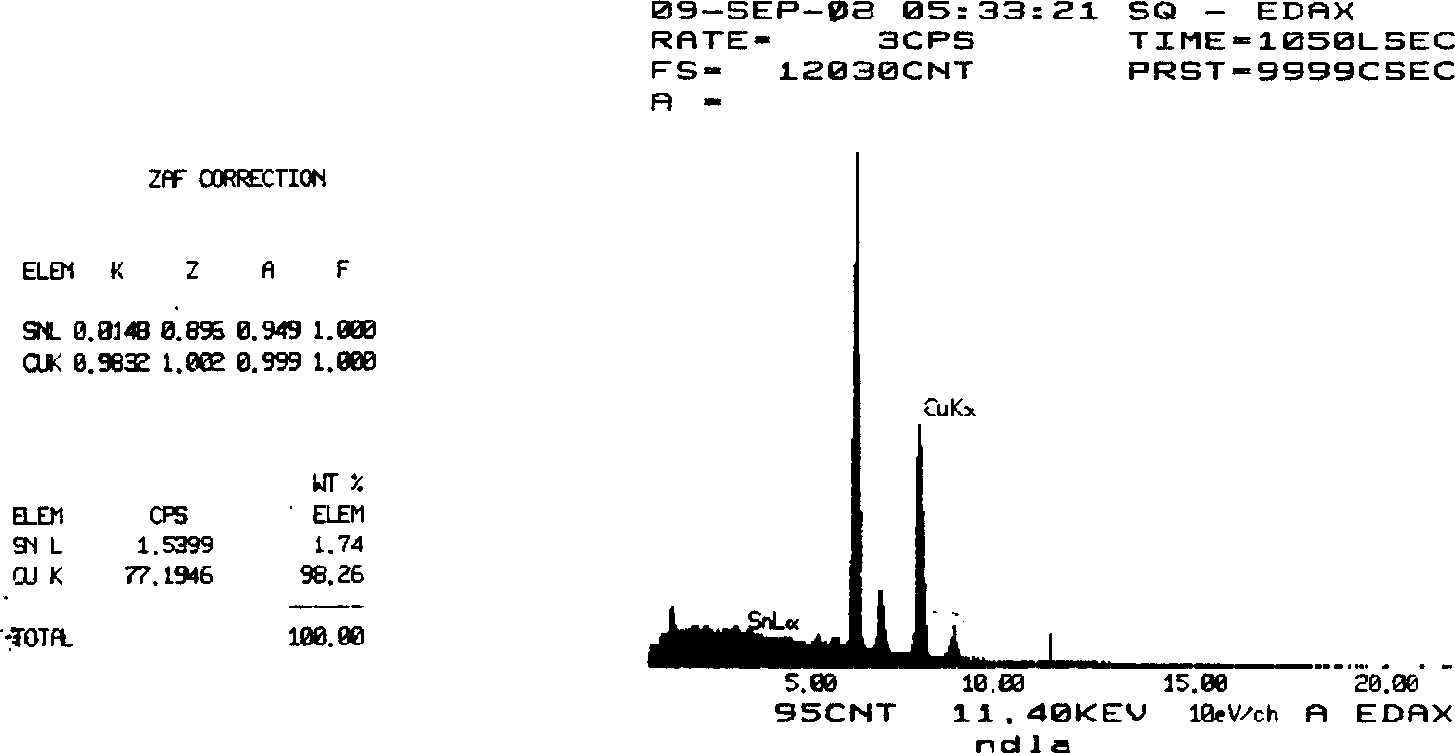

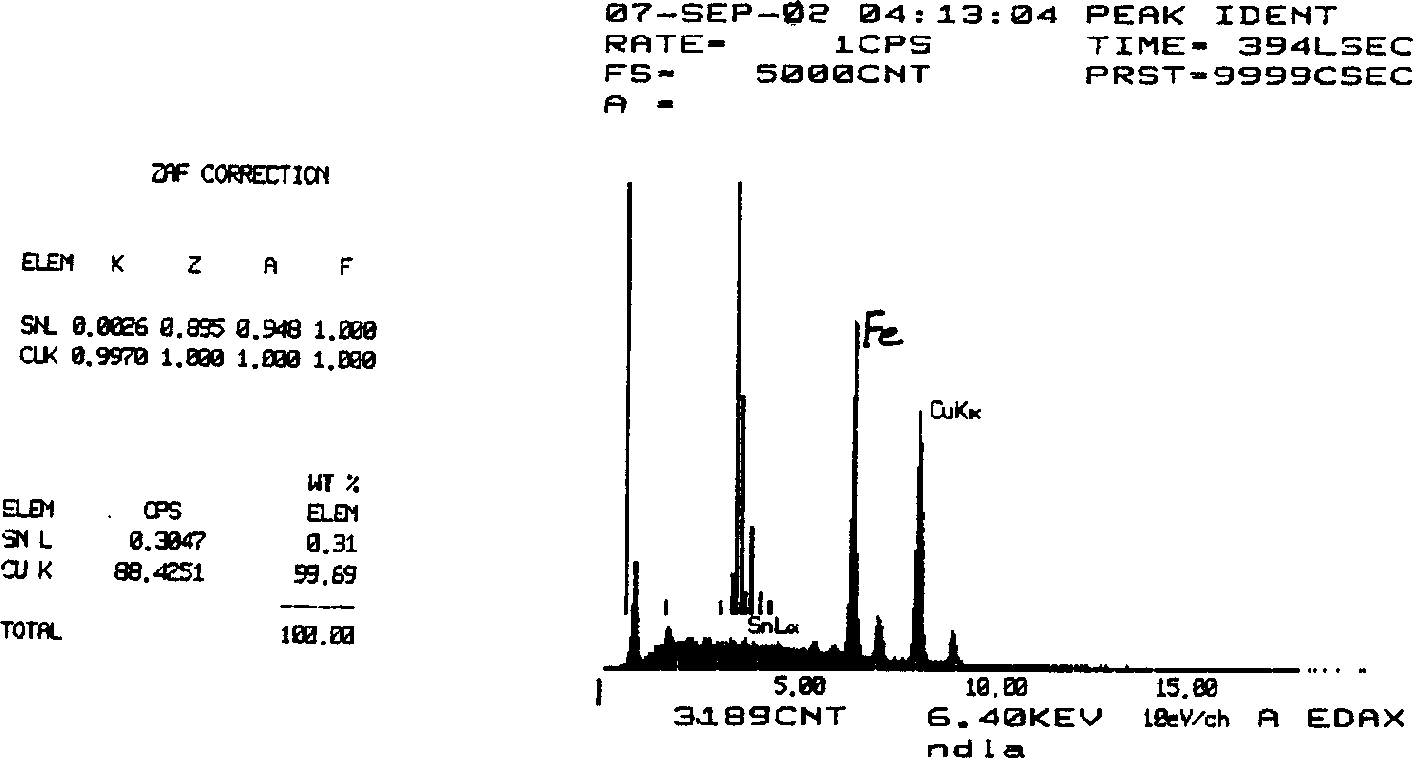

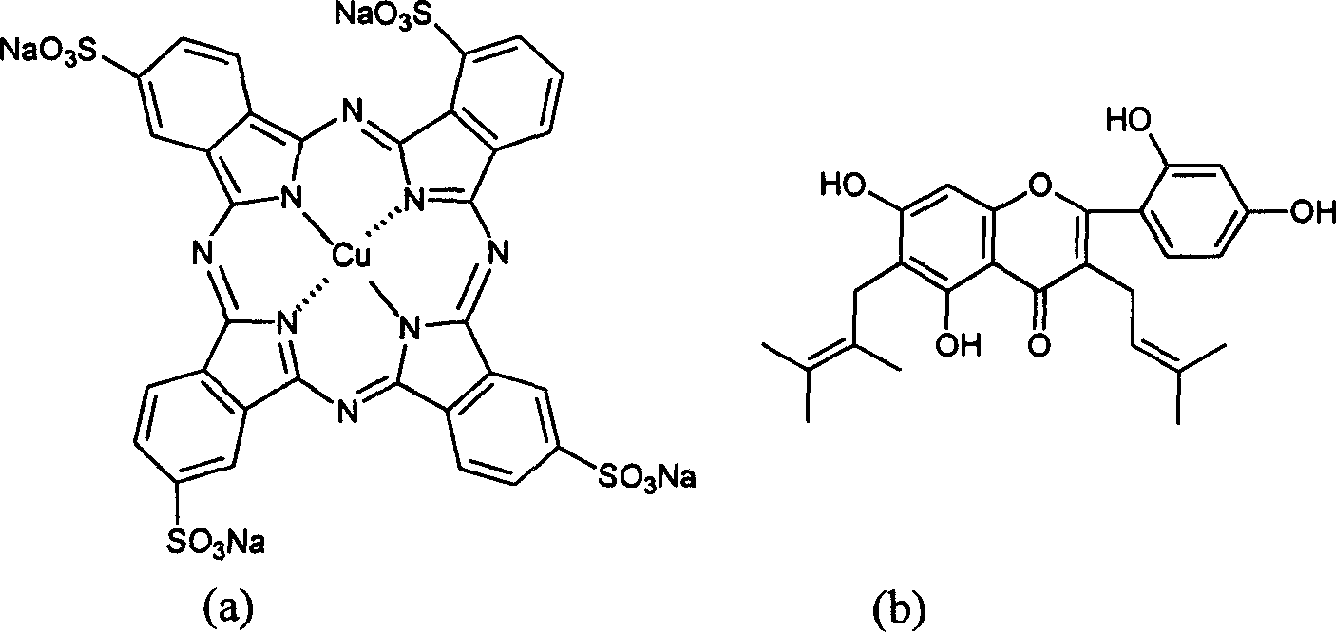

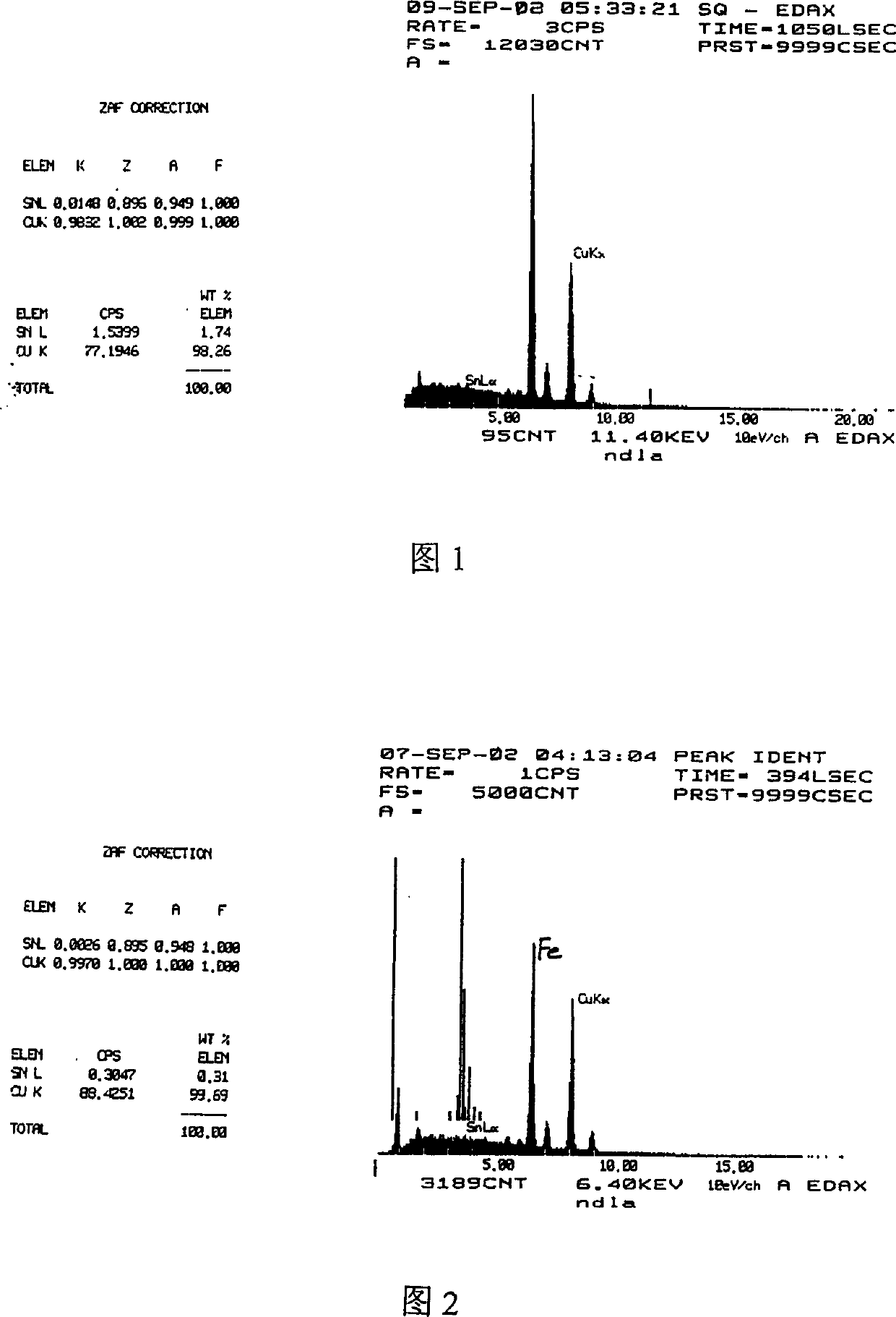

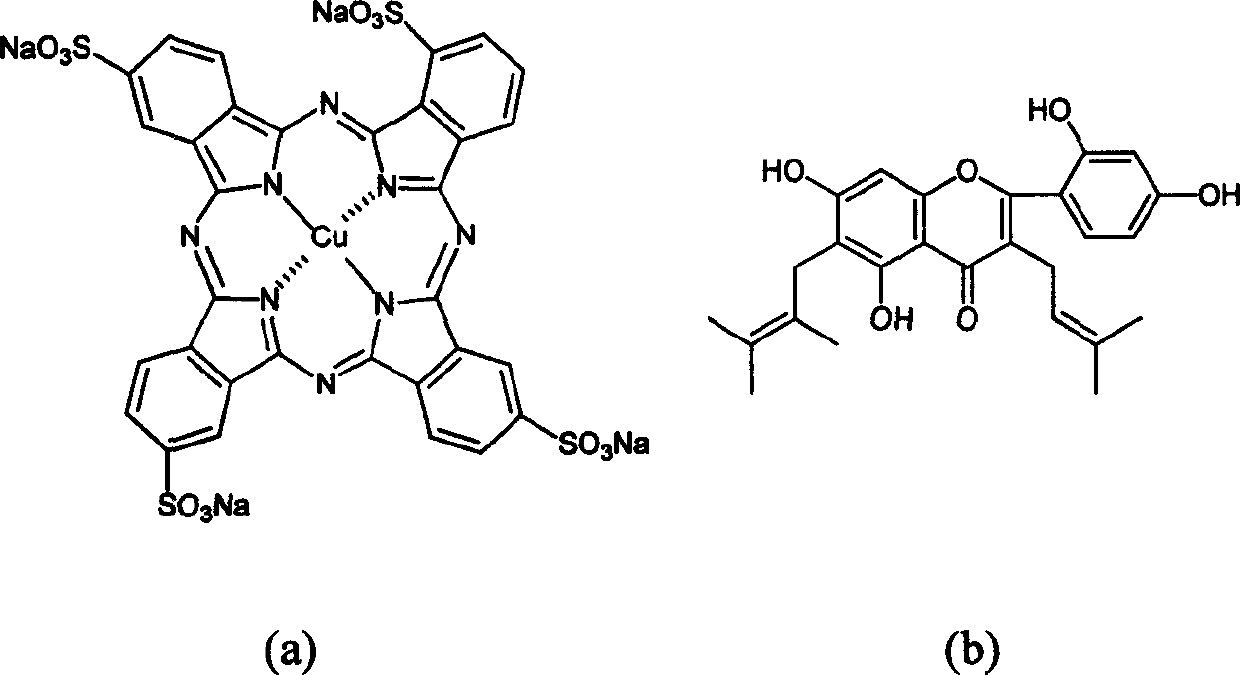

Bronze plating additive, method for making same and use in bronze plating on tread band steel wire

InactiveCN1544696ANo acid mistLiquid/solution decomposition chemical coatingSODIUM DODECYL BENZENE SULFONATETetra

The invention relates to a chemical displacement bronze plating technique, concrete a bronze plating additive and its preparing method and application in plating bronze on rim steel wire. The additive uses tetrabenzyl porphyrin, 3, 4', 4', 4''-copper tetra sulfophthalocyanine tetrasodium and mulberry skin element to compose the first component, uses sodium dithio propyl sulfonate, 2-benzimidazle, dihydroxylmethyl thiourea, 1, 1'-quintic methyl di(1-mythyl)pyrrolidine tartaric acid to compose the second component, and using polyglycol 6000, sodium dodecyl benzene sulfonate, alkyl polyoxyethylene ether sulfated ester and cobalt bichloride to compose the third component; the ratio of the first component to the second component to the third component = 1 : 50-400 : 70-450 (w / w). The method is simple. The working temperature of the additive is 20-35 deg.C, it does not produce acid mist, the plating solution has above 3 month long stable period and after plated with bronze, the steel wire does not need anticorrosive processing and the anticorrosive period can reach above half a year. The additive can also be applied to plating bronze on the iron-based sheet material.

Owner:湖南领湃达志科技股份有限公司

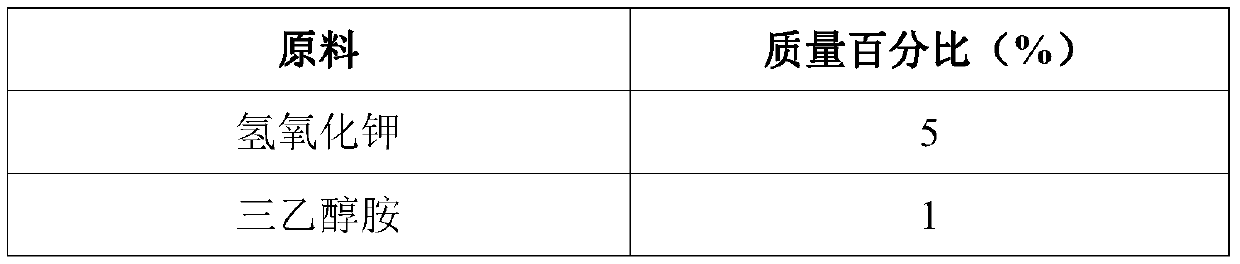

Alkaline steel rust remover and preparation method thereof

The invention discloses an alkaline steel rust remover and a preparation method thereof. The alkaline steel rust remover is prepared from the following components of, in percentage by mass, 0.1%-8% ofan alkali agent, 0.01%-5% of a complexing agent, 0.01%-3% of a corrosion inhibitor, 0.1%-3% of an emulsifier, 0.01%-0.05% of a defoaming agent, 0.02%-1% of a thickening agent and the balance water. The preparation method of the alkaline steel rust remover is very simple, and the components are mixed uniformly in batches; and the rust removal effect of the alkaline steel rust remover is good, steel is not corroded, acid mist is not generated, the hydrogen embrittlement phenomenon does not occur, the production process is simple, and safety and environmental protection are achieved.

Owner:广东中联邦精细化工有限公司

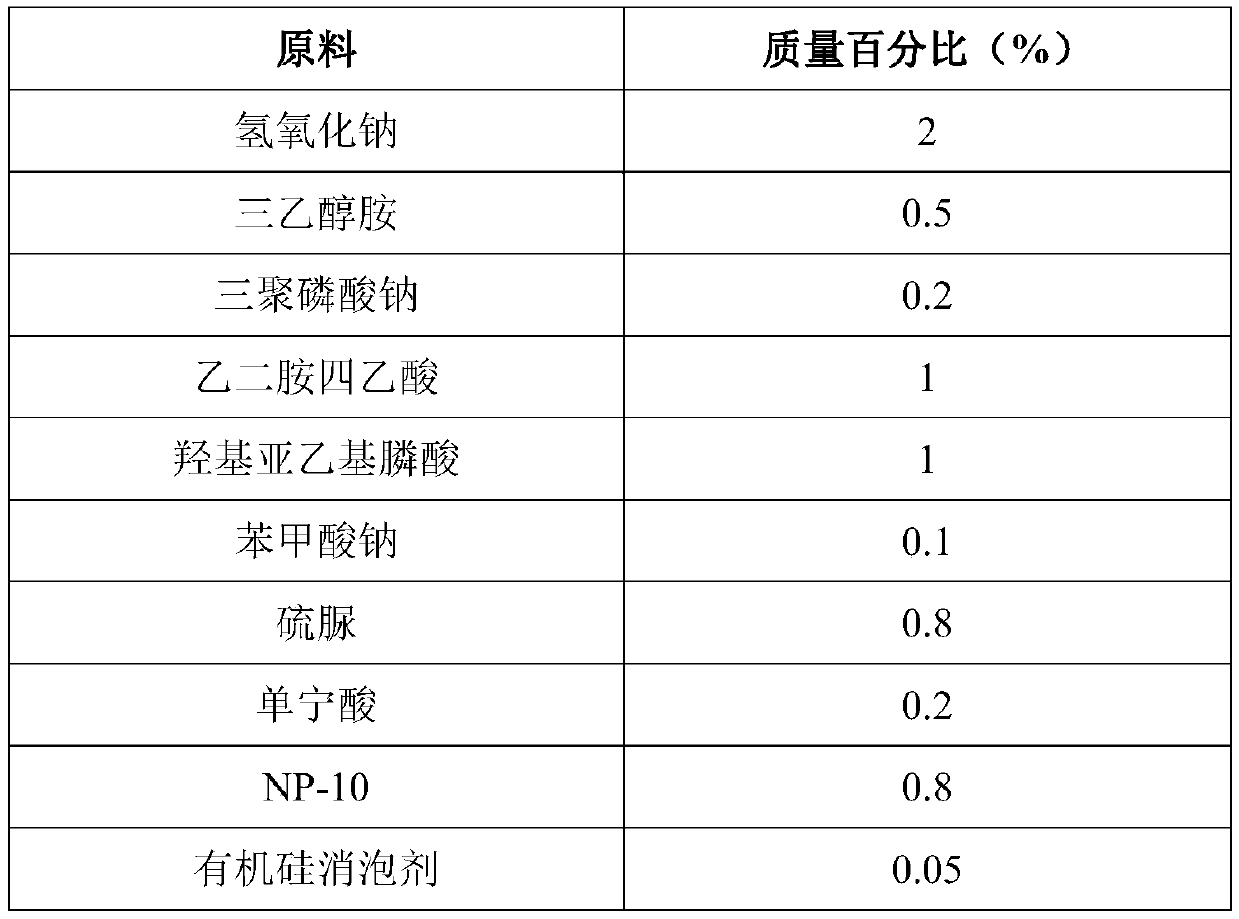

Environment-friendly neutral rust remover and preparation method thereof

PendingCN114592196APromote penetrationFast responseMetallic material coating processesProcess efficiency improvementOrganic acidActive agent

The invention discloses an environment-friendly neutral rust remover and a preparation method thereof, and the environment-friendly neutral rust remover comprises the following raw material components in parts by weight: 15-30 parts of an organic acid complexing agent, 0.2-0.5 part of an accelerant, 1.0-2.0 parts of a chelating agent, 1.0-2.0 parts of a surfactant, 0.6-0.8 part of a phosphorization oxidation accelerant, 2.0-3.0 parts of a penetrant, 10-24.5 parts of a neutralizer and the balance of deionized water. The rust remover is used for removing rust on the surface of a steel material, only reacts with rust and oxide skin on the metal surface during rust removal, does not cause corrosion and hydrogen embrittlement phenomena on the metal surface, does not generate acid mist, does not contain any substance harmful to the environment, and forms a compact complex film on the metal surface after rust removal, so that the long-acting rust-proof effect is achieved.

Owner:潍坊佳钢贸易有限公司

Water-based metal surface antirust solution and preparation method thereof

The invention discloses a water-based metal surface antirust solution prepared from the following raw materials in parts by weight: 18-23 parts of alkyd resin, 1-2 parts of sodium benzoate, 1-2 parts of ethylenediamine tetraacetic acid, 5-6 parts of polyethylene glycol, 1-2 parts of urea, 6-9 parts of glycerol, 1.9-2.7 parts of polyisobutylene, 2.1-2.9 parts of 2-aminoethyl heptadecenyl imidazoline, 1-2 parts of methacrylic acid dimethyl amino ethyl ester, 1-2 parts of allyl glycidyl ether, 1-2 parts of EDTA (ethylene diamine tetraacetic acid) disodium, 4-5 parts of an auxiliary agent and 300 parts of water. According to the water-based metal surface antirust solution disclosed by the invention, resin and a chelating agent are used, so that a relatively firm film can be formed on the surface of a metal to play roles in isolating air and moisture and fixing an antirust substance to ensure that the metal has a reliable and long-time antirust effect, the corrosion resistance of the surface of the metal can be improved, and acid mist is not generated; the water-based metal surface antirust solution is safe and reliable and is easy in operation.

Owner:FUYANG ANGU BOILER PRESSURE VESSEL MFG

Cleaning agent and cleaning method for air conditioner

InactiveCN101475878BAvoid over corrosionLow costNon-ionic surface-active compoundsFlush cleaningStrong acidsHigh pressure water

The present invention discloses a detergent and a cleaning method for a complete air-conditioner, which not only can uniformly and completely remove dirt but also cannot strongly corrupt components and parts such as aluminum, copper and stainless steel, are time-saving and labor saving, safe and reliable, and pollution-free, and have low cost. Raw materials of the detergent are at least two compositions of citric acid, inorganic weak acid and inorganic strong acid; a non-ionic surfactant or a non-ionic surfactant is mixed with an anionic surfactant; and the detergent comprises an oxygen solvent, an acid corrosion inhibitor, and the balance being water. The cleaning method comprises: disassembling a motor and a fan, and taking off the motor and the fan for independent cleaning; preparing the detergent into an aqueous solution according to the proportion of between 10 and 15 percent, hanging the complete air-conditioner after disassembly of the motor and the fan into a cleaning tank, soaking the complete air-conditioner for 30 minutes at normal temperature, and starting ultrasonic waves to clean for 10 to 30 minutes; placing the complete air-conditioner into a washing tank, and using a high-pressure water gun to spray the surface and the inside of the air-conditioner; and using hot blast to dry the air-conditioner at a temperature of 80 DEG C.

Owner:DALIAN SANDAAOKE CHEM

Neutral rust remover and preparation method thereof

The invention discloses a neutral rust remover and a preparation method thereof. The neutral rust remover comprises the following components by weight: 72-85% of water, 10-20% of hydroxyethylidene diphosphonic acid, 2-3% of malic acid, 1-2% of sodium alginate, 0.5-1% of polyacrylic alcohol PPG2000, 0.1-0.5% of triethanolamine, 0.1-0.5% of fatty alcohol polyoxyethylene ether, and 0.1-0.5% of a corrosion inhibitor. The product prepared by the method has a near-neutral pH value under working conditions, the damage to the human body is negligible even in direct contact, no bubble is generated during work, and no acid mist is generated, so that the production environment is greatly improved; and the neutral rust remover only acts on the surface rust of the workpiece without corroding the iron substrate, no excessive corrosion exists, the processing size is not influenced, and the processing safety is high.

Owner:佛山市海明威生态科技股份有限公司

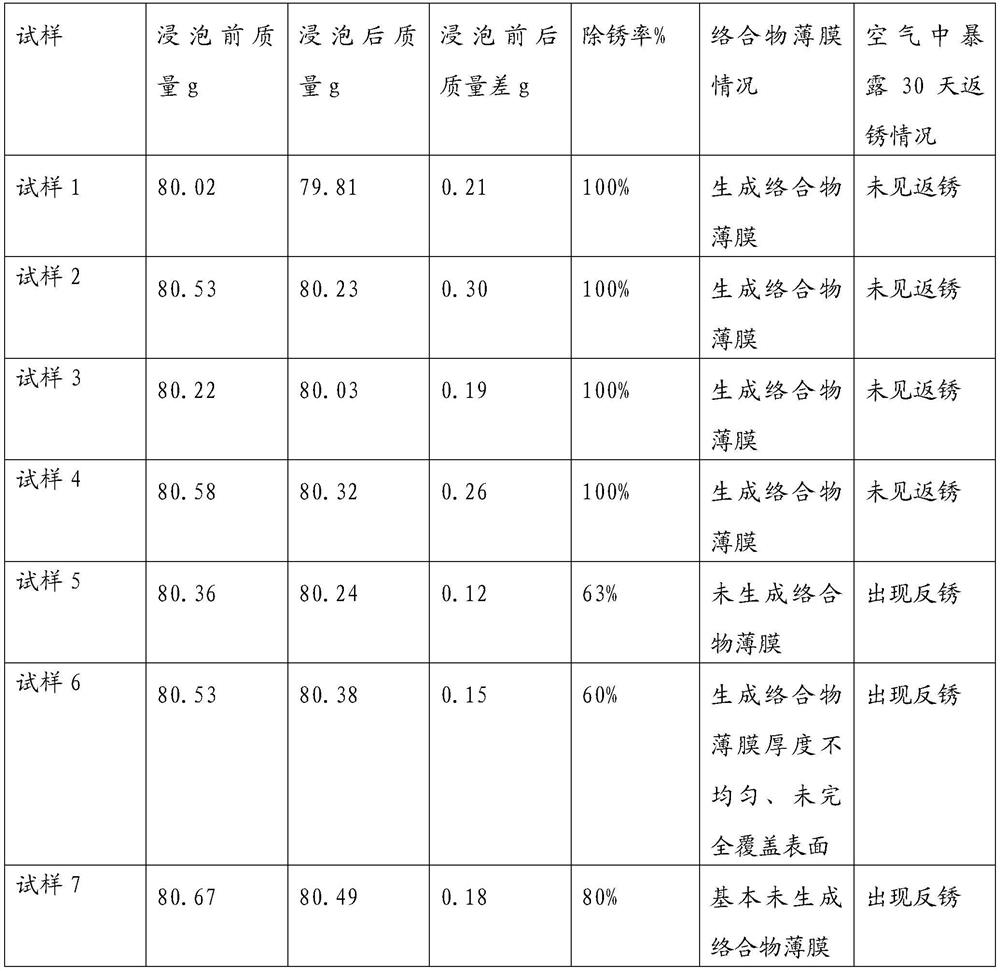

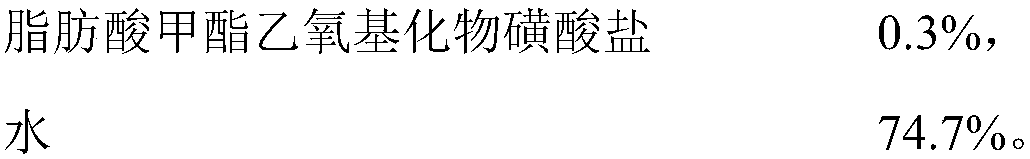

Recovery method and recovery device for valuable metals in scrap copper electrolysis anode mud

ActiveCN111733327AImprove leaching rateImprove direct yieldPhotography auxillary processesProcess efficiency improvementElectrolysisRoasting

The invention provides a recovery method and a recovery device for valuable metals in scrap copper electrolysis anode mud. The recovery method comprises the following steps of sequentially carrying out oxidizing roasting and acid leaching treatment on the scrap copper electrolysis anode mud to obtain a copper-containing acid leaching solution and acid leaching residues; carrying out electrodeposition treatment on the copper-containing acid leaching solution multiple times to obtain cathode copper; and carrying out alkaline leaching treatment on the acid leaching residues to obtain lead-tin alkaline leaching solution and precious metal residues. The method is short in process, high in copper leaching rate and high in direct recovery rate, and part of impurity elements such as nickel and arsenic are removed in advance while copper is recovered through electrodeposition in the acid leaching treatment step, so that the burden of impurity removal in the subsequent recovery process of precious metal in the precious metal residues is effectively relieved; and the method is low in process reagent consumption, and the electrodeposition process is sealed operation, so that acid mist is avoided, the working environment is good, and pollution is avoided.

Owner:CHINA ENFI ENGINEERING CORPORATION

Brightening rust removing agent

The invention relates to a material for removing rust on steel surfaces, in particular to a brightening and rust removing agent. The invention solves the problems in the prior art that the surface of the steel is dark after derusting by the derusting agent. It is composed of the following substances by weight, hydrochloric acid 30-50%, hexamethylenetetramine 1-5%, sodium lauryl sulfate 2-8%, Pingping plus OS-15 5-10%, and the rest water. It has the characteristics of rapid derusting at room temperature, brighter than before after derusting, no over-corrosion and hydrogen embrittlement, no pollution, and low cost. The rust removal time is generally within 1-5 minutes depending on the degree of corrosion.

Owner:山西银河镀锌有限公司

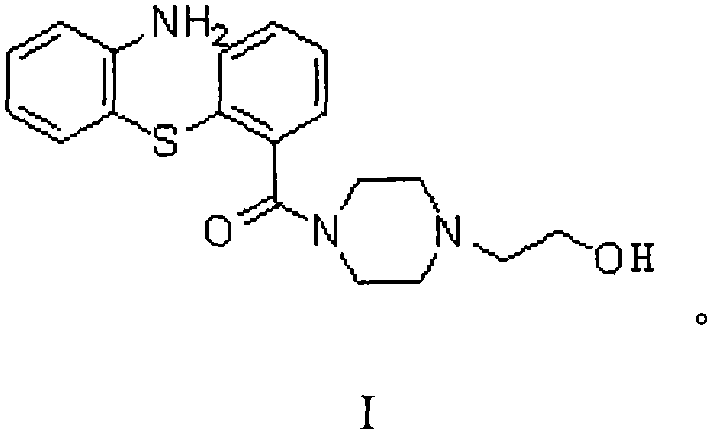

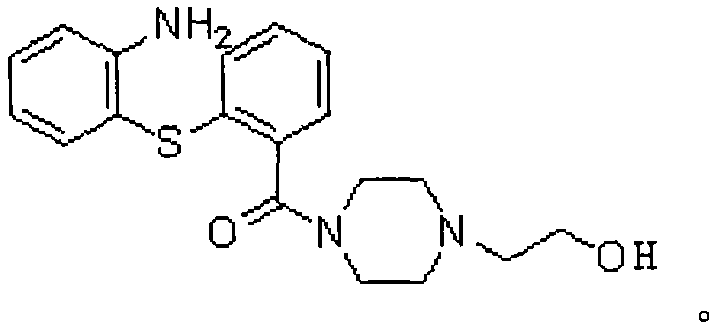

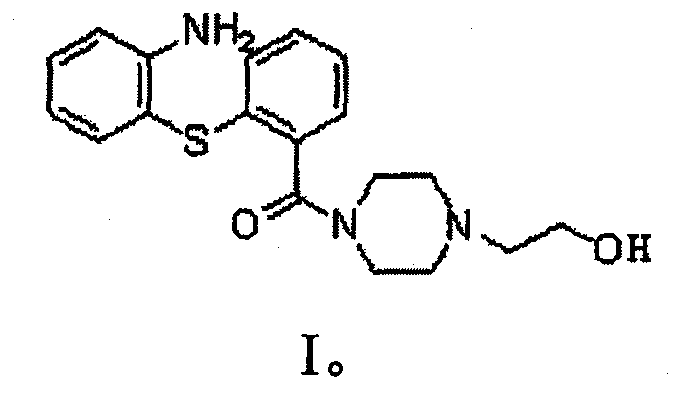

Novel derusting material

InactiveCN103304517AStable physical propertiesNo smellOrganic chemistrySURFACTANT BLENDCorrosion inhibitor

The invention relates to a novel derusting material and a composition containing the same. The derusting material has a chemical formula shown in a formula I; the composition consists of the following components: 10-20 parts of a compound shown in formula I, 1-8 parts of a penetrating agent, 2-10 parts of a surfactant, 0.5-5 parts of corrosion inhibitor and the balance of water to 100 parts by weight.

Owner:TIANDI SCI & TECH CO LTD

Air conditioner aluminum fin weak alkaline cleaner and cleaning method

InactiveCN107988613AEvenly and thoroughlyImprove heating efficiencyCleaning methodsSurface-active agents

The invention discloses an air conditioner aluminum fin weak alkaline cleaner which can evenly and thoroughly remove dirt, cannot generate high corrosion on aluminum fins, saves time and labor, and islow in cost, safe, reliable and free of pollution. The air conditioner aluminum fin weak alkaline cleaner comprises raw materials including, by mass percent, 1%-5% of citric acid, 0.1%-15% of sodiummetasilicate pentahydrate, 0.1%-5% of sodium carbonate, 0.1%-10% of sodium gluconate, 0.5%-20% of a non-ionic surface active agent, 0.5%-10% of a cationic surface active agent, 0.5%-15% of an oxygen bearing solvent and the balance water; and the pH value is 10.0-10.5. The cleaning method includes the following steps that the aluminum fins on an air conditioner in a train are detached; the cleaneris prepared into an aqueous solution according to the mass percent being 10%-15%, the detached aluminum fins are hoisted into a cleaning tank, soaking is carried out for 30 min at the normal temperature, ultrasonic cleaning is started to last for 10 min-30 min; the aluminum fins of the air conditioner are placed into a washing tank, a water torch is used for spraying and cleaning the surfaces of gaps of the aluminum fins of the air conditioner; and the aluminum fins are placed to be dried.

Owner:DALIAN SANDAAOKE CHEM

Preparation method of environmentally-friendly double-effect oil well blockage removal detergent

InactiveCN110003872AWill not corrodeNo acid mistCleaning apparatusDrilling compositionEthylenediaminePropanoic acid

The invention discloses a preparation method of an environmentally-friendly double-effect oil well blockage removal detergent. The preparation method comprises the following steps: preparing an emulsion A from a mixture of water and oleyl alcohol in the presence of a surfactant; preparing a solution B from water, soluble starch, ammonium chloride, ethylenediaminetetramethylene phosphonic acid sodium and disodium ethylenediamine tetraacetate; preparing a solution C from water, propionic acid, ethylenediamine, magnesium chloride and glyoxal; and preparing a solution D from water, sodium dodecylbenzene sulfonate, OP-10 and betaine. The environmentally-friendly double-effect oil well blockage removal detergent prepared in the invention has a pH value of 6.0-7.5; a cleaning agent and cleaningwaste liquid are neutral, do not generate acid mist, and do not corrode equipment structures made of iron and steel, thereby achieving corrosion-free and safe blockage removal and scale removal; the blockage removal detergent not only can remove polymer material scale and asphaltene scale of rod pumping wells and screw pump wells, but also can remove inorganic scale such as calcium carbonate, magnesium carbonate, calcium sulfate, iron oxide and the like, and has advantages of double-effect performance, good thermal stability, safe use and environmental protection.

Owner:UNIV OF JINAN

Derusting paste with polishing effect

ActiveCN109778212AHas a powerful rust removal functionPowerful derusting functionMetallic material coating processesPolishing compositions with abrasivesPhysical chemistryRust remover

The invention provides derusting paste with a polishing effect. A boron sulphate derusting agent is mixed with a thickening agent and abrasive; and the mass ratio of the boron sulphate derusting agent, to the thickening agent and to the abrasive is 100: 0.1-1: 0.3-1.2. The strong derusting paste has a fast and simple derusting function on serious rust, and also has a passivating effect and an oxidization preventing function; the derusting effect is superior to a strong acid or nitrogen and phosphorus derusting agent, the derusting paste is green and environment-friendly and has no toxic and side effects on human bodies, and the brightness of a derusted base material can reach 8 K or above.

Owner:苏州纳孚林科金属表面技术有限公司 +1

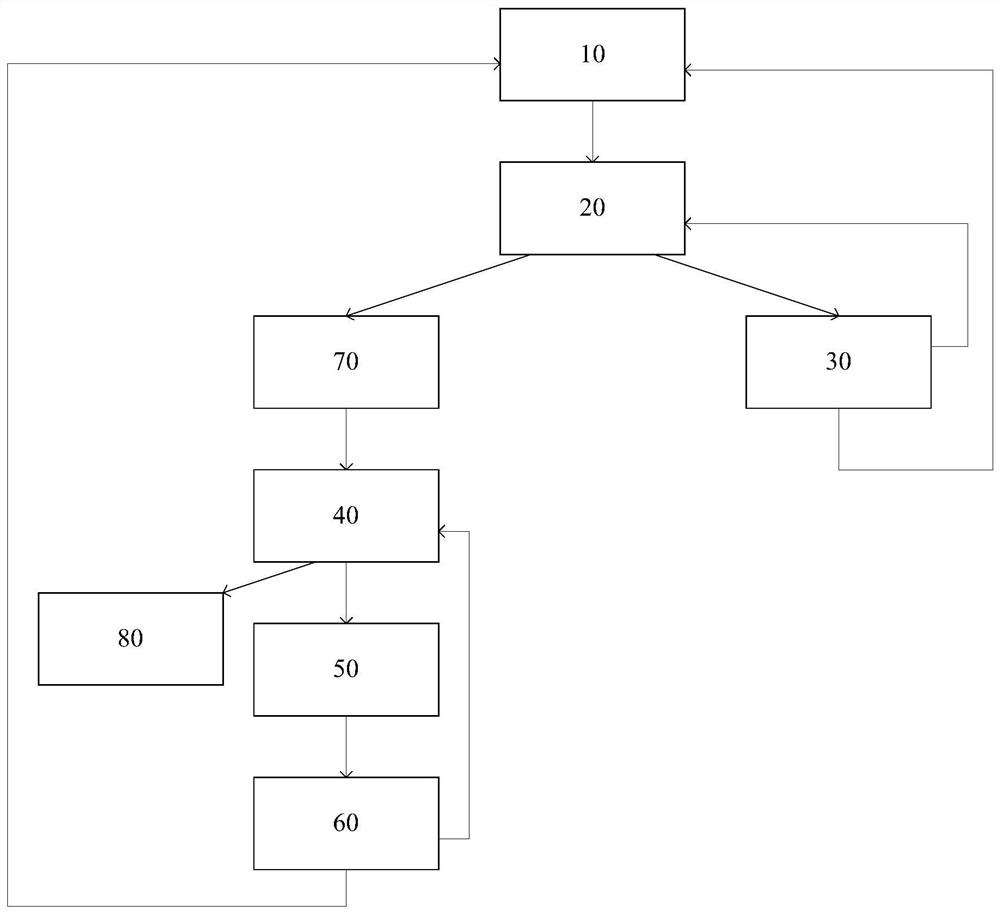

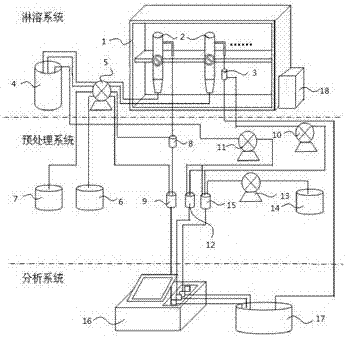

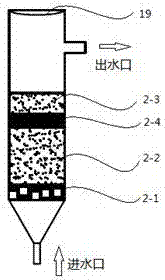

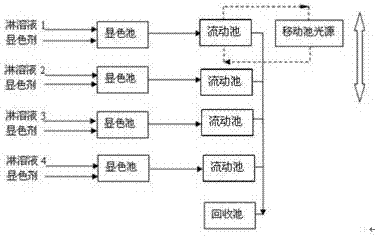

Online detecting device for water-dissolved nitrogen nutrients of chemical fertilizer

InactiveCN106872385AWill not cause lossGood repeatabilityColor/spectral properties measurementsRepeatabilityPollution

The invention provides an online detecting device for water-dissolved nitrogen nutrients of a chemical fertilizer. The online detecting device comprises a leaching system, a pre-treating system connected with the leaching system and an analyzing system connected with the pre-treating system. The online detecting device has the beneficial effects that: quick analysis comparison on concentration and mass of various water-dissolved nitrogen nutrients of the same chemical fertilizer sample or the same water-dissolved nitrogen nutrient of different chemical fertilizer samples can be realized, and the detected data is high in repeatability; a lead storage battery is adopted as a standby battery, and also can be normally used after power failure; stability of an electrolyte solution is high, so that occurrence of internal short circuit as PbO2 particles are freely dispersed into the electrolyte solution can be effectively prevented, and the cycle service life of the battery is prolonged; and moreover, a utilization rate for active substances of a positive electrode can be effectively increased, service time of the battery is prolonged, and acid mists do not generate, so that the online detecting device is green and environmental-friendly, and solves the problem of pollution to environment and equipment by the acid mists.

Owner:新昌县迪斯曼科技有限公司

Novel derusting material

The invention relates to a novel derusting material and a composition containing the same. The derusting material has a chemical formula as shown in a formula I; the composition consists of the following components: 10-20 parts of a compound shown in formula I, 1-8 parts of a penetrating agent, 2-10 parts of a surfactant, 0.5-5 parts of corrosion inhibitor and the balance of water to 100 parts by weight.

Owner:TIANDI SCI & TECH CO LTD

A kind of cross-linked borosulfate ester derusting paste

The invention provides crosslinking type boron sulphate rust removal paste. The crosslinking type boron sulphate rust removal paste is formed through mixing of a boron sulphate rust removal agent anda thickening agent with the mass ratio being 100:0.1-1. The crosslinking type boron sulphate rust removal paste is strong rust removal paste and has a rapid and simple rust removal function for severerust, and the rust prevention function is achieved. The rust removal effect is superior to the rust removal effect of a strong acid or nitrogen and phosphorus rust removal agent, and the crosslinkingtype boron sulphate rust removal paste is green, environment-friendly and free of toxic and side effects on human bodies.

Owner:苏州纳孚林科金属表面技术有限公司 +1

Crosslinking type boron sulphate rust removal paste

The invention provides crosslinking type boron sulphate rust removal paste. The crosslinking type boron sulphate rust removal paste is formed through mixing of a boron sulphate rust removal agent anda thickening agent with the mass ratio being 100:0.1-1. The crosslinking type boron sulphate rust removal paste is strong rust removal paste and has a rapid and simple rust removal function for severerust, and the rust prevention function is achieved. The rust removal effect is superior to the rust removal effect of a strong acid or nitrogen and phosphorus rust removal agent, and the crosslinkingtype boron sulphate rust removal paste is green, environment-friendly and free of toxic and side effects on human bodies.

Owner:苏州纳孚林科金属表面技术有限公司 +1

Composite acid metal surface cleaning agent and using method thereof

The invention discloses a composite acid metal surface cleaning agent and a using method thereof. The composite acid metal surface cleaning agent comprises 1% of corrosion-inhibiting component and 30%-50% of scale-removing components in mass percentage, wherein the corrosion-inhibiting component comprises 30-70 parts by weight of hexamethylene tetramine, 10-50 parts by weight of o-xylene thiourea, 10-50 parts by weight of sodium alkyl benzene sulfonate, 1-10 parts by weight of sodium erythorbate and 1-5 parts by weight of methyl benzotriazole; and the scale-removing components comprise 65-92 parts by weight of sulfamic acid, 3-30 parts by weight of citric acid and 0.1-5 parts by weight of ammonium bifluoride. The composite acid metal surface cleaning agent has the advantages of strong cleaning capacity, low cleaning temperature, no water-soluble volatility without acid mist generation, easy enforcement of cleaning engineering, low cleaning expense and the like and can be widely suitable for cleaning various large-scale boilers or heat exchangers.

Owner:SHANDONG ZHONGSHI YITONG GRP

Bronze plating additive, method for making same and use in bronze plating on tread band steel wire

InactiveCN1262688CNo acid mistLiquid/solution decomposition chemical coatingThioureaWorking temperature

The invention relates to a chemical displacement bronze plating technique, concrete a bronze plating additive and its preparing method and application in plating bronze on rim steel wire. The additive uses tetrabenzyl porphyrin, 3, 4', 4', 4''-copper tetra sulfophthalocyanine tetrasodium and mulberry skin element to compose the first component, uses sodium dithio propyl sulfonate, 2-benzimidazle, dihydroxylmethyl thiourea, 1, 1'-quintic methyl di(1-mythyl)pyrrolidine tartaric acid to compose the second component, and using polyglycol 6000, sodium dodecyl benzene sulfonate, alkyl polyoxyethylene ether sulfated ester and cobalt bichloride to compose the third component; the ratio of the first component to the second component to the third component = 1 : 50-400 : 70-450 (w / w). The method is simple. The working temperature of the additive is 20-35 deg.C, it does not produce acid mist, the plating solution has above 3 month long stable period and after plated with bronze, the steel wire does not need anticorrosive processing and the anticorrosive period can reach above half a year. The additive can also be applied to plating bronze on the iron-based sheet material.

Owner:湖南领湃科技股份有限公司

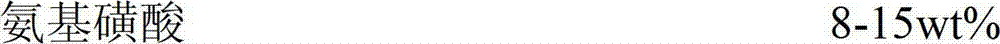

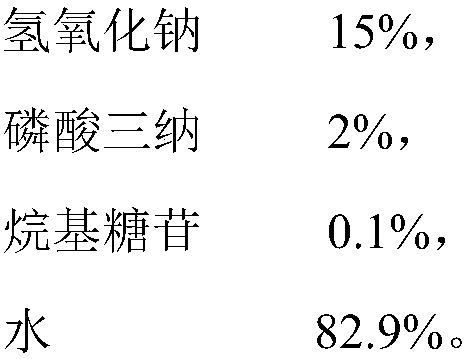

A kind of electrolytic derusting agent and electrolytic derusting method

The present invention relates to an electrolysis rust removing agent, which comprises the following components, by weight, 8-15 wt% of aminosulfonic acid, 1-5 wt% of oxalic acid, 0.7-2.2 wt% of concentrated sulfuric acid, 0.4-1.5 wt% of ferrous sulfate, 0.4-1.5 wt% of sodium chloride, and the balance of water. The electrolysis rust removing agent has characteristics of good electrolysis rust removing effect, high rust removing efficiency, and rapid, stable, safe and durable rust removing process, wherein no volatilization is generated during the rust removing process, no acid mist is generated, no harm is generated to operators, and advantages of environment protection, energy source saving, and cost reducing are provided.

Owner:无锡清源数字信息技术研究院有限公司

A method for electrolytic deplating of zinc layer and chromium passivation layer on the surface of iron parts

Disclosed in the present invention is a method for electrolytically deplating a zinc layer and a chromium passivation layer on the surface of an iron piece, comprising the steps of: connecting an iron piece to be deplated to the positive electrode of a rectifier to be used as the anode; placing a stainless steel plate in a deplating solution and connecting same to the negative electrode of the rectifier to be used as the cathode; and dissolving the zinc layer or chromium passivation layer on the surface of the iron piece by means of electrolytic deplating so as to deposit zinc powder on the surface of the stainless steel plate. The method for electrolytically deplating a zinc layer and a chromium passivation layer on the surface of an iron piece of the present invention can completely remove the unqualified zinc layer or chromium passivation layer on a workpiece, providing a high removing efficiency; and said method does not produce acid fog, being environmentally friendly. The deplating does not cause over-corrosion on workpieces and does not produce hydrogen embrittlement. Zinc powders or a chromium layer deposited on the cathode can be directly recovered. Removal of an unqualified zinc layer and a chromium passivation layer on a workpiece and zinc powder deposition on the cathode are performed simultaneously, simplifying the process.

Owner:江门市鼎翔电子科技有限公司

Acid-mist-free contamination removal and oil removal metal rust remover

InactiveCN108468054ANo acid mistNo smellMetallic material coating processesLiquid wasteHexamethylenetetramine

The invention belongs to the technical field of chemical engineering, and particularly relates to an acid-mist-free contamination removal and oil removal metal rust remover. The acid-mist-free contamination removal and oil removal metal rust remover is mainly characterized in that the formula of an existing hydrochloric acid metal rust remover is greatly modified, and the acid-mist-free contamination removal and oil removal metal rust remover is prepared by phosphoric acid, oleic acid, sulfuric acid, oxalic acid, butyl alcohol, hexamethylenetetramine, triethanolamine, OP-10 and water by a certain weight percent. Compared with the prior art, the acid-mist-free contamination removal and oil removal metal rust remover has the obvious advantages that no acid mist is generated; peculiar smellsare avoided, and use is safe; the purpose is enlarged; rust, oil dirt and water scales can be removed; waste liquid can be recycled; waste emissions are reduced; environment pollution is reduced; andsocial and economic benefits are good.

Owner:河南宗源环保科技有限公司

Acid pickling treatment process of stainless steel

The invention discloses an acid pickling treatment process of stainless steel. The acid pickling treatment process comprises the following steps: (1) preparing materials according to weight percentage: 20-22% of nitric acid, 5-7% of hydrofluoric acid and the balance of water; (2) preparing a solution, namely, uniformly mixing and stirring the prepared materials according to the mass proportion; (3) loosening an oxidation film: soaking stainless steel to be treated in sulfuric acid with the volume concentration of 10-15% at the temperature of 800 DEG C for 20-25 minutes; (4) removing the oxidation film: soaking the stainless steel to be treated in the prepared solution, performing normal temperature treatment for 10-15 minutes and then taking out, thoroughly cleaning the surface of the stainless steel with water, cleaning with an alkaline liquor for neutralizing, and finally airing after thorough cleaning. According to the acid pickling treatment process of stainless steel provided by the invention, through the strict control over technological parameters, the oxide scale removing speed and efficiency are high, the corrosion to the matrix is little, the corrosion inhibition rate is high, and no acid mist is produced during the cleaning operation process.

Owner:芜湖华普汽车部件有限公司

Recovery method and recovery device for valuable metals in waste miscellaneous copper electrolysis anode slime

ActiveCN111733327BImprove leaching rateImprove direct yieldPhotography auxillary processesProcess efficiency improvementElectrolysisSlag

The invention provides a method and a recovery device for recovering valuable metals in waste miscellaneous copper electrolysis anode slime. The recovery method comprises: sequentially performing oxidation roasting and acid leaching treatment on waste miscellaneous copper electrolytic anode slime to obtain copper-containing acid leaching solution and acid leaching residue; performing multiple electrowinning treatments on the copper-containing acid leaching solution to obtain cathode copper; The acid leaching slag is subjected to alkali leaching treatment to obtain lead-tin alkali leaching solution and precious metal slag. The process is short, the copper leaching rate is high, and the direct recovery rate is high. In the acid leaching treatment step, while copper is recovered by electrowinning, some impurity elements such as nickel and arsenic are removed in advance, which effectively reduces the precious metal recovery process in the subsequent precious metal slag. The burden of removing impurities. The process reagent consumption in the method is low, and the electrowinning process is a sealed operation without acid mist, and the working environment is good and pollution-free.

Owner:CHINA ENFI ENGINEERING CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com