Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77results about How to "Achieve the effect of treating waste with waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

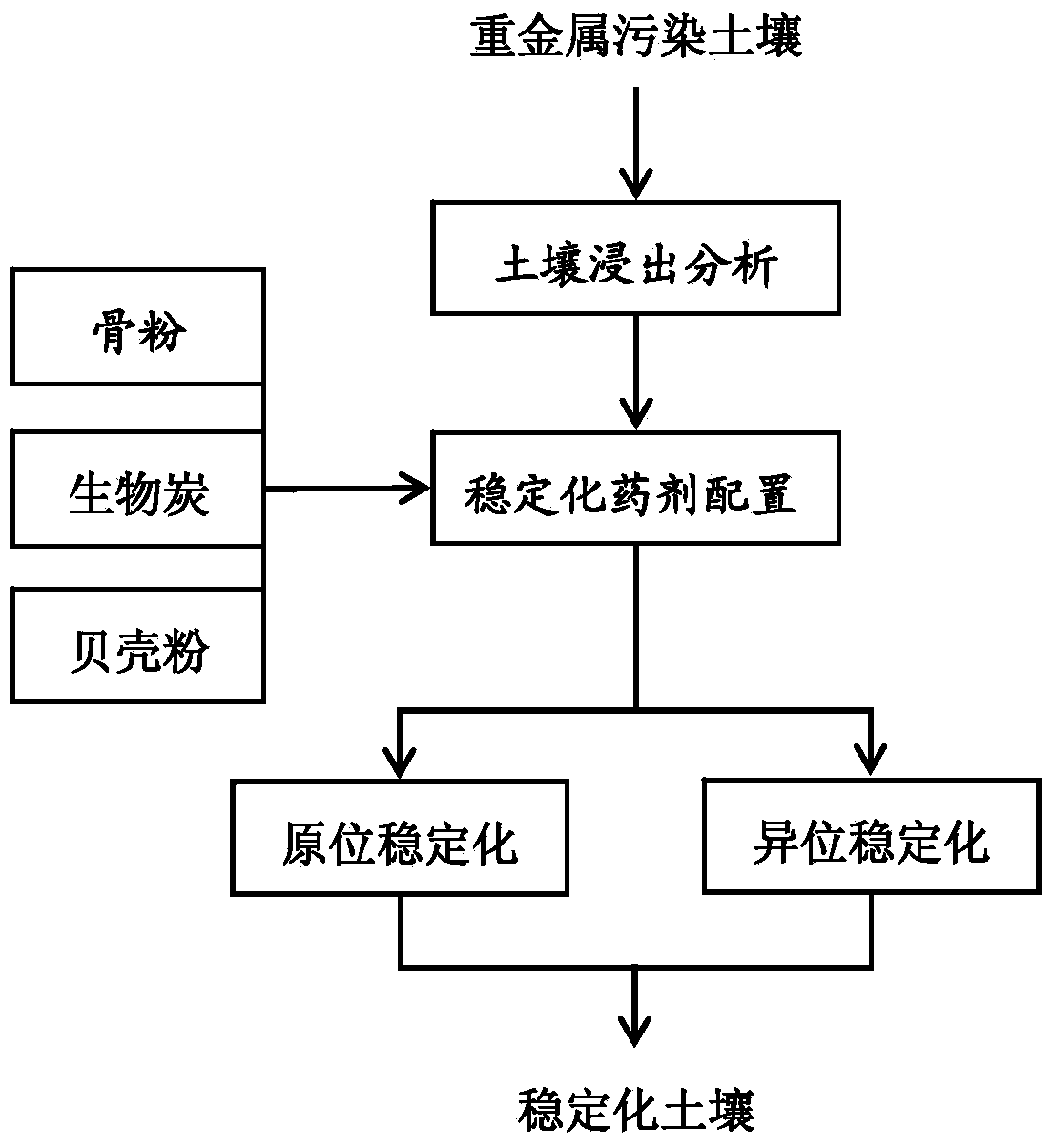

Stabilizing agent for heavy metal contaminated soil and preparation method and application thereof

ActiveCN103740373AGood pH control abilityLong-term effective stabilizationAgriculture tools and machinesContaminated soil reclamationContaminated soilsBiomass

The invention discloses a stabilizing agent for heavy metal contaminated soil and a preparation method and application thereof, and the stabilizing agent comprises the following raw materials: by weight, 20-60% of bone meal; 10-30% of biochar and 20-70% of calcined shell powder. The preparation method is as follows: (1) drying biomass in air and grinding into particles smaller than 60 meshes, cracking in a cracking furnace at 400-800 DEG C for 6-8 hours to obtain the biocar; calcining shell powder with the particle size below 20 meshes in a high temperature furnace at 800-1000 DEG C for 2 to 4 hours, naturally cooling to room temperature to obtain the calcined shell powder; and (2) proportionally mixing the biocar, the calcined shell powder and the bone meal evenly to obtain the stabilizing agent. The stabilizing agent compounding the three components in accordance with a specific proportion solves the problem of high cost, undurable stabilization effect and the like of stabilizing agents for the heavy metal contaminated soil in the prior art.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

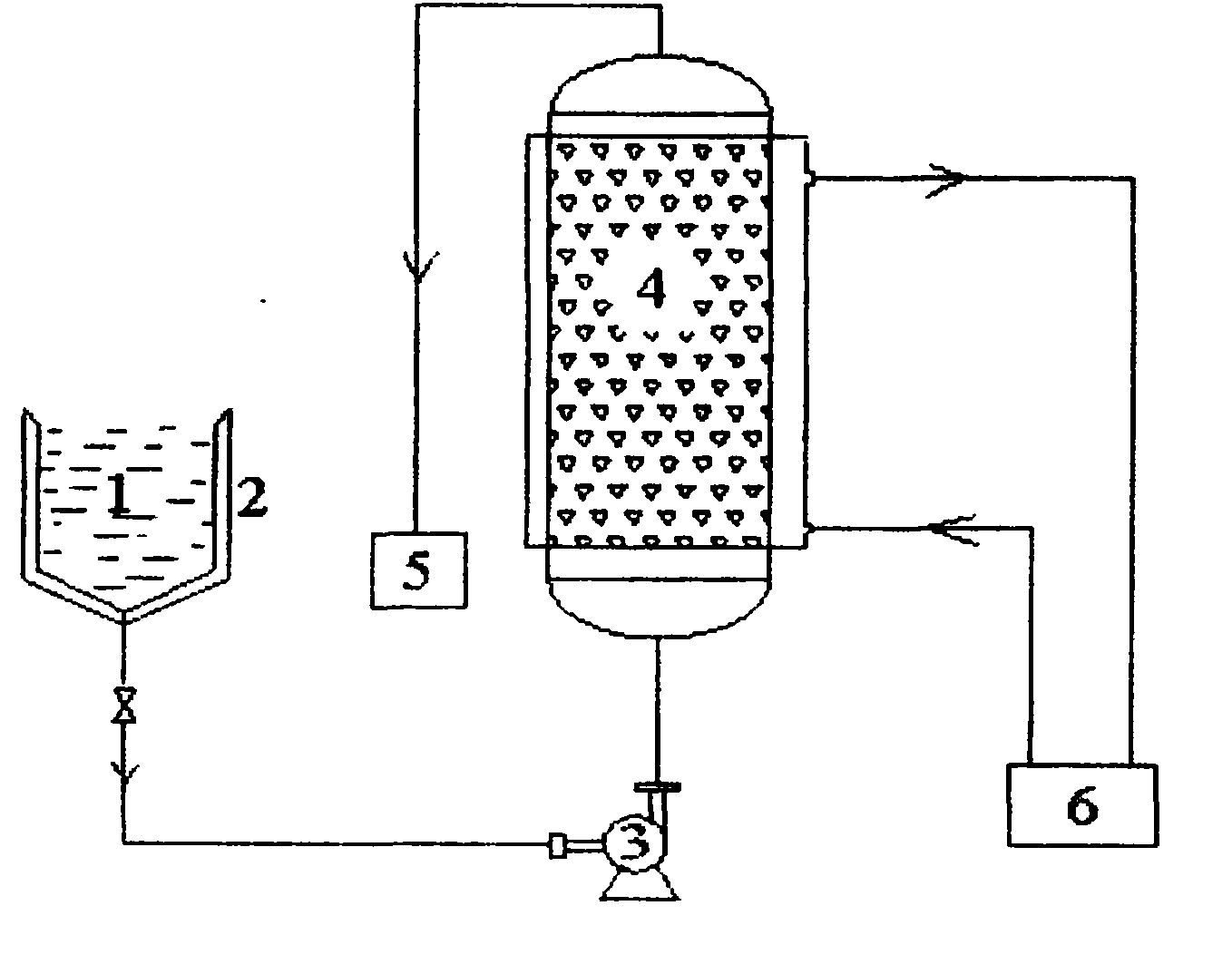

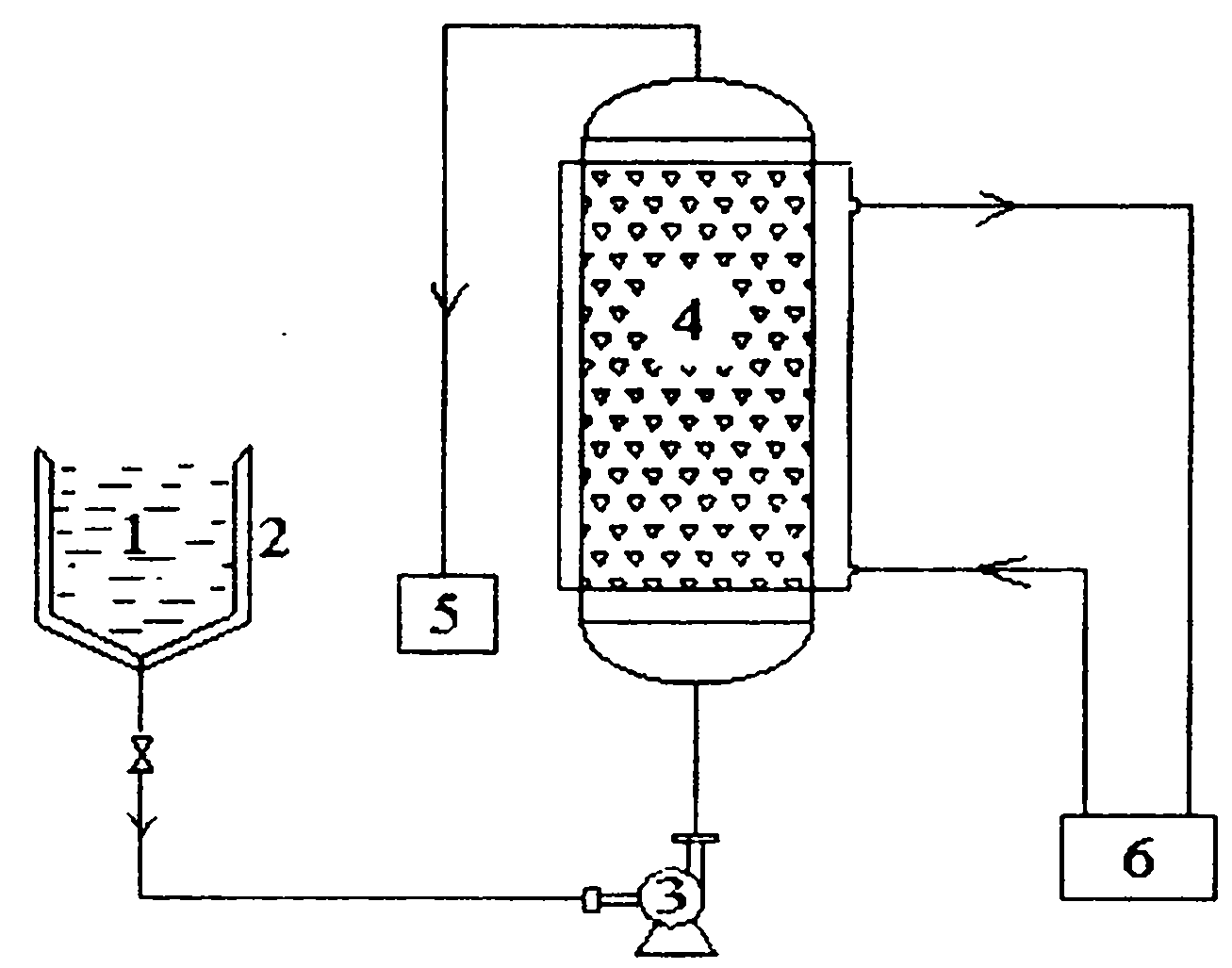

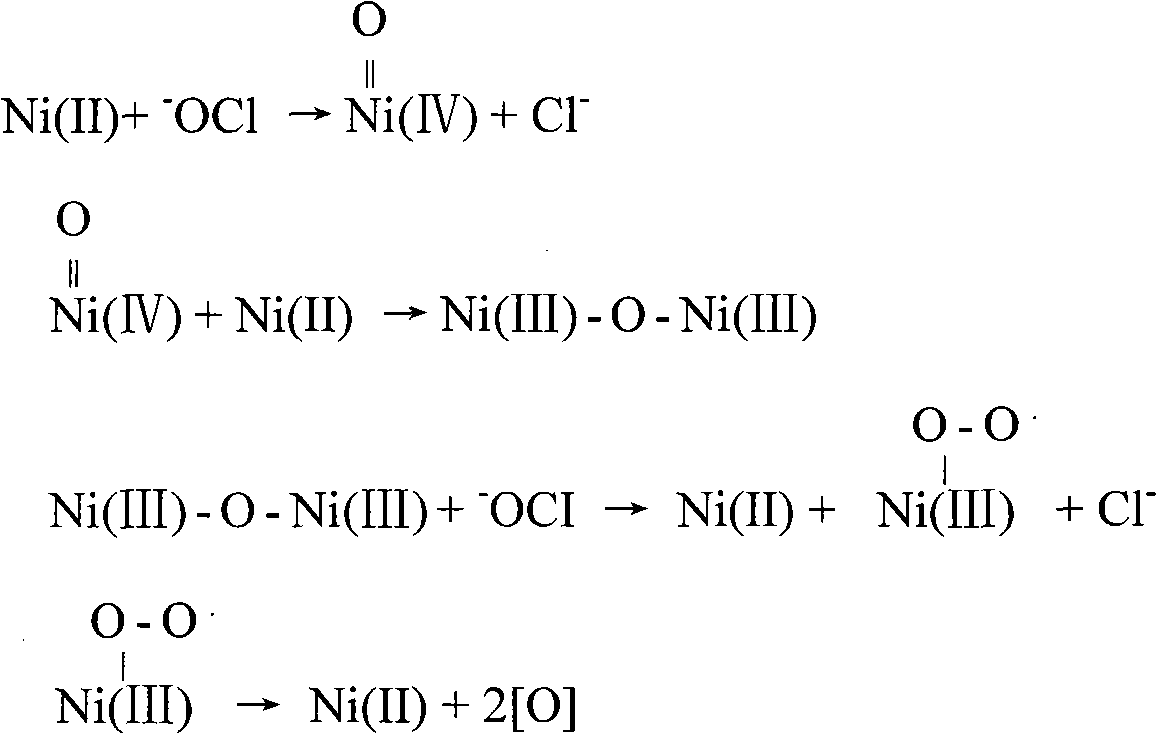

Treating method for efficiently catalyzing and oxidizing chlor-alkali industrial waste water

InactiveCN101844828AEasy to makeSimple processMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationIndustrial waste waterCatalytic oxidation

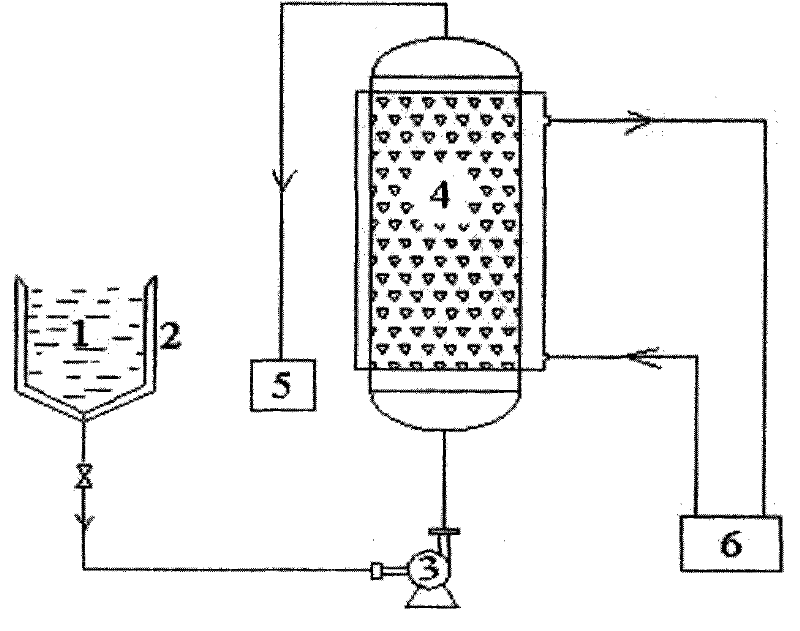

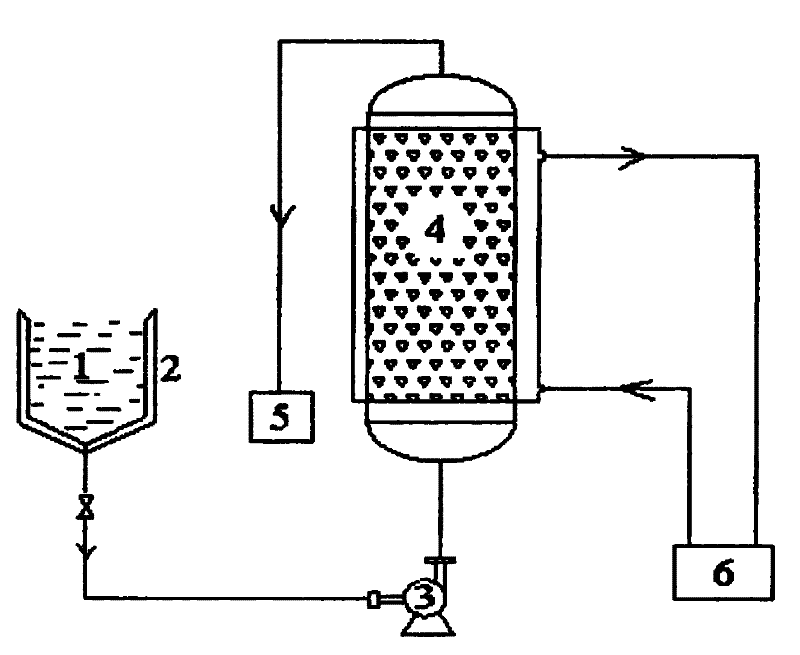

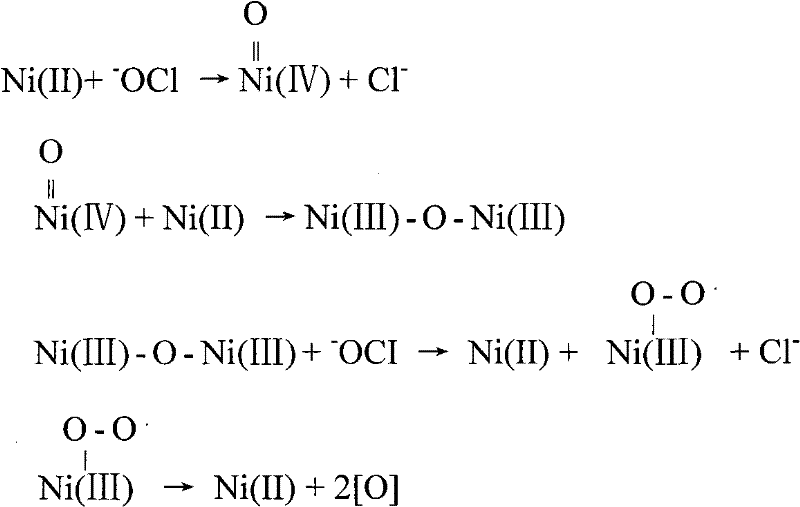

The invention discloses a treating method for efficiently catalyzing and oxidizing chlor-alkali industrial waste water. In the method, sodium hypochlorite in the chlor-alkali industrial waste water is decomposed mainly by adding a nickel oxide catalyst with an efficient surface; and simultaneously a small amount of other pollutants in the waste water is degraded. The treating method for efficiently catalyzing and oxidizing the chlor-alkali industrial waste water of the invention comprises the following step of: making sodium hypochlorite-containing alkaline waste water continuously flow through a catalytic oxidation reaction bed filled with a catalyst from the bottom to the top at an air speed of between 1.6 and 2.6 h<-1>.

Owner:NANJING UNIV OF TECH

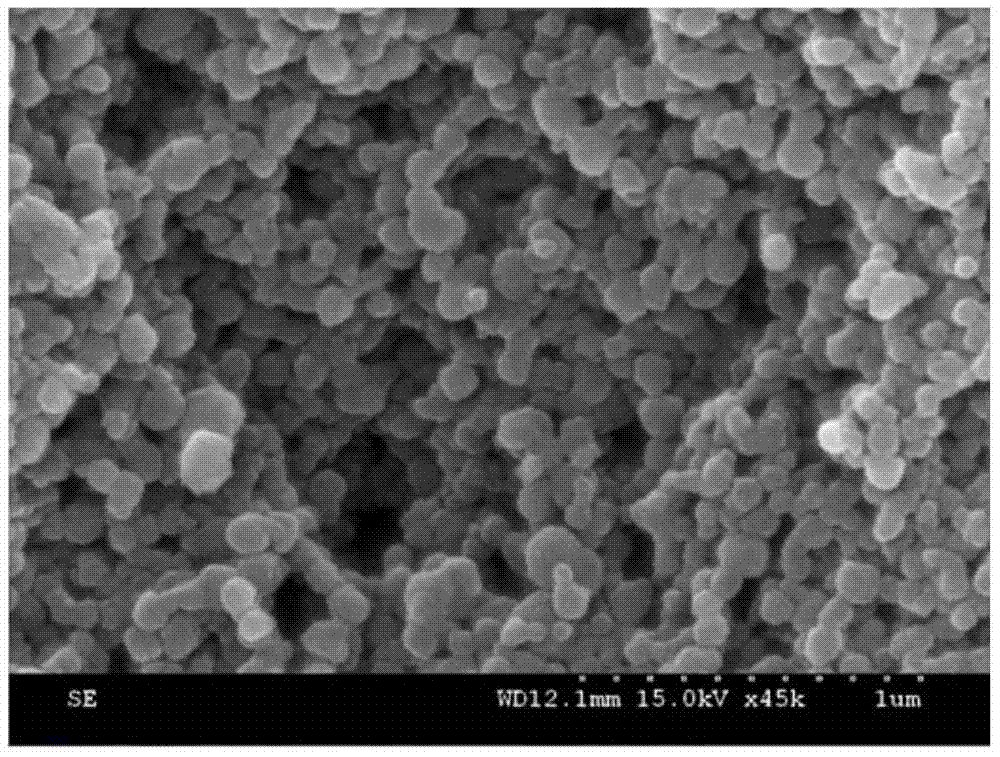

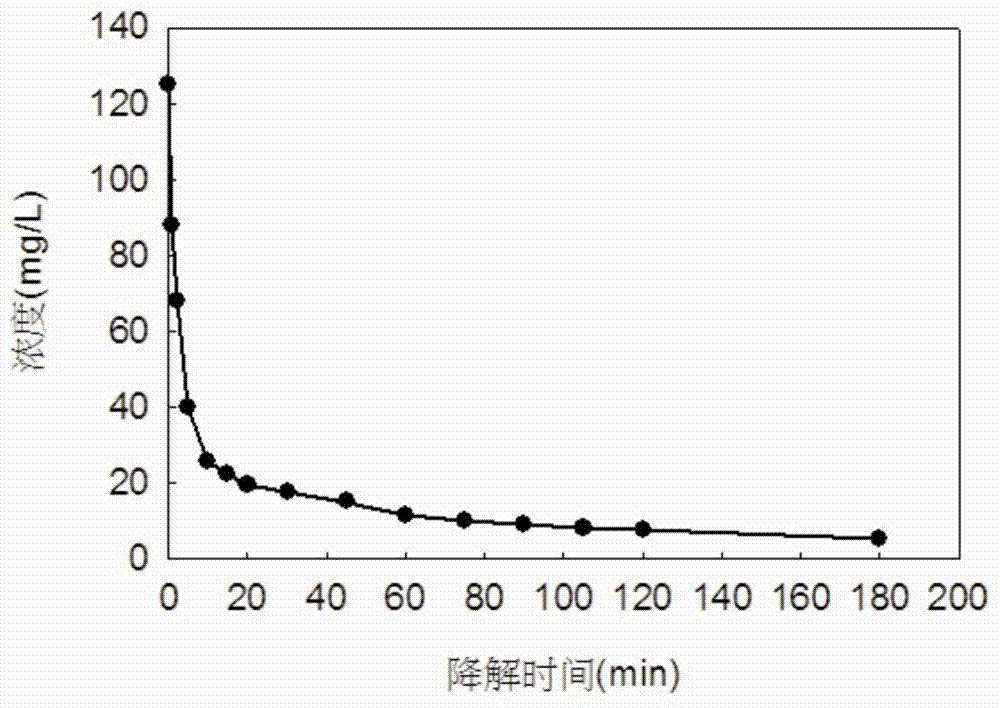

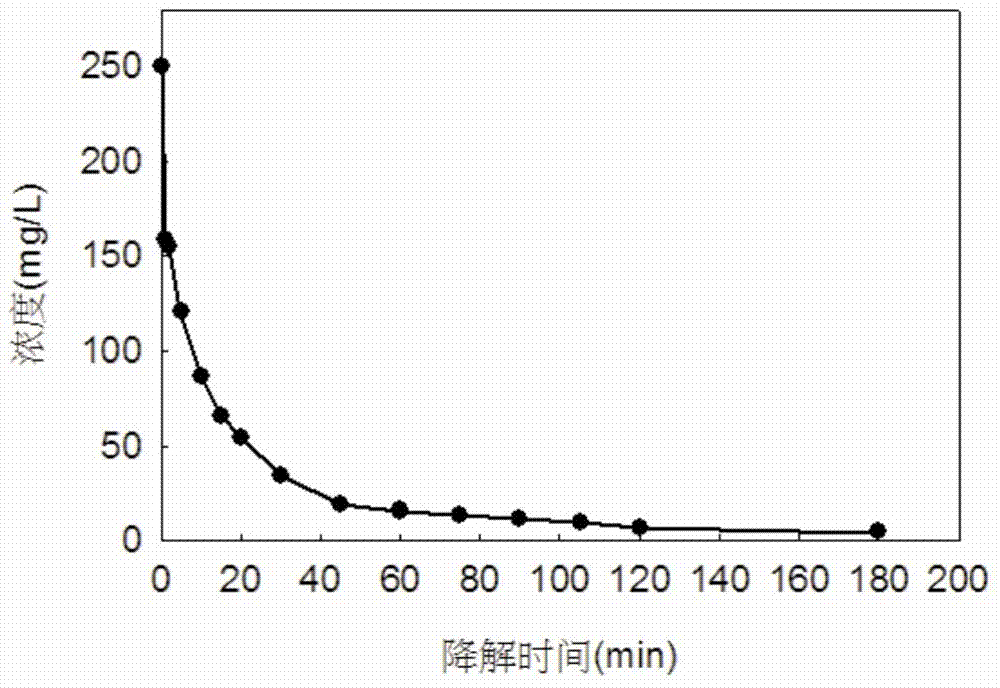

Method for synthesizing water soluble nanometer iron through mangosteen pericarp in environment-friendly mode and application of water soluble nanometer iron

ActiveCN103878385AHigh removal rateSimple processWater/sewage treatmentNanotechnologyBrilliant RedFiltration

The invention discloses a method for synthesizing water soluble nanometer iron through mangosteen pericarp in an environment-friendly mode and application of the water soluble nanometer iron, and belongs to the technical field of treatment of waste water. The method for preparing water soluble nanometer iron includes the steps that first, the mangosteen pericarp is washed with distilled water, dried, crushed and screened to 300 microns to 600 microns, and after the mangosteen pericarp particles and distilled water are mixed, heated to boiling and cooled to the room temperature, mangosteen pericarp extraction solution is obtained through filtration; second, under the condition of the room temperature, the mangosteen pericarp extraction solution and ferric salt solution are mixed according to a certain proportion, oscillated and shaken up, and then the water soluble nanometer iron is obtained. The water soluble nanometer iron prepared with the method can be used for degrading reactive brilliant blue KN-R and reactive brilliant red K-2G dye in a catalytic mode, and the degrading efficiency is high. The method for environmentally friendly synthesizing water soluble nanometer iron through mangosteen pericarp is simple in technology and low in cost, waste is treated with waste, the utilization of mangosteen pericarp resources is intensified, and dye in the waste water is also removed.

Owner:BEIJING UNIV OF TECH

Comprehensive utilization method of waste liquor in production of basic cupric carbonate

ActiveCN103449501AAchieve reuseRealize recycling of resourcesCopper chloridesCopper nitratesSulfate radicalsIndustrial waste water

The invention discloses a comprehensive utilization method of waste liquor in the production of basic cupric carbonate and relates to the field of treatment methods of industrial wastewater. The invention aims at providing a comprehensive utilization method of waste liquor in the production of basic cupric carbonate, and in particular relates to a method for reusing sodium bicarbonate in the waste liquor. The waste liquor in the production of the basic cupric carbonate is the waste liquor generated after the basic cupric carbonate is produced by a reaction between an acidic copper chloride solution or an acidic copper sulfate solution and a sodium carbonate solution. The comprehensive utilization method of the waste liquor in the production of the basic cupric carbonate mainly comprises the following steps: adding a little distilled water into a reaction kettle as a base solution; when the reaction temperature rises to 35-90 DEG C, starting a stirring device, and adding the waste liquor containing sulfate radicals or chlorine and the acidic copper solution into the reaction kettle for reaction, wherein the pH value during the addition of the solutions is controlled to be 3-6; and filtering, washing, drying and sieving reaction products to obtain the basic copper salt. The method disclosed by the invention is simple to operate, easy to control reaction conditions, and widely applicable to the recycling and reusing of the waste liquor in the production of basic cupric carbonate.

Owner:SHENZHEN SHENTOU ENVIRONMENT TECH CO LTD

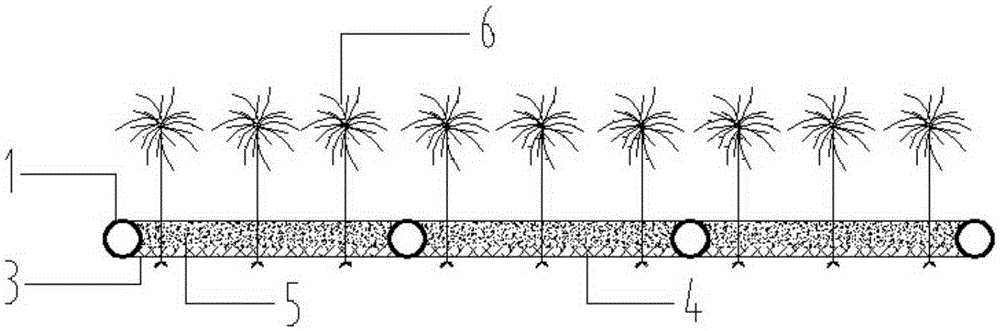

Ecological floating bed for oil-polluted water remediation

ActiveCN105293709AImprove water purification effectImprove adsorption capacityWater contaminantsBiological water/sewage treatmentPlant rootsNonwoven fabric

The invention discloses an ecological floating bed for oil-polluted water remediation. The main frame of the ecological floating bed comprises multiple assembled casing supports. Joints of the casing supports of the main frame are connected to matched PVC casing pipe joints and the joint openings are sealed by silica gel. A modified TiO2 photocatalytic material is carried by waste polyurethane foamed plastic recovered and recycled by an alcoholysis method so that the casing supports are prepared. The bottom of the main frame is wrapped by a non-woven fabric. Wrapped parts of the non-woven fabric and the main frame are tightened by a nylon rope. In each unit, a certain amount of a bottom filler layer and an upper filler layer are uniformly laid. Crops are planted in the upper filler layer. The paddy rice sprout on a floating bed can fully absorb redundant nitrogen and phosphor in water so that plant growth is promoted, the plant roots can promote floating bed bottom microbe growth so that floating bed water purification effects are improved, and the modified fly ash and the non-woven fabric have strong adsorptivity. The floating bed has three technology advantages and improves oil pollutant adsorption degradability and cleaning effects.

Owner:HOHAI UNIV

Sewage treatment filtercake by taking river sludge as raw material and manufacturing method

ActiveCN101711931ARough surfaceLarge specific surface areaSustainable biological treatmentFiltration separationSewage treatmentPorosity

The invention discloses a sewage treatment filtercake by taking river sludge as a raw material and a manufacturing method, and the filtercake comprises the following components by mass percent: 80-100% of river sludge, 0-15% of flyash, 0-5% of red mud for steel production and 2-5% of swelling agent; the filtercake is obtained by adding 25-30% of water and 2-4% of pressing binder in terms of the mass of the raw material into the above components through the steps of mixing, pelleting, drying and high-temperature sintering successively. The filtercake in the invention has high main performance indexes such as film hanging property, water-gas distribution uniformity, bulk specific weight, strength, porosity, specific area and the like, and can be manufactured with a specified aperture and an apparent density conveniently by controlling the granularity and dosage of charcoal powder or mica powder, and has the advantages of wide sources of raw materials, simple production process, no pollution, low cost and high added value; the production equipment and technology in the current cement plants can be switched to producing ball-shaped filtercake of which the performance indexes for sewage treatment conform to the environmental protection requirements, thus achieving the effect of treating waste by waste.

Owner:NANTONG SHENGYANG ELECTRIC CO LTD

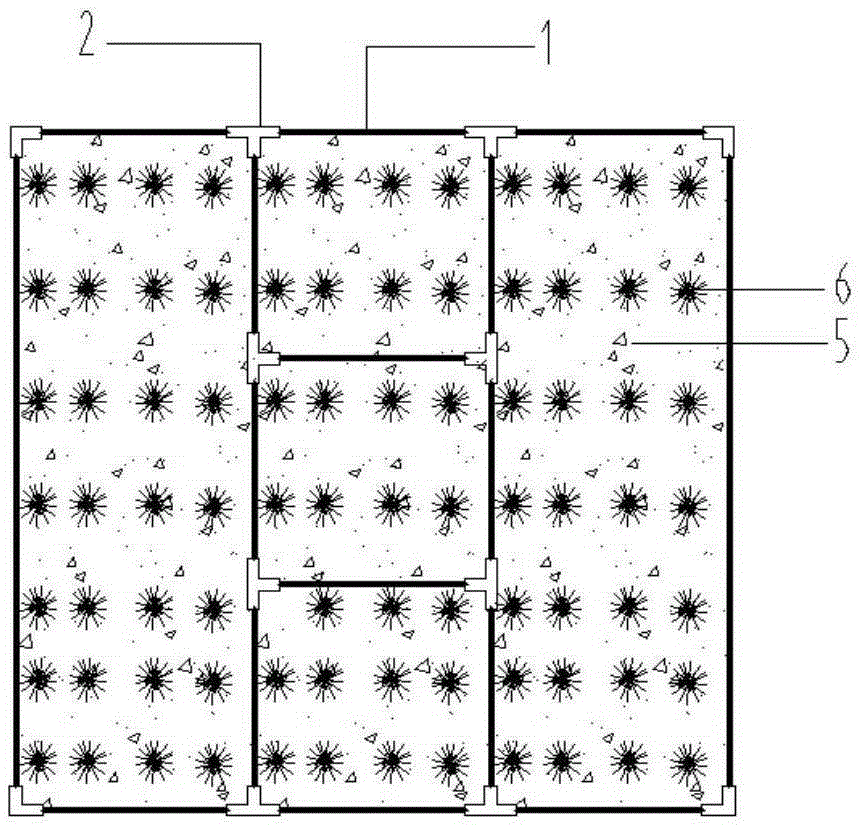

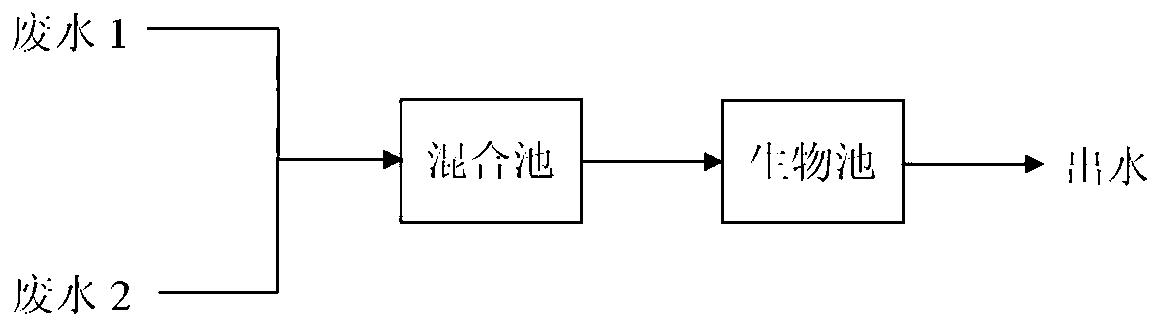

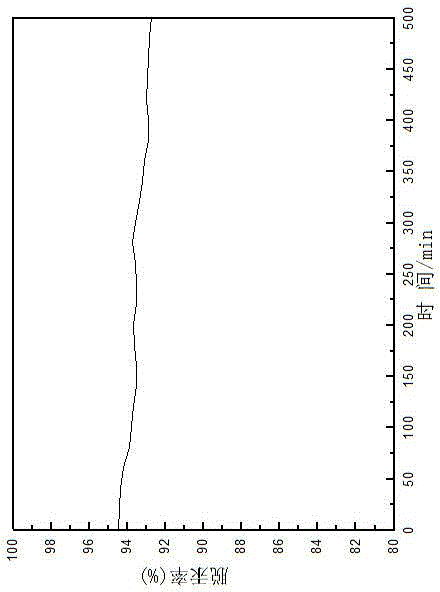

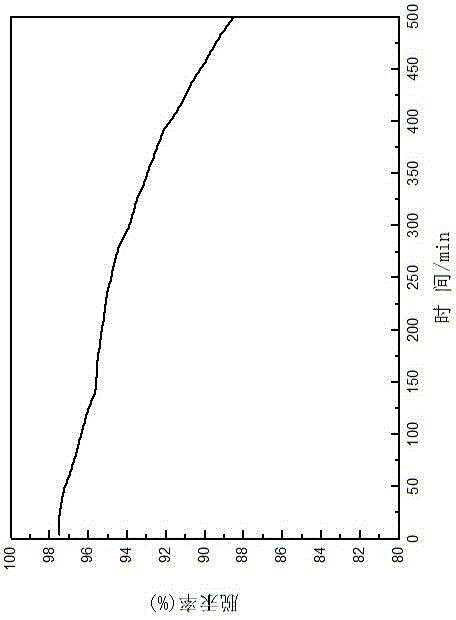

Method for low-consumption co-treatment of flue gas desulfurization wastewater and ammonia-nitrogen wastewater

ActiveCN108191050ARealize synchronous removalSync removalWater contaminantsWaste water treatment from gaseous effluentsActivated sludgeElectron donor

A method for low-consumption co-treatment of flue gas desulfurization wastewater and ammonia-nitrogen wastewater comprises steps as follows: (1) flue gas desulfurization wastewater containing sulfateand ammonia-nitrogen wastewater are guided into a mixing tank to be mixed; (2) the pH and the temperature of mixed wastewater are adjusted in the mixing tank; (3) firstly, a biological reaction tank is inoculated with cultured activated sludge, the mixed wastewater is introduced from the mixing tank, microorganisms in the activated sludge take ammonia nitrogen as an electron donor in the biological reaction tank, sulfate is reduced to elemental sulfur, besides, ammonia nitrogen is oxidized into nitrogen, and synchronous removal of sulfur and nitrogen is realized. The problems that the water quality of the flue gas desulfurization wastewater hardly reaches the standard after treatment with conventional physical and chemical methods, the biodegradability is poor and biological treatment is difficult are solved, and co-treatment of two kinds of wastewater is realized.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Method for removing mercury in flue gas by use of waste desulfurizer after being used for recycling elemental sulfur

ActiveCN104338435AReasonably solve the removal problemWell-developed pore structureDispersed particle separationSulfur productFlue gas

The invention provides a method for removing mercury in flue gas by use of a waste desulfurizer after being used for recycling elemental sulfur, and relates to an environment-friendly treatment method in which a heat-treated waste ferric oxide desulfurizer is used as a coal-fired flue gas mercury remover. According to the method comprises, rich elemental sulfur in the waste desulfurizer is recycled by use of carrier gas under a heating condition, wherein based on the total amount of the waste desulfurizer, the content of the total sulfur in the waste ferric oxide desulfurizer in 17wt%-21wt%, and the content of the elemental sulfur in the waste ferric oxide desulfurizer is 6wt%-7wt%; the condition that pores of the desulfurizer are blocked by the elemental sulfur is improved. The content of the elemental sulfur in the heat-treated waste desulfurizer is 1-2wt%; the heat-treated waste ferric oxide desulfurizer has the excellent activity to zero-valence mercury, and is capable of finally converting adsorbed mercury into stabilized mercury sulfide. The method for removing the mercury in the flue gas by use of the waste desulfurizer after being used for recycling the elemental sulfur is used for solving the problem of recycling the waste desulfurizer; as a result, a sulfur product can be obtained, and furthermore, an efficient and cheap waste gas mercury remover is found out, and the environment protection treatment cost can be reduced.

Owner:TAIYUAN UNIV OF TECH

Method for manufacturing heavy metal ion adsorbent by using orange peel

ActiveCN103894156AWide range of sources and cheapAchieve the effect of treating waste with wasteOther chemical processesWater/sewage treatment by sorptionSorbentThiobacillus

The invention discloses a method for manufacturing a heavy metal ion adsorbent by using orange peel. The manufacturing method comprises the following steps: grinding orange peel into particles; carrying out biochemical pretreatment on the orange peel by using mixed bacterial liquid consisting of lactobacillus acidophilus and ferrous oxide thiobacillus; then placing in a fermentation chamber for anaerobic digestion; and drying to obtain the heavy metal ion adsorbent. In comparison with a traditional processing method, the biological adsorbing method has the following advantages that (1) energy is saved and the processing efficiency is high; (2) metal can be selectively removed at low concentration; (3) the pH value and temperature condition range during operation is wide; (4) heavy metal can be easily separated and recycled; (5) the adsorbent can be easily recycled. The orange peel as the biological adsorbent provides an economical and feasible technology for treatment of heavy metal wastewater and soil, is wide in material source and low in cost and can achieve the effect of treating waste with waste. With continued in-depth study of orange peel, the method has wide development prospect in industrial application to purification of heavy metal wastewater and soil.

Owner:薛松晓

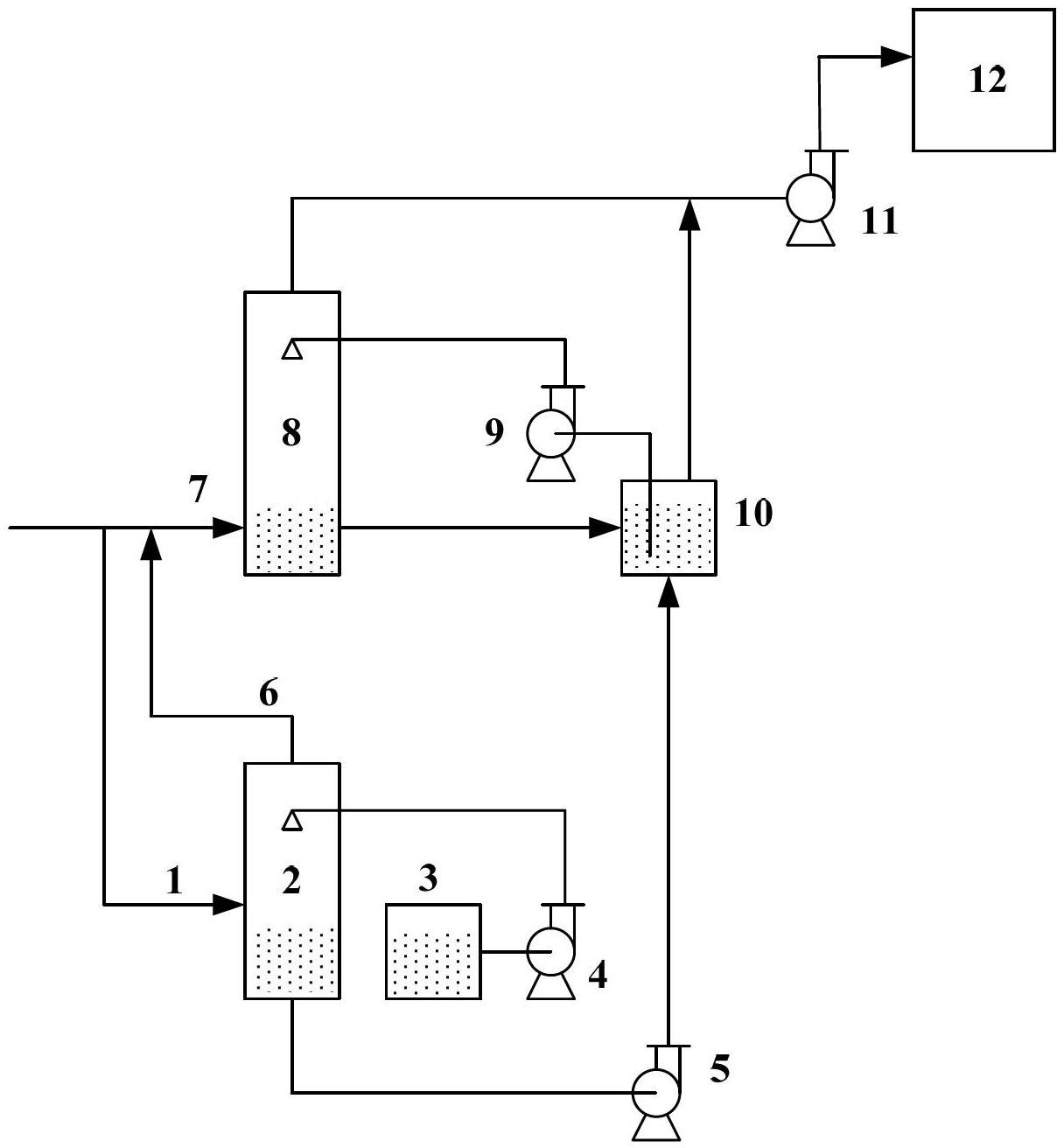

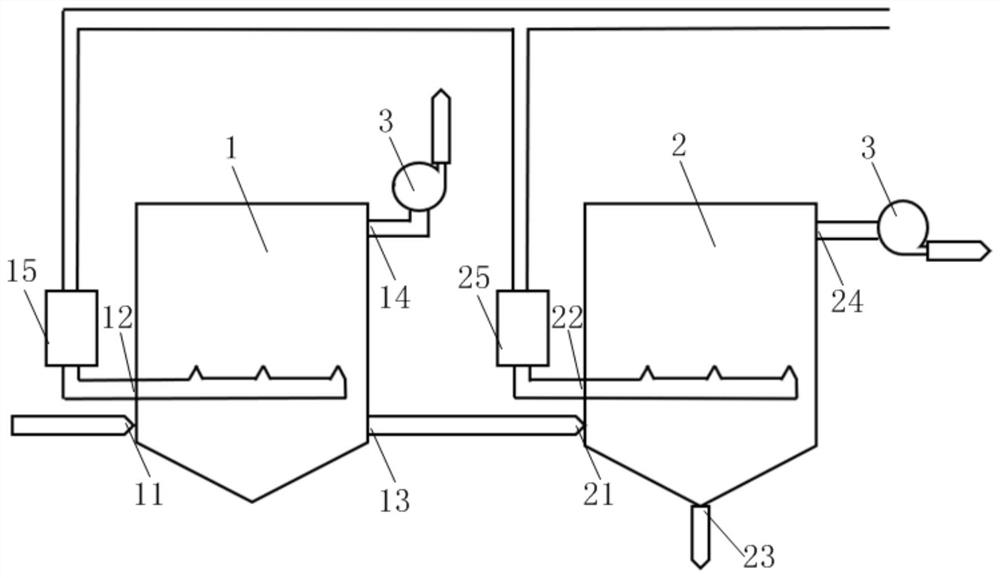

Two-stage immersing, combusting and evaporating integrated device

ActiveCN108249495AAvoid simultaneous evaporationReduce in quantityWater contaminantsEvaporationEvaporatorEvaporation chamber

The invention relates to a two-stage immersing, combusting and evaporating integrated device. The two-stage immersing, combusting and evaporating integrated device comprises an evaporation tank in a single form, wherein two evaporation chambers are formed in the evaporation tank; a treatment fluid can flow from a first evaporation chamber into a second evaporation chamber through a communicated area at the inner bottom of the tank, so that two-stage immersion, combustion and evaporation in one evaporation tank is achieved. The number of evaporators and various gas and liquid conveying pipelines is reduced, the energy is saved, and the floor area and the cost are reduced; moreover, the treatment process is simplified and operation management is facilitated.

Owner:苏州水木湛清环境科技有限公司

Treating method for efficiently catalyzing and oxidizing chlor-alkali industrial waste water

InactiveCN101844828BEasy to makeSimple processMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationIndustrial waste waterCatalytic oxidation

The invention discloses a treating method for efficiently catalyzing and oxidizing chlor-alkali industrial waste water. In the method, sodium hypochlorite in the chlor-alkali industrial waste water is decomposed mainly by adding a nickel oxide catalyst with an efficient surface; and simultaneously a small amount of other pollutants in the waste water is degraded. The treating method for efficiently catalyzing and oxidizing the chlor-alkali industrial waste water of the invention comprises the following step of: making sodium hypochlorite-containing alkaline waste water continuously flow through a catalytic oxidation reaction bed filled with a catalyst from the bottom to the top at an air speed of between 1.6 and 2.6 h<-1>.

Owner:NANJING TECH UNIV

Method for removing phosphorus from wastewater by utilizing coal ash

ActiveCN105293614AGood chemical adsorption effectFix stability issuesWater/sewage treatment by sorptionPulverized fuel ashOrganic phosphorus

The invention relates to a method for removing phosphorus from wastewater by utilizing coal ash, belonging to the field of environmental technologies. The method comprises the following steps: (1) providing phosphorus-contained wastewater containing at least one organic phosphorus, and adjusting the value of the wastewater to weak acidity; (2) adding the coal ash into the pH-adjusted wastewater, and carrying out heating under stirring and allowing the coal ash and the wastewater to react and adsorb; and (3) after the reaction is completed, separating the wastewater and the coal ash. The method provided by the invention utilizes the coal ash to remove most of inorganic phosphorus and a part of the organic phosphorus in the wastewater, and the total phosphorus-removal efficiency can reach more than 50%. After phosphorus removal, the coal ash solves the problem of stability due to high content of active calcium oxide in coal ash, and can be used as a raw material of a building material for utilization, so the effect of using wastes to treat the wastes is achieved.

Owner:NANTONG CELLULOSE FIBERS CO LTD

Method for enhancing total mercury recovery rate of metallurgical fume by reducing bivalent mercury

ActiveCN102688677AHigh recovery rateEmission reductionDispersed particle separationAbsorption columnAcid washing

The invention relates to a method for enhancing total mercury recovery rate of metallurgical fume by reducing bivalent mercury, which comprises steps as follows: (1) metallurgical fume discharged from a fume system is divided into two ways, the first way of fume directly enters an acid washing column, and the second way of fume is introduced into a sodium hydroxide washing column, so that SO2 in the fume reacts with NaOH to generate a solution of SO3<2-> or HSO3<-> or both; (2) the solution of SO3<2-> or HSO3<-> or both generated in the step (1) is introduced into the acid washing column as a reducer, wherein the introduction amount of the reducer is controlled, so that the mol ratio of the SO3<2-> or HSO3<-> concentration to the Hg<2+> concentration in the washing liquid in the acid washing column is kept within the range of 0.8-5000; and (3) the Hg<2+> in the acid washing column is directed reduced into HgO by the SO3<2-> or HSO3<-> in the reducer, and the HgO enters a subsequent mercury absorption column to be recycled through an exhaust port along with the fume. Compared with the prior art, the invention can greatly enhance the total mercury recovery rate of non-ferrous smelting fume, thereby achieving the goal of removing and recovering fume mercury more efficiently.

Owner:SHANGHAI JIAO TONG UNIV

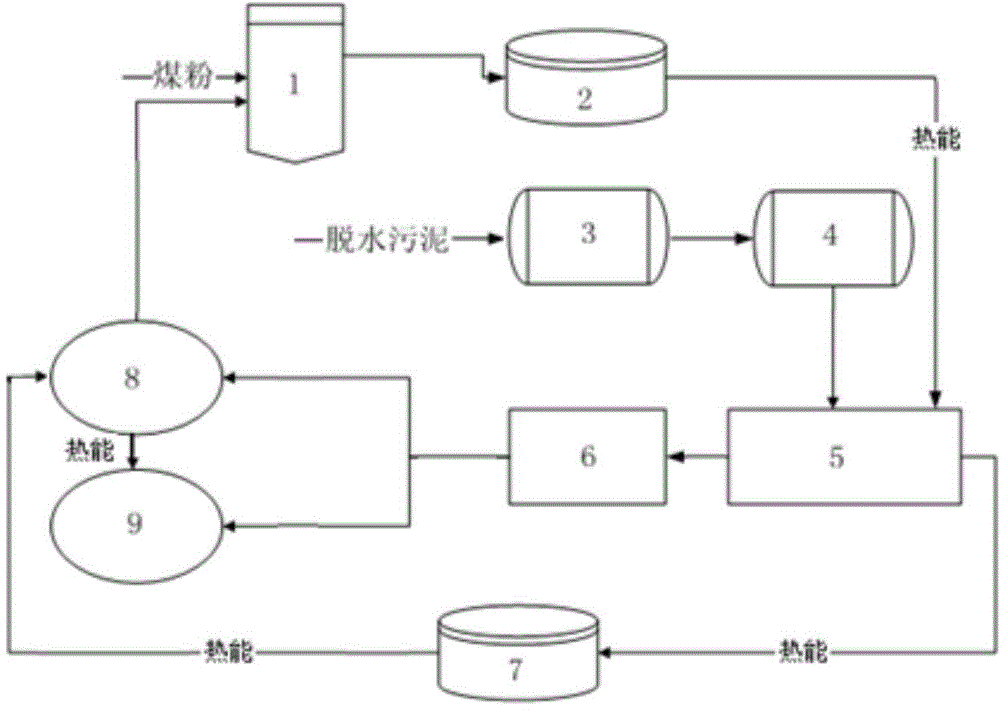

Recycling treatment system and recycling treatment method of dewatered sludge

InactiveCN104649529AEfficient resource utilizationGood removal effectSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesFlue gasFermentation

The invention relates to a recycling treatment system and a recycling treatment method of dewatered sludge. The recycling treatment system is composed of an incineration boiler, a first flue gas waste heat exchanger, a sludge storage pool, an alkaline conditioning chamber, a thermal cracking chamber, a dewatering chamber, a second flue gas waste heat exchanger, a waste heat drying chamber and an anaerobic fermentation tank. The recycling treatment method comprises the following steps: firstly, performing alkaline conditioning and thermal cracking on the dewatered sludge and then dewatering to obtain a solid phase and a liquid phase, performing drying treatment on the solid phase with thermal cracking flue gas waste heat as a heat source to obtain the dried sludge, and producing biogas from the liquid phase with drying flue gas waste heat as the heat source. The recycling treatment method realizes the removal of easily removable moisture in the sludge and also realizes sludge stabilization; meanwhile, the recycling treatment method is capable of promoting further efficient removal and biochemical degradation of the moisture content in the sludge; and as a result, the problems of low drying efficiency, easy binding and easy explosion are solved, and efficient recycling utilization of the sludge based on phase separation is realized.

Owner:TSINGHUA UNIV

Device for removing heavy metals and polycyclic aromatic hydrocarbons in bottom sediment of river channels and method thereof

ActiveCN104876409AGood controlAchieve reuseWater contaminantsBiological sludge treatmentHeavy metalsPollution

The invention relates to a device for removing heavy metals and polycyclic aromatic hydrocarbons in bottom sediment of river channels and a method thereof and belongs to the field of river-channel pollution treatment in environmental protection. The device comprises an electrolysis device, a biological fuel cell and a galvanometer, wherein the electrolysis device comprises a cathode area, a bottom-sediment area and an anode area; the negative electrode of the biological fuel cell is arranged at the outer side of a round drum, the positive electrode of the biological fuel cell is arranged at the inner side of the round drum, and a compost layer is arranged between the negative electrode and the positive electrode; a cathode rod is arranged in the cathode area, the top part of the cathode rod is electrically connected with the positive electrode, the negative electrode is connected with one end of the galvanometer, and the other end of the galvanometer is electrically connected with a positive rod; a substance exchange film is arranged between the anode area and the bottom-sediment area, a substance exchange film is also arranged between the bottom-sediment area and the cathode area, the top part of a cathode sampling area is provided with a cathode sampling port, the top part of a middle sampling area is provided with a middle sampling port, and the top part of an anode sampling area is provided with an anode sampling port. The device and the method have the advantages that the energy is saved and simultaneously the purpose of using wastes to treat wastes is achieved.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

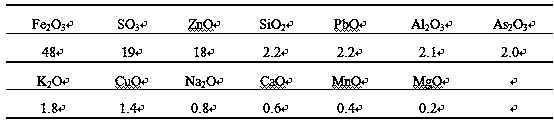

Method for treating arsenic in nonferrous smelting waste acid by jarosite slag collaborated by carbide slag

ActiveCN110255770AReduce stockpilesAchieve the effect of treating waste with wasteWater contaminantsTreatment involving filtrationSludgeSlag

The invention relates to a method for treating arsenic in nonferrous smelting waste acid by jarosite slag collaborated by carbide slag, belonging to the technical field of heavy metal pollution control. In the invention, the jarosite slag and the carbide slag are uniformly mixed, and ball milling is carried out until the particle size of the mixture is not more than 0.56 mu m to obtain mixed slag powder; the mixed slag powder and potassium permanganate are added into the nonferrous smelting waste acid to mix evenly, air is continuously introduced under the stirring condition, and oxidation dearsenization reaction is performed for 24 to 36 hours to obtain a solid-liquid mixture; the solid-liquid mixture is subjected to solid-liquid separation to obtain an arsenic-containing solid matter and filtrate, the arsenic-containing solid matter is stacked and treated, and the filtrate enters the next step of deep arsenic removal treatment. In the invention, the jarosite slag and the carbide slag are adopted to remove arsenic in the nonferrous smelting waste acid, so that the arsenic removal effect is excellent, the process operation is simple, the production cost is low, the amount of sludge generated after arsenic removal is small, and the problem of large sludge stockpiling is relieved.

Owner:KUNMING UNIV OF SCI & TECH

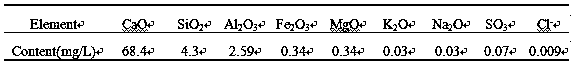

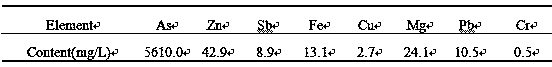

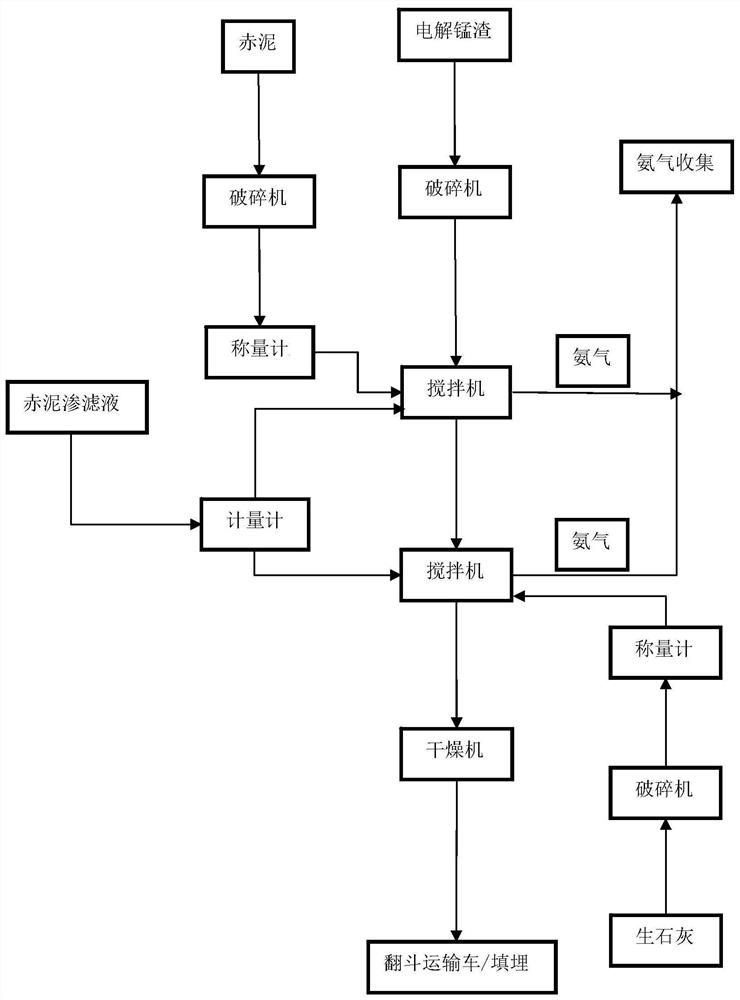

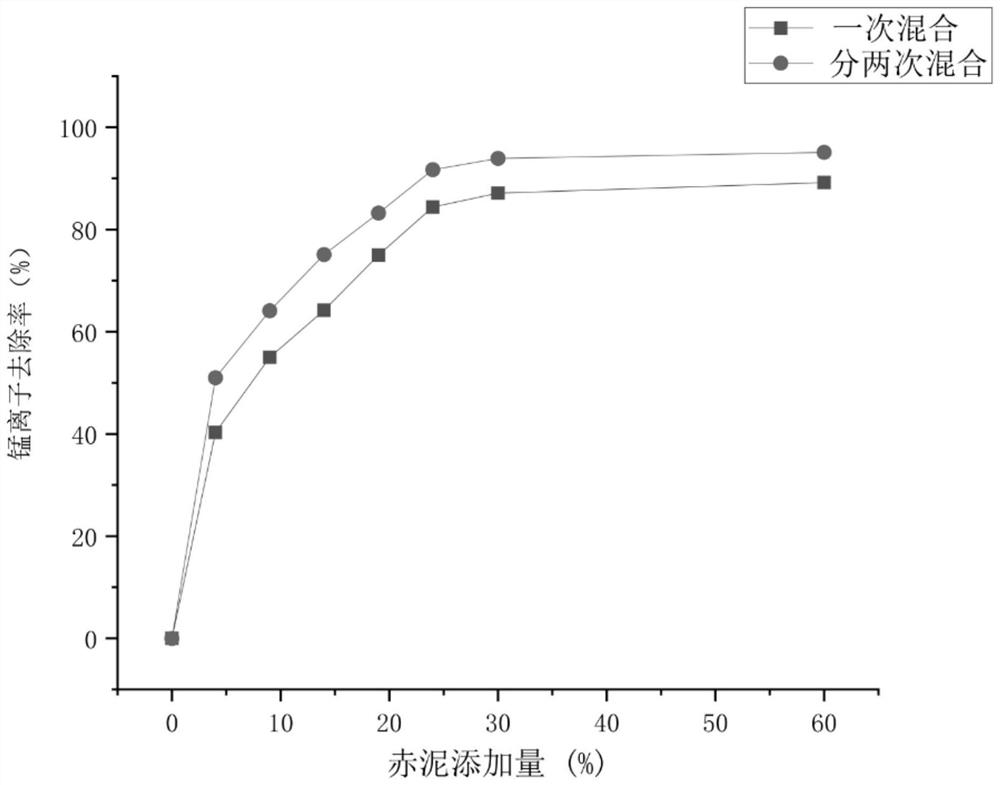

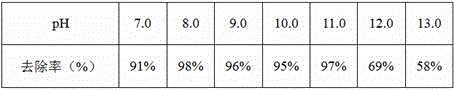

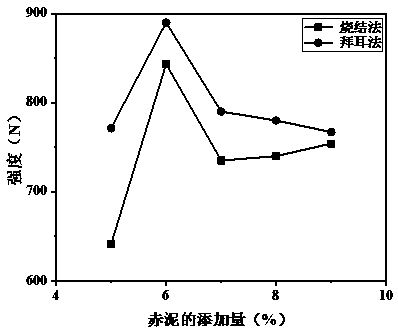

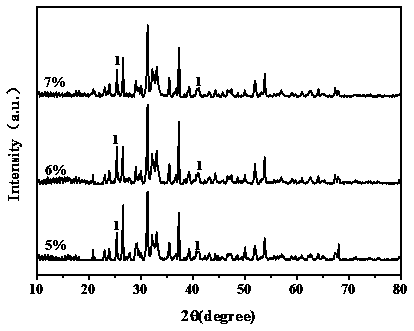

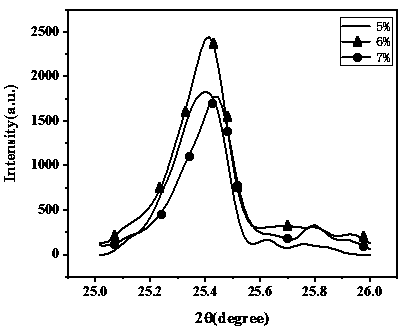

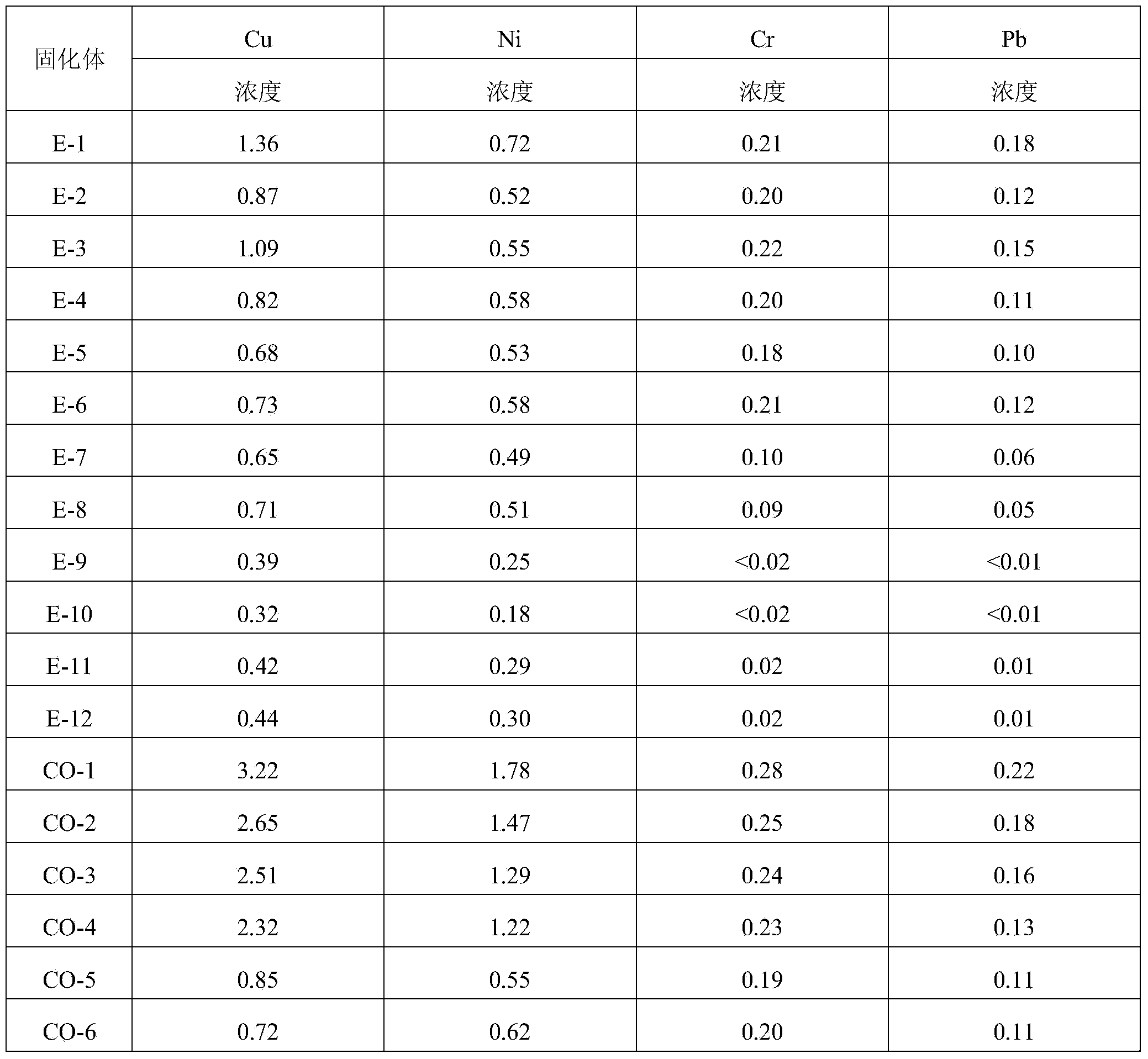

Collaborative curing treatment method for electrolytic manganese slag and red mud

InactiveCN112170441AIncrease reaction rateReduce processing costsSolid waste disposalAmmonia preparation/separationSlagPollutant

The invention provides a collaborative curing treatment method for electrolytic manganese slag and red mud. According to the method, quick lime, red mud and red mud leachate are adopted as raw materials to effectively cure and stabilize the electrolytic manganese slag, soluble alkali in the red mud exists in water in the form of OH-, reacts with manganese ions to generate precipitate, and reacts with ammonia nitrogen (NH3-N) to generate ammonia gas, and thus pollutants in the electrolytic manganese slag can be effectively removed. On one hand, the red mud leachate plays a role of a solvent, onthe other hand, alkaline substances in the red mud leachate play a role of reactants, thus the reaction rate is increased, and the treatment cost is reduced. The red mud and the red mud leachate areused, so that the use amount of the quick lime is effectively reduced, and the treatment cost is further reduced. According to the method, a step-by-step reaction means is adopted, the reaction efficiency is effectively improved, and the curing rate of manganese ions in the electrolytic manganese slag reaches 93.7% or above.

Owner:GUIZHOU ACAD OF ENVIRONMENTAL SCI & DESIGNING

Method for preparing organic hydrotalcite

InactiveCN102847513AImprove adsorption capacityEfficient Adsorption RemovalOther chemical processesWater/sewage treatment by sorptionHydrotalciteWastewater

A method for preparing organic hydrotalcite includes the steps of firstly, filtering washing wastewater to remove solid impurities so as to obtain washing wastewater without solid impurities; and secondly, adding hydrotalcite into the washing wastewater, mixing, performing precipitation separation, drying, and grinding to obtain anionic surfactant modified hydrotalcite. Due to the fact that surfactant used during washing is most anionic surfactant, the anionic surfactant in the washing wastewater is used as modifier to synthesize the organic hydrotalcite, the organic hydrotalcite is prepared while the anionic surfactant in the washing wastewater can be absorbed effectively, and waste recycling is achieved. The prepared organic hydrotalcite is low in price, wastewater treating effect is evident, wastes are treated with wastes, and high economical and practical values are achieved.

Owner:CHANGZHOU UNIV

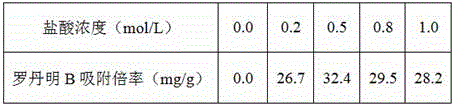

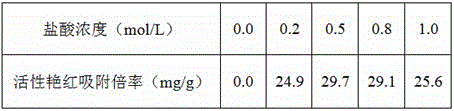

Method for preparing environment-friendly dye adsorbent from shrimp and crab shells

InactiveCN106268681AReduce processing costsRealize resource utilizationOther chemical processesWater contaminantsShrimpDyeing wastewater

The invention discloses a method for preparing an environment-friendly dye adsorbent from shrimp and crab shells. Waste shrimp and crab shells are used as raw materials, cleaned up with water, dried in the air, crushed, soaked in hydrochloric acid, taken out, washed with water to be neutral and dried, and the dye adsorbent is obtained. The characteristic that chitin in the shrimp and crab shells and porous structures formed in the process of removal of calcium carbonate with hydrochloric acid have a good adsorption effect on dye substances is used, an efficient adsorption material is prepared from the waste shrimp and crab shells through simple treatment and mixed with dye wastewater, the removal rate of dye molecules can reach 97% or above, solid-liquid separation can be realized, and efficient, quick and low-cost treatment of the dye wastewater is facilitated.

Owner:XIAMEN UNIV TAN KAH KEE COLLEGE

Device and method for extracting and separating lignin from papermaking black liquid

ActiveCN105088847ARelieve loadAchieve the effect of "treating waste with waste"Pulp by-products recoveryPrecipitationWater treatment

The invention relates to the technical field of papermaking waste water treatment, particularly relates to a device and method for extracting and separating lignin from papermaking black liquid. According to the device and the method provided by the invention, CO2, SO2 and other acid gases in exhaust gas of an alkali recovery boiler are used for treating the black liquid so as to enable lignin to separate out in a precipitation form; although real help on removal of nitrogen and sulphur generated by a whole slurry making system is not realized, partial nitrogen oxide and sulfur oxide partially stay on a lignin extraction system, so that the exhaust gas treatment load is relieved, the effect of waste control by waste is realized, and meanwhile, a production process is not required to be adjusted greatly since the whole slurry making system does not introduce new impurities.

Owner:武汉凯比思电力设备有限公司

Deep dehydration conditioner for sewage sludge and preparation method thereof

InactiveCN105217923AWide variety of sourcesLow priceSludge treatment by de-watering/drying/thickeningSludgeSimple component

The invention discloses a deep dehydration conditioner for sewage sludge. The deep dehydration conditioner comprises, by mass, 30 to 70% of fly ash, 5 to 20% of active carbon powder, 10 to 30% of bentonite, 5 to 20% of quicklime powder and 4 to 10% of polyaluminum ferric chloride. The invention also comprises a preparation method for the deep dehydration conditioner. The preparation method comprises the following steps: mixing weighed fly ash, active carbon powder, bentonite and quicklime powder together to obtain a mixture; then putting weighed polyaluminum ferric chloride into a container, adding a same amount of water and carrying out blending to prepare mixed liquor; and finally, adding the mixture and the mixed liquor into a mixer and carrying out uniform stirring. The preparation method provided by the invention has the advantages of simple components, easiness, wide sources of raw materials and low cost; and most important, the preparation method is free of secondary pollution and enables waste water to be discharged after reaching the standard.

Owner:TAIZHOU FEIJIANG METAL PROD CO LTD

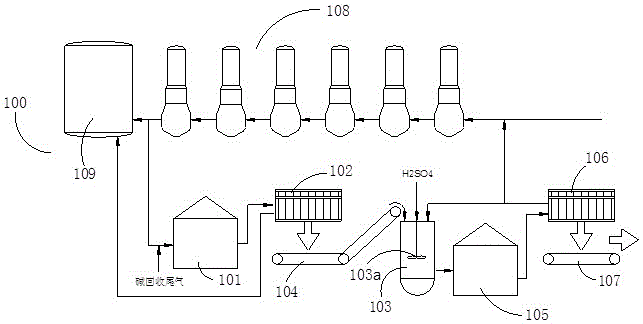

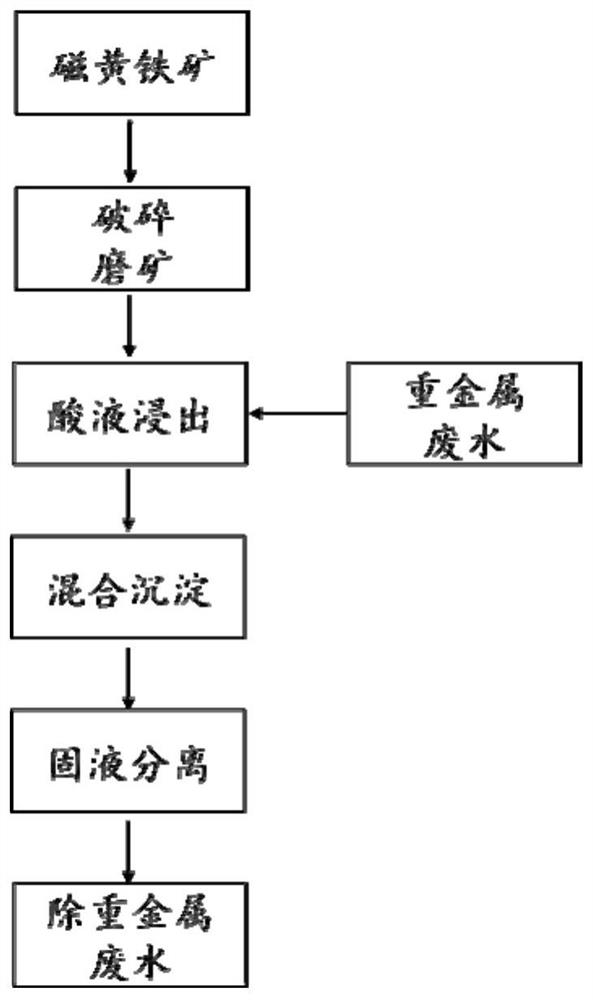

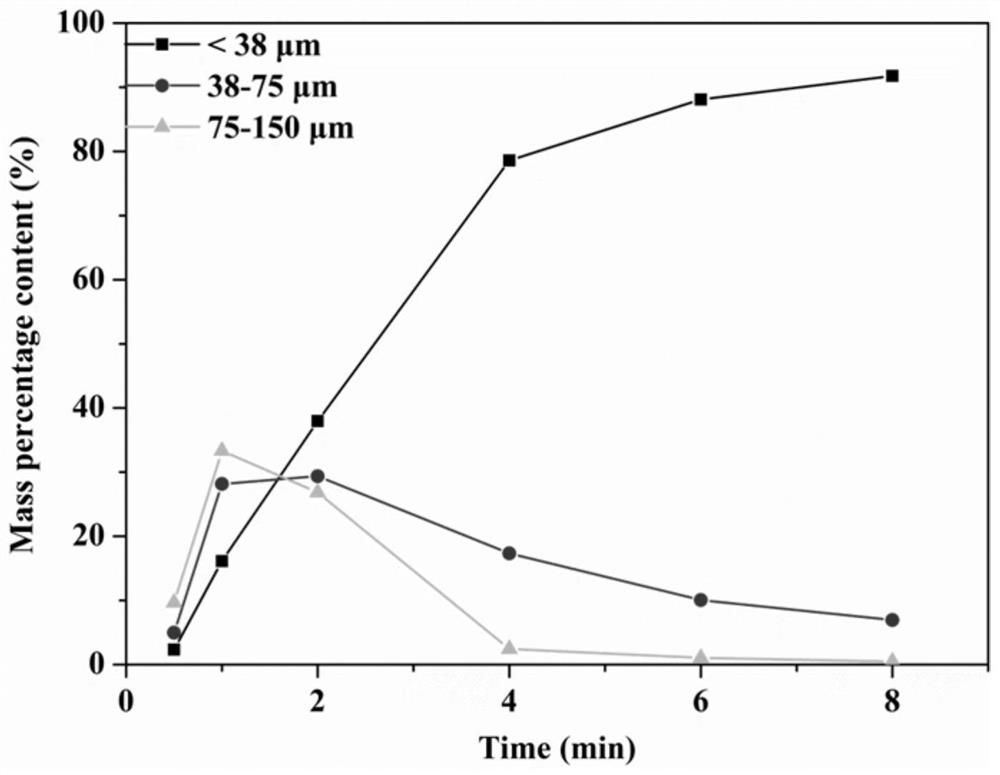

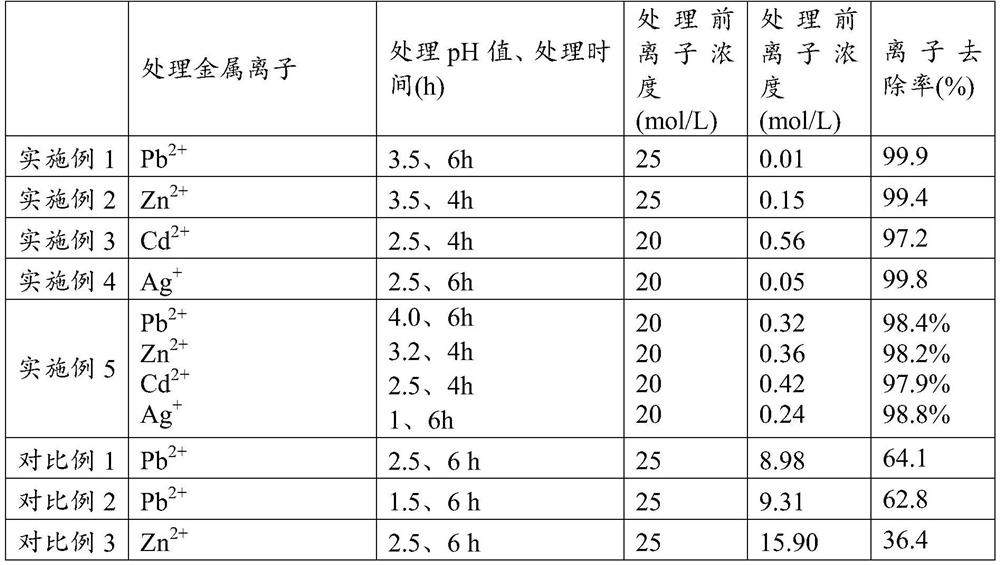

Method for treating acidic mine wastewater containing heavy metal ions

PendingCN112537856AAchieve the effect of "treating waste with waste"To achieve the effect of "treating waste with waste"Waste water treatment from quariesWater contaminantsMagnetiteWastewater

The invention relates to a method for treating acidic mine wastewater containing heavy metal ions, which comprises the following steps: crushing and grinding magnetite to obtain magnetite particles; digesting the magnetite particles with sulfuric acid to obtain hydrogen sulfide gas; and introducing the hydrogen sulfide into the acidic mine wastewater containing heavy metal ions, and carrying out solid-liquid separation to obtain sulfide precipitates and wastewater without heavy metal ions. According to the method, pyrrhotite which is one of acidic mine wastewater sources serves as a vulcanizing agent source to treat heavy metal ions in the wastewater, and the effect of treating waste with waste is achieved.

Owner:WUHAN UNIV OF TECH

Red mud-containing briquette and preparation method thereof

The invention provides a red mud-containing briquette and a preparation method thereof. The red mud-containing briquette comprises, by weight, 60-70 parts of coal, 5-9 parts of red mud, 1-5 parts of adispersant and 2-5 parts of gelatinized starch, the dispersant is a naphthalene dispersant, and the coal is semi-coke or anthracite. The energy-saving, emission-reducing and environmentally-friendlybriquette is prepared by using pulverized coal as a main body and the red mud as a sulfur fixing agent and adding other substances such as a binding agent and the like, so the problem of red mud utilization can be solved, the problem of environmental pollution caused by the red mud and fire coal can also be solved, and the effect of treating wastes with wastes is achieved.

Owner:HENAN CHANGXING IND CO LTD

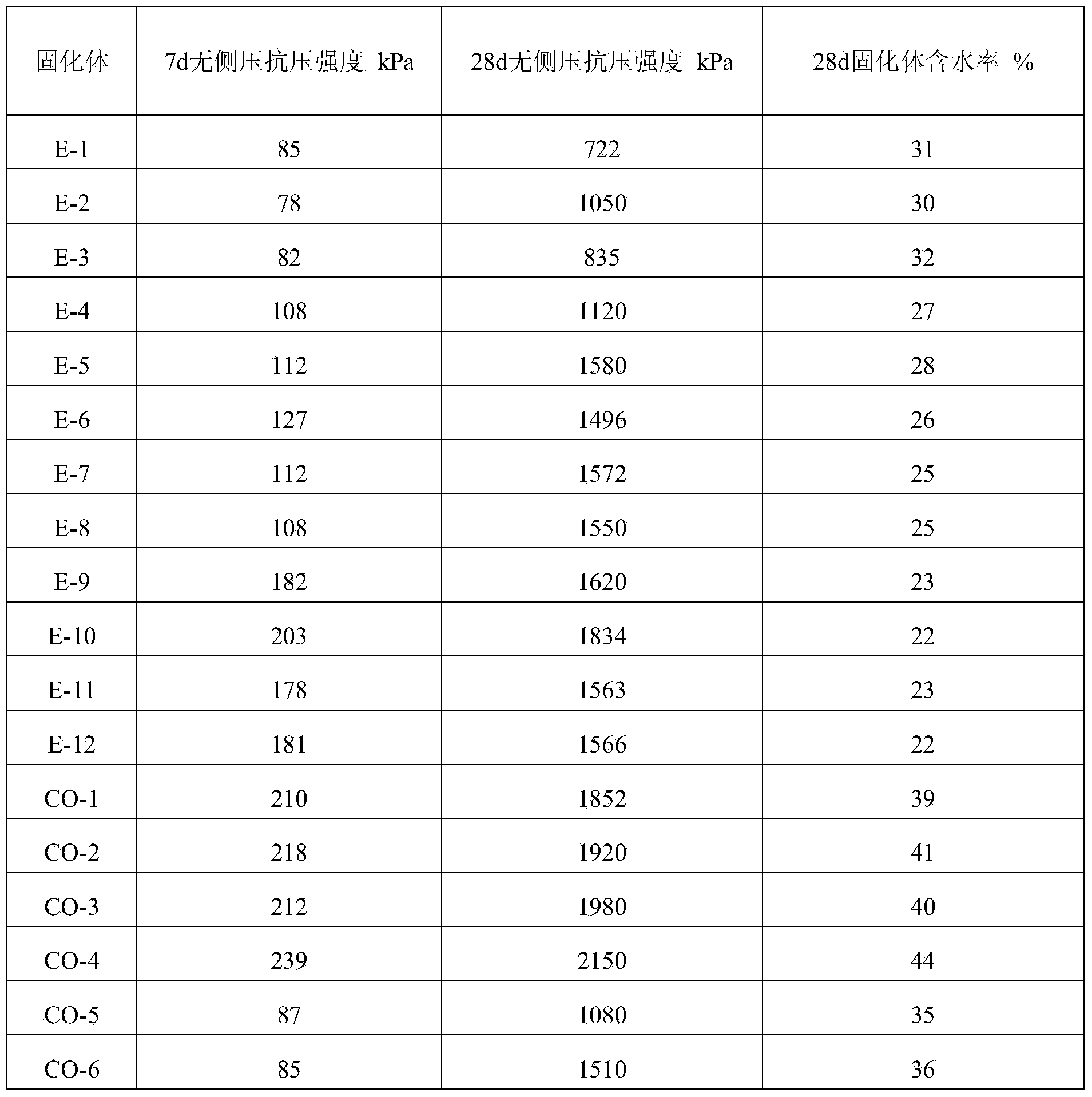

Solidification and stabilization method for washing sludge of port engineering vehicle

InactiveCN104030545AIncrease productionEasy accessSludge treatment by de-watering/drying/thickeningSludgeSlag

The invention relates to a solidification and stabilization method for washing sludge of a port engineering vehicle. The water content of the washing sludge is 88-93%. The method comprises the following steps: by using a mixture of furnace slag and silicate cement as a solidification and stabilization agent, adding the solidification and stabilization agent into the washing sludge, and uniformly stirring to obtain a solidified body capable of realizing direct landfilling or recycling, wherein the furnace slag is coal-fired furnace slag, fly ash or a combination thereof, and the solid content of the furnace slag is above 90%; and by taking the weight of the washing sludge as a reference, the adding amount of the furnace slag is 60-120%, and the adding amount of the silicate cement is 4-13%. According to the solidification and stabilization method provided by the invention, the coal-fired furnace slag is used for solidification and stabilization of sludge, thus effectively preventing the washing sludge from causing secondary pollution in the solidification treatment process, and realizing the recycling of the solid waste.

Owner:RIZHAO PORT GRP LANSHAN PORT

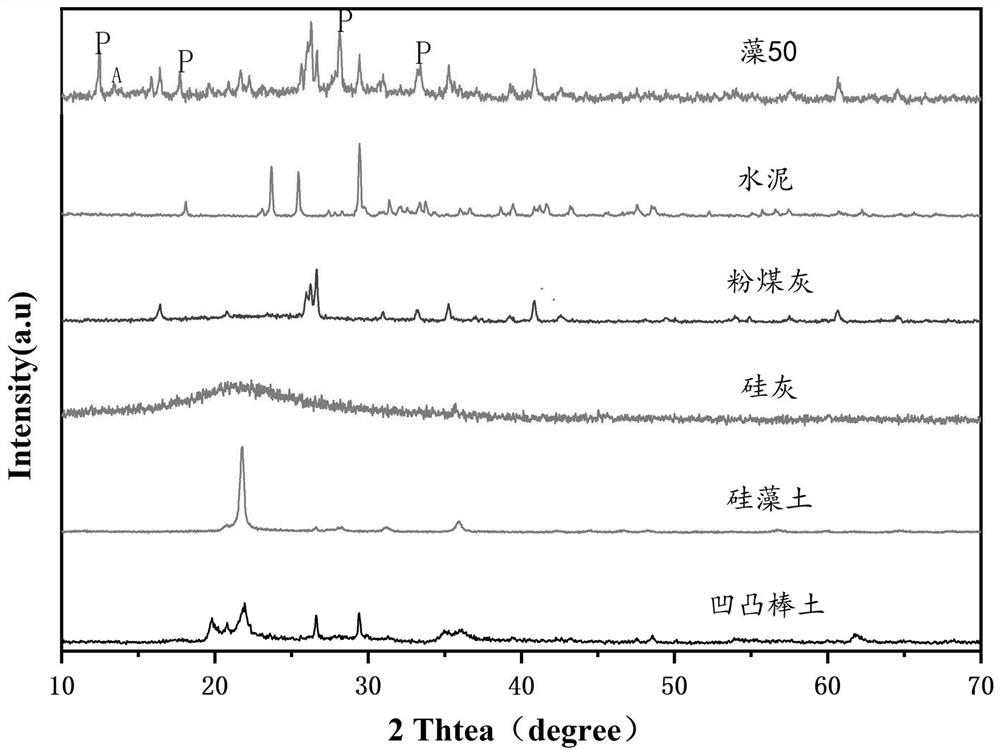

Solid-waste-based high-strength unfired fly ash ceramsite and preparation method thereof

The invention belongs to the technical field of auxiliary materials of building materials, and provides solid-waste-based high-strength unfired fly ash ceramsite and a preparation method thereof in order to solve the problems that ceramsite prepared from single fly ash is low in strength, cost is increased as the strength of fly ash ceramsite needs to be increased at present and the like in the prior art. The strength of the prepared fly ash ceramsite in the invention reaches 10-14 Mpa. The preparation method comprises the following steps: mixing fly ash, attapulgite, cement, silica fume and diatomite according to a mass ratio of 70: 10: 10: 5: 5, and adding a sodium hydroxide solution accounting for 20-25% of the total mass of the mixed raw materials, a hydrogen peroxide solution accounting for 0.5-5% of the total mass of the mixed raw materials and water glass accounting for 5% of the total mass of the mixed raw materials. According to the invention, the problem of low strength of fly ash serving as concrete aggregate is solved; and the problem that fly ash powder is not easy to recycle as a sewage filter material is solved, and the adsorption performance of common unfired fly ash ceramsite is improved.

Owner:TAIYUAN UNIV OF TECH

Method for enhancing anaerobic digestion of excess sludge by utilizing freezing and free nitrous acid combined pretreatment

InactiveCN110818217APromote rupturePromote degradationSludge treatment by thermal conditioningWaste based fuelPOLYMER SUBSTANCEMethane production

The invention provides a method for enhancing anaerobic digestion of excess sludge by utilizing freezing and free nitrous acid combined pretreatment, and belongs to the field of resourceful treatmentand disposal of solid waste excess sludge. According to the invention, a freezing and free nitrous acid combined treatment technology is mainly adopted; finally, anaerobic digestion is performed to produce methane, so that rupture of extracellular polymeric substances and cells of the excess sludge is promoted, release of organic matters and biodegradability of soluble organic matters are improved, and the yield of the methane in the anaerobic digestion process of the excess sludge is greatly increased in a short time period. Compared with conventional heat treatment and alkali treatment, themethod has the advantages of lower energy consumption, lower consumption of chemical agents, better methane production effect of residual sludge and better sludge dewatering performance after anaerobic digestion.

Owner:HUNAN UNIV

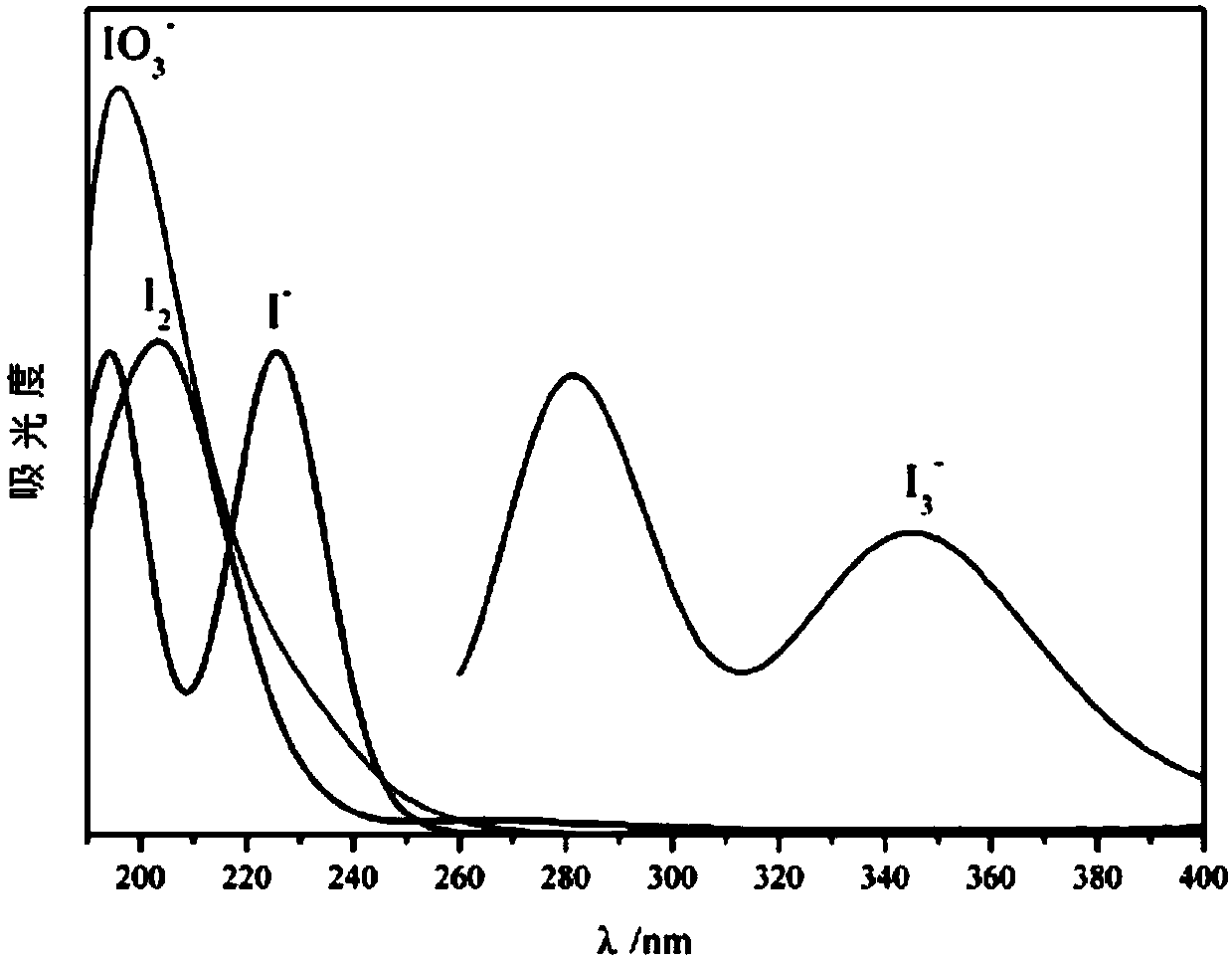

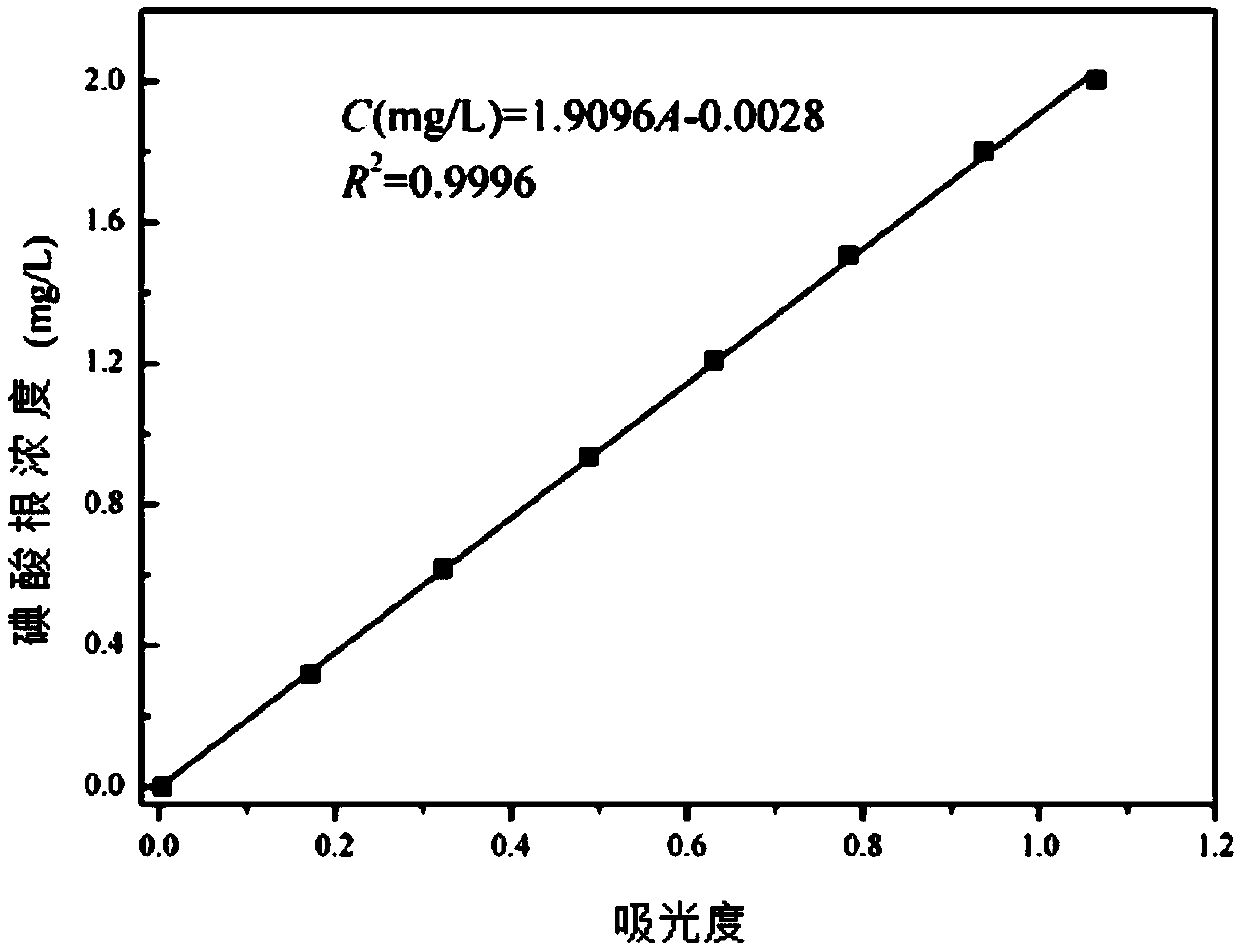

Biological charcoal material for removing iodate in water and preparation method thereof

InactiveCN108654563AWide variety of sourcesLow priceOther chemical processesWater contaminantsChemistryCarbonization

The invention provides a biological charcoal material for removing iodate in water and a preparation method thereof. The biological charcoal material comprises the following steps: taking waste plantstraws as raw materials and preparing the raw materials in powder; carrying out carbonization reaction at certain temperature; then carrying out post-treatment on carbonized powder, so as to obtain the biological charcoal material for removing iodate, wherein the removing efficiency of the biological charcoal material reaches 90 percent or more; the biological charcoal material has the advantagesof high efficiency of removing iodate in the water, low cost, wide material source, environment friendliness, no secondary pollution and simple preparation method; the reclamation of wastes is realized, and the biological charcoal material has social benefits and economic benefits; the invention further provides carbonization equipment for preparing the biological charcoal material; the equipmentis simple, convenient to use and low in cost, and is easy to popularize.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

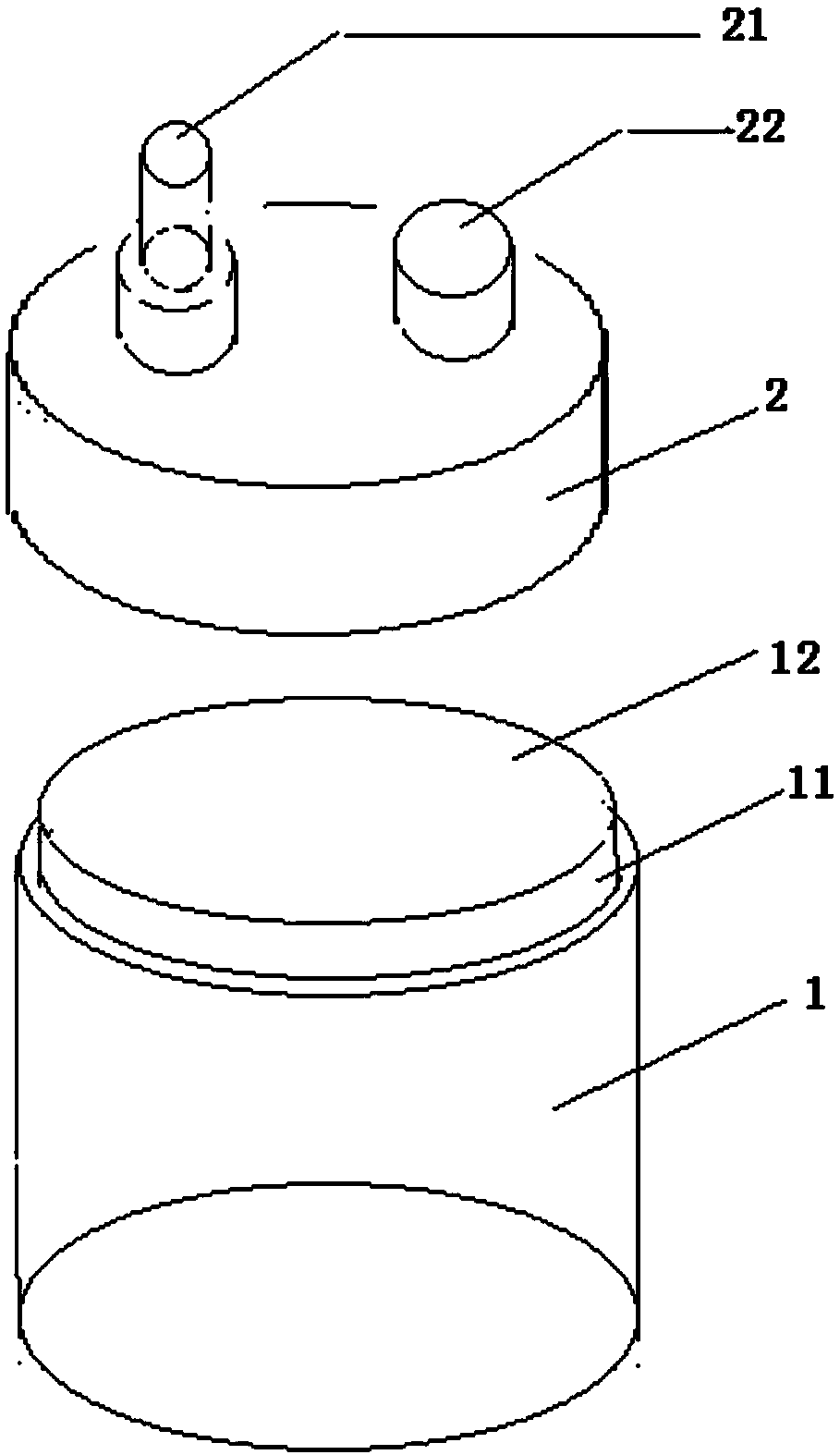

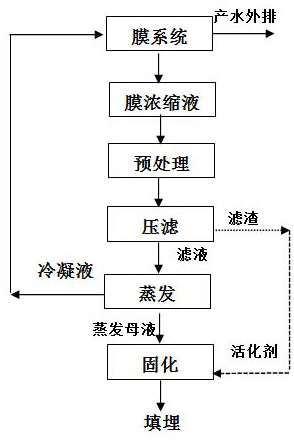

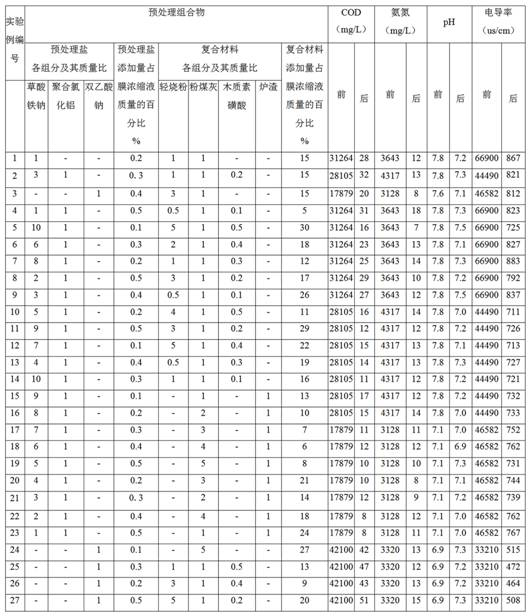

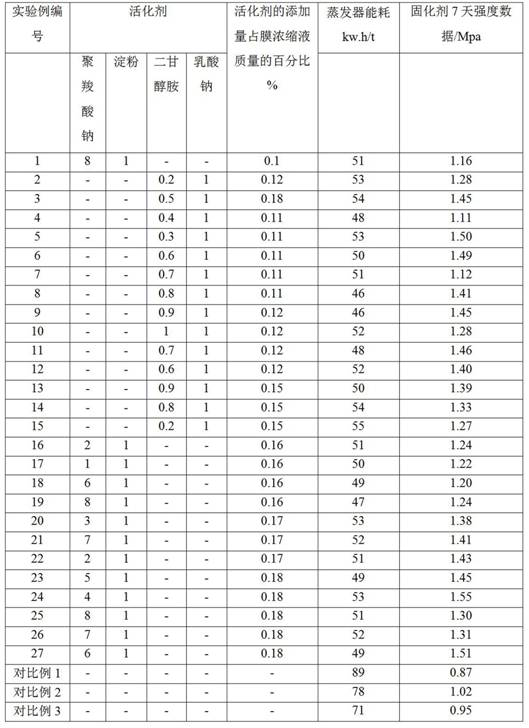

High-concentration landfill leachate membrane concentrated solution treatment process and application thereof

ActiveCN113511771AReduce foulingReduce energy consumptionWater contaminantsTreatment involving filtrationFerric oxalateSodium acetate

The invention discloses a high-concentration landfill leachate membrane concentrated solution treatment process and application thereof, and belongs to the field of wastewater treatment. The high-concentration landfill leachate membrane concentrated solution treatment process is characterized by comprising the following steps: pretreating the high-concentration landfill leachate membrane concentrated solution with pretreatment salt and a composite material, wherein the pretreatment salt is selected from ferric sodium oxalate or sodium diacetate; and the composite material is selected from the group consisting of light burning powder, sodium lignin sulfonate, fly ash, and slag. According to the process, efficient pretreatment is carried out before evaporation treatment, scaling of the evaporator is greatly relieved, and energy consumption of the evaporator is reduced; and in the curing process, active components in the filter residues and the evaporation mother liquor are utilized, a cured body meeting the landfill requirement is formed through activation, and the cost is reduced.

Owner:湖南天为环保科技有限公司

Direct contact evaporation treatment equipment and method using flue gas heat

ActiveCN110482630BAchieve unified processingReduce consumptionWater treatment parameter controlSpecific water treatment objectivesFlue gasCombustible gas

The present invention provides a direct contact evaporation treatment apparatus and method by utilizing flue gas heat, wherein the apparatus comprises: a first evaporator, which provided with a firstfeed port, a first discharge port, a first gas inlet and a first gas outlet, wherein the first gas inlet is used for receiving high temperature flue gas, and the first gas outlet is connected to an incinerator; a second evaporator, which is provided with a second feeding port, a second discharging port, a second air inlet and a second air outlet, wherein the second gas inlet is used for receivinghigh-temperature flue gas, the second feeding port is connected with the first discharging port and used for receiving a first-stage concentrated solution formed by evaporating to-be-treated liquid inthe first evaporator from the first evaporator, and the second exhaust port is connected with a flue gas treatment system of the incinerator or directly leads to the outside atmosphere. Unified treatment of two secondary pollution sources of high-temperature flue gas and high-salinity wastewater is achieved, the effect of treating waste with waste is achieved, consumption of combustible gas is reduced, and the treatment cost of high-salinity water is reduced.

Owner:TSINGHUA UNIV +1

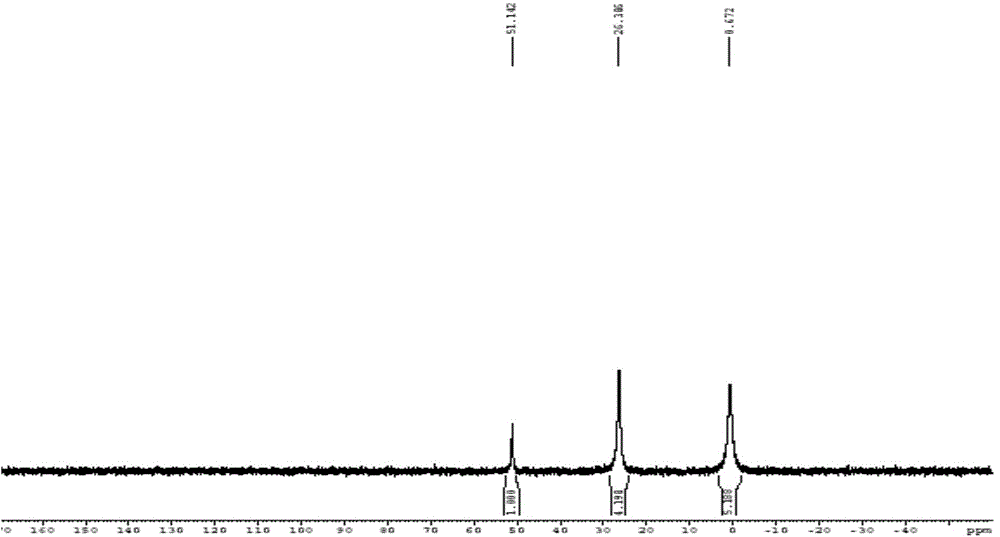

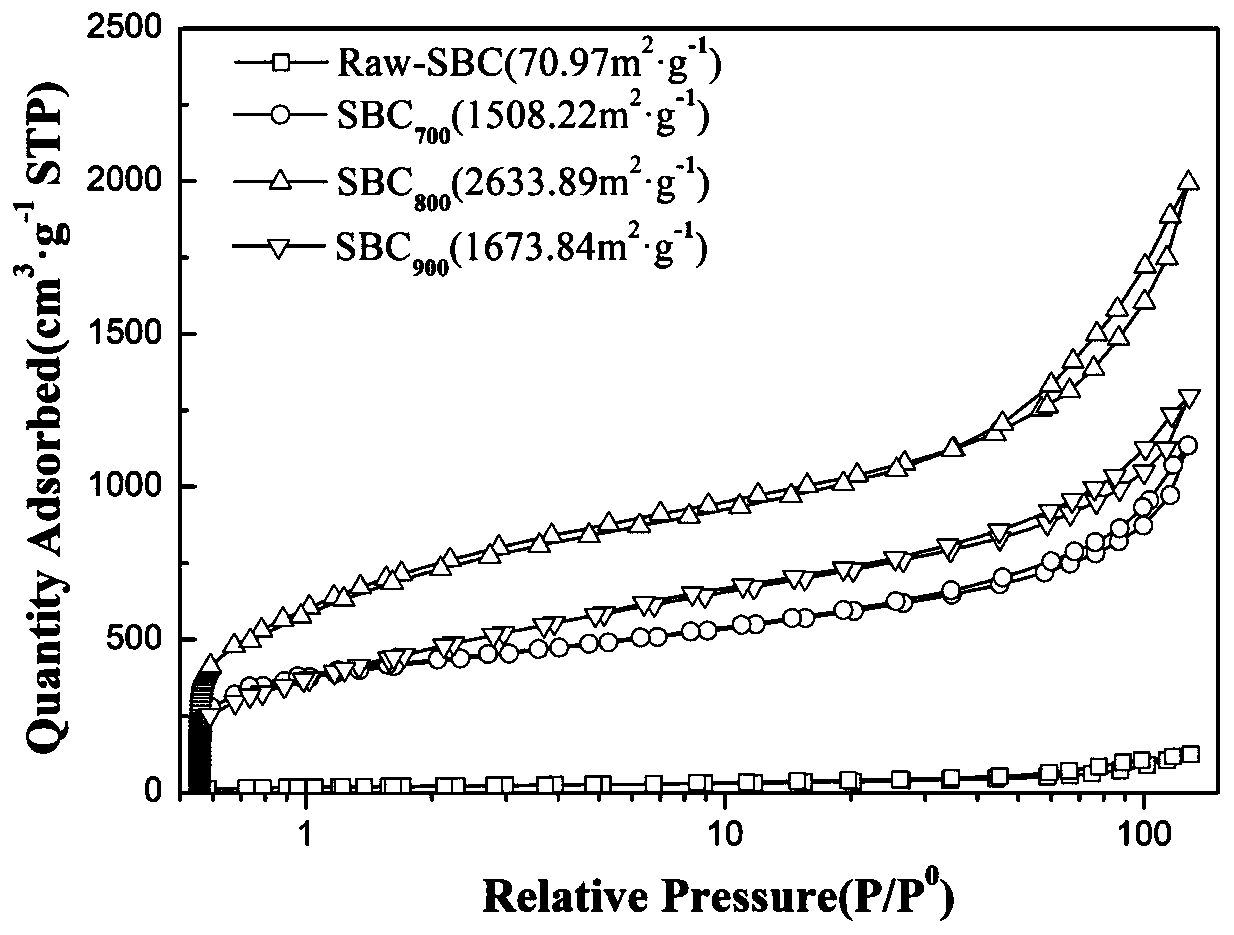

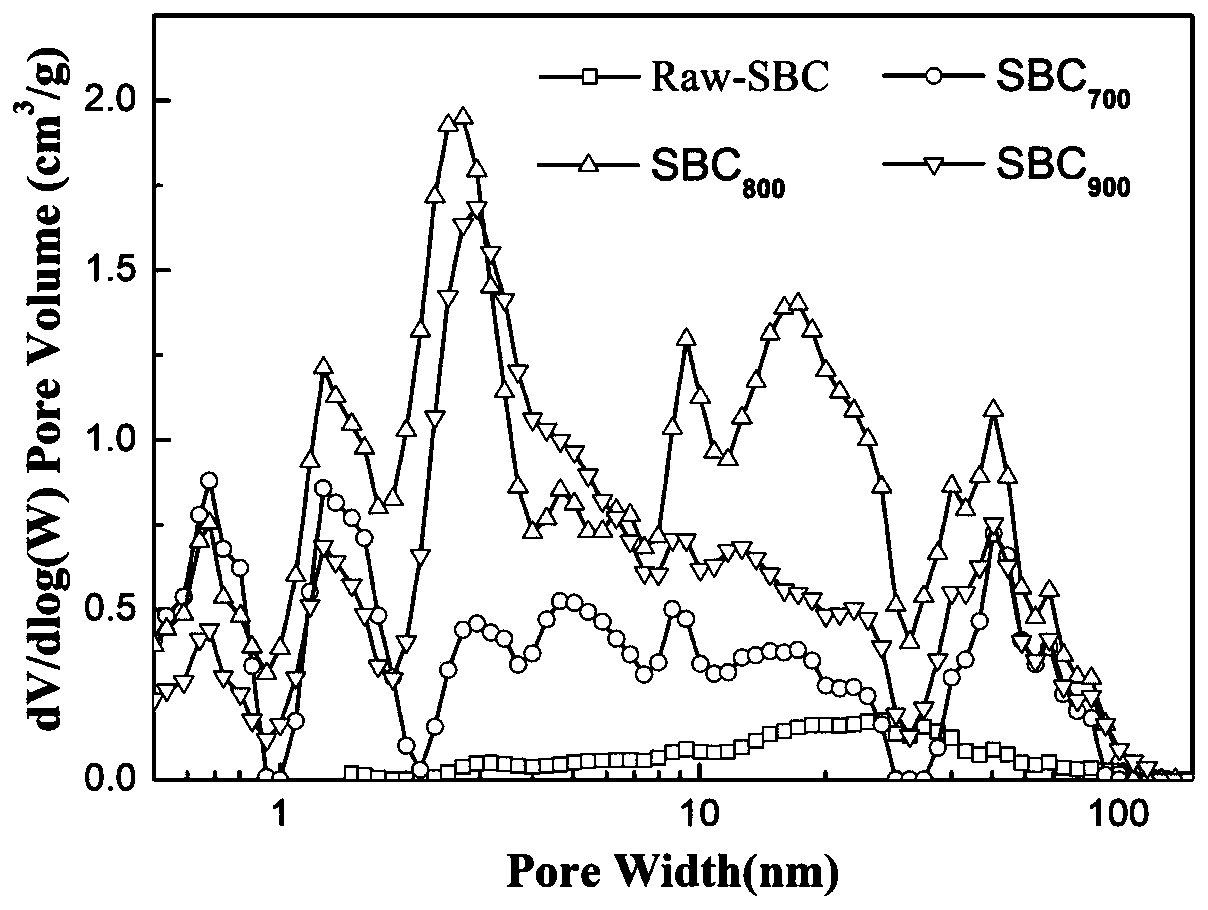

Super-high specific surface area carbon-based functional material and preparation method and application thereof

ActiveCN110368896ASolve the difficulties of low specific surface area and poor practical application effect of catalytic pyrolysisCatalyzedOther chemical processesAlkali metal oxides/hydroxidesSludgeCoupling

The invention discloses a super-high specific surface area carbon-based functional material and a preparation method and application thereof. The preparation method of the super-high specific surfacearea carbon-based functional material through coupling catalytic pyrolysis of sludge organic matter includes the following steps that firstly centrifugal filtration of sludge is conducted after alkalitreatment, supernatant is retained, the supernatant is dried and ground to powder, and then the powder is calcined at 700-900 DEG C to obtain a carbon-based adsorbent material. According to the super-high specific surface area carbon-based functional material and the preparation method and application thereof, coupling of sludge organic matter recovery and the super-high specific surface area carbon-based functional material is realized;, a sewage treatment method adopts the super-high specific surface area carbon-based functional material prepared by the preparation method to treat sewage; and the preparation method is not directly activated, compared with a general preparation method, the preparation method is simpler in step and lower in cost, we chose KOH to release the sludge organicmatter and extract SEPS during alkali treatment, at the same time, the residual KOH plays a catalytic role to the material during re-pyrolysis, and the effect of 'killing two birds with one stone' isachieved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com