Cleaning device in front of chip potential barrier and cleaning process

A technology for cleaning devices and barriers, which is applied in the field of cleaning technology before chip barriers, to achieve the effects of reducing consumption, reliable operation, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

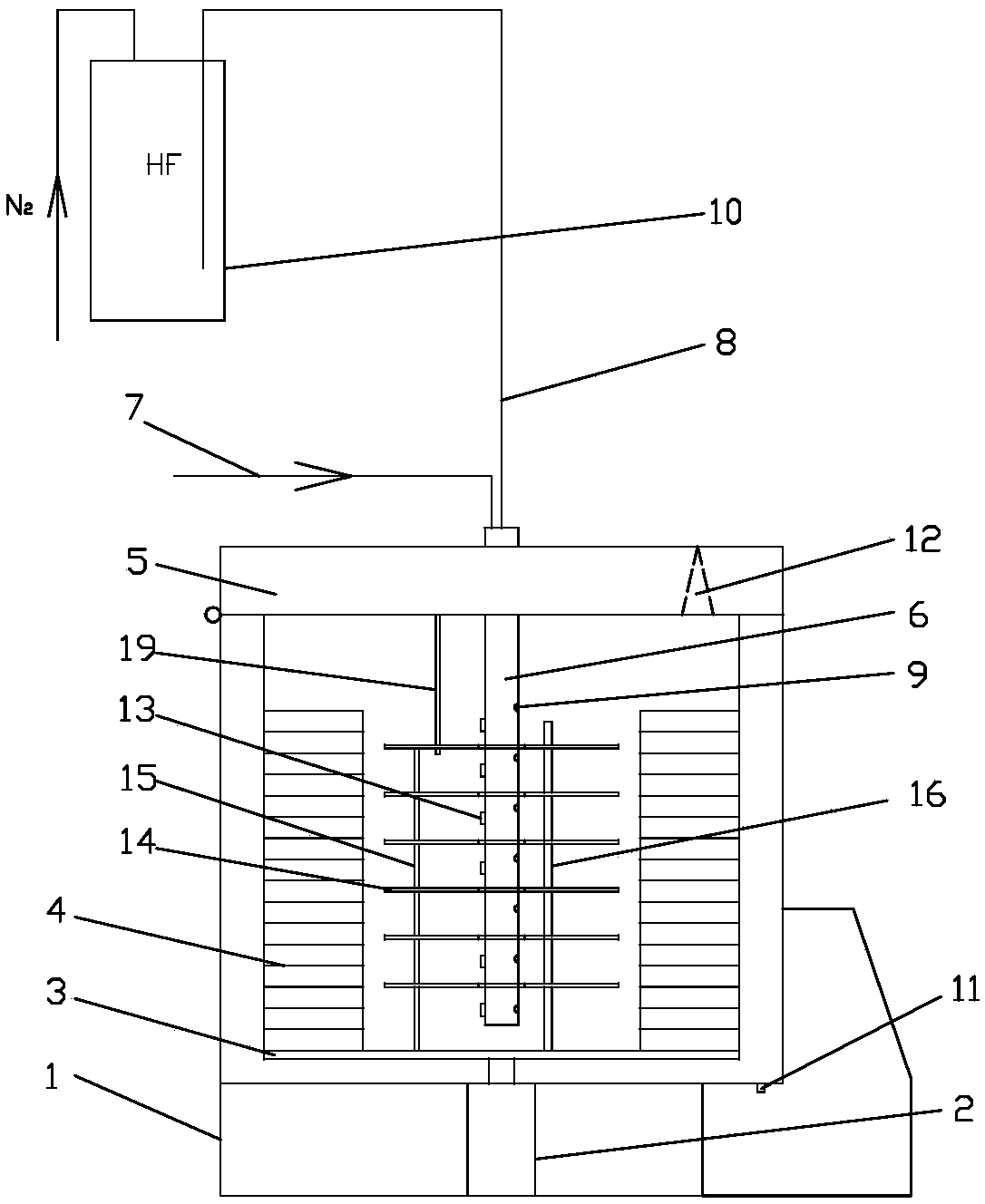

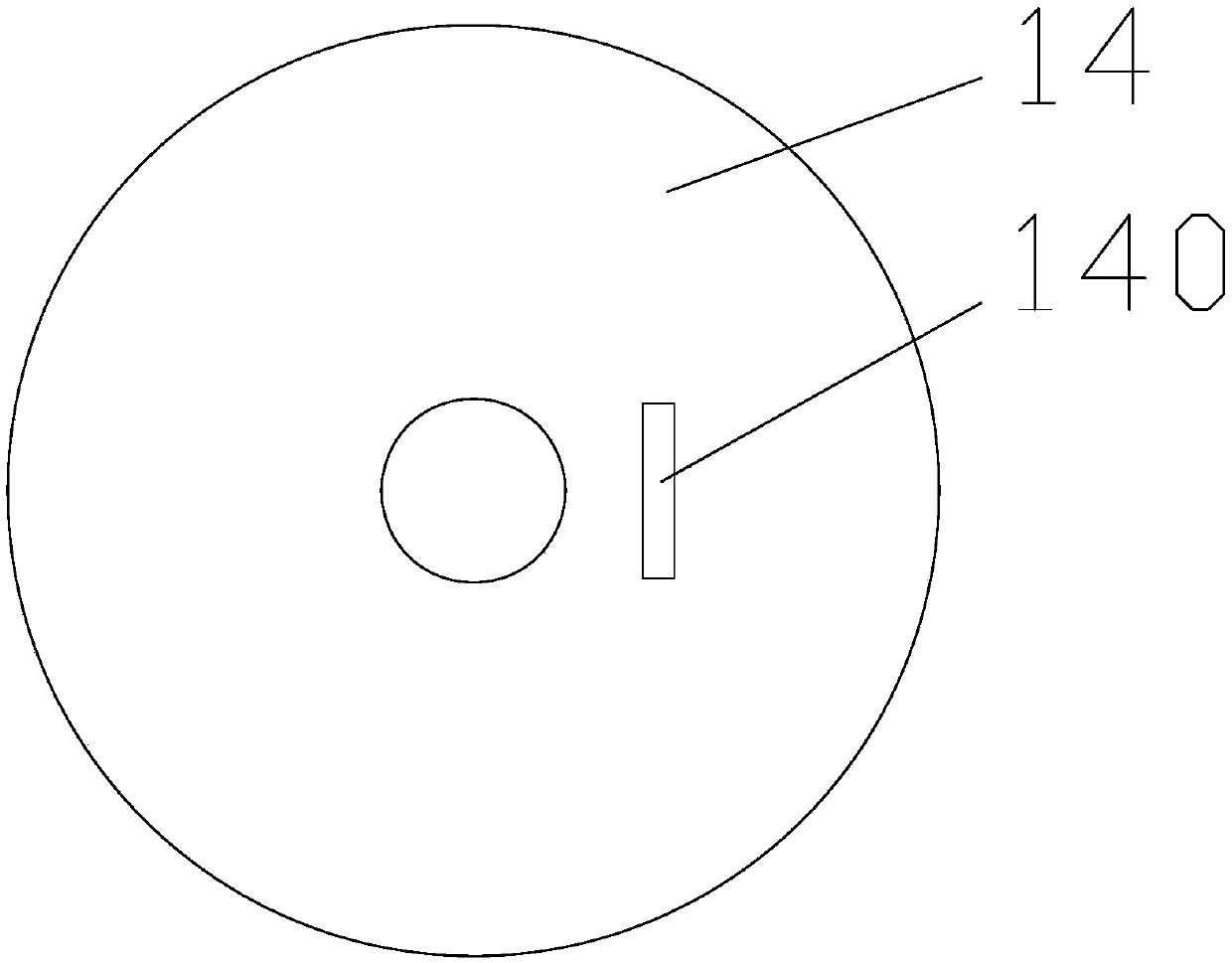

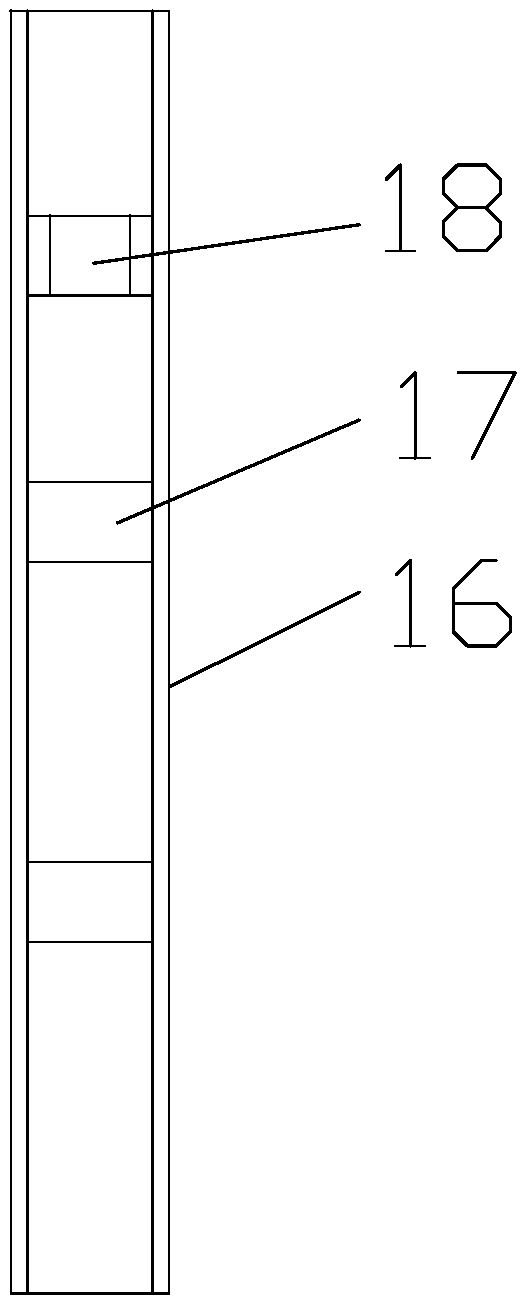

[0028] The present invention as Figure 1-3 As shown, it includes a box body 1, a support platform 3 driven by a driver 2 is provided in the middle of the box body, and several frames 4 are arranged on the support platform, and several frames are evenly distributed in a ring, and the frames are used for placing A number of wafers, the top opening of the box is hingedly provided with a box cover 5, and the center of the box cover is provided with a nozzle 6, and the nozzle is located at the top of the box cover to communicate with pipeline one 7 and pipeline two 8, and is located in the box The lower part of the cover is provided with several spouts 9 .

[0029] During work, the wafer is placed on the frame, the driver (ie, the motor) drives the support table to rotate, and the solutions in the first and second pipes are sprayed out from the nozzles to clean the wafer and remove organic matter and particles remaining on the surface.

[0030] The second pipeline is used to conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com