Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

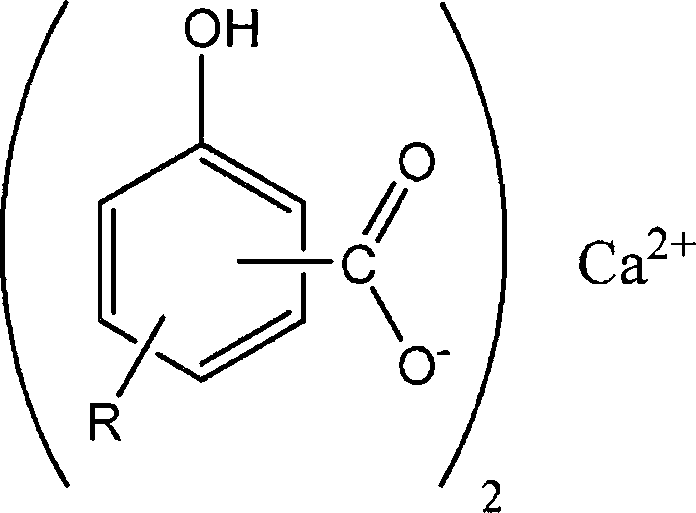

98 results about "Calcium Salicylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lubricating oil compositions

Lubricating oil compositions having a sulfated ash content of no more than 1.0 mass %, which contain a major amount of oil of lubricating viscosity, a minor amount of calcium salicylate detergent, an amount of a magnesium-based detergent providing at least 200 ppm of magnesium, and a basic, low molecular weight, nitrogen-containing dispersant, which compositions provide improved top ring wear protection in internal combustion engines.

Owner:INFINEUM INT LTD

Lubricating oil compositions

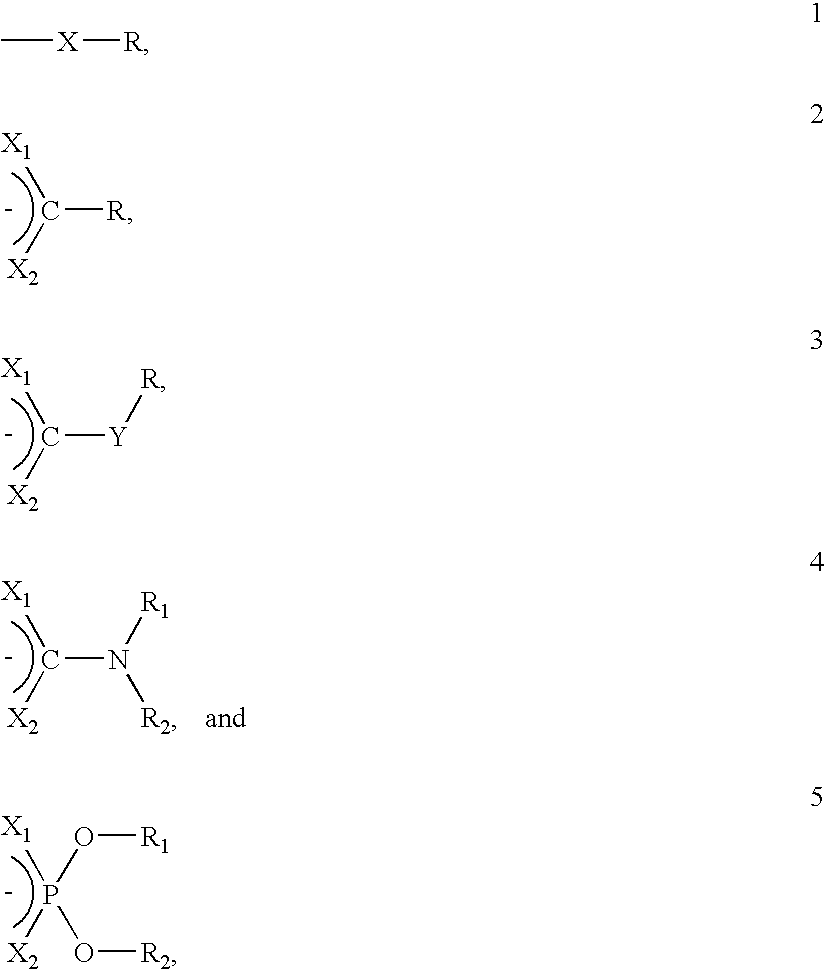

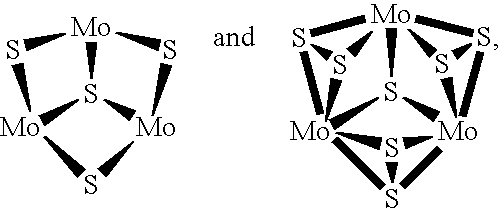

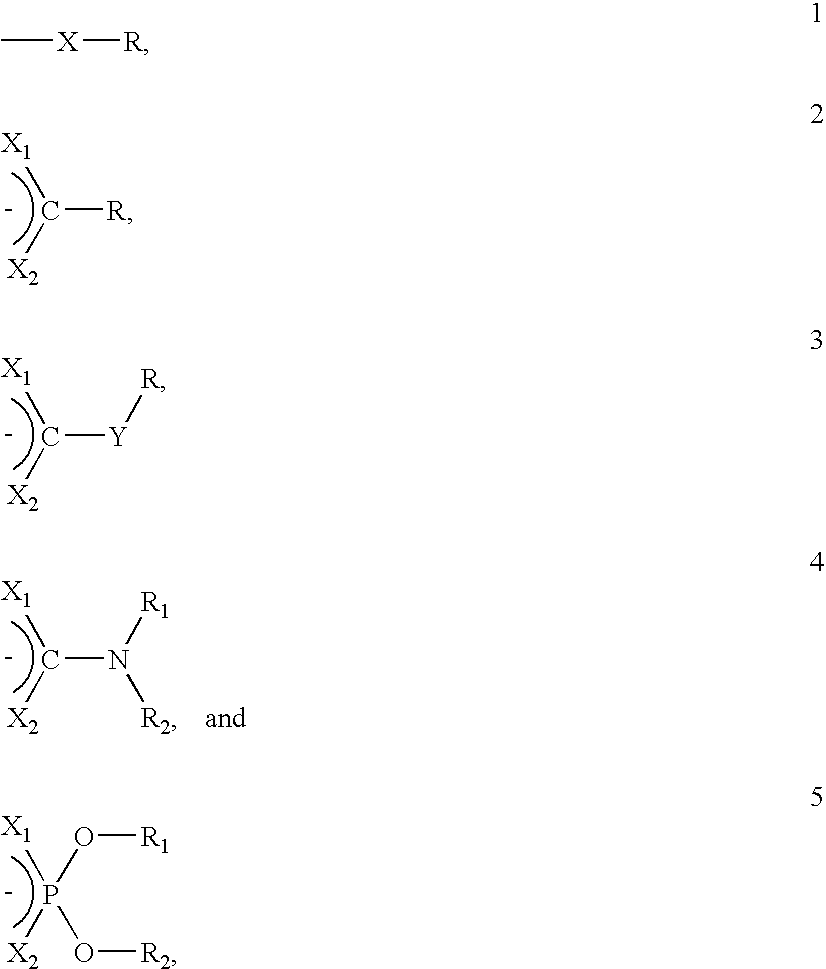

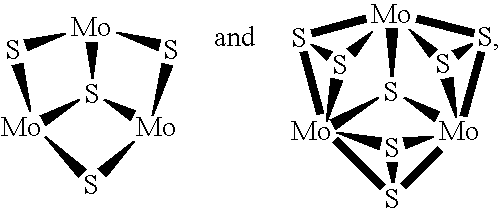

Lubricating oil compositions having a sulfated ash content of no more than 1.0 mass %, which contain a major amount of oil of lubricating viscosity, a minor amount of calcium salicylate detergent, an amount of a magnesium-based detergent providing the lubricating oil composition with at least 200 ppm of magnesium, an amount of a sulfur-containing molybdenum compound providing the lubricating oil composition with at least 20 ppm of molybdenum, and at least one nitrogen-containing dispersant providing the lubricating oil composition with at least 0.9 mass % nitrogen, which compositions provide improved top ring wear protection in internal combustion engines.

Owner:INFINEUM INT LTD

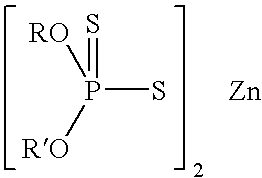

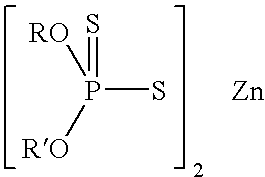

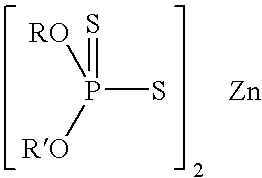

Lubricating oil composition for marine medium-speed cylindrical diesel engine

The invention relates to a lubricating oil composition for a marine medium-speed cylindrical diesel engine, which comprises the following components in percentage by weight: 12-22% of high temperature detergent, 1-3% of ashless dispersant, 0.5-1.5% of antioxidant, 0.002-0.005% of antifoam agent and the balance of base oil, wherein the high temperature detergent is compounded from the following components in percentage by weight: 30-70% of high base number alkyl calcium salicylate and 30-70% of high base number sulfurized calcium alkyl phenate; the ashless dispersant is bis-succinimide; the antioxidant is zinc dialkyl dithiophosphate; and the antifoam agent is methylsilicone oil. The invention can satisfy the operational requirements of advanced marine medium-speed cylindrical piston diesel engine oil; and the lubricating oil composition has the function of inhibiting the generation of black oil sludge, reduces the faults of the medium-speed cylindrical piston diesel engine due to bad lubrication and the like, prolongs the service life of the engine, and has the advantages of accessible raw materials, simple production technique and low cost.

Owner:PETROCHINA CO LTD

Fuel economical lubricating oil compositions for internal combustion engines

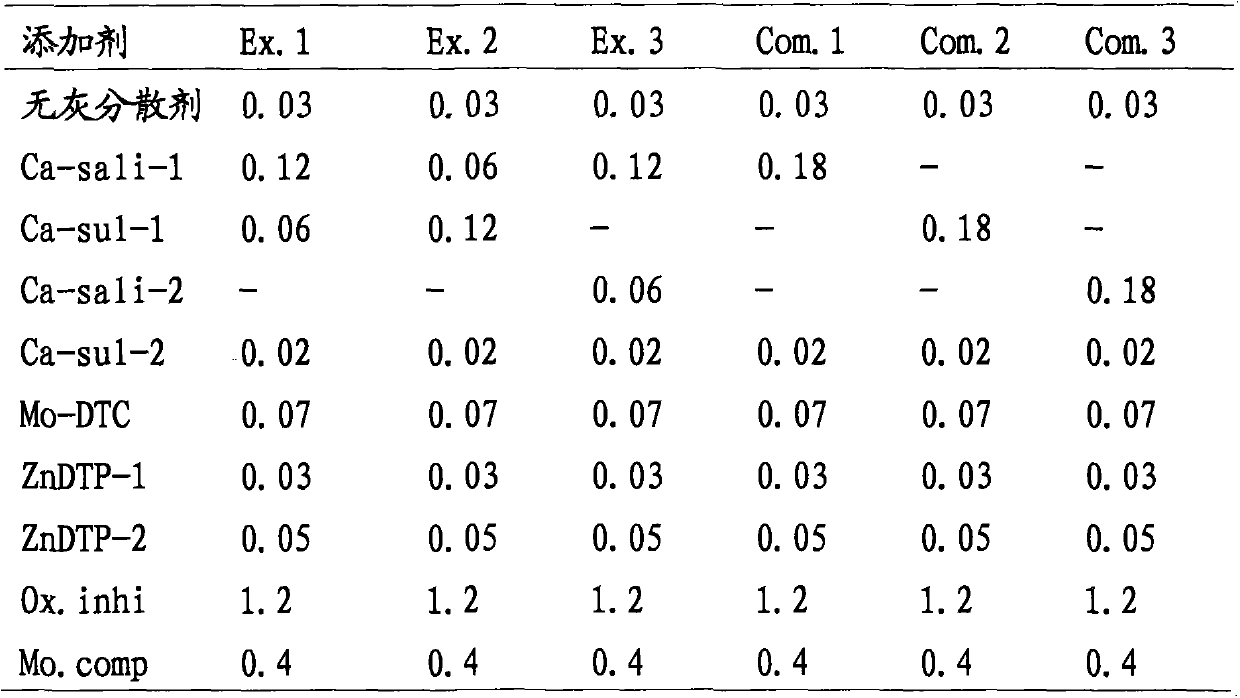

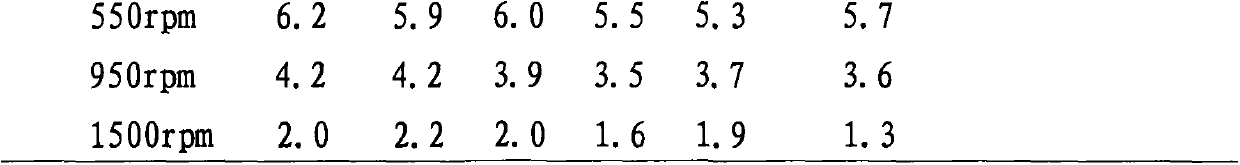

A fuel economical lubricating oil composition for internal combustion engines comprises a base oil and an additive composition comprising an overbased metal-containing detergent and a molybdenum-containing friction modifier, in which the overbased metal-containing detergent comprises calcium salicylate having an alkyl group having an average carbon atom number of 14-18, at least 60 mol.% of the alkyl group having a carbon atom number of 14-18, and calcium sulfonate having an alkyl group having an average carbon atom number of 20-24, at least 60 mol.% of the alkyl group having a carbon atom number of 20-24, and / or calcium salicylate having an alkyl group having an average carbon atom number of 20-28, at least 60 mol.% of the alkyl group having a carbon atom number of 20-28.

Owner:CHEVRON JAPAN

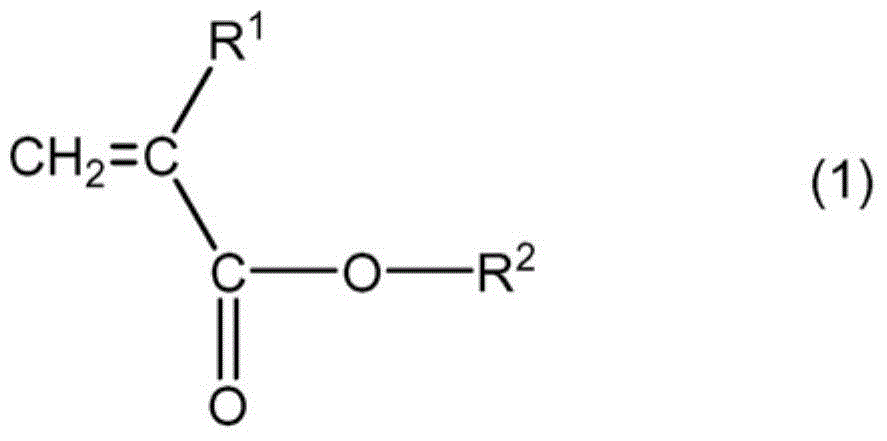

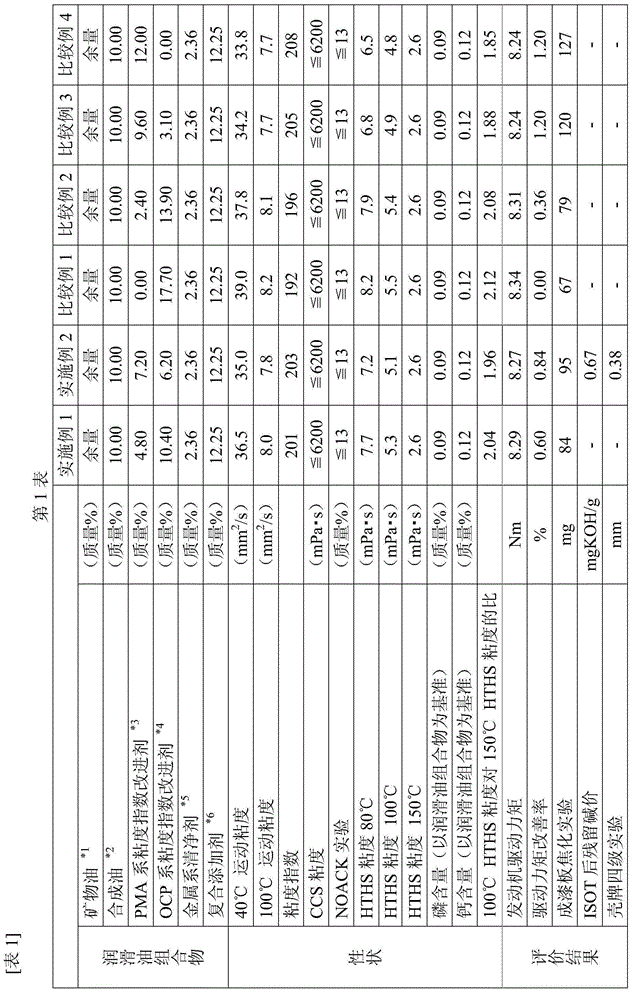

Lubricating oil composition

InactiveUS20150218482A1Increased durabilityImprove efficiencyAdditivesFuel efficiencyInternal combustion engine

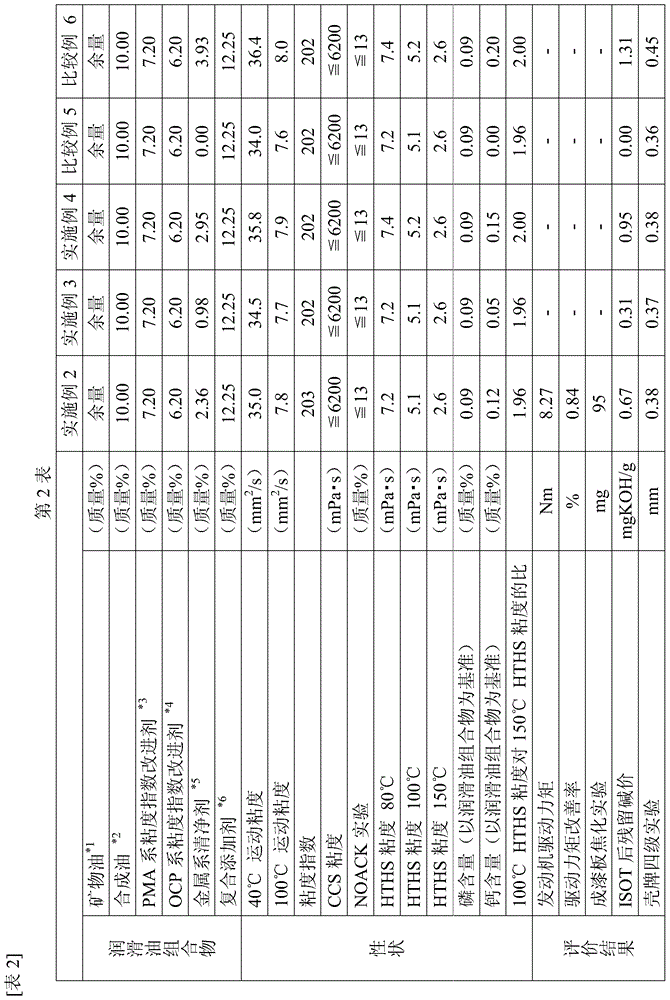

[Problem]To provide a lubricating oil composition capable of attaining high-level fuel efficiency, durability and piston detergency in internal-combustion engines.[Means for Resolution]The lubricating oil composition according to the present invention contains a viscosity index improver and a metallic detergent in at least one base oil selected from mineral oils and synthetic oils therein, wherein the viscosity index improver contains a polymethacrylate viscosity index improver and an olefin copolymer viscosity index improver, the polymethacrylate viscosity index improver is contained in an amount of from 3.0% by mass to 9.5% by mass based on the total amount of the lubricating oil composition, the metallic detergent is at least one selected from calcium sulfonate, calcium phenate and calcium salicylate, the calcium amount derived from the metallic detergent is from 500 ppm to 1500 ppm based on the total amount of the lubricating oil composition, the high-temperature high-shear viscosity at 150° C. of the lubricating oil composition is 2.6 mPa·s or more, the high-temperature high-shear viscosity at 80° C. of the lubricating oil composition is 7.8 mPa·s or less, and the ratio of the high-temperature high-shear viscosity at 100° C. of the lubricating oil composition to the high-temperature high-shear viscosity at 150° C. thereof is 2.05 or less.

Owner:IDEMITSU KOSAN CO LTD +1

Synthesis method of calcium-magnesium salicylate composite detergent

InactiveCN104496786AImprove heat resistanceExcellent high temperature detergencyOrganic compound preparationAdditivesXylyleneSalicylic acid

The invention discloses a synthesis method of a calcium-magnesium salicylate composite detergent in the field of lubricant additives. The method comprises the following steps: adding alkyl salicylic acid and solvent xylene in a reaction container, adding calcium oxide, accelerant, auxiliary promoter and the like in a stirring state, and carrying out a neutralization reaction when a reaction temperature rises to the temperature needed by the neutralization reaction; after the neutralization reaction is ended, adding magnesium oxide, water, ammonia water, auxiliary promoter and the like, charging carbon dioxide and carrying out a carbonation reaction; after the carbonation reaction is ended, carrying out product post-treatment to obtain a lubricant detergent product. The method disclosed by the invention achieves the following beneficial effects: the alkali number of the calcium-magnesium salicylate composite detergent prepared by the method is greater than 400mg KOH / g, the thermal oxidation stability and the high-temperature detergency of lubricant oil are obviously improved, the dispersibility and the wear resistance of the lubricant oil are improved to a certain extent, and the product stability is great.

Owner:QINGDAO BAIZHONG CHEM TECH

Lubricating oil composition and method for producing same

The lubricating oil composition of the present invention is a lubricating oil composition containing a lubricating base oil, a metal-based detergent, a molybdenum dialkyldithiocarbamate compound, and a boron-containing compound, wherein the metal-based detergent contains a calcium salicylate and at least one selected from the group consisting of a calcium sulfonate and a magnesium-based detergent; the lubricating oil composition arbitrarily contains an ashless friction modifier; the content of a calcium atom is 0.12 to 0.16 mass % on the basis of the whole amount of the lubricating oil composition; the content of a molybdenum atom is 0.05 to 0.10 mass % on the basis of the whole amount of the lubricating oil composition; and a predetermined coefficient X is less than 0.050.

Owner:IDEMITSU KOSAN CO LTD +1

Lubricating oil composition

InactiveCN104818081AAchieve fuel efficiencyClean thoroughlyAdditivesFuel efficiencyInternal combustion engine

[Problem] To provide a lubricating oil composition capable of attaining high-level fuel efficiency, durability and piston detergency in internal-combustion engines. [Means for Resolution] The lubricating oil composition according to the present invention contains a viscosity index improver and a metallic detergent in at least one base oil selected from mineral oils and synthetic oils therein, wherein the viscosity index improver contains a polymethacrylate viscosity index improver and an olefin copolymer viscosity index improver, the polymethacrylate viscosity index improver is contained in an amount of from 3.0% by mass to 9.5% by mass based on the total amount of the lubricating oil composition, the metallic detergent is at least one selected from calcium sulfonate, calcium phenate and calcium salicylate, the calcium amount derived from the metallic detergent is from 500 ppm to 1500 ppm based on the total amount of the lubricating oil composition, the high-temperature high-shear viscosity at 150°C of the lubricating oil composition is 2.6 mPa·s or more, the high-temperature high-shear viscosity at 80°C of the lubricating oil composition is 7.8 mPa·s or less, and the ratio of the high-temperature high-shear viscosity at 100°C of the lubricating oil composition to the high-temperature high-shear viscosity at 150°C thereof is 2.05 or less.

Owner:IDEMITSU KOSAN CO LTD +1

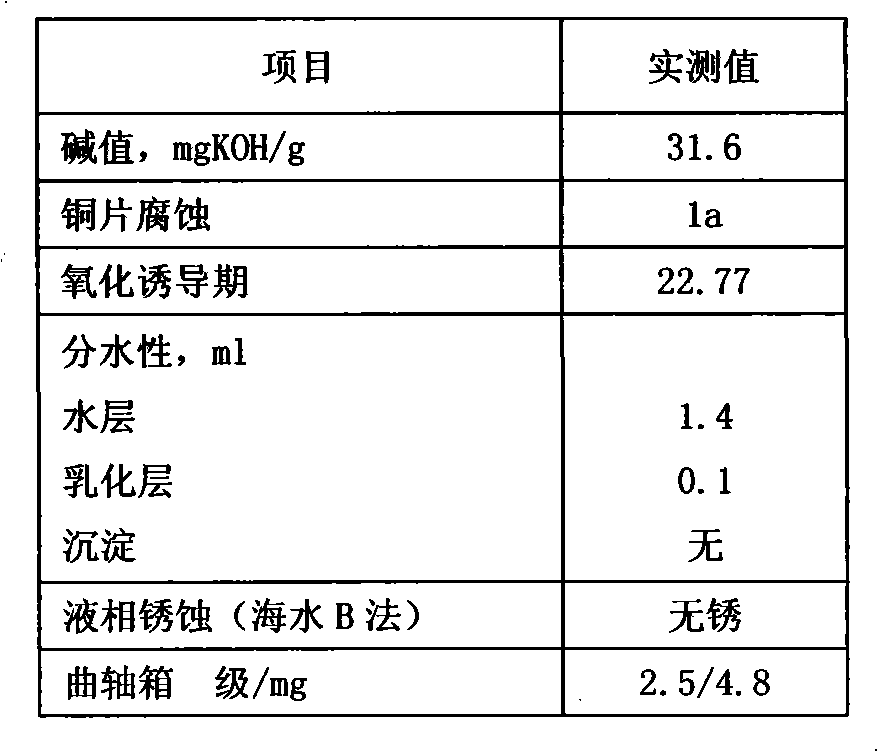

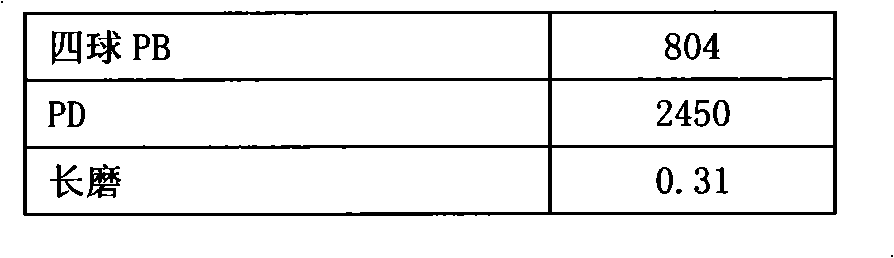

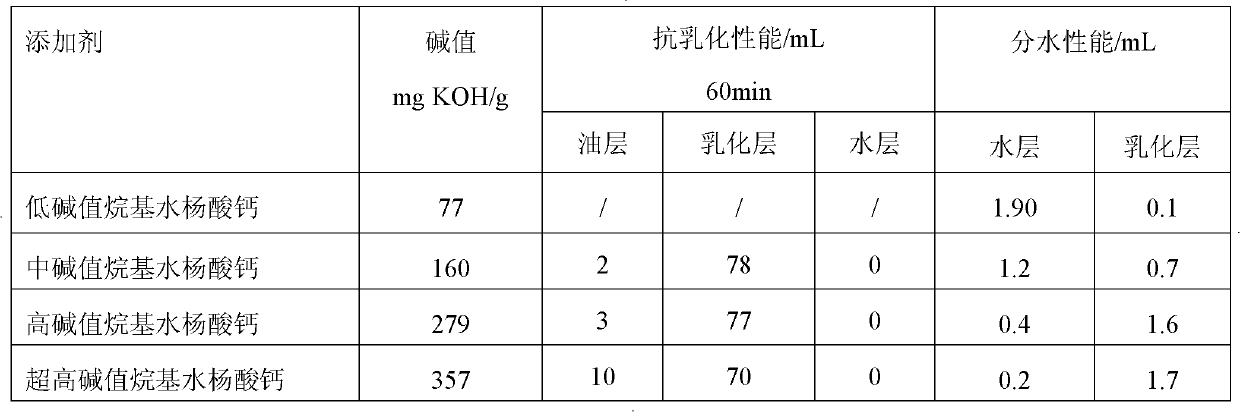

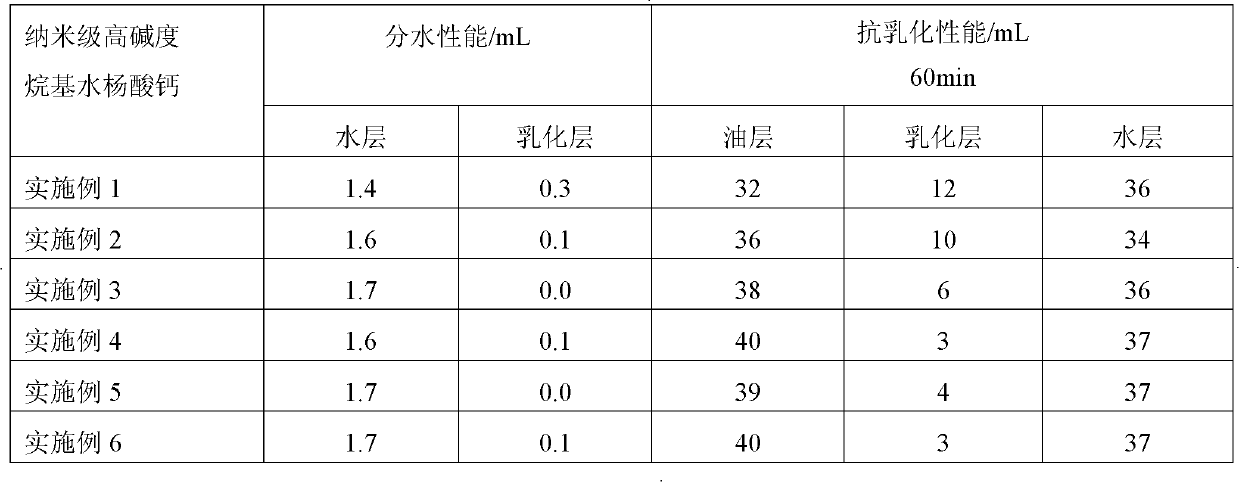

Preparation of nanoscale high-alkalinity calcium alkyl salicylate additive

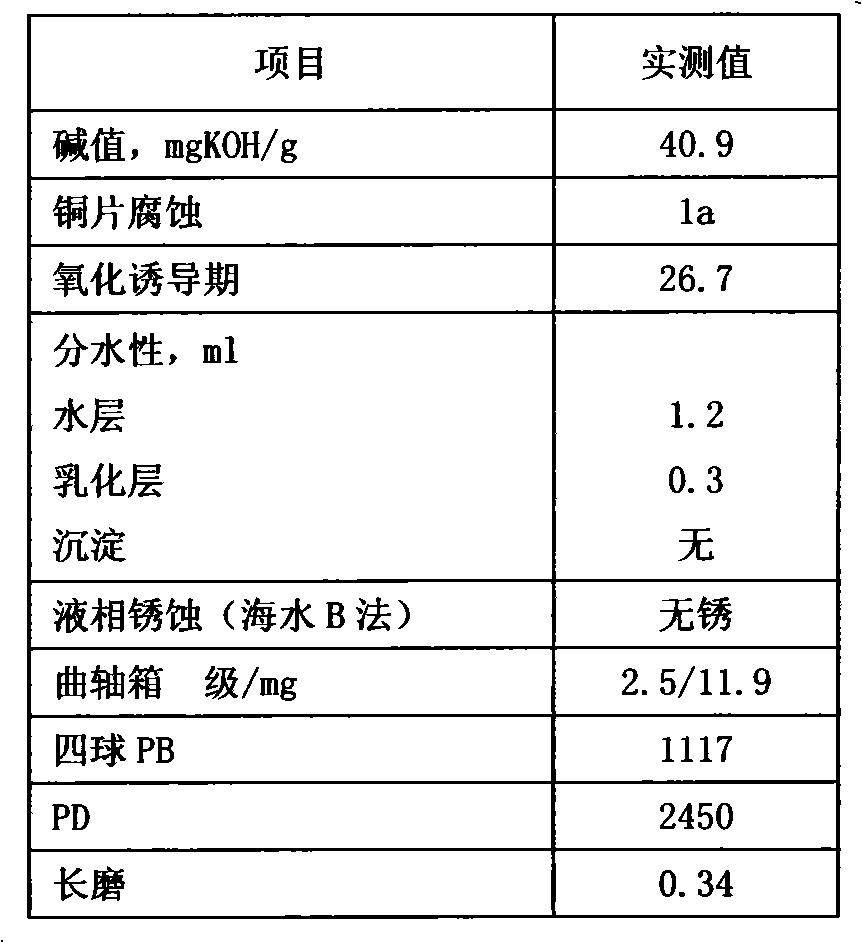

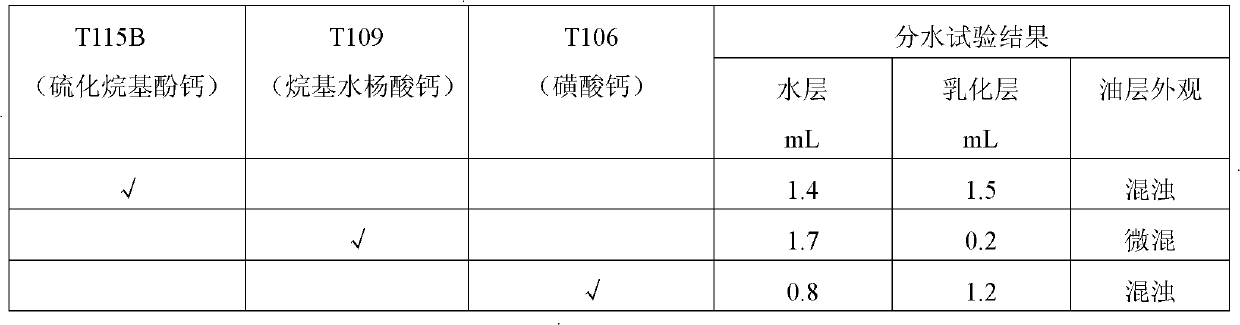

The invention relates to a nanoscale high-alkalinity calcium alkyl salicylate additive and a preparation method of the nanoscale high-alkalinity calcium alkyl salicylate additive. The method comprises the following steps of: using alkyl salicylic acid, calcium hydroxide and surfactant and the like as raw materials, performing processes of neutralization and high alkalinity reaction on the ingredients according to a certain proportion to prepare a high-alkalinity calcium alkyl salicylate metal cleaner with the total alkalinity higher than 280mgKOH / g. The high-alkalinity calcium alkyl salicylate provided by the invention not only has all the basic properties of a traditional high-alkalinity calcium alkyl salicylate product, but also has good sub-aqueous and anti-emulsifying properties, not only satisfies the use requirement of high-grade internal combustion engine oil, but also is suitable for the use in the oil products such as ship oil with a high requirement on the sub-aqueous property, and thus the high-alkalinity calcium alkyl salicylate provided by the invention is a lubricant additive with a perfect property.

Owner:PETROCHINA CO LTD

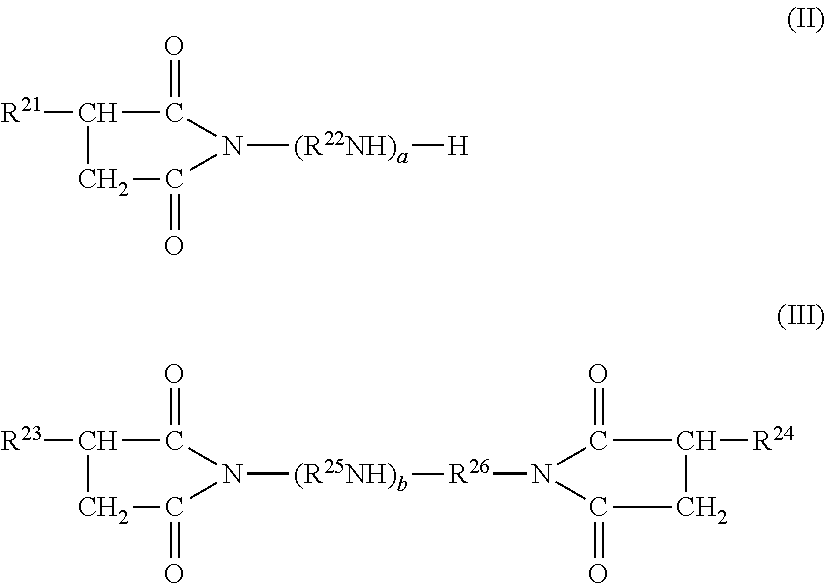

Scale inhibitor for oil refining equipment and preparation method of scale inhibitor

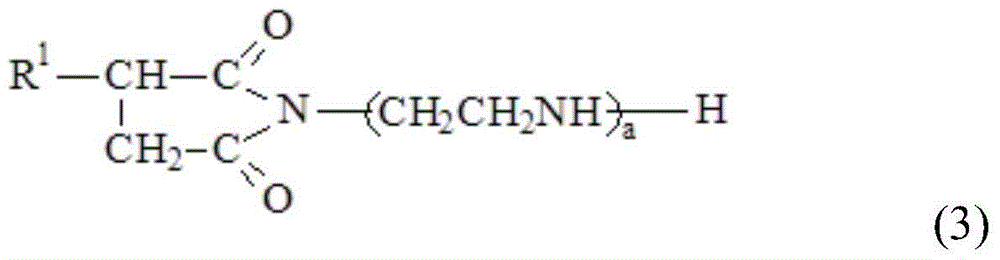

InactiveCN106701194AWide variety of sourcesInhibition of coking and foulingTreatment apparatus corrosion/fouling inhibitionDiimidePolyisobutylene succinimide

The invention discloses a scale inhibitor for oil refining equipment. The scale inhibitor is prepared from the following raw materials: purified water, polyisobutylene succinimide, N,N'-disalicylidene-promethylene diamine, calcium alkyl salicylate, heavy aromatics, hexadecyl dimethyl amine, 2,2,6,6-tetramethylpiperidinooxyl, toluene, sodium persulfate, hydrogen peroxide and potassium superphosphate. The scale inhibitor is used for inhibiting coking and scale deposition of various devices and equipment in petroleum refining and petrochemical processes, particularly for coking and scale deposition of hydrogenation process equipment; coking and scale deposition of heat exchangers and steam generators for catalytic cracking, delayed coking and crude oil distillation processes are inhibited; and a high scale inhibition rate is achieved with the filling amount of 80 to 100 [mu]m / g in a crude oil heat exchanger, a reactor and a heating furnace, and each component synergistically acts to achieve the carbon steel corrosion rate of 0.001 to 0.003 [mu]m*a<-1> and the calcium carbonate scale inhibition rate of 85 to 95 percent.

Owner:JIANGSU JINGWEI TECH INNOVATION CONSULTING CO LTD

Ship lubricant oil

The invention discloses a liquid composition of accessory ship diesel lubricate, which is characterized by the following: adopting middle basic oil as main component; mating fitful high-alkaline value calcium naphthenate, disuccinimide, dioctyl dithio-zinc phosphate, middle-alkaline alkyl calcium salicylate, high-grade lipoamide, polyoxypropylene polyoxyethylene block-typed polyether and silicon oil; allocating the system oil through scientific method.

Owner:彭美东

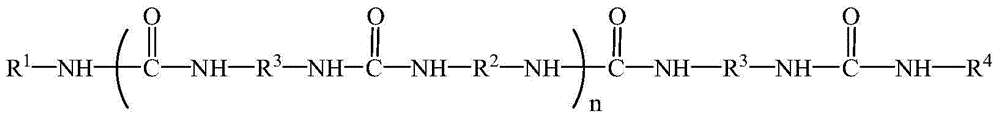

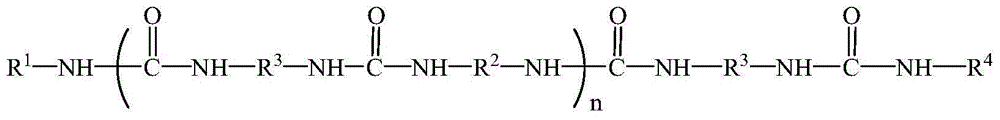

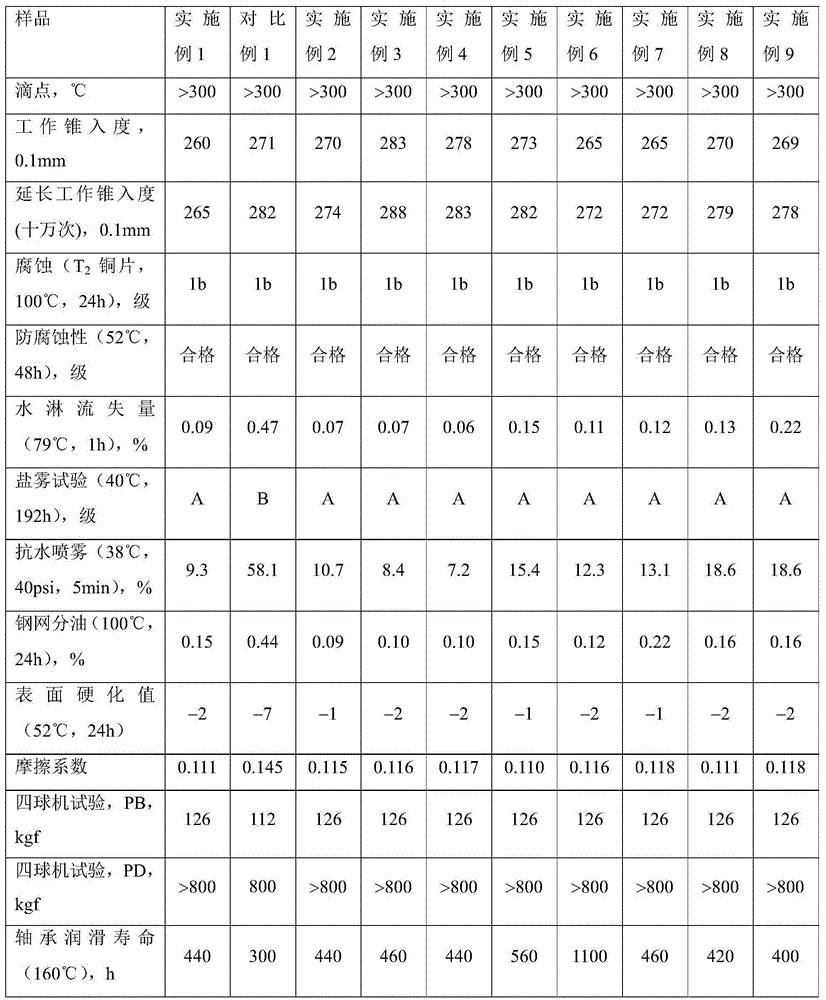

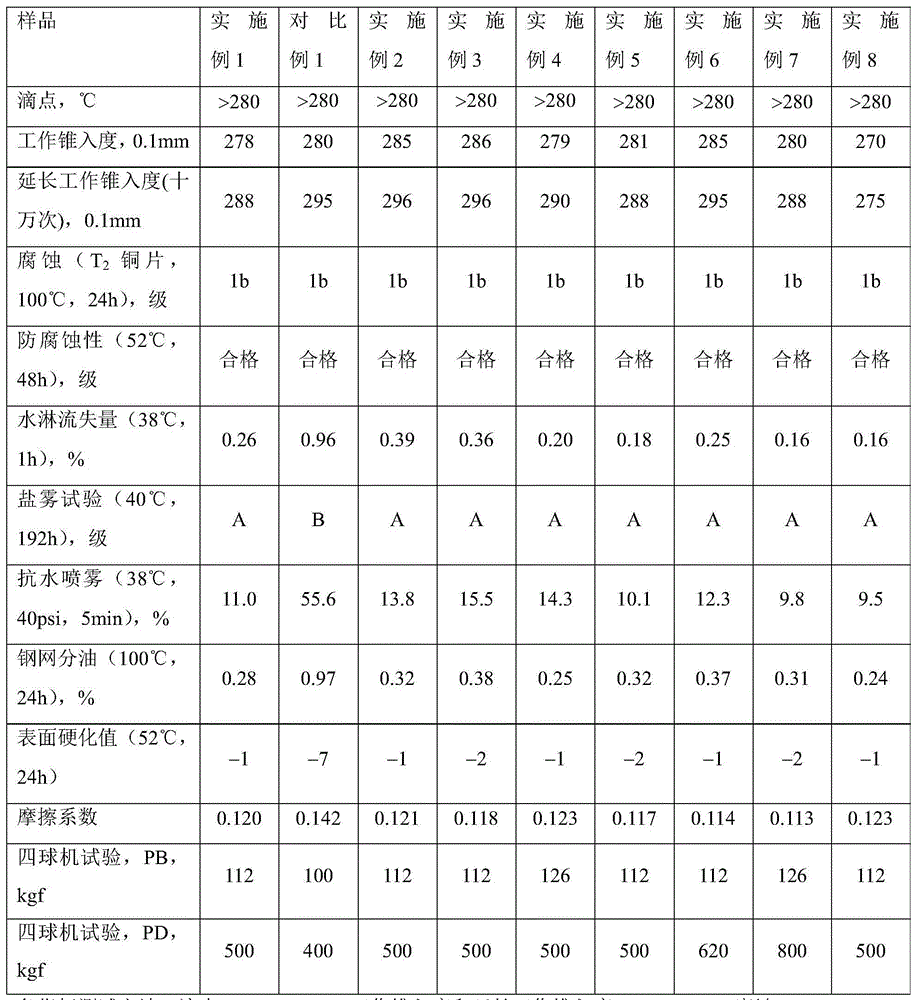

Lubricating grease composition and preparation method thereof

ActiveCN106032486AExcellent anti-rustImprove corrosion resistanceLubricant compositionCalcium SalicylateChemistry

A lubricating grease composition and a preparation method thereof are disclosed. The invention relates to the field of lubricating grease, and discloses a lubricating grease composition. The lubricating grease composition comprises base oil (10-80 wt%) and a thickening agent, which comprises non-Newton fluid sulfurized calcium alkyl phenate (10-70 wt%), and also optionally comprises one or more of non-Newton fluid calcium sulfonate (0-70 wt%), non-Newton fluid calcium naphthenate (0-70 wt%), and non-Newton fluid calcium salicylate (0-70 wt%). The invention also discloses a preparation method of the lubricating grease composition. The provided lubricating grease composition has excellent performances.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lubricating grease composition and preparation method thereof

A lubricating grease composition and a preparation method thereof are disclosed. The invention relates to the field of lubricating grease, and discloses a lubricating grease composition. The lubricating grease composition comprises base oil (10-80 wt%) and a thickening agent, which comprises non-Newton fluid sulfurized calcium alkyl phenate-calcium sulfonate (10-70 wt%), zircon salts of higher fatty acid (1-10 wt%), and polyurea compounds (0.5-30 wt%), and also optionally comprises one or more of non-Newton fluid calcium naphthenate (0-70 wt%), non-Newton fluid calcium salicylate (0-70 wt%), non-Newton fluid calcium oleate (0-70 wt%), zircon salts of aromatic acid (0-15 wt%), and zircon salts of micro-molecular inorganic acid and / or lower fatty acid (0-15 wt%). The invention also discloses a preparation method of the lubricating grease composition. The provided lubricating grease composition has excellent performances.

Owner:CHINA PETROLEUM & CHEM CORP +1

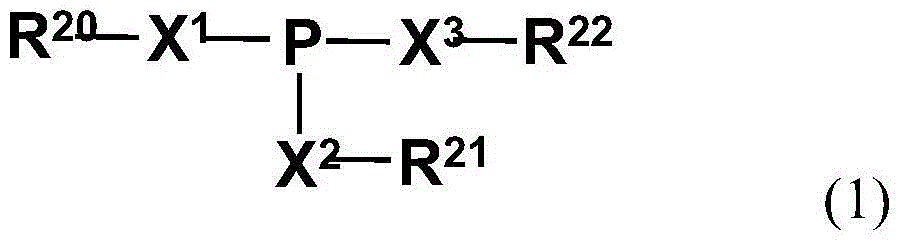

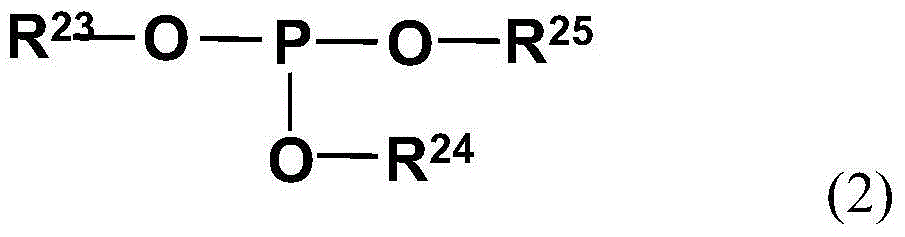

Lubricating oil composition for continuously variable transmission

ActiveCN104487557AReduce coefficient of frictionLow friction propertiesAdditivesChemical compositionEngineering

Provided is a lubricating oil composition for a continuously variable transmission, said composition exhibiting a low viscosity whilst maintaining the viscosity required of the lubricating oil composition throughout a period of use in a mechanism, and maintaining a high friction coefficient between metals so as to ensure a high power-transmitting force provide the wet clutch friction characteristics and the shudder prevention properties required in a transmission. The composition also achieves improved fuel economy due to a low traction coefficient. In the composition, (B) a phosphorus compound, (C) a calcium salicylate and / or a calcium sulfonate, (D) a boron-modified ashless dispersant, and (E) a friction regulating agent are included, each at a specified amount, in a base-oil that has been adjusted so that the product (ECxV40) of the mass percent (EC(mass%)) of a saturated cyclic component, as based on the total base-oil mass, and the kinematic viscosity (V40(mm2 / s)) at 40 DEG is equal to or less than 500, and the kinetic viscosity at 100 DEG is 3.6-4.1mm2 / s. The lubricating oil composition has a kinematic viscosity at 100 DEG of 5.2-5.6mm2 / s and a viscosity index of equal to or greater than 165.

Owner:JX NIPPON OIL & ENERGY CORP

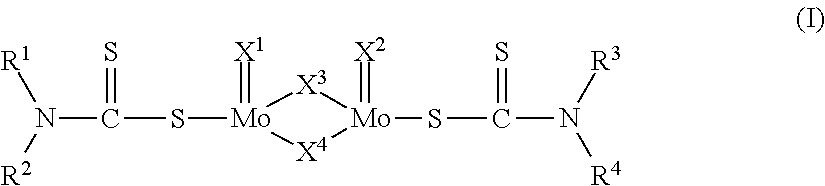

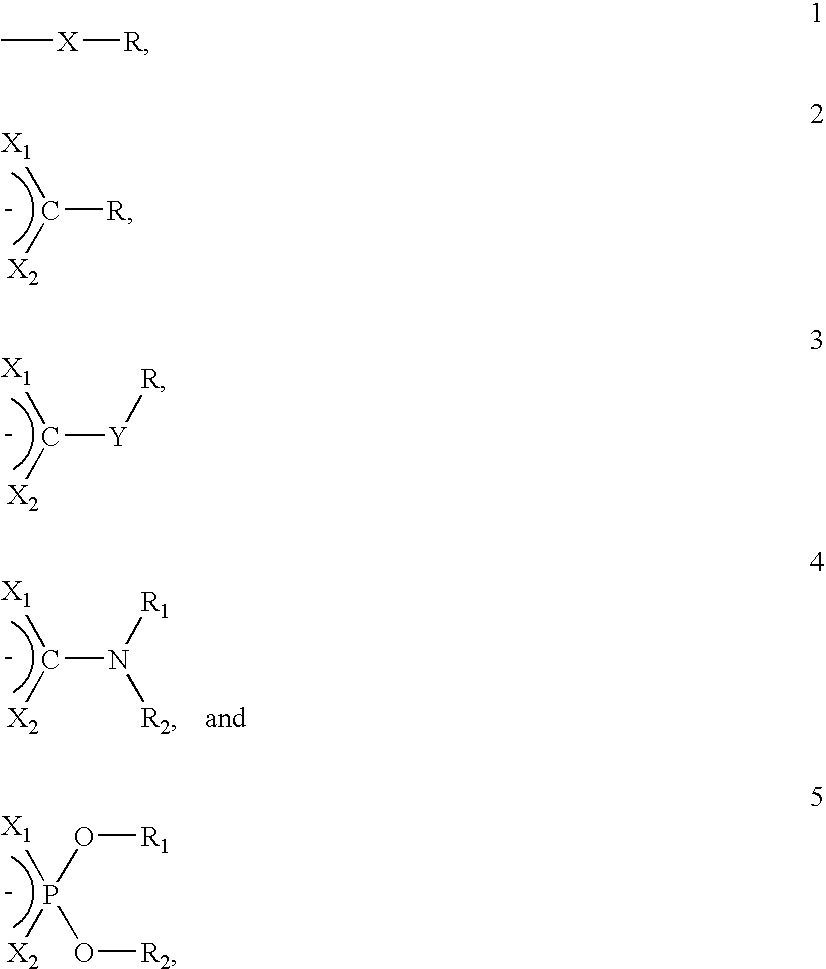

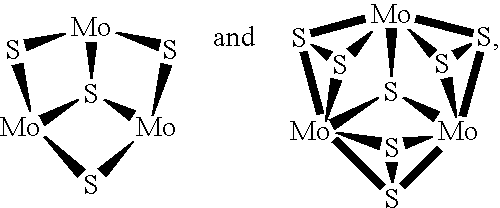

Lubricating oil composition for internal combustion engine

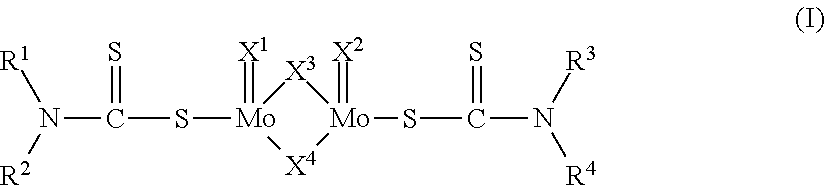

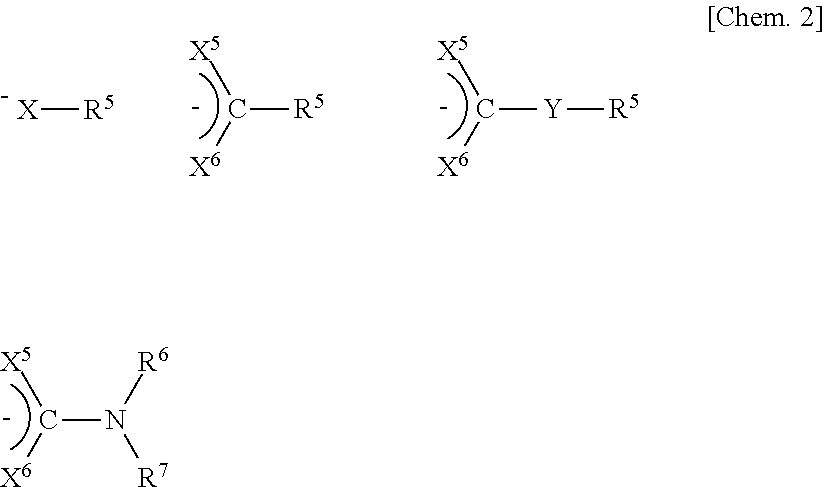

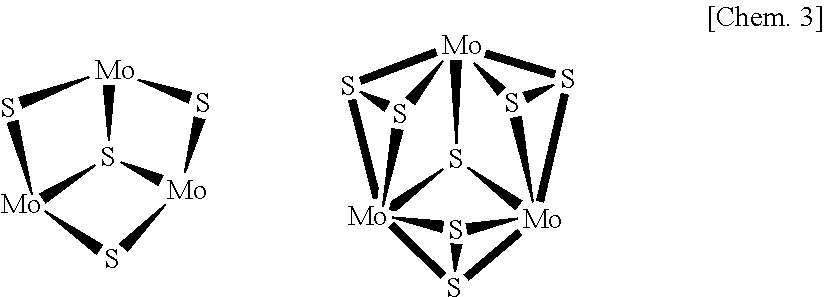

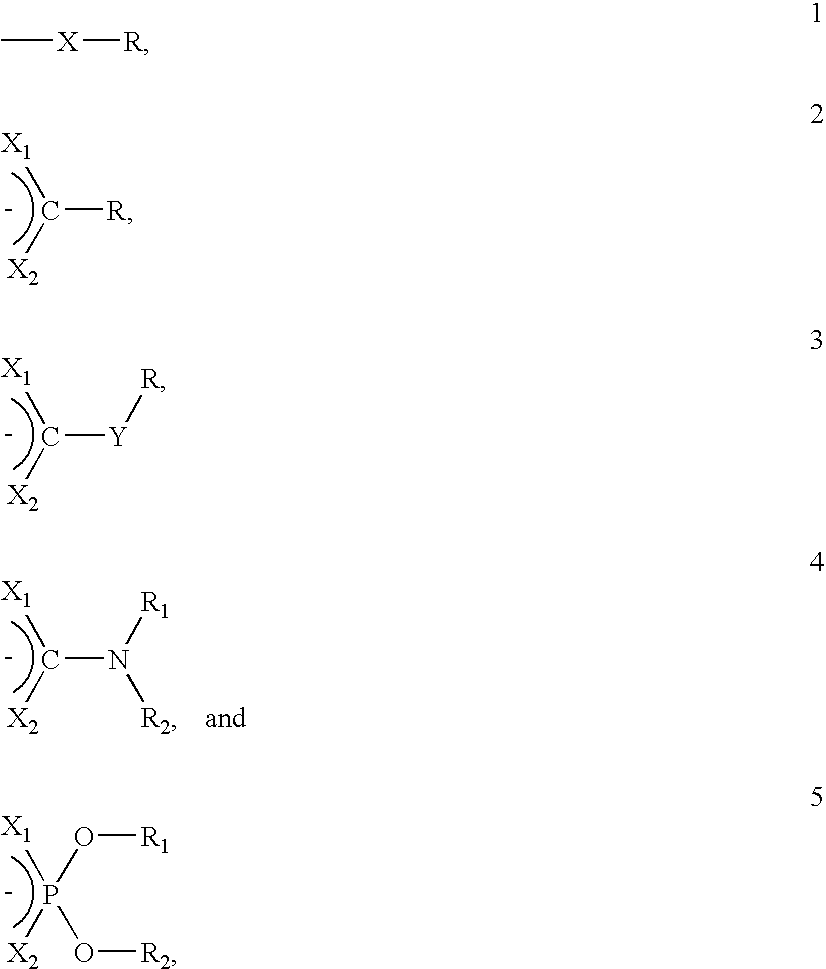

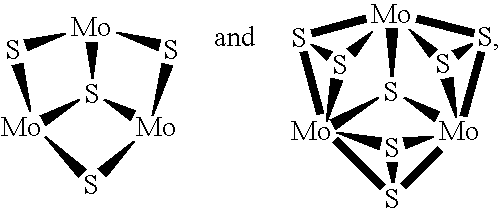

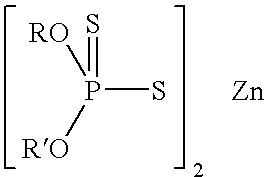

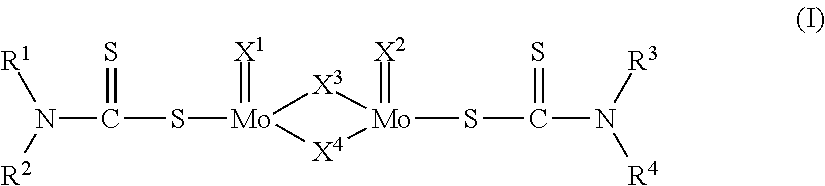

ActiveUS20170121627A1Low sulfuric acid ash contentSuppressing decreaseAdditivesChemical compositionPhenolic antioxidant

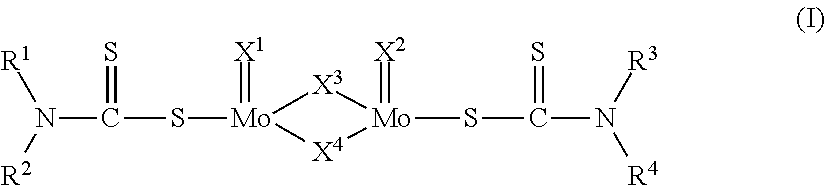

Provided are a lubricating oil composition for internal combustion engine, containing a lubricating base oil containing a mineral oil and / or a synthetic oil, (A) an overbased calcium salicylate, (B) an overbased magnesium detergent, (C) a binuclear and / or trinuclear organic molybdenum compound, (D) a phenol-based antioxidant, and (E) an amine-based antioxidant, wherein the component (C), the component (D), and the component (E) are contained in specified contents on the basis of the whole amount of the lubricating oil composition; a method for producing the lubricating oil composition for internal combustion engine; and a lubrication method including using the lubricating oil composition for internal combustion engine.

Owner:IDEMITSU KOSAN CO LTD

Lubricating oil compositions

Owner:INFINEUM INT LTD

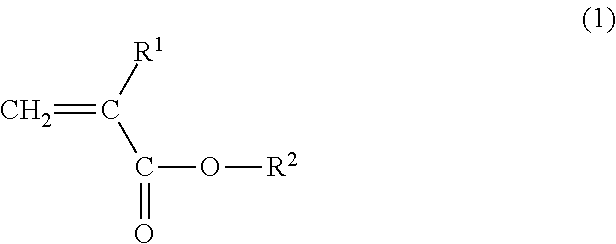

Lubricating oil composition for internal combustion engine

ActiveUS20160348027A1Improve high-temperature oxidation stabilityImprove detergencyAdditivesMeth-Chemical composition

Owner:IDEMITSU KOSAN CO LTD

A lubricating grease composition and a preparing method thereof

ActiveCN106032488AExcellent anti-rustImprove corrosion resistanceLubricant compositionLithiumFatty acid

The invention relates to the field of lubricating grease, and discloses a lubricating grease composition. The composition comprises base oil and a thickening agent. The thickening agent comprises non-Newtonian fluid sulfurized calcium alkyl phenate and a lithium salt of a higher aliphatic acid, and optionally comprises one or more selected from a group consisting non-Newtonian fluid calcium sulfonate, non-Newtonian fluid calcium naphthenate, non-Newtonian fluid calcium salicylate, non-Newtonian fluid calcium oleate, a lithium salt of an aromatic acid, and a lithium salt of a small-molecule inorganic acid and / or a lower aliphatic acid. Based on the weight of the composition, the content of the base oil is 10-80% by weight, the content of the non-Newtonian fluid sulfurized calcium alkyl phenate is 10-70% by weight, the content of the lithium salt of the higher aliphatic acid is 1-20% by weight, and contents of other optional components are respectively 0-70% by weight, 0-70% by weight, 0-70% by weight, 0-70% by weight, 0-15% by weight and 0-15% by weight. A preparing method of the composition is also disclosed. The composition has excellent properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthesis method of salicylic acid/sulfonic acid mixed medium calcium-magnesium composite clearing agent

The invention discloses a synthesis method of a salicylic acid / sulfonic acid mixed medium calcium-magnesium composite clearing agent, belonging to the field of lubricating oil additives. The method comprises the following steps: by using salicylic acid and ammonium sulfonate as raw materials, enabling the raw materials to react with calcium oxide under the action of methanol to generate normal calcium salicylate and normal calcium sulfonate; and enabling the obtained normal calcium salicylate and normal calcium sulfonate to react with magnesium oxide and carbon dioxide under the action of methanol, water, promoter and the like to generate micelles which take nano magnesium carbonate particles as the core and are wrapped by the normal calcium salicylate and normal calcium sulfonate molecules, wherein the micelles are uniformly dispersed in an oil phase to form a stable colloid system. The invention achieves the following beneficial effects: the total base numbers (TBN) of the products prepared by the method are all more than 400mgKOH.g<-1>, the viscosity and turbidity are small, and the dispersivity is favorable.

Owner:QINGDAO BAIZHONG CHEM TECH

Natural gas and gasoline double-fuel engine lubricating oil composition

InactiveCN106753713AAvoid high temperature oxidationInhibit the rate of oxidative decayLubricant compositionAntioxidantEngineering

The invention provides a natural gas and gasoline double-fuel engine lubricating oil composition. The natural gas and gasoline double-fuel engine lubricating oil composition comprises 20W / 50, 10W / 40 and 5W / 30. The natural gas and gasoline double-fuel engine lubricating oil composition adopts a cleaning agent prepared from middle calcium alkylbenzensulfonate, alkyl calcium salicylate and sulfurized calcium alkyl phenolate; an antioxidant prepared from octyl / butyl diphenylamine with strong anti-oxidizing property and an phenolic-ester antioxidant; an abrasion-resistant agent prepared from zinc dialkyl dithiophosphate, zinc dialkyl dithiocarbamate and sulfurized isobutylene, so as to overcome the defects of overhigh ash content in gasoline engine oil, and insufficient anti-oxidizing property and anti-abrasion property. The natural gas and gasoline double-fuel engine lubricating oil composition has the advantages that compared with the gasoline engine oil, the anti-oxidizing property, friction property, anti-abrasion property, a maximum non-seizure load PB value, an ash value and low-temperature property are significantly better; the average oil replacing cycle is prolonged by 54.55%.

Owner:长春市新华石油化工有限公司

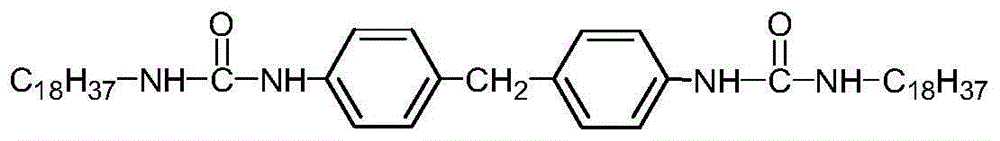

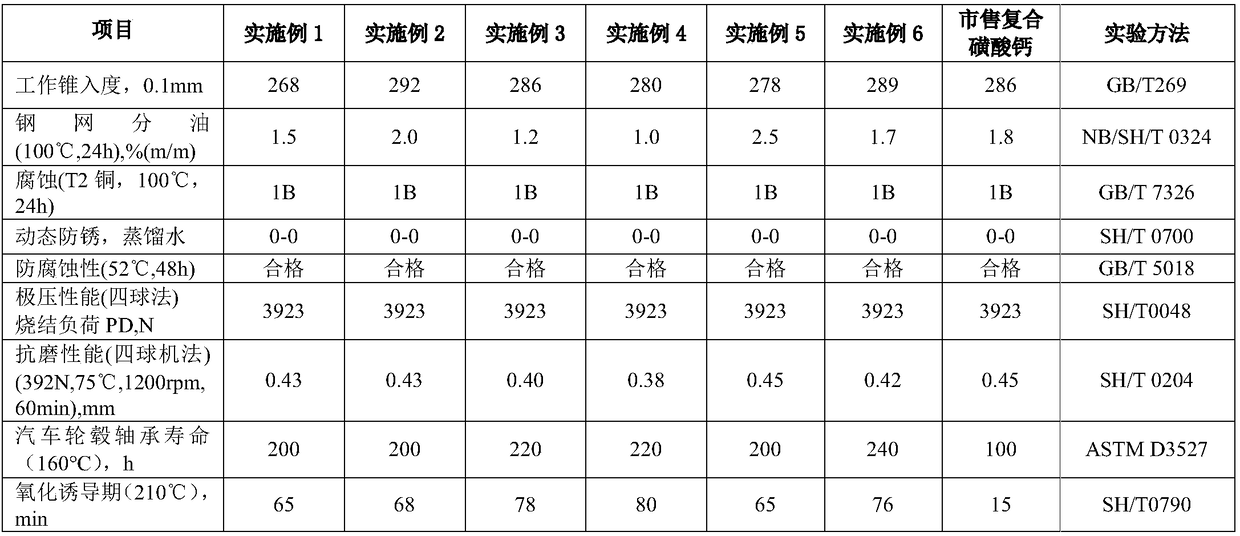

Modified composite calcium sulfonate lubricating grease composition and preparation method thereof

InactiveCN109266420AGood high temperature oxidation resistance lifeGood bearing lifeAdditivesCalcium hydroxideAntioxidant

The invention relates to a modified composite calcium sulfonate lubricating grease composition and a preparation method thereof, wherein the modified composite calcium sulfonate lubricating grease composition comprises, by weight, 24-51% of high base value synthetic calcium sulfonate, 8-16% of high base value calcium salicylate, 31-54.25% of base oil, 3-4% of a conversion agent, 1-2% of calcium hydroxide, 4-8% of a compounding agent, and 0.5-1% of an antioxidant. According to the present invention, the modified composite calcium sulfonate lubricating grease has advantages of good high temperature anti-oxidation life, good bearing life, good extreme pressure anti-wear performance and excellent comprehensive performance, breaks through the performance defects of short high-temperature (210 DEG C) oxidation induction period, not outstanding 160 DEG C vehicle wheel hub bearing service life and the like of the traditional composite calcium sulfonate, and can be used in bearings with requirements on high temperature and long service life.

Owner:CHINA PETROLEUM & CHEM CORP

Graphite lubricant with good high temperature adhesion

InactiveCN105273813AImprove wear resistanceImprove antioxidant capacityLubricant compositionContact pressureToluene diisocyanate

The present invention discloses a graphite lubricant with good high temperature adhesion, the graphite lubricant is prepared from the following raw materials in parts by weight: 25-35 parts of petroleum ether, 4-8 parts of absolute ethanol, 5-9 parts of engine oil, 0.2-0.4 part of calcium salicylate, 1-2 parts of ethylene bis stearamide, 2-4 parts of polyethylene wax, 2.5-4 parts of nano-graphite, 3-5 parts of sodium gluconate, 1-2 parts of polyacrylamide, 1-2 parts of toluene diisocyanate, 4-9 parts of methyl isobutyl ketone and 15-25 parts of modified graphite powder; the graphite lubricant is reasonable in raw material distribution, both can ensure good low-temperature film forming performance, also ensures good high temperature adhesion and suspension dispersion property, and has high temperature resistance, high contact pressure resistance and adequate load wear-resisting capacity, the manufacturing process can meet the needs of aluminum extrusion, the cost is moderate, and the performance cost ratio is high.

Owner:DANGTU WEISIGONGCHUANG IND PROD DESIGN CO LTD

Fuel Economical Lubricating Oil Composition for Internal Combustion Engines.

ActiveUS20140171349A1Improve fuel economyPropertyOrganic chemistryLiquid carbonaceous fuelsCombustionChemical composition

A fuel economical lubricating oil composition for internal combustion engines comprises a base oil and an additive composition comprising an overbased metal-containing detergent and a molybdenum-containing friction modifier, in which the overbased metal-containing detergent comprises calcium salicylate having an alkyl group having an average carbon atom number of 14-18, at least 60 mol. % of the alkyl group having a carbon atom number of 14-18, and calcium sulfonate having an alkyl group having an average carbon atom number of 20-24, at least 60 mol. % of the alkyl group having a carbon atom number of 20-24, and / or calcium salicylate having an alkyl group having an average carbon atom number of 20-28, at least 60 mol. % of the alkyl group having a carbon atom number of 20-28.

Owner:CHEVRON JAPAN

Lubricating oil compositions

Lubricating oil compositions having a sulfated ash content of no more than 1.0 mass %, which contain a major amount of oil of lubricating viscosity, a minor amount of calcium salicylate detergent, an amount of a magnesium-based detergent providing at least 200 ppm of magnesium, and a basic, low molecular weight, nitrogen-containing dispersant, which compositions provide improved top ring wear protection in internal combustion engines.

Owner:INFINEUM INT LTD

Lubricant composition for trunk piston diesel engine

A lubricant composition for medium-speed trunk piston diesel engines which comprises: as a base oil for the lubricant, one or more members selected from the group consisting of a mineral oil and a synthetic oil having a dynamic viscosity at 100 DEG C of 3 mm2 / s or more but less than 6 mm2 / s, a mineral oil and a synthetic oil having a dynamic viscosity at 100 DEG C of 6 mm2 / s or more but less than 9 mm2 / s and a mineral oil and a synthetic oil having a dynamic viscosity at 100 DEG C of 9 mm2 / s or more but less than 13 mm2 / s; and, as a metal-based detergent, one or more kinds of calcium salicylate detergents optionally combined with a calcium phenate detergent, has a dynamic viscosity at 100 DEG C of 7.0-11.0 mm2 / s or lower and a high shear viscosity at 70 DEG C of 7.0-20.0 mPa.s, and has a base number determined by the perchloric acid method of 7-55 mgKOH / g.

Owner:JX NIPPON OIL & ENERGY CORP

Environment-friendly synthetic lubricating oil and preparation method thereof

InactiveCN107987938AImprove wear resistanceGood dispersionLubricant compositionRapeseedChlorinated paraffins

The invention discloses environment-friendly synthetic lubricating oil and a preparation method thereof. The environment-friendly synthetic lubricating oil is prepared from the following raw materialsin parts by weight: soybean oil, castor oil, rapeseed oil, 1 to 2 parts of dodecenylsuccinic acid, 0.1 to 1 part of molybdenum dialkyl dithioformate, 2 to 5 parts of eleostearic acid, 2 to 3 parts oftall oil acid, methyl silicone oil grease, 0.5 to 2.5 parts of polymethacrylate, 0.5 to 2.5 parts of calcium salicylate, 0.5 to 2 parts of nano nickel, 0.5 to 2 parts of nano cobalt, 2 to 5 parts ofmolybdenum disulfide, 10 to 15 parts of carbon tetrachloride, accelerant, 5 to 9 parts of chlorinated paraffin, 4 to 10 parts of stearic acid, antiwear agent and 6 to 8 parts of methylsalicylic acid.The environment-friendly synthetic lubricating oil has an advantage of aiming at providing lubricating oil with good biodegradation performance and further low toxicity; the biodegradability of a lubricating agent can be decreased by some cleaning dispersants, which influence the activity and a nutritional component of a microbe, in the environment-friendly lubricating oil mixed and confected through the preparation method; however, some phosphorus and nitrogen containing additives are beneficial to the growth and the reproduction of the microbe, and therefore, the biodegradability of the lubricating agent can be improved.

Owner:SHANDONG HIMARK PETROLEUM TECH

Lubricating grease composition and preparation method thereof

ActiveCN106032485AExcellent anti-rustImprove corrosion resistanceLubricant compositionZirconInorganic acids

A lubricating grease composition and a preparation method thereof are disclosed. The invention relates to the field of lubricating grease, and discloses a lubricating grease composition. The lubricating grease composition comprises base oil (10-80 wt%) and a thickening agent, which comprises non-Newton fluid sulfurized calcium alkyl phenate-calcium sulfonate (10-70 wt%), and zircon salts of higher fatty acid (1-20 wt%), and also optionally comprises one or more of non-Newton fluid calcium sulfonate (0-70 wt%), non-Newton fluid calcium naphthenate (0-70 wt%), non-Newton fluid calcium salicylate (0-70 wt%), non-Newton fluid calcium oleate (0-70 wt%), zircon salts of aromatic acid (0-15 wt%), and zircon salts of micro-molecular inorganic acid and / or lower fatty acid (0-15 wt%). The invention also discloses a preparation method of the lubricating grease composition. The provided lubricating grease composition has excellent performances.

Owner:CHINA PETROLEUM & CHEM CORP +1

Graphene oxide lubricant and preparing method thereof

InactiveCN106701251ALow costEnergy saving and environmental protectionAdditivesSolubilityPhosphorus pentasulfide

The invention discloses graphene oxide lubricant and a preparing method thereof. The preparing method includes the steps that graphite used as a basis reacts with concentrated nitric acid, sodium sulfate and potassium permanganate, hydrogen peroxide, butyl amine and high-base-number alkyl calcium salicylate are added, the method of adjusting the pH value is adopted to obtain graphene oxide beneficial for good reaction in the next step, then graphene oxide reacts with phosphorus pentasulfide, octanol and tertiary carbon primary amine, and a two-step partial pressure decompression method is adopted to prepare the graphene oxide lubricant high in oil solubility and wear resistance. The production method is simple, low in cost, high in oil solubility and high in yield.

Owner:王禹丁

Engine lubricating oil and preparation method thereof

The invention discloses engine lubricating oil and a preparation method thereof. The engine lubricating oil is prepared from components in percentage by weight as follows: 34%-38% of VHVI 250N base oil, 16%-19% of poly-alpha-olefin PAO4, 10%-11% of poly-alpha-olefin PAO150, 14.5%-15.5% of a complexing agent, 1.5%-1.7% of calcium salicylate, 0.25%-0.35% of organic molybdenum salt, 0.6%-0.7% of magnesium sulfonate, 0.24%-0.26% of borate, 7.4%-7.7% of alkyl naphthalene and 10%-13% of polyol ester, wherein the complexing agent is Chevron OLOA59110. The engine lubricating oil is environment-friendly, has slight engine wear degree and has long oil change mileage.

Owner:广州康尔克润滑油有限公司

Marine engine lubrication

Trunk piston marine engine lubrication, when the engine is fuelled by heavy fuel oil, is effected by a composition of TBN in the range of 20 to 60 comprising a major amount of an oil of lubricating viscosity containing 50 mass % or more of a Group 1 basestock, and respective minor amounts of an overbased metal calcium alkyl salicylate detergent providing 40 to 90 mmol of calcium alkyl salicylate per kg of the composition, and 0.1 to 10 mass %, based on the mass of the composition, of an oil-soluble linear alkyl-substituted phenol. Asphaltene precipitation in the lubricant (black paint), caused by the presence of contaminant heavy fuel oil, is prevented or inhibited.

Owner:INFINEUM INT LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com