Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

119 results about "Metal cleaner" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

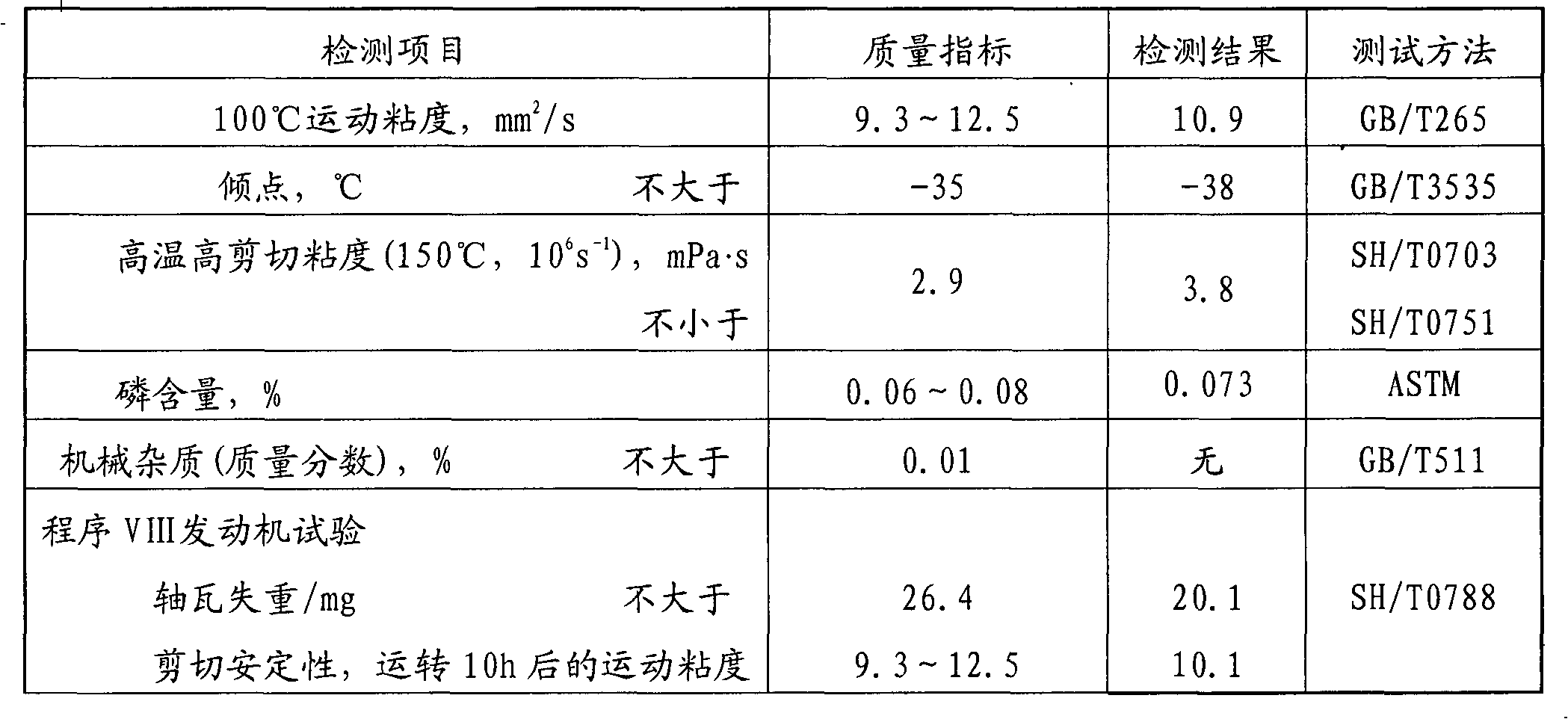

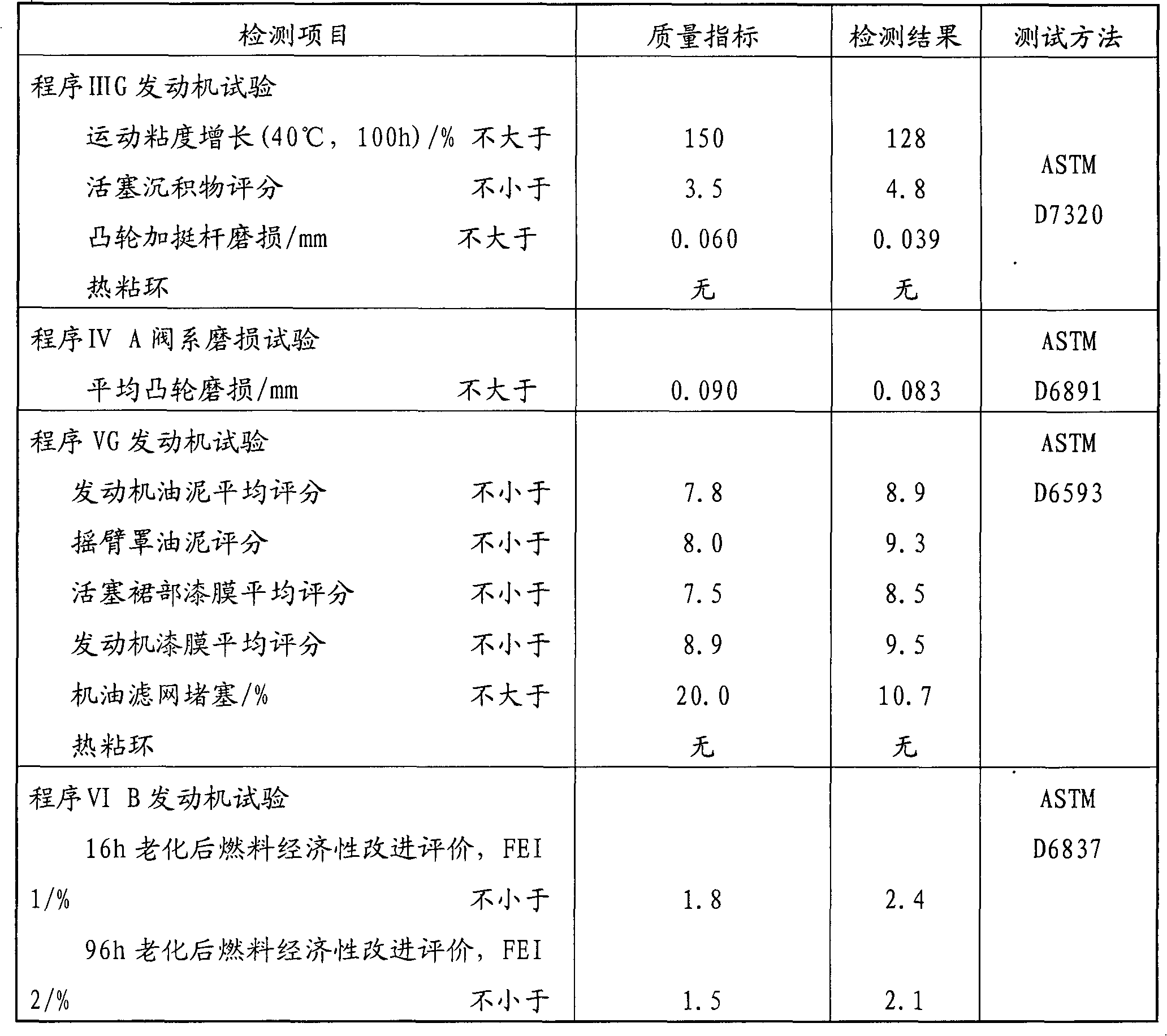

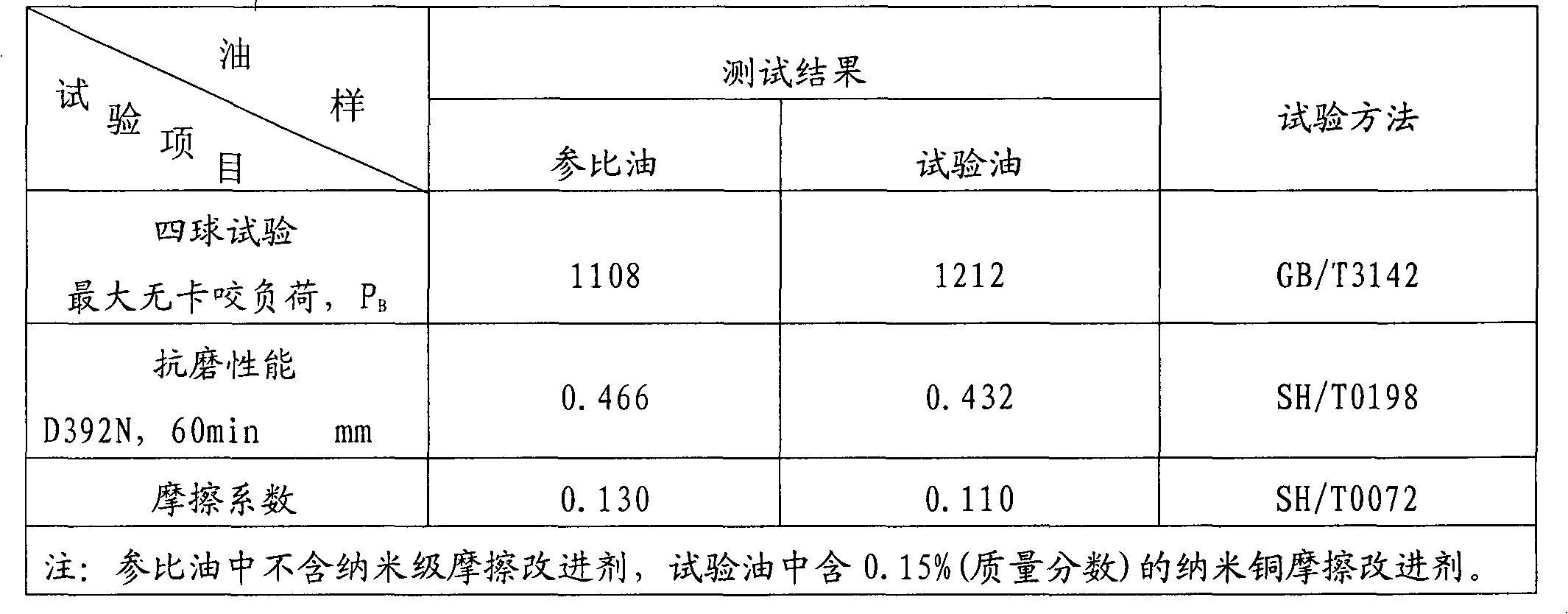

Energy-efficient long-life gasoline engine oil

InactiveCN101982534AReduce sulfur and phosphorus contentImprove carrying capacityLubricant compositionEcological environmentOil sludge

The invention discloses energy-efficient long-life gasoline engine oil prepared from the following components: synthetic base oil, a composite antioxygen, a metal cleaning agent, an ashless dispersant, a nano-level friction improver, a viscosity improver and a pour point reducer. The gasoline engine oil provided by the invention has the following advantages: requirements of API SM, ILSAC GF-4 and SAEJ300 are met and the service life is long; the complete synthetic base oil features low pour point, high viscosity index, good economy of fuel, degradability and reduced harm to the ecological environment; the phenol type antioxygen is combined with ZDDP, the anti-oxygen and antifriction properties are good and the catalyst poisoning in a tail gas processing unit is prevented; the acid neutralization capacity is good, the cleaning dispersibility is good and the oil sludge and carbon deposit are prevented from being generated; and the nano-level friction improver is added, the frictional factor is low, and the oil film features high carrying capacity and can automatically repair abraded surface and lengthen the service life of the engine.

Owner:GUANGDONG SANVO CHEM IND TECH

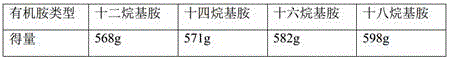

Modified graphene oxide, engine lubricating oil and application thereof

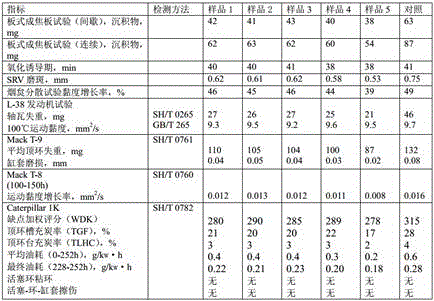

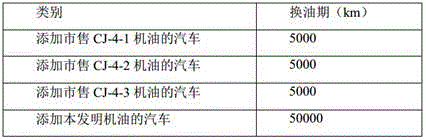

The invention discloses a graphene oxide modifying method and application thereof in engine lubricating oil. The method comprises the following steps: firstly preparing graphene oxide (GO) by adopting an improved Hummers process, and modifying the graphene oxide with long-chain fatty amine and organic silicon to obtain modified graphene derivative; and secondly, taking the modified graphene oxide as A), and compounding a friction modifier with a metal cleaning agent B), a metal corrosion inhibitor C), a complex antioxidant, an anti-foaming agent, a viscosity index improver, synthetic ester base oil and base oil, so that the engine lubricating oil added with the graphene oxide modifying agent is obtained. The method disclosed by the invention has the advantages that abrasion of an engine is greatly reduced by adding the graphene oxide modifying agent, so that oil draining period of automobile engine oil is prolonged to 50000 kilometers from 5000 kilometers, and fuel oil can be saved by 7-10% in the aspect of fuel economy.

Owner:江苏悦尔科技有限公司

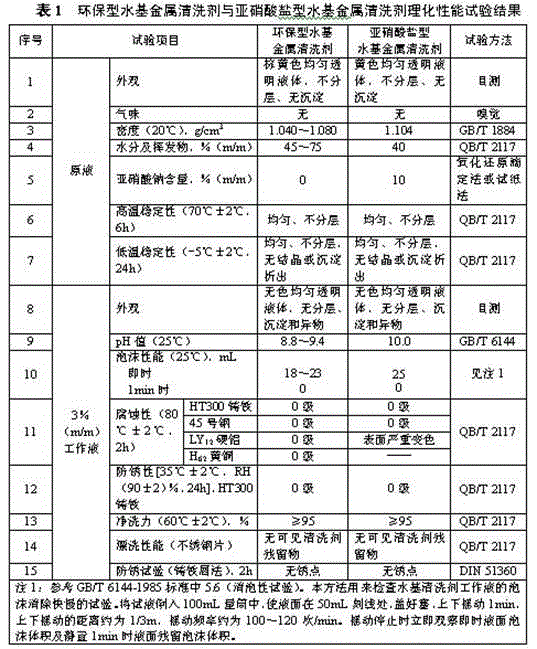

Environment-friendly metal cleaner

An environment-friendly metal cleaner comprises the following chief constituents: a surface active agent, a hydrophobic anti-rust agent, a builder, an additive (a disinfectant and PH modifier), water and the like. The metal cleaner has scientific and reasonable formula, moderate PH, and is specially applicable to cleaning mineral oil and oxide impurities on the surfaces of various metal parts in a spraying manner during the processes of mechanical production and maintenance; and the foam is extremely little during the cleaning process, the cleaning capacity is strong, the speed is quick, the continuity is good, the service life is long, the corrosion on equipment is low, and the usage is safe and reliable. The contained hydrophilic anti-rust agent can lead the surface of the metal to form an anti-rust protective film after being cleaned, thus ensuring the cleaned metal parts have certain anti-rust performance. The cleaner is an environment-friendly cleaner without ODS (ozone layer depleting substance).

Owner:南通鑫凯界面工程科技有限公司

Water-based metal cleaner and preparation method thereof

The invention discloses a water-based metal cleaner and a preparation method thereof. The water-based metal cleaner is prepared from sodium dodecylbenzene sulfonate, fatty alcohol-polyoxyethylene ether, alkylphenol polyoxyethylene, triethanolamine oleate, triethanolamine, 3-methyl-3-methoxy-1-butanol, polyphosphate, silicate, glycerol, primary sodium alkyl sulfate, isooctyl phosphate, benzotriazole, polyethylene glycol, dimethylaminoethyl methacrylate, 2-hydroyl-3-sulfopropyl starch ether and deionized water; the preparation method of the water-based metal cleaner comprises the following steps: firstly, adding a surfactant and the triethanolamine oleate to the glycerol, heating and stirring, next, adding the triethanolamine, the 3-methyl-3-methoxy-1-butanol, the polyphosphate and the silicate, adding the primary sodium alkyl sulfate, the isooctyl phosphate, the benzotriazole and the polyethylene glycol under the conditions of stirring and preserving heating, and finally adding the rest components under the conditions of stirring and preserving heating, and heating and stirring to obtain the cleaner. The water-based metal cleaner has excellent cleaning performance and relatively high corrosion inhibition period.

Owner:SUZHOU CHANGSHENG ELECTROMECHANICAL

Low-foam middle-cloud-point environment-friendly water base metal cleaner composition and preparing method thereof

The invention provides a low-foam middle-cloud-point environment-friendly water base metal cleaner composition and a preparing method thereof, and belongs to the field of metal cleaners. The low-foam middle-cloud-point environment-friendly water base metal cleaner composition is composed of low-foam low-cloud-point nonionic surface active agents, low-foam anion surface active agents, triethanolamine oleic soap, triethanolamine, styrene acrylic three azole nitrogen, ethylene diamine tetraacetic acid, sodium carbonate, polyether, organosilicone, sodium hydroxide and deionized water, wherein solid-phase raw material and liquid-phase raw material are sequentially added to a reaction container according to a formulation and metering, the organosilicone and the deionized water are finally added to the reaction container, stirring is conducted for 10min to 20min under the condition of indoor temperature, and clear products with a pH value ranging from 9 to 10 are obtained. The triethanolamine oleic soap is a cloud point improving agent, good water solubility is achieved after the triethanolamine oleic soap and the triethanolamine are re-compounded according to the ratio, solubilizing ability of the low-foam low-cloud-point nonionic surface active agents is enhanced, therefore the temperature of the solution cloud point of the cleaner is improved to 45 DEG C, cleaning efficiency of the cleaner is improved, and the low-foam middle-cloud-point environment-friendly water base metal cleaner particularly suitable for high-pressure spraying cleaning is obtained.

Owner:BOER TECH WUHAN

Metal cleaner

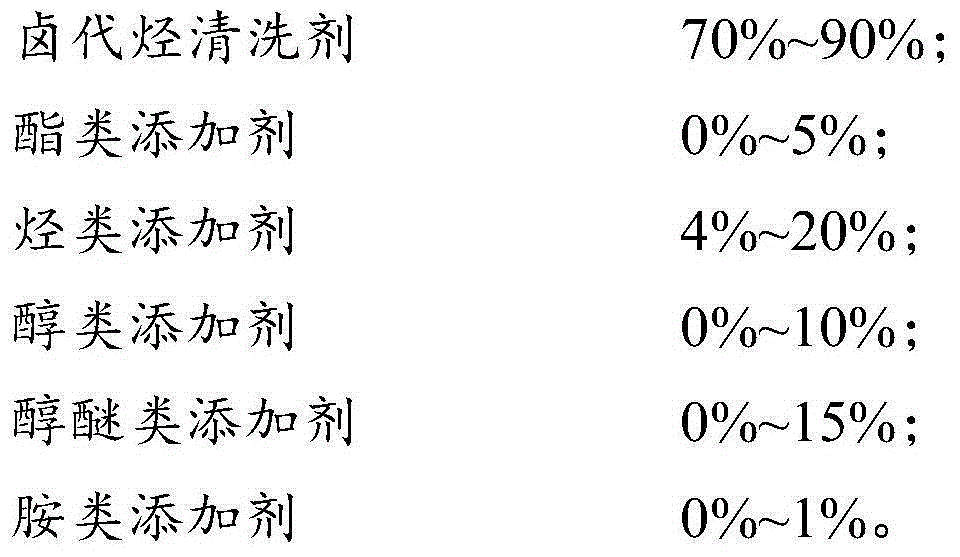

The invention discloses a metal cleaner. The metal cleaner is prepared from, by weight, 50%-90% of halohydrocarbon cleaners, 0%-10% of ester additives, 2%-30% of hydrocarbon additives, 0%-20% of alcohol additives, 0%-25% of alcohol ether additives and 0%-5% of amine additives, wherein the halohydrocarbon cleaners are chlorohydrocarbon and / or chloro-fluoro-hydrocarbon, chlorohydrocarbon is tetrachloroethylene and / or dichloromethane, and chloro-fluoro-hydrocarbon is 1-fluoro-1,1-dichloroethane. The metal cleaner is large in cleaning force, high in permeability and dispersity, capable of cleaning wax, ink, punching oil, cutting oil and lubricating oil, small in smell and free of toxicity.

Owner:SHENZHEN XINJUNXIANG TECHCAL

Environment-friendly water-based metal cleaner and preparation method thereof

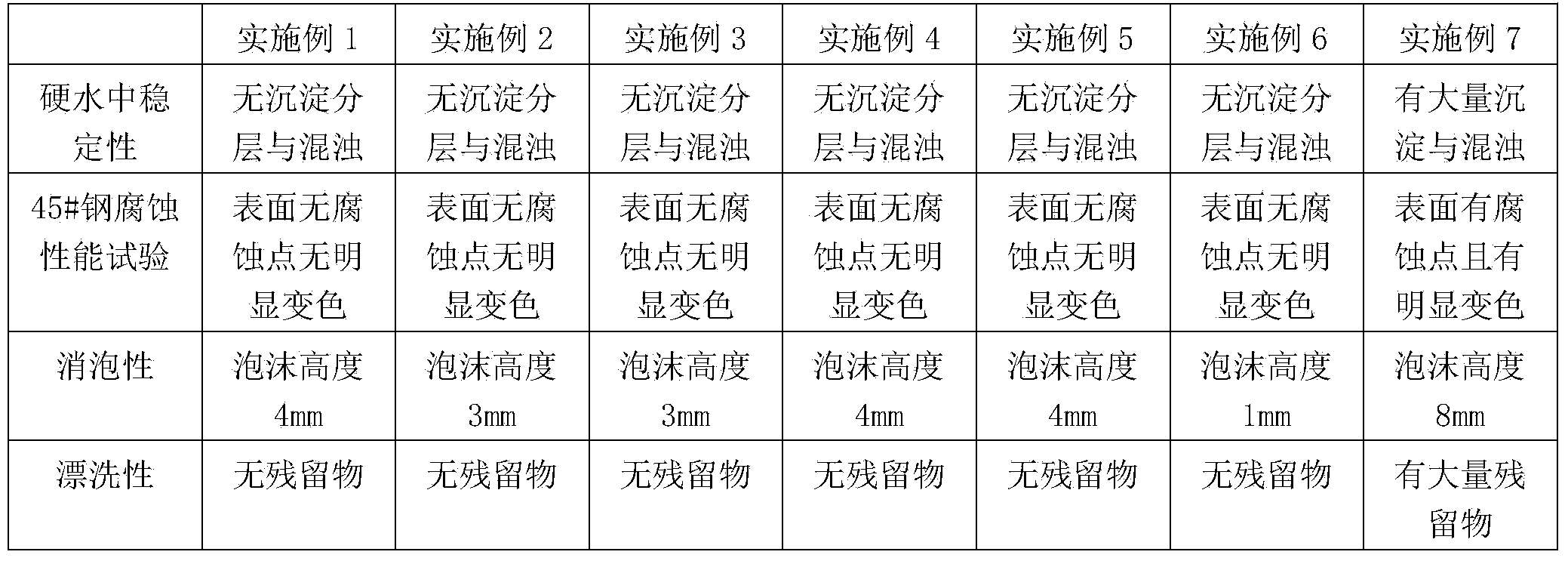

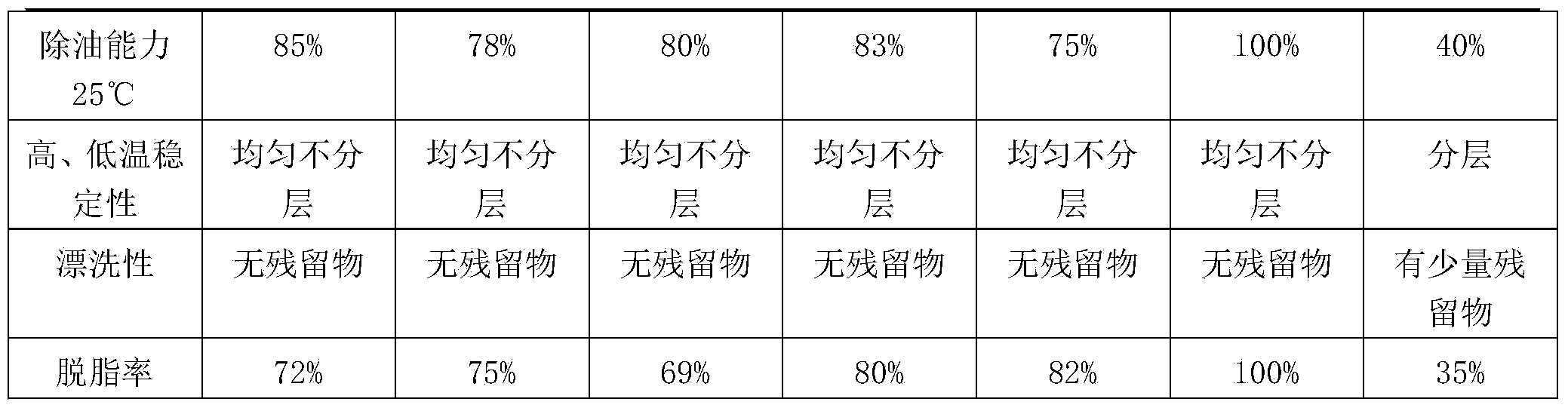

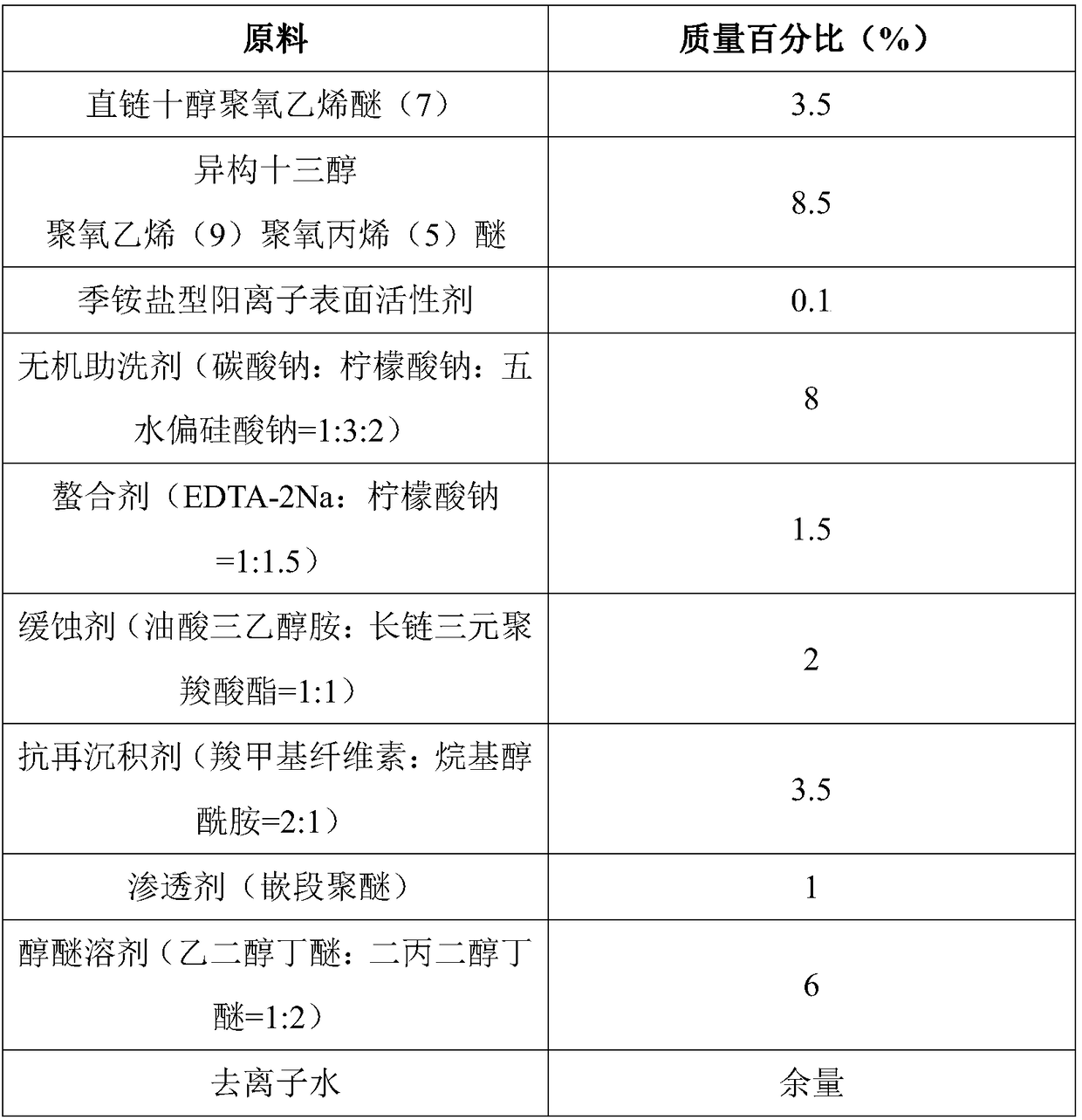

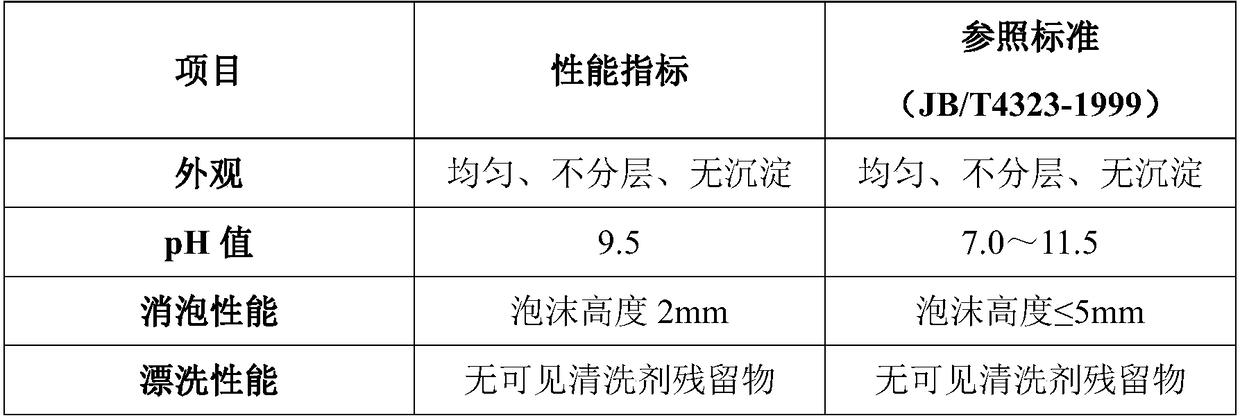

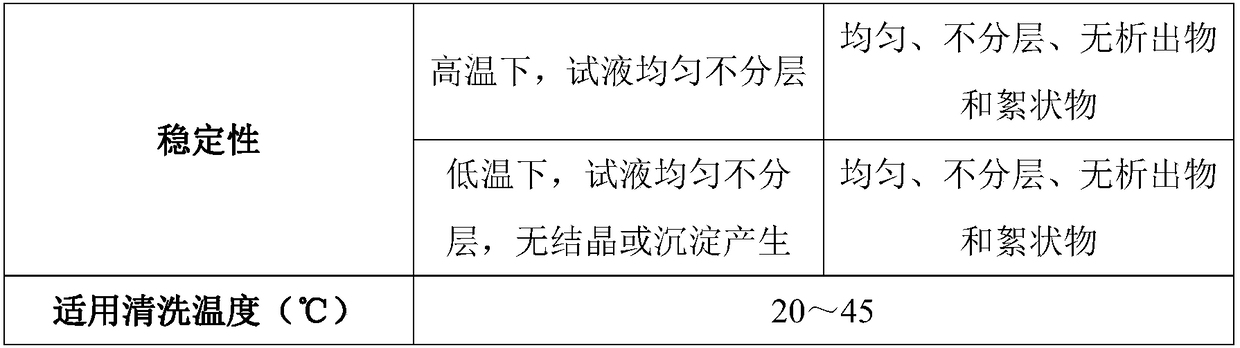

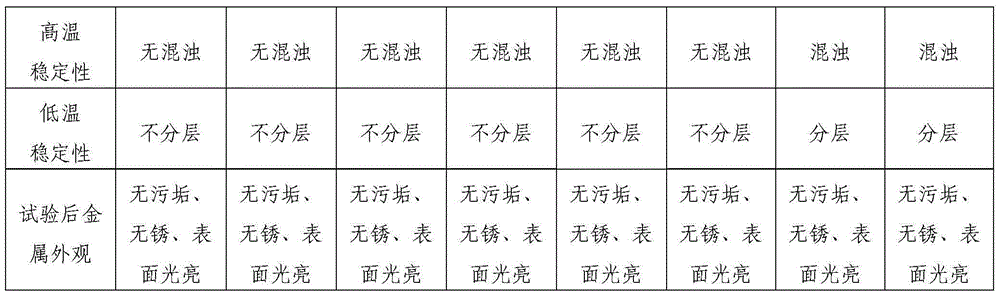

The invention discloses an environment-friendly water-based metal cleaner and a preparation method thereof. The environment-friendly water-based metal cleaner is composed of the following components of, by mass, 5-30% of a nonionic surfactant without APEO, 0.1-5% of a cationic surfactant, 0.1-15% of an inorganic washing assistant, 0.3-5% of a chelating agent, 0.5-6% of a corrosion inhibitor, 0.5-7% of an anti-redeposition agent, 0.5-3% of a penetrating agent, 0.1-8% of an alcohol ether solvent, and the balance water. The preparation method of the environment-friendly water-based metal cleanercomprises the following steps that the inorganic washing assistant and the chelating agent are added in the water and evenly mixed; then the nonionic surfactant without the APEO, the cationic surfactant, the corrosion inhibitor, the anti-redeposition agent, the penetrating agent and the alcohol ether solvent are added and evenly mixed; and the environment-friendly water-based metal cleaner is obtained. The environment-friendly water-based metal cleaner is free of phosphorus, nitrite and the APEO, good in anti-rust performance, good in stability, free of stimulation, safe, environmentally friendly and simple in preparation technology.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Metal cleaner

The invention relates to a metal cleaner used for metals such as gold, silver, copper, stainless steel, and the like. The metal cleaner comprises the following active constituents in parts by weight: 1-10 parts of nonionic surfactant, 2-20 parts of cathode surfactant, 5-15 parts of silicon dioxide abrasive and 0.05-2 parts of stabilizing agent. The product has the advantages of stronger decontamination effect and strong stability and can also be used for ensuring that the metals become bright.

Owner:BEIJING REWARD HOME CARE CHEM

Normal temperature metal cleaner and technique of preparing the same

ActiveCN101333664AEasy to prepareImprove decontamination abilityTriethanolamine oleateRoom temperature

The invention relates to a normal temperature metal cleaner as well as a preparation process thereof. The cleaner comprises the following components by weight: 6 to 8 parts of amphoteric surfactant; 0.2 to 0.4 parts of potassium permanganate; 1 to 2 parts of emulsifying agent; 4 to 8 parts of oxalic acid; 10 to 20 parts of acid fog inhibitor; 5 to 10 parts of triethanolamine oleate; 2 to 4 parts of surface conditioning agent; 3 to 6 parts of pickling inhibitor; 50 to 100 parts of hydrochloric acid with concentration of 31 to 36 percent; and 20 to 40 parts of water. Compared with the prior art, the normal temperature metal cleaner and the preparation process thereof have the advantages of: 1. convenience: the product is applied to the cleaning of various metallic products, and is simple and convenient in operation. 2. High efficiency: the operation process is simple, and the cleaning efficiency is greatly improved. 3. Economy: surfaces of various metal workpieces can be effectively cleaned and treated, the consumption of cleaner is low, and the production speed is expedited for users. 4. Environmental protection: the cleaner has no acid mist and is safe for human body.

Owner:万晓茂

Water-based metal cleaner

The invention provides a water-based metal cleaner, relating to a technology of pretreatment of processes of metal coating, electroplating, hot dipping coating and the like, in particular to a technology of cleaning the pretreatment surface of carbon steel. The water-based metal cleaner provided by the method comprises the following components of: 190 to 220 g / L of industrial hydrochloric acid, 1.7 to 8.5 g / L of phosphoric acid, 1 to 5 g / L of oxalic acid or 1 to 5 g / L of tartaric acid, 1 to 2.2 g / L of fatty alcohol polyoxyethylene lauryl ether sulfate sodium AES or 1.5 to 2 g / L of sodium dodecyl sulfate, 0.6 to 1.6 g / L of peregal 0-15, and 2 to 2.3 g / L of fatty alcohol-polyoxyethylene ether AEO-9. The cleaner can fast, effectively and synchronously complete two processes of deoiling and derusting on the metal pretreatment surface, can effectively prevent acid mist from volatilizing, prolongs the service life of equipment and improves the working environment of labor workers.

Owner:BEIJING JJRS TECH DEV +1

Metal cleaner

The invention discloses a metal cleaner, which relates to the field of chemical articles. The compositional ratio of a formula of the metal cleaner is as follows: 16 percent to 20 percent of hydrochloric acid, 2 percent to 4 percent of stabilizer, 1 percent to 2 percent of reducer, 1 percent to 2 percent of synergist, 1 percent to 2 percent of chelator, 1 percent to 2 percent of corrosion inhibitor and 60 percent to 70 percent of water. The metal cleaner has the advantages of good rust removal effect, high speed, low cost, convenience in use, non-ignition, non-explosion, no pollution to the environment, no irritation or damage to human bodies or metal, safety, non-toxicity and no volatilization.

Owner:ZHENJIANG XINTAI CHEM MATERIAL

Metal cleaner containing polyethylene imine

InactiveUS20070270323A1Clean effectEasy to cleanCationic surface-active compoundsDetergent mixture composition preparationPolyethylene glycolGlycol ethers

A process for cleaning metal surfaces is provided using a neutral industrial cleaner, which comprises a combination of non-ionic surfactants and / or glycol ethers, and polyethylene imine. The cleaner has a demulsifying effect on fats and / or oils on metal surfaces and in the cleaning solution allowing separation and reuse of the cleaner. The cleaner is low-foaming and can advantageously be used in spray application.

Owner:HENKEL KGAA

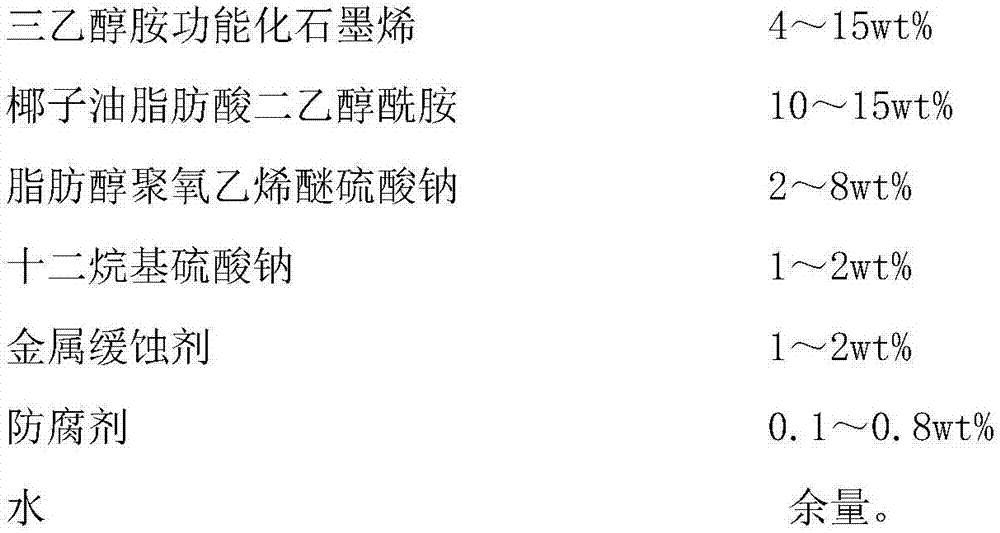

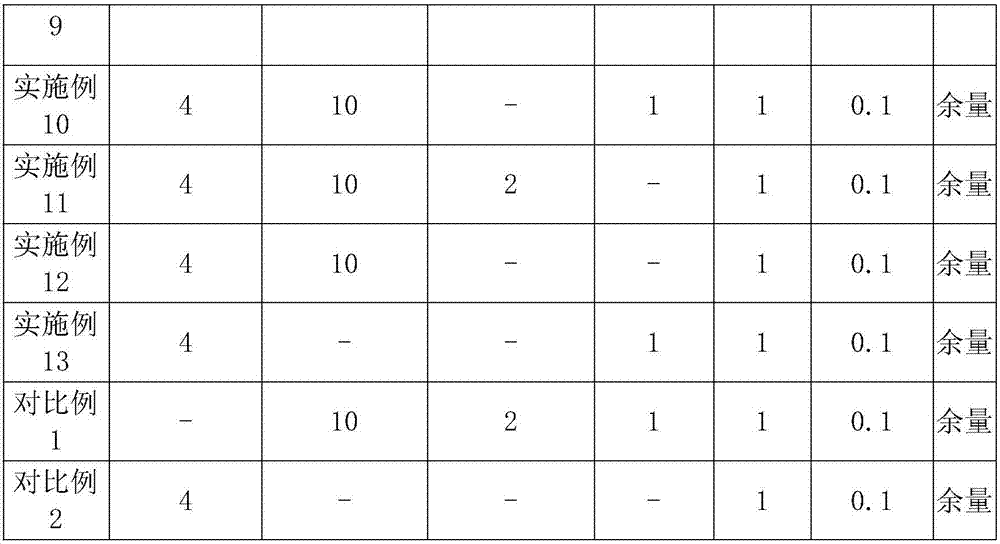

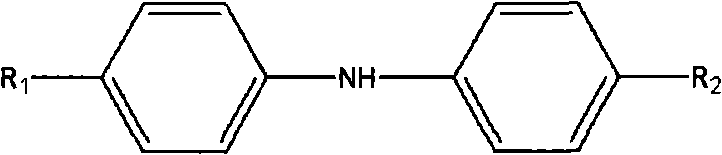

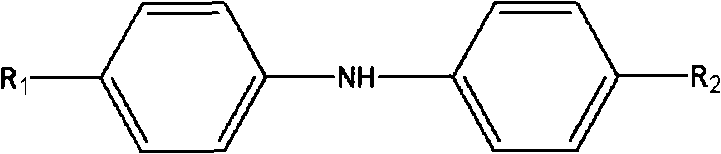

Metal cleaning agent added with functional modified graphene and preparing method of metal cleaning agent

The invention relates to a metal cleaning agent, and discloses a metal cleaning agent added with functional modified graphene and a preparing method of the metal cleaning agent. The metal cleaning agent is composed of 4-15wt% of triethanolamine functional graphene, 13-25wt% of surfactant, 1-2wt% of metal corrosion inhibitor, 0.1-0.8wt% preservative and the balance water. According to the metal cleaning agent, the triethanolamine functional graphene is creatively used to be added into the metal cleaning agent, triethanolamine of the triethanolamine functional graphene and the graphene are bonded as covalent bond, and the surface of the metal cleaning agent contains a large amount of tertiary amine nitrogen and hydroxyl active functional groups; and amino ionic liquid functional graphene achieves graphene modification through the non-covalent interaction between imidazole rings and graphite rings, the graphene has the super large specific surface area, the strong complexing effect is achieved after the grapheme and the triethanolamine are functionalized, so that the strong adsorption capacity is achieved, the hydrophilic and lipophilicity of the triethanolamine are retained, the strong adsorption capacity also can be achieved, and the metal cleaning agent is used without matching of an additional complexing agent.

Owner:郴州国盛新材科技有限公司

Multi-effect lubricating oil additive and preparation method thereof

The invention discloses a multi-effect lubricating oil additive which comprises the following components in parts by weight: 10-25 parts of metal cleaner, 8-18 parts of ash-less dispersant, 8-15 parts of amine ash-less antioxidant, 10-25 parts of anti-wear agent and 5-16 parts of viscosity improvement agent. The invention also discloses a preparation method of the multi-effect lubricating oil additive. The multi-effect lubricating oil additive can effectively prevent lubricating oil from generating deposits in a use process, has good wear resistance and rust protection, is an excellent friction modifier, and can ensure that the oil consumption of a motor vehicle is low, the noise is reduced, the exhaust emission reaches the standard, and the service life of the whole vehicle is prolonged.

Owner:JINAN DEV ZONE XINGHUO SCI & TECH RES INST

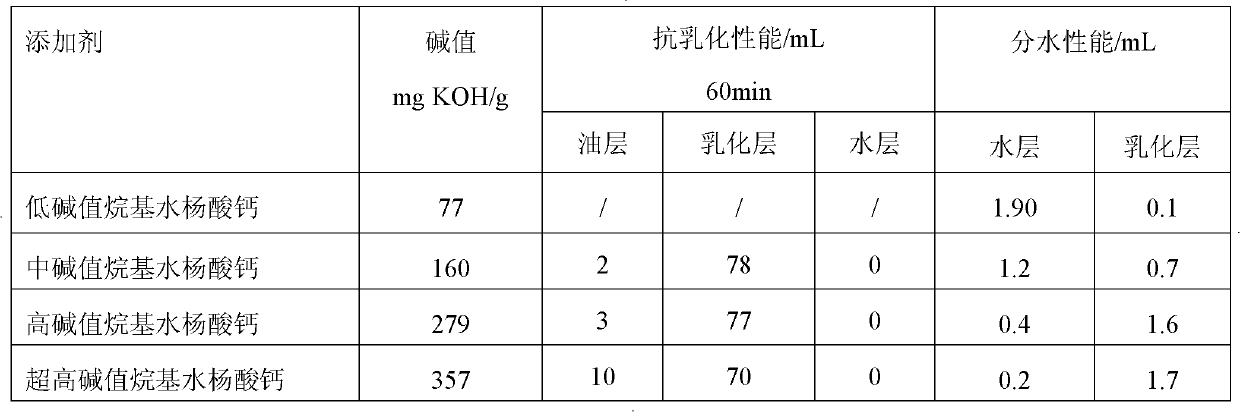

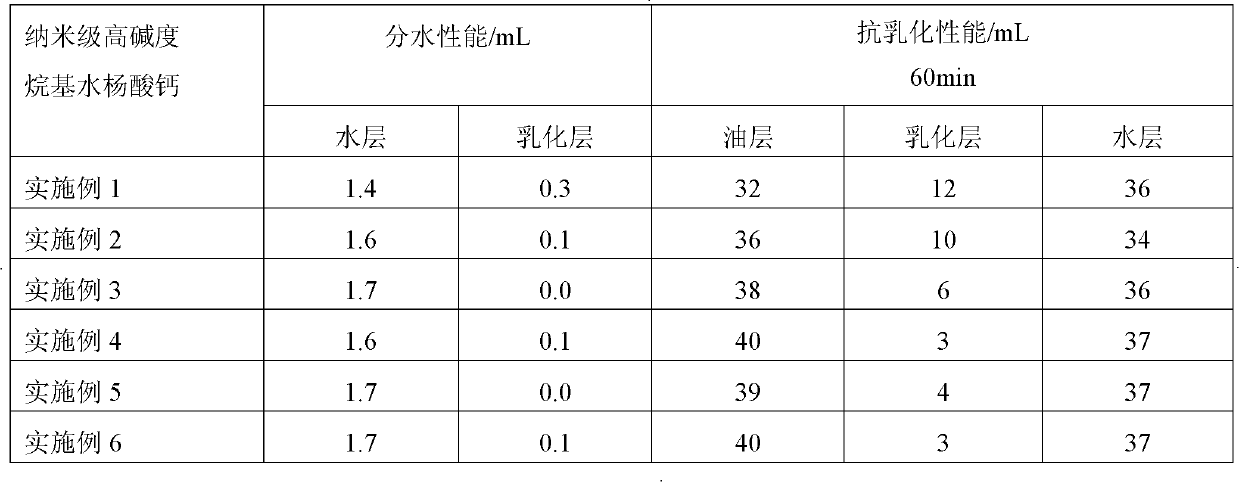

Preparation of nanoscale high-alkalinity calcium alkyl salicylate additive

The invention relates to a nanoscale high-alkalinity calcium alkyl salicylate additive and a preparation method of the nanoscale high-alkalinity calcium alkyl salicylate additive. The method comprises the following steps of: using alkyl salicylic acid, calcium hydroxide and surfactant and the like as raw materials, performing processes of neutralization and high alkalinity reaction on the ingredients according to a certain proportion to prepare a high-alkalinity calcium alkyl salicylate metal cleaner with the total alkalinity higher than 280mgKOH / g. The high-alkalinity calcium alkyl salicylate provided by the invention not only has all the basic properties of a traditional high-alkalinity calcium alkyl salicylate product, but also has good sub-aqueous and anti-emulsifying properties, not only satisfies the use requirement of high-grade internal combustion engine oil, but also is suitable for the use in the oil products such as ship oil with a high requirement on the sub-aqueous property, and thus the high-alkalinity calcium alkyl salicylate provided by the invention is a lubricant additive with a perfect property.

Owner:PETROCHINA CO LTD

Environment-friendly water-based metal cleaner

The invention relates to an environment-friendly water-based metal cleaner. The environment-friendly water-based metal cleaner is characterized in that: a process for preparing the environment-friendly water-based metal cleaner comprises the following steps of: mixing, stirring and heating dodecanedioic fatty acid and triethanolamine in a reaction vessel in a mass ratio of 1:3 to synthesize water-soluble amine soap serving as an antirusting agent monomer; adding water into the vessel, heating to 50 DEG C, and maintaining the temperature; slowly adding sodium carbonate and hydroxy benzotriazole under stirring, sufficiently and uniformly dissolving; slowly adding the triethanolamine and the antirusting agent while stirring and dissolving uniformly; slowly adding alkylphenol ethoxylates OP-10, alkylolamide6501 and alkylolamide phosphate ester 6503, and stirring and dissolving uniformly; slowly adding organic modified phosphate EAK8190 and polyethyleneglycol, and stirring and dissolving uniformly; and slowly adding polyether defoamer SPG-10 and mouldproof bactericide NEUF652, and stirring and dissolving uniformly to obtain the final water-based metal cleaner. The environment-friendly water-based metal cleaner is applicable to cleaning in the iron casting and steel mechanical processing procedure, cleaning before antirust sealing and cleaning in aluminum, copper and other nonferrous metal mechanical processing procedure, has interprocess and short-term rust prevention and corrosion resistance, can be matched with electroplating, spray painting, baking finishing, mopping and other processes, can be used for cleaning at normal temperature, and has better cleaning effect when heated.

Owner:CHINA FIRST AUTOMOBILE

Metal cleaner and application thereof

The invention provides a metal cleaner. The metal cleaner comprises the following components in parts by weight: 0.5-1 part of ultra-low interfacial tension surfactant, 0.5-1 part of acid cleaner, 0.1-0.5 part of acid inhibitor, 0.01-0.05 part of bactericide, 0.01-0.05 part of pH conditioner, 3-10 parts of organic solvent, and 80-150 parts of water. The metal cleaner can be used for cleaning a metal part. The metal cleaner is good in cleaning effect, free of residue, free of corrosion on metal and stable in property.

Owner:CHINA PETROLEUM & CHEM CORP

Four-function treating liquid for surface of iron or steel

InactiveCN101245458ANo pollutionProduction operation safetyMetallic material coating processesPolyvinyl alcoholPhosphoric acid

The invention relates to tetrafunctional surface treatment fluid for steel, the ingredients of which are: phosphoric acid: 60kg, polyvinyl alcohol: 0.2kg, zinc oxide: 2kg, zinc nitrate: 0.5kg, tartaric acid: 1.5kg, metal cleaner: 8611kg, ammonium molybdate: 0.36 kg and the rest of water. The product does not lead to environmental pollution and can guarantee the safety of production operation. Scientific material proportion ensures the product is limpid and has good stability. The invention has excellent derusting ability and can dispose of scale cinder attached on the surface of the steel, prevent an electrolyte from expansion and effectively control filiform corrosion under a film and corrosion in the breakage of a film coating. As for the usage method, dipping, spraying, brushing and wiping are all allowed. Simplification ensures that the operation process can be completed at one time.

Owner:天津新技术产业园区科茂化学试剂有限公司

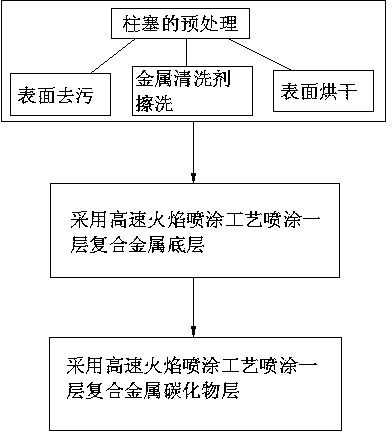

Spraying process for abrasion resistant layer of plunger contact surface

InactiveCN104032254AIncreased durabilityImprove wear resistanceMolten spray coatingWarm waterCarbide

The invention discloses a spraying process for an abrasion resistant layer of a plunger contact surface, and relates to the technical field of abrasion resistance of a plunger pump. The spraying process comprises the following steps: various oil stain pollutants on the surface of a plunger are removed through baking for 3 hours in an oven; metal cleaner is mixed with warm water at a temperature of 68 DEG C in a clean container; the plunger is scrubbed and cleaned by wetting a broad cloth; the surface of the plunger is evenly polished by wetting a piece of waterproof abrasive paper; the polished surface is scrubbed for cleaning by using a clean cloth, and is dried in the oven; a composite metal bottom layer is sprayed on the surface of the plunger through a high-speed flame spraying process; and a composite metal carbide layer is sprayed on the surface of the bottom layer by the high-speed flame spraying process. The spraying process is simple, largely improves the durability and abrasion resistance of the plunger, enhances the stability of the plunger pump, and reduces the production cost; and the ultrahigh-speed spraying process is adopted, so that the carbide element oxidation burning loss is small, and the effective protection effect on the plunger is acted.

Owner:ZHEJIANG OUYAO MACHINERY

Water-based metal cleaner and preparation method thereof

The invention discloses a water-based metal cleaning agent, which is made of the following raw materials in parts by mass: 3-8 parts of anionic surfactant, 1-10 parts of non-ionic surfactant A, 1-10 parts of non-ionic surfactant Ionic surfactant B, 2~5 parts of dispersant, 1.5~2.2 parts of complexing aid, 10~20 parts of silicate, 3~10 parts of inorganic base, 2~5 parts of organic base, 0.1 ~0.5 parts of defoamer, 37.3~76.4 parts of water. The invention also discloses a method for preparing the water-based metal cleaning agent. The invention has the advantages of good cleaning effect, no blind area in cleaning, less residue after cleaning, and less corrosion to metal workpieces after cleaning.

Owner:MAANSHAN TUORUI METAL SURFACE TECH

Metal cleaner

InactiveCN103014734AGood cleaning and rust removalSimple preparation processMetal cleanerCleansing Agents

The invention discloses a metal cleaner, which comprises the raw materials in parts by mass: 50-60 parts of sodium alkyl benzene sulfonate, 20-34 parts of sodium hydroxide, 12-18 parts of potassium pyrophosphate, 38-42 parts of ethylenediamine tetraacetic acid, 10-14 parts of glycol, 10-20 parts of fatty alcohol-polyoxyethylene ether, 8-16 parts of isopropanol, 8-16 parts of borax, and 40-60 parts of deionized water. The metal cleaner has good rust removal effect, less harm to environment, simple preparation technology and low cost.

Owner:南通市华东润滑设备有限公司

Environment-friendly water-based metal cleaner

The invention discloses an environment-friendly water-based metal cleaner. The environment-friendly water-based metal cleaner comprises the following components: 4-10g / L of surfactant, 1-10g / L of alkali compound, 1-10g / L of nitrate, 1-10g / L of phosphate and 1-5g / L of amine salt. By adopting the cleaner, the oil removing effect on the surface of a workpiece is increased, simultaneously the corrosion to the workpiece is low and the cleaning residual solution hardly causes environmental pollution.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

Acid metal cleaner

The invention relates to an acid metal cleaner. The acid metal cleaner comprises the following components by weight percentage: 40% of hydrochloric acid, 5-10% of urotropin, 3-5% of sodium gluconate, 1-3% of oxalic acid, 2-3% of sodium dodecyl benzene sulfonate, 1-3% of AC1830 (N-Polyoxyethylated-N-octadecylamine), 1-3% of penetrant JFC, and the balance of water. According to the acid metal cleaner, rust stain, incrustation and oil stain of metal sections and equipment are effectively removed through the synergistic effect of acidic materials and surfactants, furthermore, the formula of the acid metal cleaner is simple, the acid metal cleaner can effectively lower the contamination degree, the cleaning period is long, and the production cost is lowered.

Owner:东莞市恒天表面处理材料有限公司

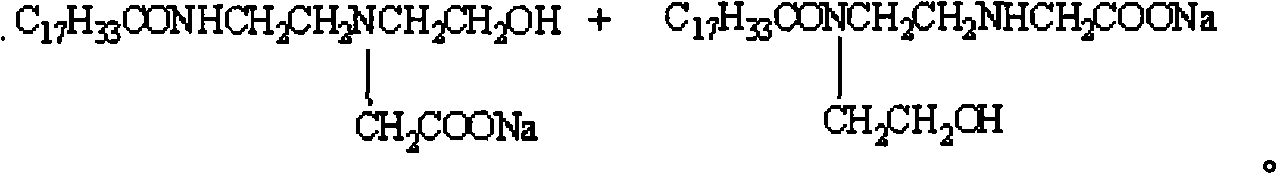

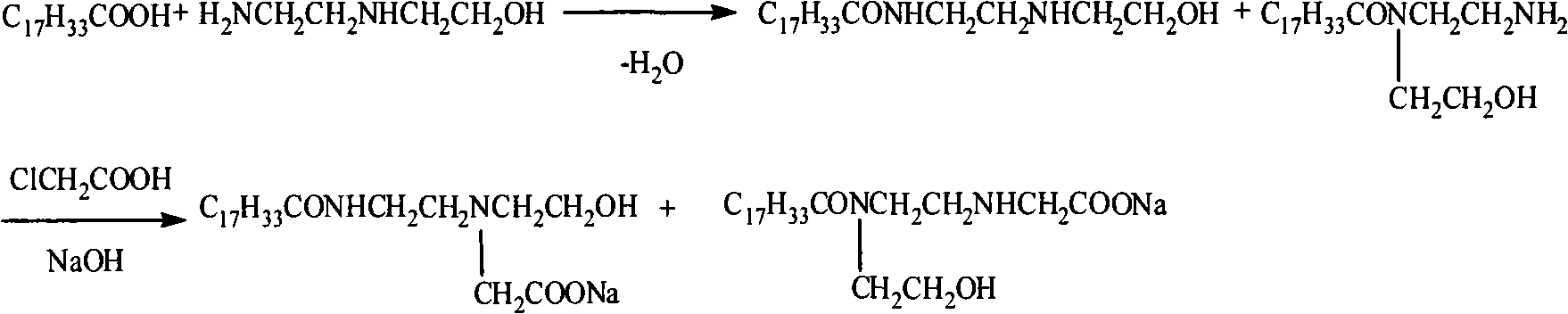

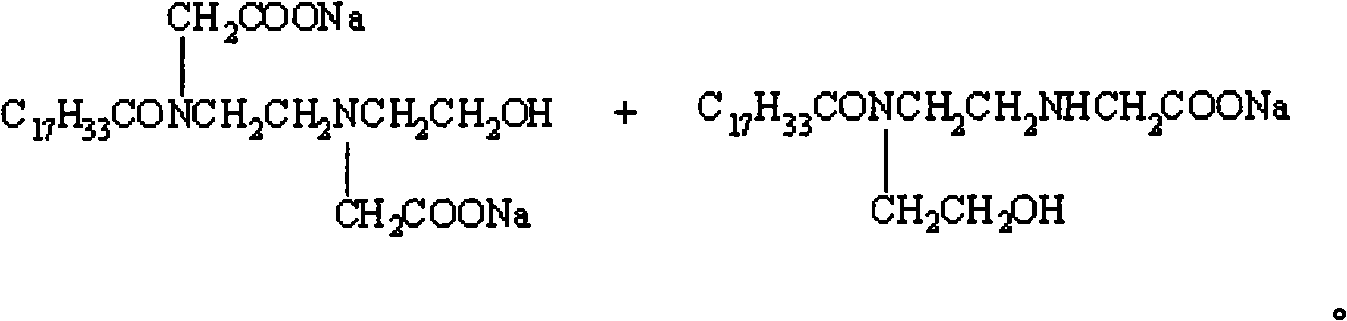

Oleic acid acidamide surfactant and synthetic method

InactiveCN101254437AGood suspensionPrevent redepositionTransportation and packagingMixingVegetable oilActive agent

An oleamide surfactant and a synthetic method thereof are provided. The inventive oleic amide surfactant has the structural formula as above. The synthetic method includes the following steps: synthesizing an oleic amide surfactant intermediate from oleic acid and hydroxyethylethylene diamine as raw materials, and then performing amphoteric reaction by 'chloroacetic acid process' to obtain the oleic amide surfactant. Based on the summery of research findings by the predecessors, the invention is novel in direct synthesis of amide surfactants by vacuum-amphoteric method without ring closing reactions. The inventive oleic amide surfactant has good effects of emulsifying, dispersing and suspending greasy dirt in mineral and vegetable oils, helps prevent re-deposition of greasy dirt, and has excellent effect of preventing rust formation on steel, cast iron and other metals. Additionally, the oleic amide surfactant can enhance the stability of anionic and non-ionic emulsions and the lubricating capability of emulsified oils. The oleic amide surfactant is widely used in products such as metal cleaners, drilling oil, machining oil and viscosity reducers in petroleum extraction.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Preparation method for efficient environmental-friendly rustproof water-based metal cleaning agent

The invention discloses a preparation method for an efficient environmental-friendly rustproof water-based metal cleaning agent and belongs to the technical field of preparation of metal cleaning agents. According to the preparation method, stearic acid, oleic acid, monoethanolamine and triethanolamine generate a reaction, anionic surfactant organic amine fatty acid soap is prepared and is compouned with nonionic surfactant starch-based dodecyl glucoside, water-soluble polyol ether and a solubilizing cleaning agent are added, and all components of the water-soluble polyol ether and the solubilizing cleaning agent are capable of promoting emulsified dispersion of oil stain; and coconut oil fat diethanol amide and fatty alcohol-polyoxyethylene ether are added and serve as a hard water stabilizer, corrosion inhibitor sodium benzoate protection metal is added, washing auxiliary sodium metasilicate is added to improve the decontamination capacity and the cleaning efficiency of a surfactant, defoamer dimethyl siloxane is added after even mixing, and the efficient environmental-friendly rust-proof water-based metal cleaning agent is prepared. It is proved by the examples that the metal cleaning agent is clean and environmentally friendly, free of corrosion to metal and free of harm to the human body and the environment and has the wide future development.

Owner:丁玉琴

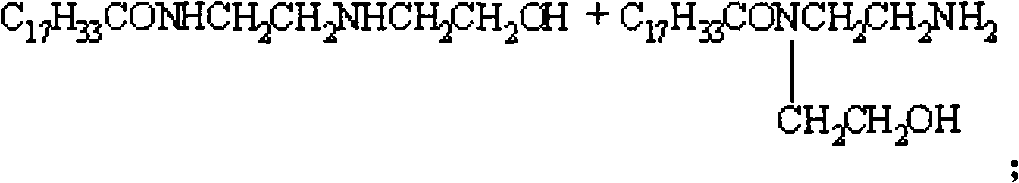

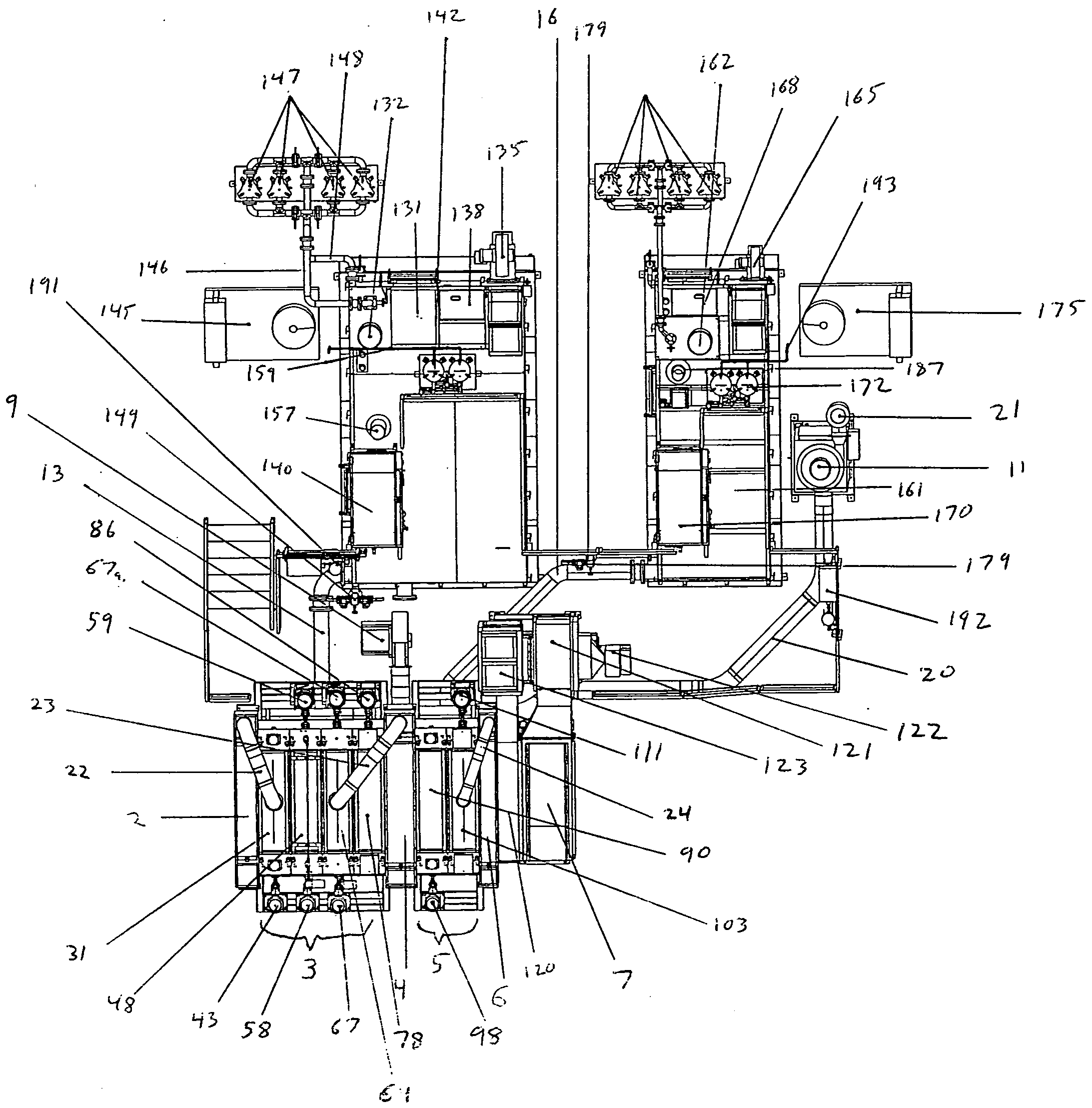

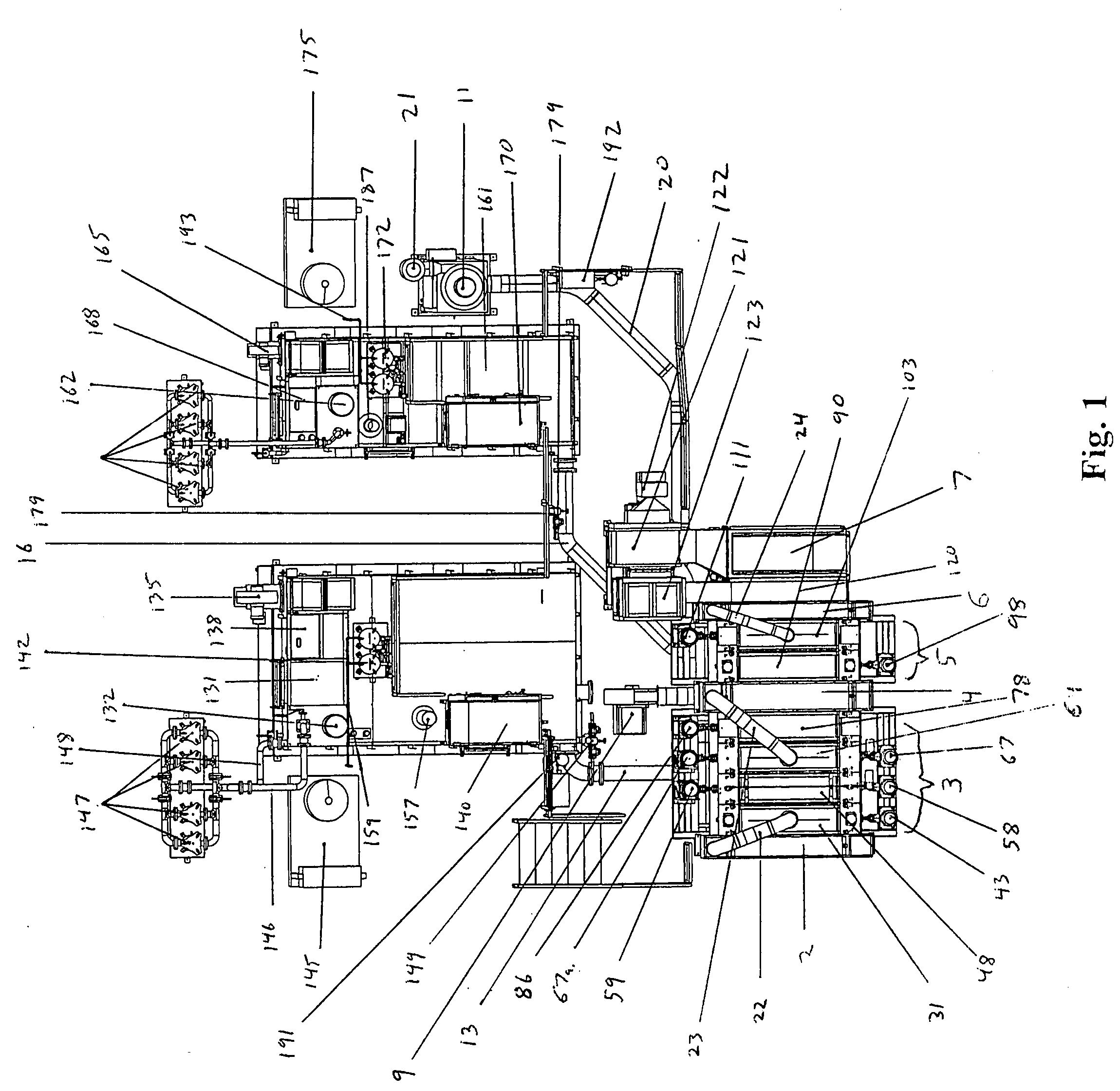

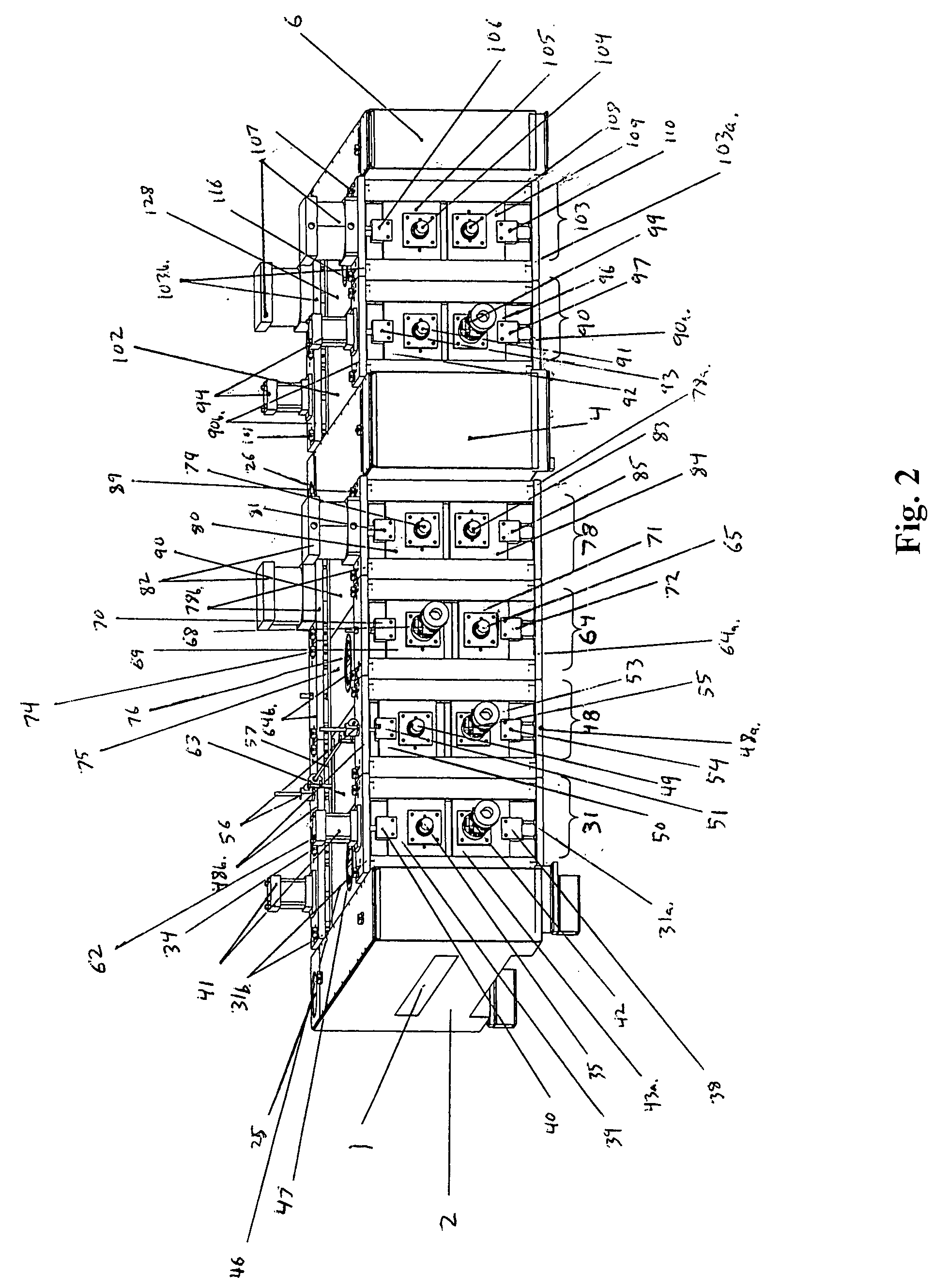

Multi-stage metal cleaner

InactiveUS20090038640A1Protect environmentAvoid wastingCleaning using toolsCleaning using liquidsWater useSystems design

The multi-stage coil washer is a system for removing oil and other contaminants from flat metal feed stock for further processing. The system utilizes wash, rinse and dry off stages to remove all of the contaminants and leave a small amount of oil to prevent flash rusting, in the case of a metal feed stock that rusts, and allow for storage. The wash and rinse system use a series of rolls in cartridges, individually motor driven, to clean the metal feed stock comprising of a combination of hard chrome, abrasive embedded non-woven and fibrous rolls. Each cartridge containing a top and bottom roll can be removed. Separate heated wash and rinse fluids are used wash and rinse fluid are separately contained in individual tanks which contain multiple cleaning apparatuses. Each tank cleans the water using micron filters, bacteria filters, magnets, oil separators and centrifuges. The centrifuges remove oil from the water and recycle the cleaned water back into the tank. A mist containment unit prevents mist and steam from escaping in the assembly and the mist collector recycles the recaptured water back into the rinse water tank. The multi-stage metal feed stock washer is an environmentally friendly system designed to continually recycle its wash and rinse water with little waste.

Owner:MARK ONE CORP

Industrial metal cleaner and preparation method thereof

The invention relates to a cleaner, particularly relates to an industrial metal cleaner, and belongs to the technical field of cleaning of industrial equipment. The industrial metal cleaner comprises the following components in percentages by weight: 2.0-6.0% of short fatty alcohol polyoxyethylene ether, 1.5-2.5% of propylene glycol, 0.6-1.2% of sodium silicate, 0.6-1.2% of oxalic acid, 0.6-2.2% of anionic polyacrylamide, 1.2-2.5% of p-nitrobenzoic acid, 0.6-1.2% of linoleic acid, 2.0-7.0% of ethylenediamine tetraacetic acid (EDTA), 4.0-5.0% of benzotriazole, 3.2-3.9% of polyvinylpyrrolidone, 4.0-5.5% of mesoporous silica and the balance of deionized water. The particle size of the mesoporous silica ranges from 100 nm to 500 nm. The industrial metal cleaner is scientific and reasonable in design, meets market situations according to the present demands, and has huge market economy prospects.

Owner:青岛友诚高新技术有限公司

A metal cleaning agent and a preparation method thereof

The invention discloses a metal cleaning agent and a preparation method thereof. The metal cleaning agent comprises following raw materials by weight: 8-10 parts of sodium dodecylbenzenesulfonate, 2-6 parts of sodium hydrogen carbonate, 10-12 parts of magnesium carbonate, 4-6 parts of trisodium phosphate, 2-9 parts of zirconium oxychloride, 5-10 parts of butyl stearate, 10-15 parts of propylene glycol, 20-22 parts of ethylene oxide, 10-20 parts of zinc peroxide and 30-40 parts of water. Dirt on metal surfaces and other dirt difficult to remove can be easily removed by the metal cleaning agent provided by the invention. Cleaned metals can maintain rustless for 30 days when being exposed in the air. In addition, the metal cleaning agent is low in cost.

Owner:上海兆立纸业发展有限公司

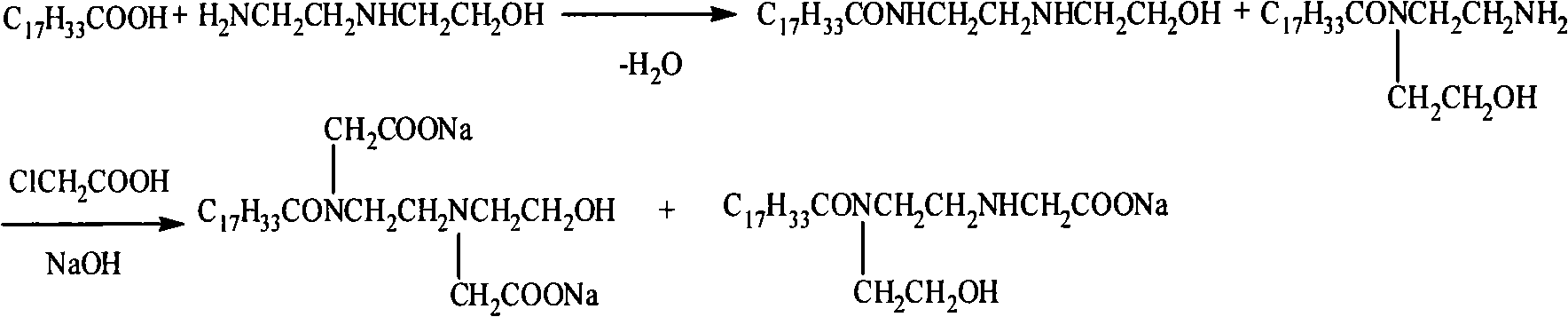

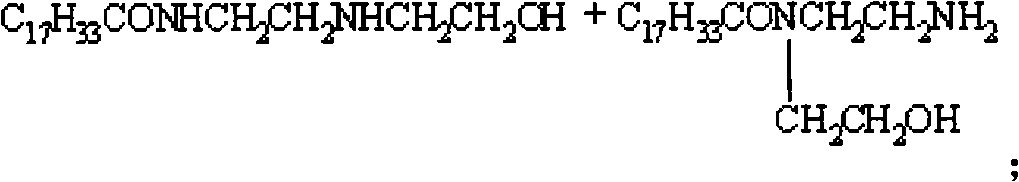

Dicarboxy oleic acid acidamide surfactant and synthetic method

InactiveCN101254438AImprove the lubrication effectGood dispersionTransportation and packagingMixingVegetable oilChloroacetic acids

A dicarboxyl oleic amide surfactant and a synthetic method thereof are provided. The inventive dicarboxyl oleic amide surfactant has the structural formula as above. The synthetic method is novel in the direct synthesis of amide surfactants by vacuum-amphoteric method without ring closing reactions. The method includes the following steps: synthesizing a dicarboxyl oleic amide surfactant intermediate from oleic acid and hydroxyethylethylene diamine as raw materials, and then performing amphoteric reaction by 'chloroacetic acid process' to obtain the dicarboxyl oleic amide surfactant, wherein the mole ratio of dicarboxyl oleic amide intermediate to chloroacetic acid to NaOH is 1: (2-2.6):(4-5.2). The inventive dicarboxyl oleic amide surfactant has good effects of emulsifying, dispersing and suspending greasy dirt in mineral and vegetable oils, helps prevent re-deposition of greasy dirt, and has excellent effect of preventing rust formation on steel, cast iron and other metals. Additionally, the oleic amide surfactant can enhance the stability of anionic and non-ionic emulsions and the lubricating capability of emulsified oils. The oleic amide surfactant is widely used in products such as metal cleaners, drilling oil, machining oil and viscosity reducers in petroleum extraction.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Titanium-based doped titania photocatalytic net and manufacturing method thereof

ActiveCN107866210ALarge specific surface areaImprove passabilityPhysical/chemical process catalystsMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a manufacturing method of a titanium-based doped nanometer titania photocatalytic net. The manufacturing method comprises (1) preparing a photocatalytic net from a titanium-based drawn net as a substrate, (2) pre-treating the photocatalytic net and washing the photocatalytic net in an ultrasonic cleaner through an alkaline metal cleaner to remove oil, (3) carrying out micro-arc oxidation on the pre-treated photocatalytic net for 5-10min at current density of 1-10 A / dm<2>, and (4) putting the photocatalytic net subjected to micro-arc oxidation into a closed tank, carrying out hot water sealing, carrying out drying, carrying out annealing at an annealing temperature of 450-550 DEG C for 60-120min, and carrying out cooling to obtain the titanium-based doped nanometer titania photocatalytic net. The preparation method has simple processes and is environmentally friendly. A metal oxide film is formed on the surface of the substrate in situ and the bonding effect between the film layer and the substrate is very good.

Owner:长沙立兴环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com