Collaborative curing treatment method for electrolytic manganese slag and red mud

A technology for electrolytic manganese slag and solidification treatment, which is applied in chemical instruments and methods, inorganic chemistry, ammonia compounds, etc., to achieve the effects of reducing dosage, cost, and treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

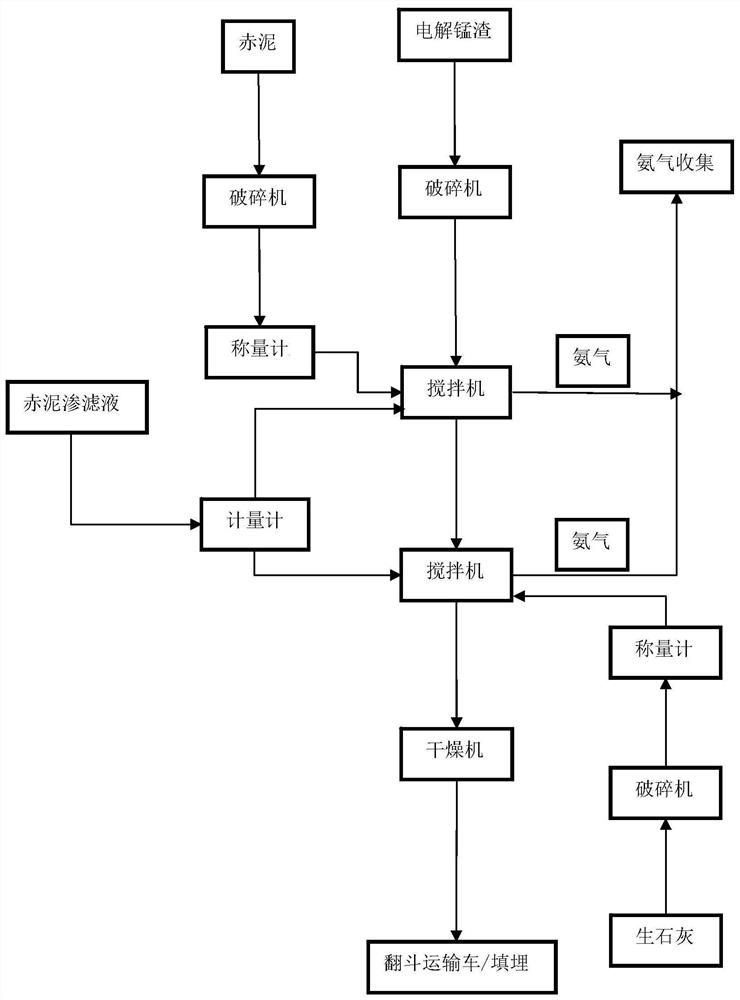

[0056] A method for synergistic solidification treatment of electrolytic manganese slag and red mud, comprising the following steps:

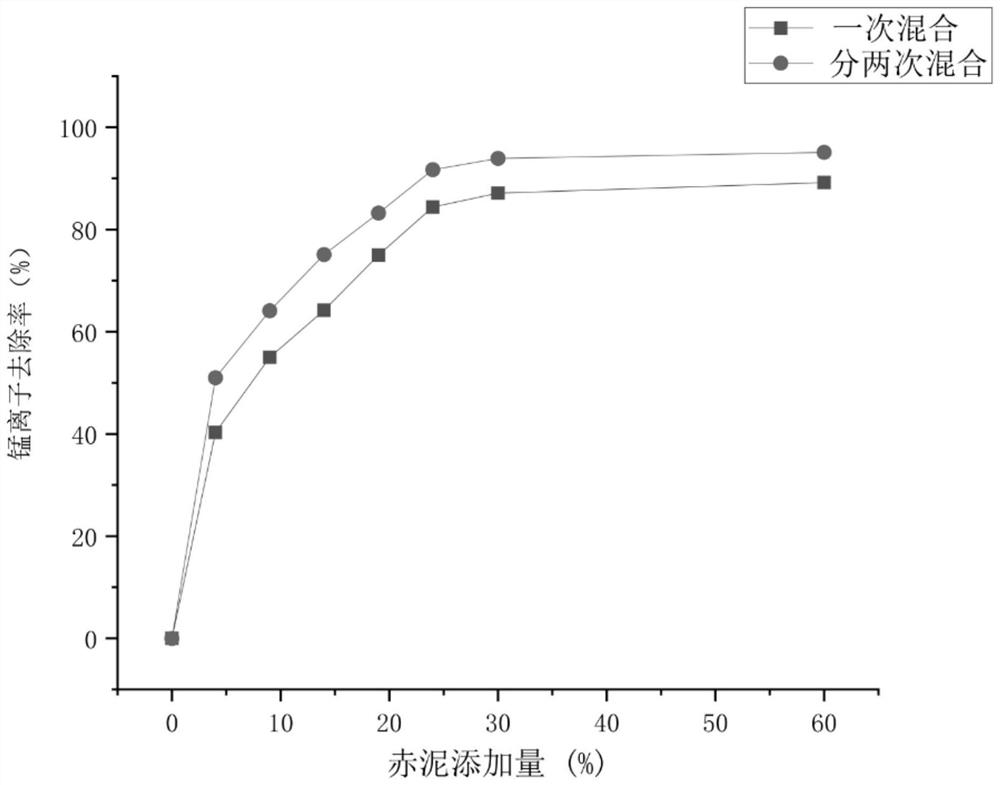

[0057] (1) Take electrolytic manganese slag and old red mud and air-dry until the water content is below 20wt%, and then transport electrolytic manganese slag, old red mud and quicklime to the crusher for crushing to obtain electrolytic manganese slag powder and old red mud. Mud powder and quicklime powder, the particle size of electrolytic manganese slag powder is 50 mesh, the particle size of old red mud powder is 50 mesh, and the particle size of quicklime powder is 140 mesh; then take 10kg of electrolytic manganese slag powder, old red mud powder Add 3kg into the mixer, then add 2L of the first red mud leachate, the pH of the first red mud leachate is 10, carry out the first stirring, the stirring speed is 100r / min, the stirring time is 10-15min, and the ammonia gas is recovered , to obtain the first mixture;

[0058] (2) Transfer the firs...

Embodiment 2

[0062] A method for synergistic solidification treatment of electrolytic manganese slag and red mud, comprising the following steps:

[0063] (1) Take electrolytic manganese slag and fresh red mud and air-dry until the water content is below 20wt%, then transport electrolytic manganese slag, fresh red mud and quicklime to the crusher for crushing treatment to obtain electrolytic manganese slag powder and fresh red mud powder and quicklime powder, the particle diameter of electrolytic manganese slag powder is 120 mesh, the particle diameter of fresh red mud powder is 100 mesh, and the particle diameter of quicklime powder is 80 mesh; then take electrolytic manganese slag powder 10kg, fresh red mud powder 3kg and add to In the mixer, add 2L of the first red mud leachate, the pH of the first red mud leachate is 12.5, carry out the first stirring, the stirring speed is 150r / min, the stirring time is 10-15min, recover the ammonia gas, and obtain the second a mixture;

[0064] (2) ...

Embodiment 3

[0068] A method for synergistic solidification treatment of electrolytic manganese slag and red mud, comprising the following steps:

[0069] (1) Transport the electrolytic manganese slag, old red mud and quicklime to the crusher for crushing, and obtain electrolytic manganese slag powder, old red mud powder and quicklime powder. The particle size of the electrolytic manganese slag powder is 120 mesh, and the old The particle size of permanent red mud powder is 120 mesh, and the particle size of unslaked lime powder is 50 mesh; then take 10kg of electrolytic manganese slag powder and 6kg of old red mud powder and add them to the mixer, then add 3L of the first red mud leachate, the second 1. The pH of the red mud leachate is 12.5, and the first stirring is performed at a stirring rate of 150 r / min for 10 to 15 minutes, and ammonia gas is recovered to obtain the first mixture;

[0070] (2) The first mixture that step (1) obtains is transferred into the first mixer, then add the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com