Method for repairing NiCrAlYSi coating on DZ125 blade surface

A DZ125, repair method technology, applied in coating, metal material coating process, ion implantation plating and other directions, can solve the problems of over-corrosion of blade substrate, scrapped blade, coating peeling, etc., to achieve stable performance and state, production The effect of low cost and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Remove the original coating: heat the coating removal bath to 38°C, place the DZ125 blade coated with NiCrAlYSi coating to be treated in the coating removal bath, stir the bath at the same time, and treat for 25 minutes;

[0022] Take out the treated blade, and use a wool felt wheel with 180 mesh emery to smooth the blade until there is no visible coating residue on the surface of the blade;

[0023] (2) Vacuum arc plating coating: adopt vacuum arc plating device, set working pressure -2 Pa, the working current is 600A, the working voltage is 250V, and the blade surface is ion-cleaned for 6 minutes, then the working current is set to 700A, the working voltage is 30V, and the NiCrAlYSi coating is coated on the blade surface for 130 minutes, and then the blade is cooled for 2 hours;

[0024] (3) Vacuum heat treatment: place the cooled blade in a vacuum heat treatment furnace, and keep it warm at 860°C for 20h.

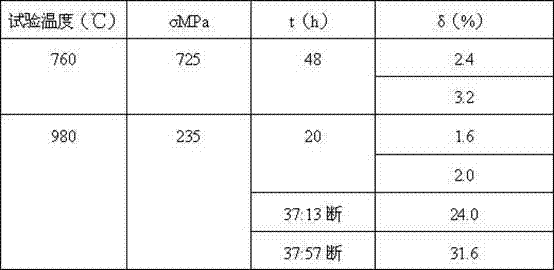

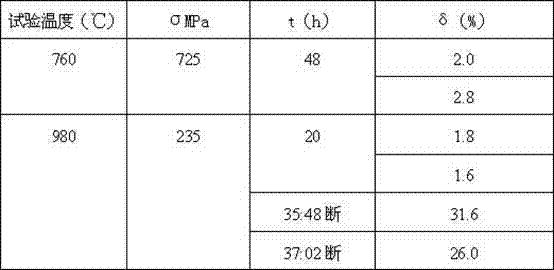

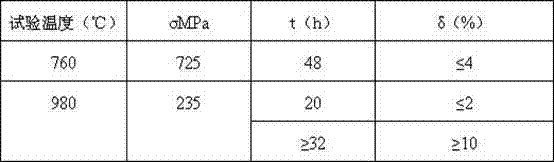

[0025] The industrial requirements for the durability o...

Embodiment 2

[0036] (1) Remove the original coating: heat the coating removal bath to 40°C, place the DZ125 blade coated with NiCrAlYSi coating to be treated in the coating removal bath, stir the bath at the same time, and treat for 8 minutes;

[0037] Take out the treated blade, and use a wool felt wheel with 180 mesh emery to smooth the blade until there is no visible coating residue on the surface of the blade;

[0038] (2) Vacuum arc plating coating: adopt vacuum arc plating device, set working pressure -2 Pa, the working current is 700A, the working voltage is 250V, and the blade surface is ion cleaned for 2 minutes, then the working current is set to 750A, the working voltage is 34V, and the NiCrAlYSi coating is coated on the blade surface for 110 minutes, and then the blade is cooled for 2.5 hours;

[0039] (3) Vacuum heat treatment: place the cooled blade in a vacuum heat treatment furnace, and keep it warm at 880°C for 20h.

Embodiment 3

[0041] (1) Remove the original coating: heat the coating removal bath to 39°C, place the DZ125 blade coated with NiCrAlYSi coating in the coating removal bath, stir the bath at the same time, treat for 10 minutes, take out For the leaves, use a brush to remove the residue on the leaf body in flowing warm water, observe the coating removal situation, place the side of the leaf body with more remaining coating facing down in the bath, and continue the treatment for 5 minutes;

[0042] Take out the treated blade, and use a wool felt wheel with 180 mesh emery to smooth the blade until there is no visible coating residue on the surface of the blade;

[0043] (2) Vacuum arc plating coating: adopt vacuum arc plating device, set working pressure -2 Pa, the working current is 650A, the working voltage is 250V, and the blade surface is ion cleaned for 4 minutes, then the working current is set to 720A, the working voltage is 32V, the NiCrAlYSi coating is coated on the blade surface for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com