Environment-friendly water-based metal cleaner

A metal-based and cleaning agent technology, applied in the field of environmentally friendly water-based metal cleaning agents, can solve problems such as high cost, unsatisfactory rust resistance, and indirect carcinogenicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

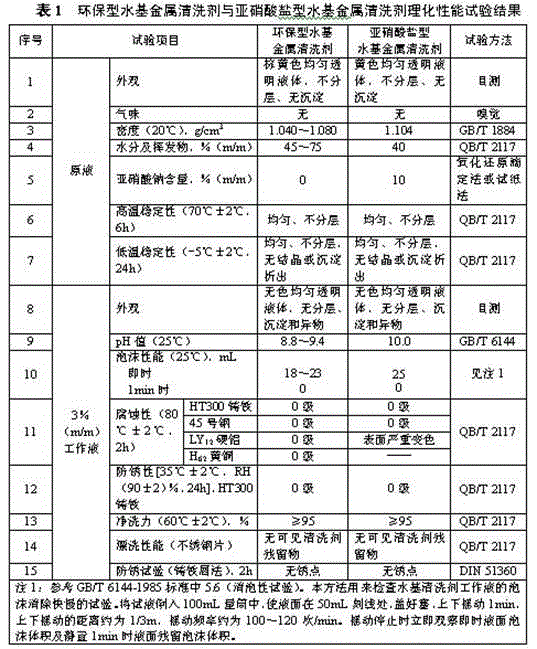

Image

Examples

Embodiment 1

[0015] (1) First, mix and heat the twelve-carbon dibasic fatty acid and triethanolamine in a reaction vessel at a mass ratio of 1:3. The heating temperature is controlled at 87°C, and the temperature is maintained at this temperature for 2 hours to synthesize water-soluble amines. Soap is used as the antirust agent monomer, and the mass ratio of dodecyl carbon dibasic fatty acid and triethanolamine in the total preparation content is 5%;

[0016] (2) Add water into the container, the mass ratio of water to the total content of the preparation is 43%, heat to 50°C and keep at this temperature, slowly add sodium carbonate and benzotriazole under stirring, fully dissolve and evenly; The mass ratio of sodium in the total content is 1%, and the mass ratio of benzotriazole in the total content is 0.5%;

[0017] (3) Slowly add triethanolamine and antirust agent monomers to the above solution, stir and dissolve evenly at the same time, the mass ratio of triethanolamine in the total co...

Embodiment 2

[0021] (1) First, mix and heat the twelve-carbon dibasic fatty acid and triethanolamine in a reaction vessel at a mass ratio of 1:3. The heating temperature is controlled at 83°C, and the temperature is maintained at this temperature for 2 hours to synthesize water-soluble amines. Soap is used as a rust inhibitor monomer, and the mass ratio of dodecyl carbon dibasic fatty acid and triethanolamine in the total preparation content is 10%;

[0022] (2) Add water into the container, the mass ratio of water to the total content of the preparation is 43%, heat to 50°C and keep at this temperature, slowly add sodium carbonate and benzotriazole under stirring, fully dissolve and evenly; The mass ratio of sodium in the total content is 3%, and the mass ratio of benzotriazole in the total content is 2%;

[0023] (3) Slowly add triethanolamine and rust inhibitor monomer into the above solution, stir and dissolve evenly at the same time, the mass ratio of triethanolamine in the total cont...

Embodiment 3

[0027] (1) First, mix and heat the twelve-carbon dibasic fatty acid and triethanolamine in a reaction vessel at a mass ratio of 1:3. The heating temperature is controlled at 85°C, and the temperature is maintained at this temperature for 2 hours to synthesize water-soluble amines. Soap is used as a rust inhibitor monomer, and the mass ratio of dodecyl carbon dibasic fatty acid and triethanolamine in the total preparation content is 7.5%;

[0028] (2) Add water into the container, the mass ratio of water to the total content of the preparation is 58.5%, heat to 50°C and keep at this temperature, slowly add sodium carbonate and benzotriazole under stirring, fully dissolve and evenly; The mass ratio of sodium in the total content is 2%, and the mass ratio of benzotriazole in the total content is 1%;

[0029] (3) Slowly add triethanolamine and antirust agent monomers to the above solution, stir and dissolve evenly at the same time, the mass ratio of triethanolamine in the total co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com