Method for preparing environment-friendly dye adsorbent from shrimp and crab shells

An environmentally friendly and adsorbent technology, applied in chemical instruments and methods, adsorption of water/sewage treatment, water pollutants, etc., can solve problems such as high cost and complicated process, and achieve reduced treatment costs, simple preparation process, and improved The effect of adsorption capacity and adsorption speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

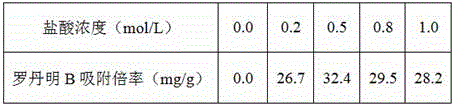

[0016] Clean the discarded shrimp shells with water, then dry them in the sun, break them into pieces with a size of about 1 cm, stir them in 0.0, 0.2, 0.5, 0.8, 1.0 mol / L hydrochloric acid for 2 hours, take them out and rinse them with water repeatedly until Neutral, dry in a drying oven at 60°C for 3 hours to obtain dye-absorbing materials treated with different hydrochloric acids.

[0017] Take 100 mg of the obtained dye-adsorbing material and add it to 200 mL of 10 -3 In the rhodamine B solution of M, let it stand for 5h, centrifuge, and then use spectrophotometry to detect the treated water, the results are shown in Table 1.

[0018] Table 1 Adsorption test of rhodamine B on dye-absorbing materials treated with different concentrations of hydrochloric acid

[0019]

Embodiment 2

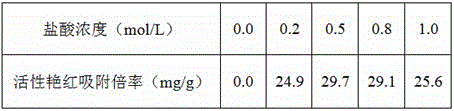

[0021] Clean the discarded crab shells with water, then dry them in the sun, break them into pieces with a size of about 1 cm, stir them in 0.0, 0.2, 0.5, 0.8, 1.0 mol / L hydrochloric acid for 2 hours, take them out and rinse them with water repeatedly until Neutral, dry in a drying oven at 60°C for 3 hours to obtain dye-absorbing materials treated with different hydrochloric acids.

[0022] Take 100 mg of the obtained dye-adsorbing material and add it to 200 mL of 10 -3 In the reactive brilliant red solution of M, let it stand for 5h, centrifuge, then adopt the spectrophotometric method to detect the treated water, the results are shown in Table 2.

[0023] Table 2 Adsorption test of reactive brilliant red by dye-absorbing materials treated with different concentrations of hydrochloric acid

[0024]

[0025] From the above experiments, it can be found that the dye adsorption materials obtained have dye adsorption effect when the concentration of hydrochloric acid is in the...

Embodiment 3

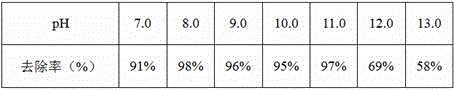

[0028] 1. Clean the discarded shrimp and crab shells with water, then dry them in the sun, break them into pieces with a size of about 1cm, soak them in 0.5mol / L hydrochloric acid for 2-4 hours to remove calcium carbonate, take them out and rinse them repeatedly with water until Neutral, dry in a drying oven at 60°C for 3 hours to obtain the adsorption material;

[0029] 2. Measure 200 mL of 10 -3 M simulated dye wastewater (Congo red solution), which was added to a beaker with 100 mg of adsorbent material;

[0030] 3. Stir the solution in the beaker with a glass rod, and then let it stand for a while, so that the adsorption material can fully absorb the dye in the wastewater;

[0031] 4. Separation of solid and liquid to separate the adsorbent material and obtain treated water.

[0032] The treated water was detected by spectrophotometry, and the results showed that the removal rate of Congo red could reach more than 98.0%, and the obtained adsorption material with dye coul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com