Alkaline steel rust remover and preparation method thereof

A rust remover, steel technology, applied in the field of metal surface treatment, can solve the problems of easy corrosion of steel substrates, serious dust pollution, damage to the health of workers, etc., to achieve environmental and human friendliness, simple production process, rust removal effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

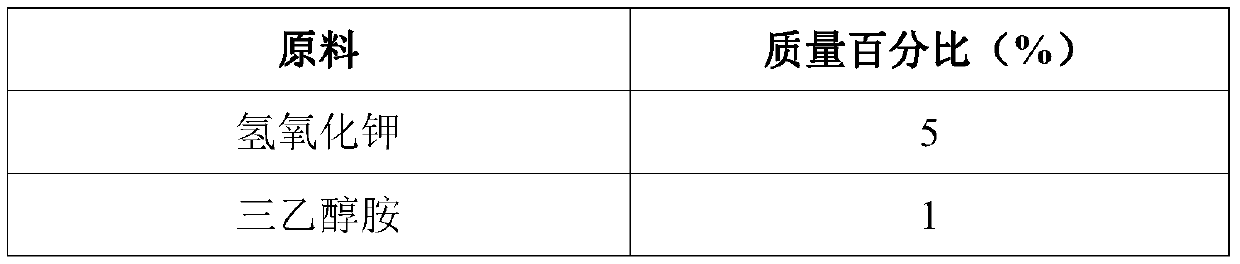

[0044] A kind of alkaline iron and steel derusting agent, its composition is as shown in the following table:

[0045] The composition table of a kind of alkaline iron and steel derusting agent of table 1

[0046] raw material Mass percentage (%) Potassium hydroxide 3 Triethanolamine 0.8 Ethylenediaminetetraacetic acid 0.5 Hydroxyethylenephosphonic acid 1 sodium benzoate 0.3 Thiourea 0.5 Tannic acid 0.2 NP-10 1.2 Silicone defoamer 0.03 carboxymethyl cellulose 0.08 Deionized water margin

[0047] The preparation method of above-mentioned alkaline iron and steel derusting agent, comprises the following steps:

[0048] 1) Add potassium hydroxide and deionized water to the reaction kettle, and stir for 15 minutes;

[0049] 2) Add triethanolamine, ethylenediaminetetraacetic acid, hydroxyethylene phosphonic acid, sodium benzoate, thiourea and tannic acid into the reaction kettle, and stir for 15 minut...

Embodiment 2

[0053] A kind of alkaline iron and steel derusting agent, its composition is as shown in the following table:

[0054] The composition table of a kind of alkaline iron and steel derusting agent of table 2

[0055]

[0056]

[0057] The preparation method of above-mentioned alkaline iron and steel derusting agent, comprises the following steps:

[0058] 1) Add potassium hydroxide and deionized water to the reaction kettle, and stir for 15 minutes;

[0059] 2) Add triethanolamine, sodium tripolyphosphate, hydroxyethylene phosphonic acid, sodium benzoate, thiourea and tannic acid into the reaction kettle, and stir for 15 minutes;

[0060] 3) Add NP-10 and polyether defoamer into the reactor, and stir for 15 minutes;

[0061] 4) Add carboxymethyl cellulose into the reaction kettle and stir for 15 minutes to obtain a basic iron and steel rust remover.

Embodiment 3

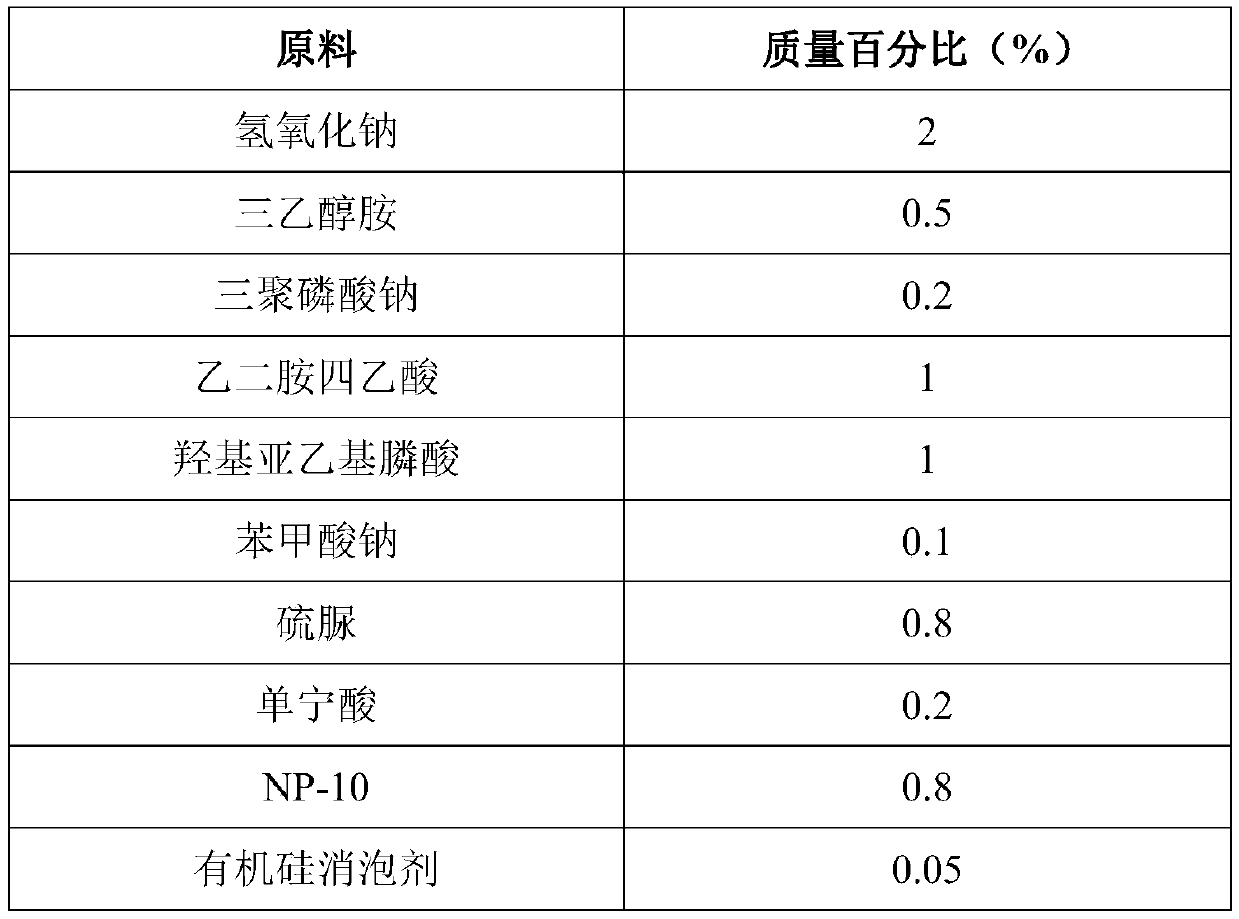

[0063] A kind of alkaline iron and steel derusting agent, its composition is as shown in the following table:

[0064] The composition table of a kind of basic iron and steel derusting agent of table 3

[0065]

[0066]

[0067] The preparation method of above-mentioned alkaline iron and steel derusting agent, comprises the following steps:

[0068] 1) Add sodium hydroxide and deionized water to the reaction kettle, and stir for 15 minutes;

[0069] 2) Add triethanolamine, sodium tripolyphosphate, ethylenediaminetetraacetic acid, hydroxyethylene phosphonic acid, sodium benzoate, thiourea and tannic acid into the reaction kettle, and stir for 15 minutes;

[0070] 3) Add NP-10 and silicone defoamer into the reaction kettle, and stir for 15 minutes;

[0071] 4) Add carboxymethyl cellulose into the reaction kettle and stir for 15 minutes to obtain a basic iron and steel rust remover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com