Preparation method of semiconductor device

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as difficult filling of metals, slow etching rate, and recessed side walls of openings 121, to achieve good adhesion, Effect of avoiding excessive corrosion and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

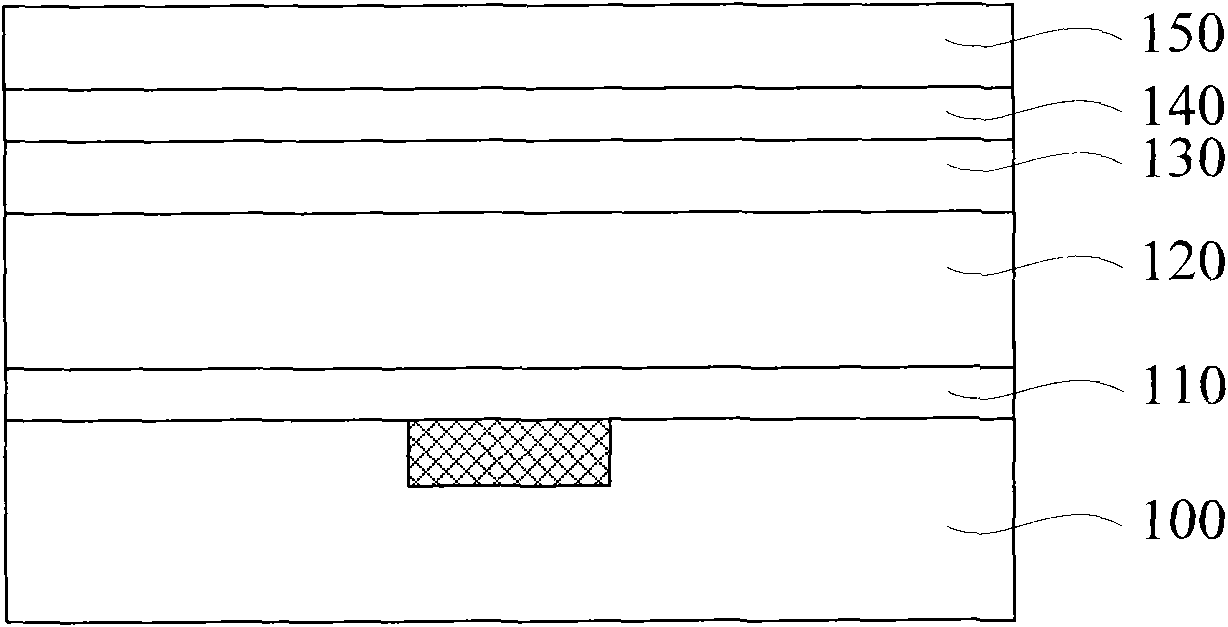

[0022] The core idea of the present invention is to provide a method for manufacturing a semiconductor device. The method for manufacturing a semiconductor device uses a nitrogen-doped silicon carbide layer to replace the existing octamethyltetrasilane layer. The nitrogen-doped silicon carbide layer It has good adhesion to the dielectric layer, and the nitrogen-doped silicon carbide layer is relatively dense, and its etching rate is slow when performing a wet cleaning process, which can avoid excessive corrosion of the nitrogen-doped silicon carbide layer, The reliability of the semiconductor device is improved.

[0023] Please refer to figure 2 , which is a flowchart of a method for manufacturing a semiconductor device provided by an embodiment of the present invention, the method for the semiconductor device includes the following steps:

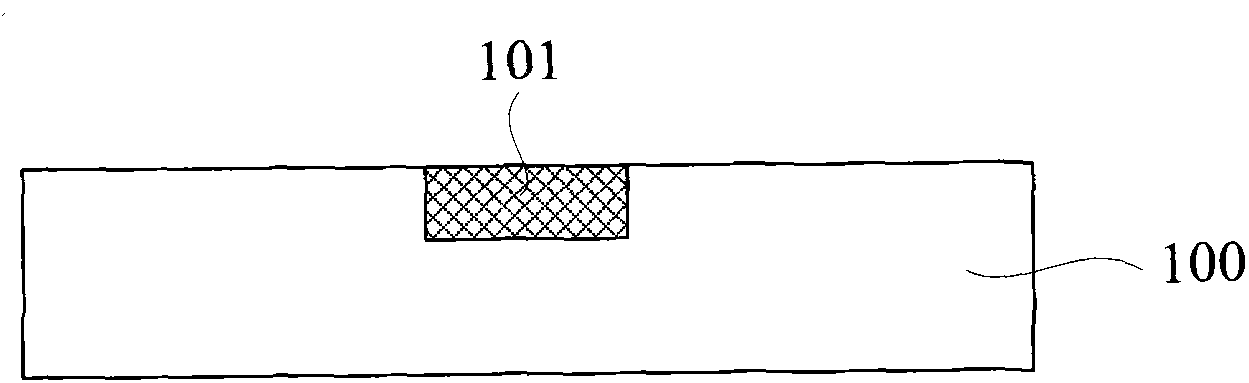

[0024] Step S200, providing a semiconductor substrate formed with metal interconnection lines;

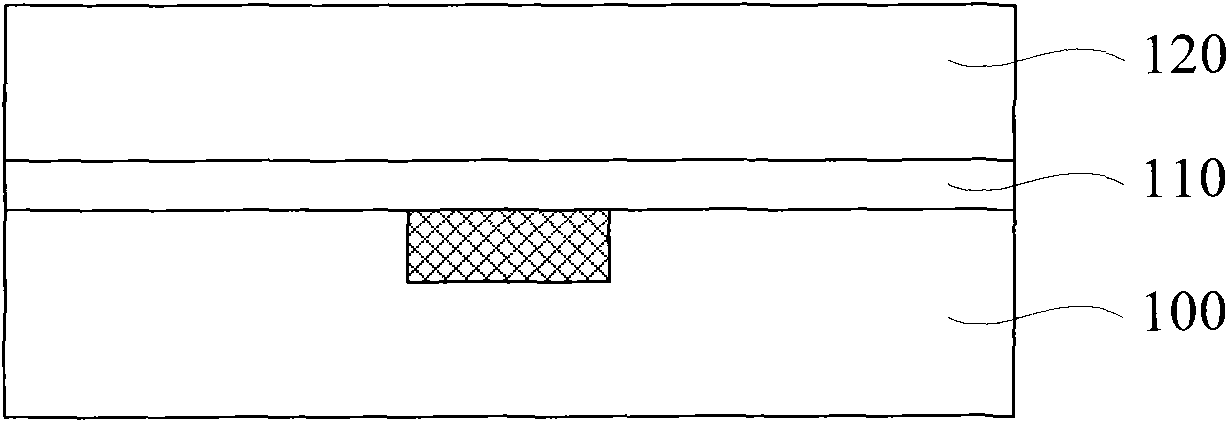

[0025] Step S210, forming a dielect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com