An Adaptive Circulating Lubrication System for Sliding Bearings

A sliding bearing and circulating lubrication technology, used in the lubrication of engines, shafts and bearings, bearing components, etc., can solve the problems of inability to quickly and effectively maintain, limit the wide application of solutions, and block the internal oil, saving floor space, Reduce power consumption and ensure the effect of normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

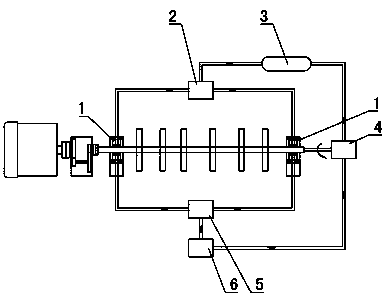

[0039] Such as figure 1 Shown: In this embodiment, a sliding bearing 1 is respectively installed at both ends of the rotating shaft. The liquid inlet end of the filter 2 is connected with a coarse filter module, and the liquid inlet end of the coarse filter module is connected with the oil outlet holes of two sliding bearings 1 at the same time, and an oil supply tank is arranged between the filter 2 and the oil cutting device 4 3, so that lubricating oil can be provided, and when adding lubricating oil to the system, it can be added through the oil supply tank 3. The liquid outlet of the heat exchanger 6 is connected with a buffer tank 5, and the liquid outlet of the buffer tank 5 communicates with the oil inlet holes of the two sliding bearings 1 at the same time, thereby realizing the circulation oil supply lubrication.

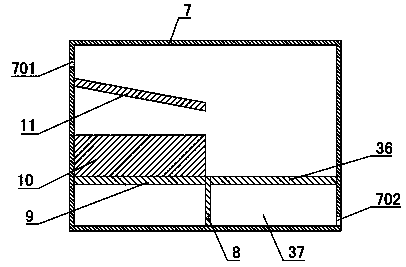

[0040] Such as figure 2 As shown: the filter 2 includes a glass substrate 11 , a magnet on the lower side of the glass substrate 11 , a filter plate 36...

Embodiment 2

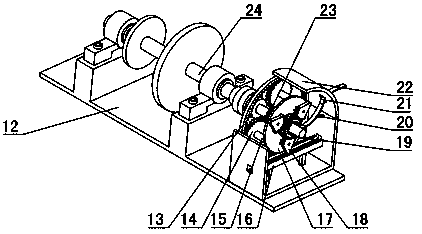

[0052] Such as Figure 9 As shown: the difference between embodiment 2 and embodiment 1 is: the upper part of the hose groove 16 is symmetrically provided with extrusion guide rails 1601 on both sides, and the right end of the extrusion guide rail 1601 is in the shape of an arc gradually upward from left to right. Extruding block 35 is installed in hose groove 16, and the left end of extruding block 35 is the inclined shape gradually upward from left to right. It is connected and drives the extruding block 35 to move to the right and separate from the extruding guide rail 1601 . When the wheel disc 17 drives the cutting and pressing head 18 to rotate, the cutting and pressing head 18 pushes the extrusion block 35 to move to the left, and under the action of the extrusion guide rail 1601, the extrusion block 35 moves downwards to squeeze the oil hose, squeezing The briquetting block 35 moves to the left at the same time, thereby conveying the lubricating oil and improving the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com