Spraying process for abrasion resistant layer of plunger contact surface

A contact surface and plunger technology, which is applied in the field of anti-abrasion layer spraying technology on the contact surface of the plunger, can solve the problems of low bonding strength, short service life, high porosity of the coating, etc., and achieve improved durability and wear resistance, effectively The protective effect and the effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

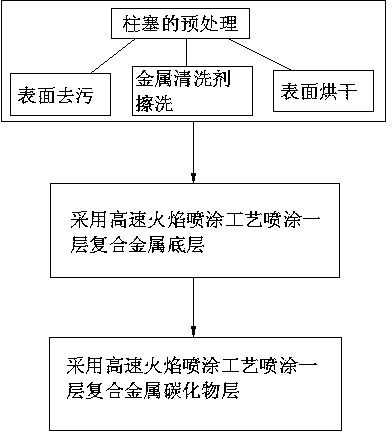

[0022] Embodiment 1: (a), the pretreatment of plunger: firstly adopt the heating method of 180 ℃ to remove all kinds of oil stains on the surface of the plunger, and then mix the metal cleaning agent with the warm water of 65 ℃ in a clean container, Wipe the plunger with a fine flat cloth and wipe it clean twice, then use water abrasive paper to polish the surface of the plunger evenly, and wipe the polished surface with a clean cloth; (b), spray the bottom layer: on the plunger The surface of the surface is sprayed with a layer of composite metal bottom layer by high-speed flame spraying process, (c), spraying protective layer, adopting a high-speed flame spraying process to spray a layer of composite metal carbide layer on the surface of the bottom layer; the spray gun used for spraying bottom layer ultra-high-speed flame spraying The jet flame speed is 1800m / s, the distance from the spray gun to the plunger surface is 15cm, the moving speed of the spray gun is 0.8m / s, the th...

Embodiment 2

[0023] Embodiment 2: (a), the pretreatment of plunger: firstly adopt the heating method of 190 ℃ to remove all kinds of oil stains on the surface of the plunger, and then mix the metal cleaning agent with the warm water of 68 ℃ in a clean container, Wipe the plunger with a fine flat cloth and wipe it clean twice, then use water abrasive paper to polish the surface of the plunger evenly, and wipe the polished surface with a clean cloth; (b), spray the bottom layer: on the plunger The surface of the surface is sprayed with a layer of composite metal bottom layer by high-speed flame spraying process, (c), spraying protective layer, adopting a high-speed flame spraying process to spray a layer of composite metal carbide layer on the surface of the bottom layer; the spray gun used for spraying bottom layer ultra-high-speed flame spraying The jet flame speed is 1900m / s, the distance from the spray gun to the plunger surface is 17cm, the moving speed of the spray gun is 1.0m / s, the th...

Embodiment 3

[0024]Embodiment 3: (a), the pretreatment of plunger: firstly adopt the heating method of 200 ℃ to remove all kinds of oil stains on the surface of the plunger, and then mix the metal cleaning agent with 70 ℃ warm water in a clean container, Wipe the plunger with a fine flat cloth and wipe it clean for 3 times, then polish the surface of the plunger evenly with a water abrasive paper, and wipe the polished surface with a clean cloth; (b), spray the bottom layer: on the plunger The surface of the surface is sprayed with a layer of composite metal bottom layer by high-speed flame spraying process, (c), spraying protective layer, adopting a high-speed flame spraying process to spray a layer of composite metal carbide layer on the surface of the bottom layer; the spray gun used for spraying bottom layer ultra-high-speed flame spraying The jet flame speed is: 2000m / s, the distance from the spray gun to the plunger surface is 20cm, the moving speed of the spray gun is 1.3m / s, the thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com