Solidification and stabilization method for washing sludge of port engineering vehicle

A technology for engineering vehicles and sludge, which is applied in the direction of dehydration/drying/thickened sludge treatment, etc. It can solve the problems of large amount of iron tailings slag and Portland cement, long curing time is difficult to meet, and the composition of curing agent is complex, etc., to achieve The effect of large output, less material used and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

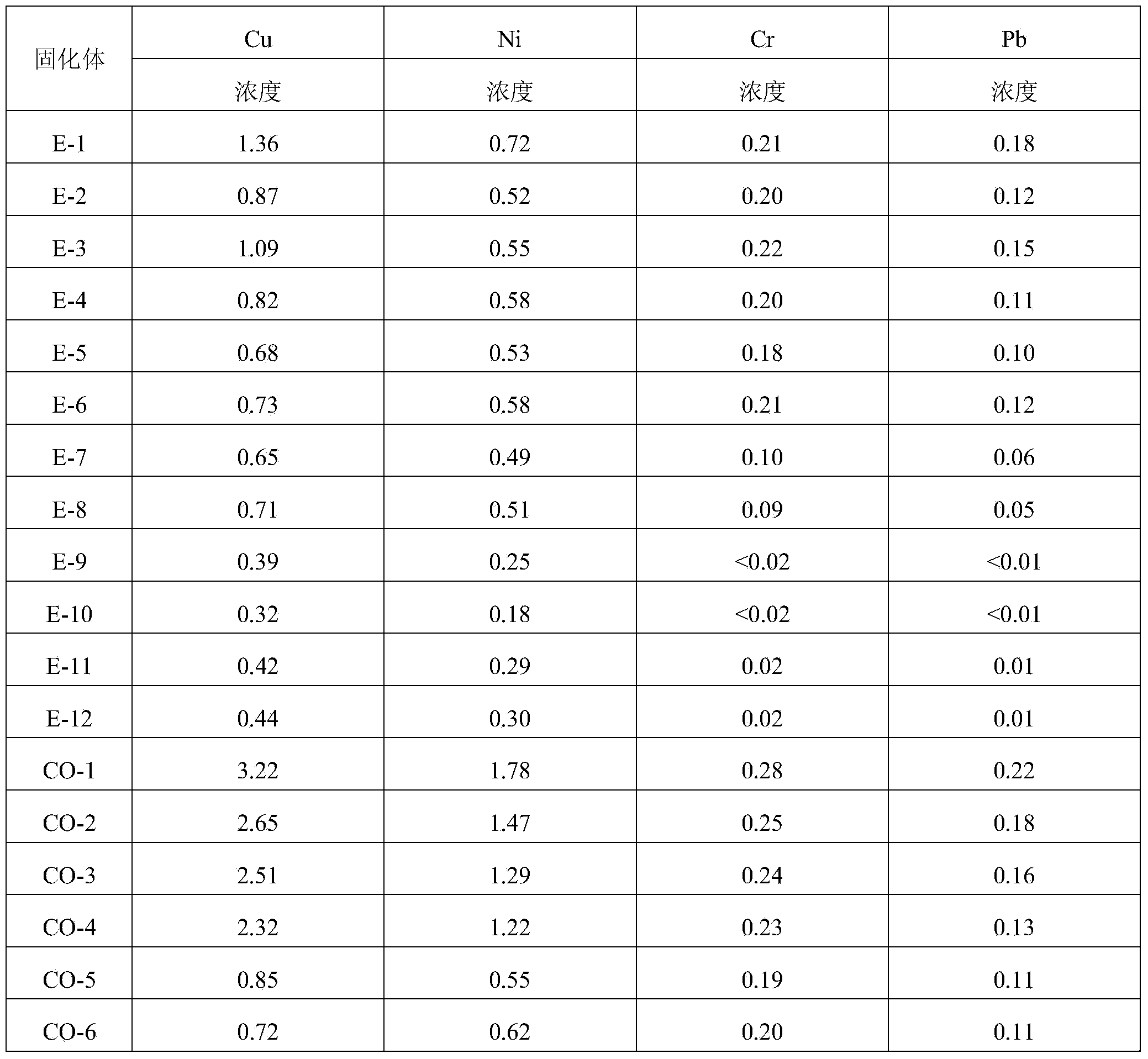

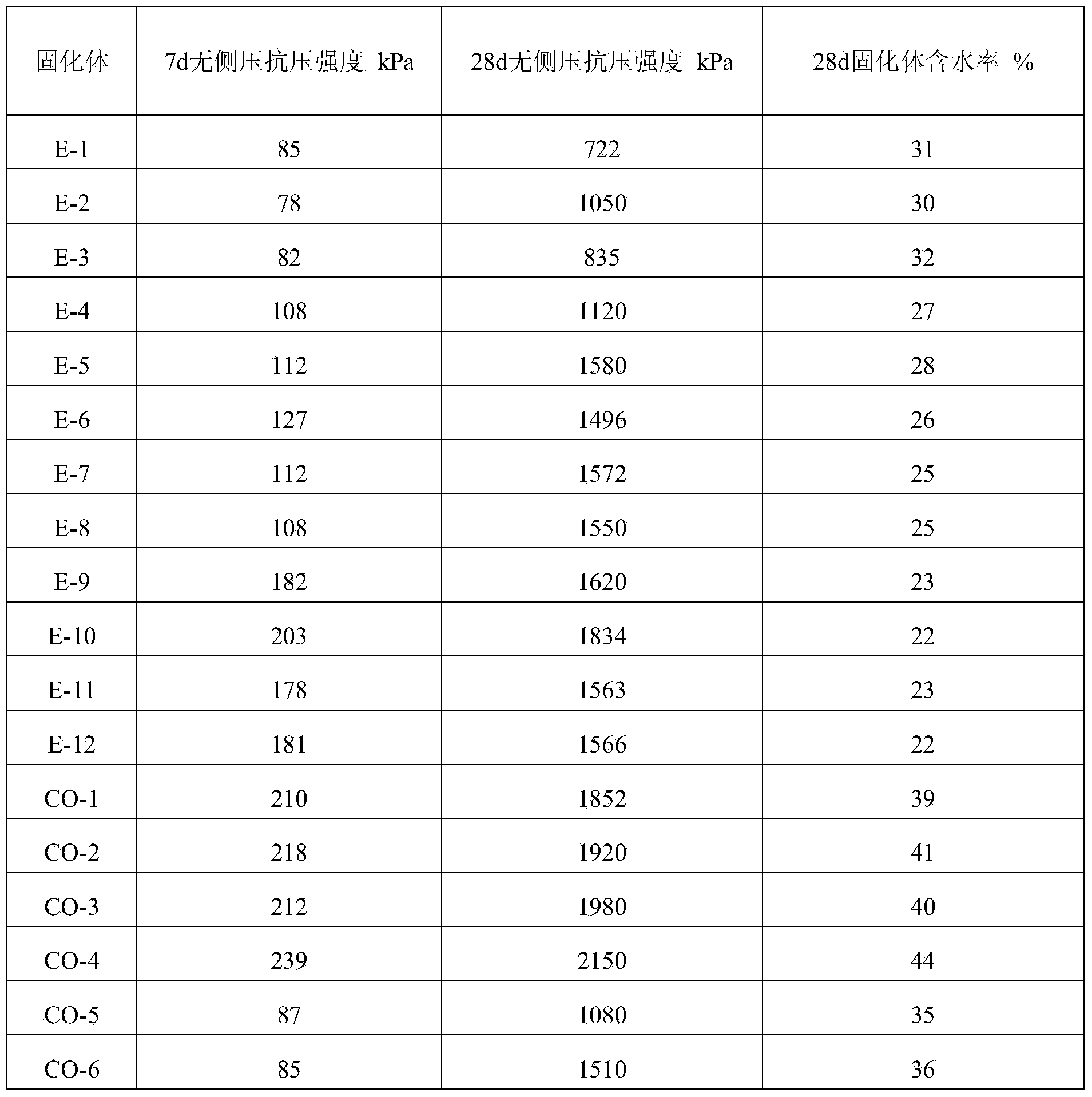

Examples

Embodiment 1

[0026] The solidified body after treatment is used as landfill. Based on the weight of sludge, the amount of coal-fired slag added is 60%, and the amount of Portland cement added is 4%.

Embodiment 2

[0028] The solidified body after treatment is used as a landfill. Based on the weight of the sludge, the amount of coal-fired slag added is 60%, and the amount of Portland cement added is 9%.

Embodiment 3

[0030] The solidified body after treatment is used as landfill. Based on the weight of sludge, the mixing amount of coal-fired slag is 50%, the mixing amount of fly ash is 10%, and the adding amount of Portland cement is 6%. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com