Preparation of nanoscale high-alkalinity calcium alkyl salicylate additive

A technology of calcium alkyl salicylate and high alkalinity, which is applied in the field of lubricating oil, can solve problems such as difficulty in high alkalinity, poor water separation performance, and poor water separation performance, so as to improve overall performance and benefit Water-separation performance, anti-emulsification ability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

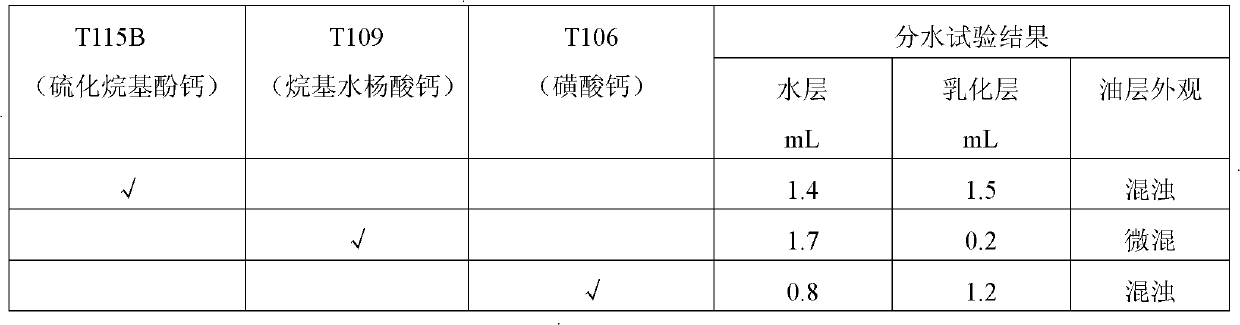

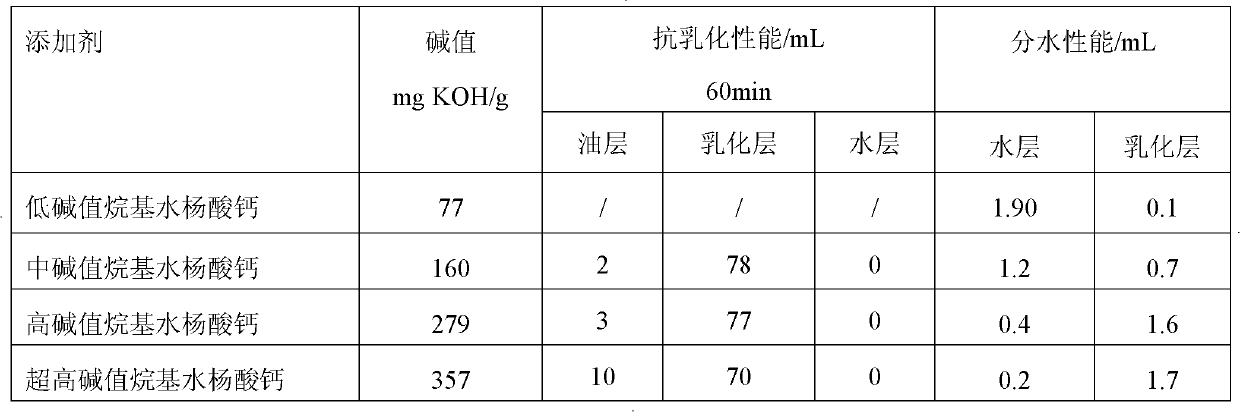

Problems solved by technology

Method used

Image

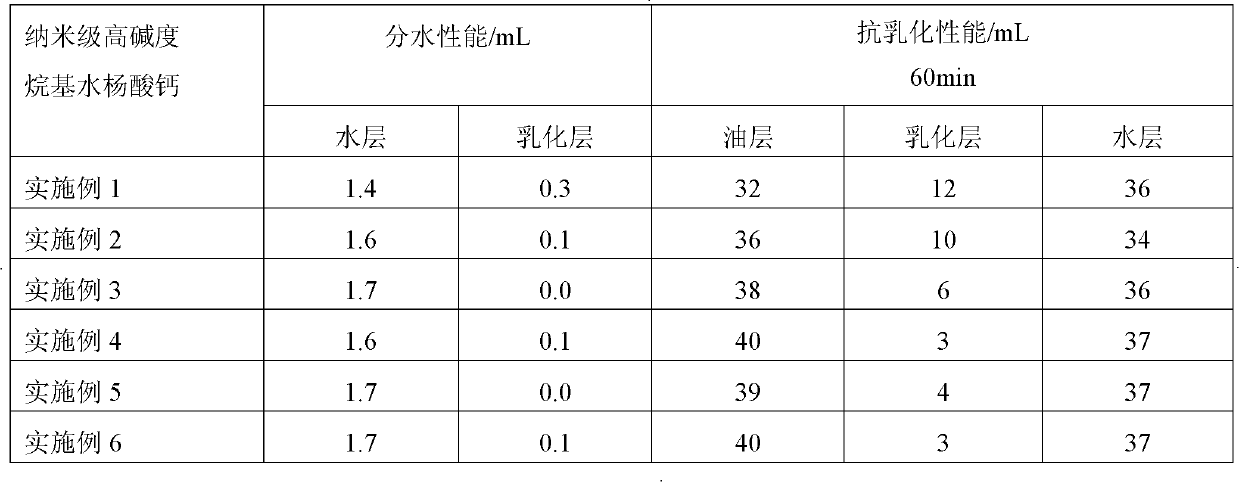

Examples

Embodiment 1

[0023] Embodiment 1: Add straight-run gasoline 120ml, methanol 120ml (industrial product), calcium hydroxide 37.0g, water 9.5g in the 500mL four-neck flask with electric stirrer and condensation dehydrator, start stirring and be warming up to 40- 50°C, then add 5.0g of alkylbenzenesulfonic acid, 90.0g of alkyl salicylic acid, 0.85g of anti-emulsifier (polyether ester), at this time, it can be seen that the system has a temperature rise phenomenon, and the reaction temperature is controlled at 45-55°C , for neutralization reaction 1.0h. Then feed a certain amount of carbon dioxide gas (control the ventilation rate 200-250ml / min) to carry out the high alkalinity reaction for about 2.0 hours. After the reaction is completed, the temperature is raised to 110°C, water and alcohol accelerators are removed, diluted with a solvent and centrifuged The residue was removed, and finally the solvent was removed by distillation under reduced pressure to obtain a product with a base number o...

Embodiment 2

[0024] Embodiment 2: Add straight-run gasoline 120mL, methanol 120ml (industrial product), calcium hydroxide 37.0g, water 9.5g in the 500mL four-neck flask with electric stirrer and condensation dehydrator, start stirring and be warming up to 40- 50°C, then add 10.0g of alkylbenzenesulfonic acid, 90.0g of alkyl salicylic acid, 0.85g of anti-emulsifier (polyether ester), control the reaction temperature at 45-55°C, react for 1.0h, and carry out neutralization reaction. Then feed a certain amount of carbon dioxide gas (control the ventilation rate 200-250ml / min) to carry out the high alkalinity reaction for about 2.0 hours. After the reaction is completed, the temperature is raised to 110°C, water and alcohol accelerators are removed, diluted with a solvent and centrifuged The slag was removed, and finally the solvent was removed by distillation under reduced pressure to obtain a product with a base number of 322 mg KOH / g, a Ca content of 11.69%, an S content of 0.58%, and a turb...

Embodiment 3

[0025]Embodiment 3: Add straight-run gasoline 120mL, methanol 120ml (industrial product), calcium hydroxide 30.0g, water 9.5g in the 500mL four-neck flask with electric stirrer and condensation dehydrator, start stirring and be warming up to 40- 50°C, then add 15.0g of alkylbenzenesulfonic acid, 90.0g of alkyl salicylic acid, 0.85g of anti-emulsifier (polyether ester), control the reaction temperature at 45-55°C, react for 1.0h, and carry out neutralization reaction. Then feed a certain amount of carbon dioxide gas (control the ventilation rate 200-250ml / min) to carry out the high alkalinity reaction for about 2.0 hours. After the reaction is completed, the temperature is raised to 110°C, water and alcohol accelerators are removed, diluted with a solvent and centrifuged The slag was removed, and finally the solvent was evaporated under reduced pressure to obtain a product with a base value of 326 mg KOH / g, a Ca content of 12.70%, and a turbidity of 107.5 JTU.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Base value | aaaaa | aaaaa |

| Base value | aaaaa | aaaaa |

| Base value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com