Multi-effect lubricating oil additive and preparation method thereof

A technology of lubricating oil additives and anti-wear agents, applied in the directions of additives, lubricating compositions, petroleum industry, etc. Oil performance decline and other problems, to achieve the effect of noise reduction, exhaust emission compliance, excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

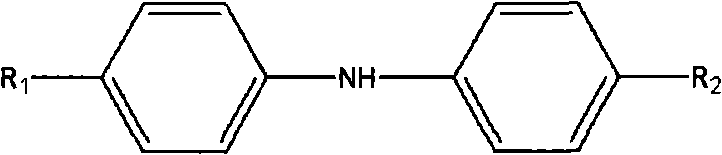

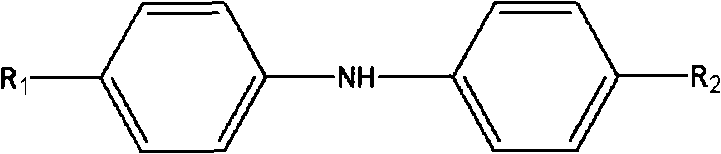

Embodiment 1

[0032] Under normal temperature and pressure, weigh 3 parts of metal detergent calcium alkyl sulfonate, 5 parts of sulfurized alkyl phenate calcium and 4 parts of alkyl magnesium salicylate, 8 parts of ashless dispersant polyisobutylene succinimide, anti-wear Add 2 parts of tri-n-butyl borate and 10 parts of di-n-butyl phosphite into the reaction kettle in turn, stir to make them evenly mixed, then raise the temperature to 120°C, add ashless antioxidant 4,4'-di-n-butyl 10 parts of diphenylamine, 1 part of viscosity index improver alkylnaphthalene, 2 parts of ethylene-propylene copolymer and 4 parts of polymethacrylate, and stir evenly to obtain the multi-effect lubricating oil additive of the present invention.

Embodiment 2

[0034] Under normal temperature and pressure, weigh 5 parts of metal detergent calcium alkyl sulfonate, 7 parts of magnesium sulfurized alkyl phenate and 5 parts of calcium alkyl salicylate, 10 parts of ashless dispersant polyisobutylene succinimide, anti-wear Add 10 parts of tri-n-pentyl borate and 8 parts of di-n-butyl phosphite into the reaction kettle in turn, stir to make them evenly mixed, then raise the temperature to 120°C, add ashless antioxidant 4-n-pentyl-4' - 8 parts of n-butyl diphenylamine, 1 part of viscosity index improver alkylnaphthalene, 2 parts of ethylene-propylene copolymer and 2 parts of polymethacrylate, and stir evenly to obtain the multi-effect lubricating oil additive of the present invention.

Embodiment 3

[0036] Under normal temperature and pressure, weigh 3 parts of metal detergent magnesium alkyl sulfonate, 5 parts of sulfurized calcium alkylphenate and 2 parts of calcium alkyl salicylate, 8 parts of ashless dispersant polyisobutylene succinimide, anti-wear Add 5 parts of tri-n-hexyl borate and 13 parts of di-n-butyl phosphite into the reaction kettle in turn, stir to make them evenly mixed, then raise the temperature to 150°C, add ashless antioxidant 4-isoamyl-4'- 12 parts of n-hexyl-diphenylamine, 3 parts of viscosity index improver alkylnaphthalene, 2 parts of ethylene-propylene copolymer and 6 parts of polymethacrylate are mixed evenly to obtain the multi-effect lubricating oil additive of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com