Method for removing mercury in flue gas by use of waste desulfurizer after being used for recycling elemental sulfur

A technology of waste desulfurizer and desulfurizer, which is applied in separation methods, chemical instruments and methods, dispersion particle separation, etc. Increase, improve adsorption effect, enhance the effect of reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The waste iron oxide-based desulfurizer replaced by a chemical plant was used for testing. The carbon and sulfur analyzer determined that the total sulfur content in the spent iron oxide desulfurizer was about 21wt%, and the elemental sulfur content was about 7wt%. The waste iron oxide-based desulfurizer was dried in an electric blast drying oven for 4 hours, and the temperature was set at 120°C. Then take out the dried waste desulfurizer and pulverize it to 40-60 mesh, then weigh 2g, put it into the center of a quartz tube with a diameter of 8.6mm and a length of 642mm, and plug both ends of the desulfurizer with quartz wool to fix it. The quartz tube was placed in a tube furnace for heating at 290 °C. The inlet of the quartz tube is fed into N 2 , the gas flow rate is controlled at 300ml / min, and the outlet is connected to a set of gas cooling device to recover steam sulfur. The whole waste desulfurizer heat treatment process time is controlled at about 8 minutes. ...

Embodiment 2

[0036] Another waste iron oxide-based desulfurizer was used for testing. The measurement shows that the total sulfur content in the waste desulfurizer is about 17wt%, and the sulfur content is about 6wt%. The above waste iron oxide-based desulfurizer was placed in an electric blast drying oven for 3 hours, and the temperature was set at 120°C. Then take out the dried waste desulfurizer and pulverize it to 40-60 mesh, then weigh 2g, put it into the center of a quartz tube with a diameter of 8.6mm and a length of 642mm, and plug both ends of the desulfurizer with quartz wool to fix it. The quartz tube was heated in a tube atmosphere furnace at a temperature of 380 °C. The inlet of the quartz tube is fed into CO 2 , the gas flow rate is controlled at 300ml / min, and the outlet is connected to a set of gas cooling device to recover steam sulfur. The whole waste desulfurizer heat treatment process time is controlled at about 1.5min. After the heat treatment, the waste desulfuriz...

Embodiment 3

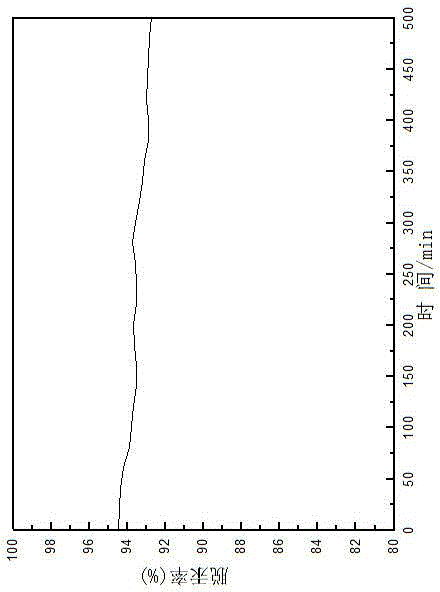

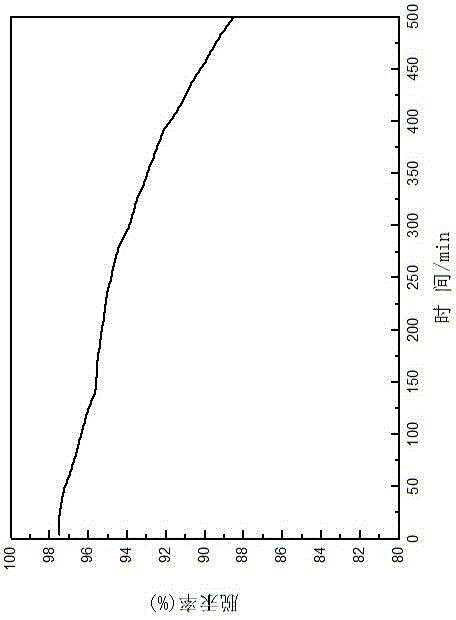

[0040] The waste desulfurization agent with a sulfur content of 1.3 wt% after heat treatment in Example 1 was used as a flue gas mercury removal agent to conduct direct injection type mercury removal activity evaluation. The experiment was carried out in a simulated flue gas pipeline. A quartz tube with an inner diameter of 20mm and a length of 600mm was placed vertically, and the temperature was kept at 80°C by electric heating. Inject simulated mercury-containing flue gas, the composition of simulated mercury-containing flue gas is 40μg / m 3 Hg, 12v / v%CO 2 , 6v / v%O 2 , 1500ppmSO 2 , 500ppmNO, 10ppmHCl and 1v / v%H 2 O, the balance is balance gas N 2 ; Keep the mercury-containing flue gas flow flowing through the quartz tube from top to bottom, and the average flow rate of the mercury-containing flue gas flow is 6m 3 / h, a small cyclone dust collector is installed at the gas outlet of the quartz tube. Spray the waste desulfurizer with a sulfur content of 1.3wt% after heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com