Device and method for extracting and separating lignin from papermaking black liquid

A paper-making black liquor and lignin technology, which is applied in the field of paper-making wastewater treatment, can solve the problems of ineffective use of materials and increase the operating load of the alkali recovery furnace, and achieve the effect of alleviating the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

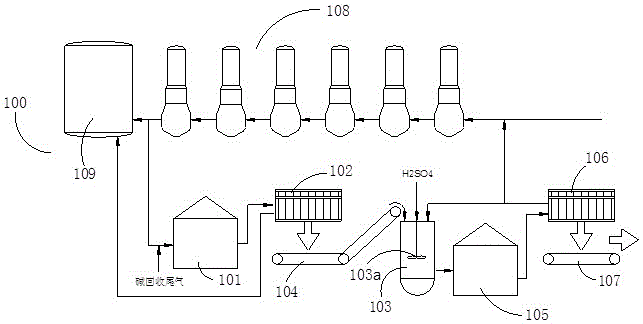

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0028] The extraction of lignin in the prior art mainly includes acid analysis method, alkali method, slow coagulation precipitation method and the like. Among them, the inorganic acid analysis method usually uses H 2 SO 4 , HCl or CO in flue gas 2 , SO 2 Adjust the pH of papermaking black liquor (usually adjusted to below 5), so that the sodium lignin phenate in the alkaline solution will remove sodium ions and become insoluble lignin precipitates, and carry out corresponding post-treatment. Alkali analysis method precipitates by adding metal (transition metal) ions that can chelate w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com