Lubricating grease composition and preparation method thereof

A technology of lubricating grease composition and compound, applied in lubricating composition, petroleum industry, etc., can solve the problems of high base value calcium sulfonate, high price, not being promoted rapidly, easy hardening during storage, etc., and achieve excellent rust prevention and corrosion resistance, excellent storage stability, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention also provides a preparation method of the above lubricating grease composition.

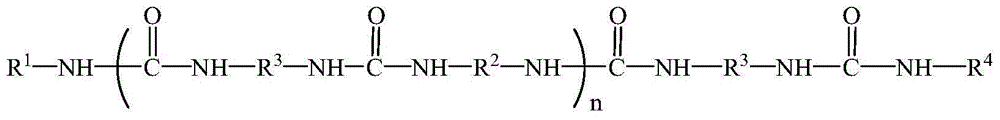

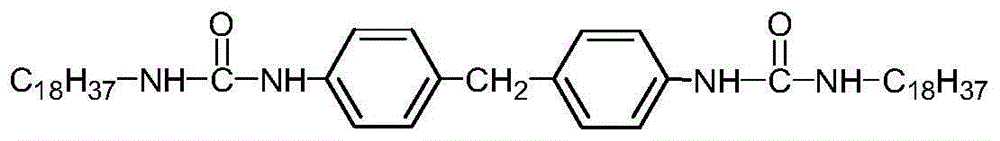

[0025] On the one hand, the present invention provides a kind of lubricating grease composition, and described lubricating grease composition contains base oil and thickening agent, and described thickening agent contains non-Newton body sulfurized alkylphenate calcium-calcium sulfonate, higher fatty acid Zirconium salt and polyurea compound, the thickener optionally also contains non-Newtonian calcium naphthenate, non-Newtonian calcium salicylate, non-Newtonian calcium oleate, zirconium salt of aromatic acid, small molecule inorganic acid and / or one or more of the zirconium salts of lower fatty acids, based on the weight of the grease, the content of the base oil is 10-80% by weight, non-Newtonian sulfurized calcium alkylphenate-calcium sulfonate The content is 10-70% by weight, the content of zirconium salt of higher fatty acid is 1-10% by weight, the content of pol...

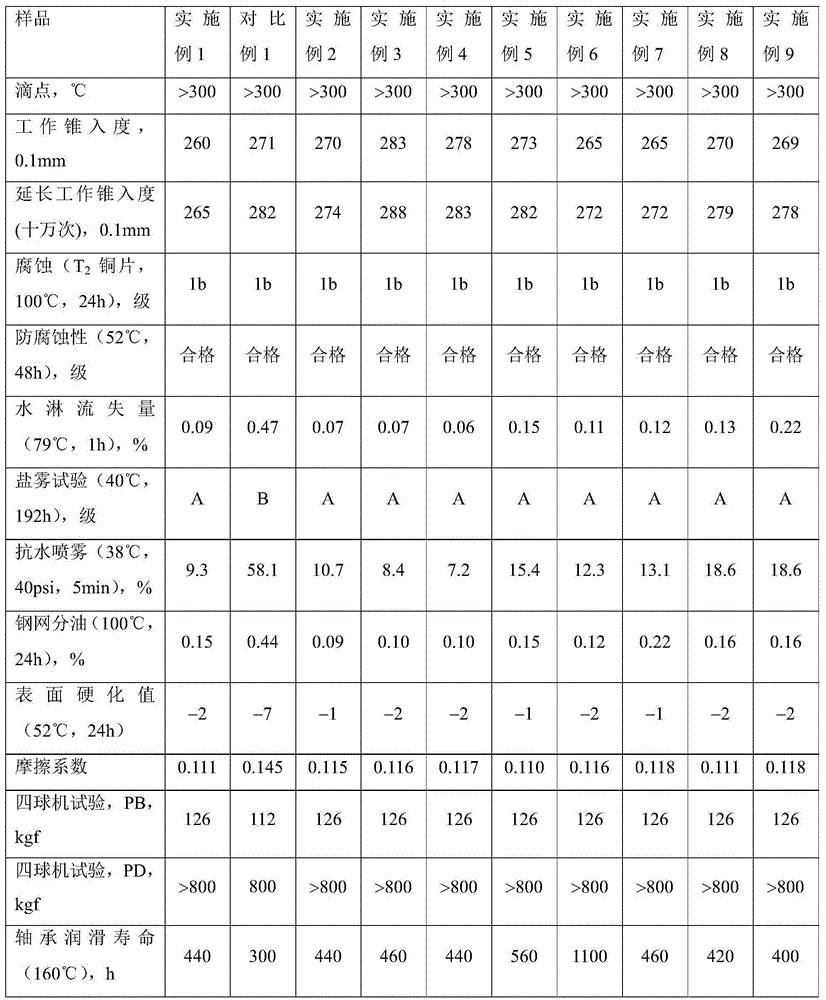

Embodiment 1

[0093] This example is used to illustrate the grease composition prepared by the present invention.

[0094] Raw material components: ultra-high base value calcium sulfonate (total base value 400mgKOH / g, 24kg); ultra-high base value sulfurized calcium alkylphenate (total base value 400mgKOH / g, 6kg); HVI150BS lubricating base oil (100 ℃ Kinematic viscosity is 31mm 2 / s, 30kg); 4-octadecylphenol (2.8kg); Methanol (1kg); Acetic acid (0.56kg); Zr(OH) 4 (3.9kg); 12-hydroxystearic acid (2kg); terephthalic acid (3.5kg); octadecylamine (1.5kg); MDI (0.7kg); HVI500SN lubricating base oil (100 ℃ kinematic viscosity is 11mm 2 / s, 17kg).

[0095] Add 24kg of super high alkali value calcium sulfonate with total base value of 400mgKOH / g and 6kg of super high alkali value calcium sulfonate with total base value of 400mgKOH / g Base value sulfurized alkyl phenate calcium and 30kg of HVI150BS lubricating base oil, stirring, heating up to 95°C, adding Zr(OH) with a solid content of 20% by weig...

Embodiment 2

[0098] This example is used to illustrate the grease composition prepared by the present invention.

[0099] Raw material components: ultra-high alkalinity calcium sulfonate (total alkalinity 400mgKOH / g, 6kg); high alkalinity sulfurized alkylphenate calcium (total alkalinity 320mgKOH / g, 24kg); HVI150BS lubricating base oil (100℃ Kinematic viscosity is 31mm 2 / s, 20kg); 4-octadecylphenol (2.8kg); Acetic acid (0.56kg); Zirconium n-butoxide (7.83k); Zr(OH) 4 (0.65kg); stearic acid (1.9kg); phthalic acid (3.5kg); laurylamine (1.31kg); MDI (0.89kg); 2 / s, 27kg).

[0100] Add 6kg of ultra-high alkalinity calcium sulfonate with a total alkalinity of 400mgKOH / g and 24kg of superalkali with a total alkalinity of 320mgKOH / g in a 160L atmospheric pressure reactor with heating, stirring, circulation, and cooling Sulfurized alkyl phenate calcium and 20kg of HVI150BS lubricating base oil, stir; heat up to 100°C, add 0.2kg of HVI500SN lubricating base oil and 0.131kg of laurylamine, stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com