Solid-waste-based high-strength unfired fly ash ceramsite and preparation method thereof

A fly ash ceramsite, high-strength technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems of low strength of ceramsite and increase in cost, and achieve the effect of promoting adsorption performance, saving time and cost, and slowing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

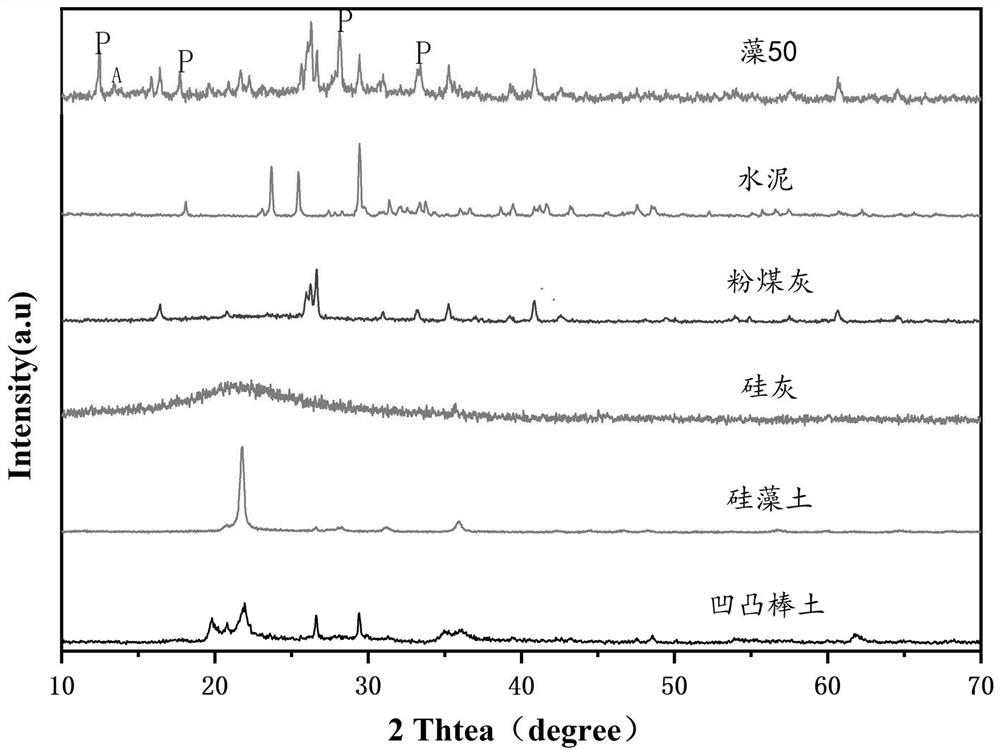

[0040] Example 1: Mix fly ash, attapulgite, cement, silica fume, and diatomaceous earth according to the mass ratio of 70:10:10:5:5, and put them into a granulator for further mixing after preliminary mixing Uniform; after mixing evenly, slowly add 10% of the mass of the solid mixture of sodium hydroxide solution with a concentration of 8mol / L; then slowly add 0.5% of the mass of the solid mixture of hydrogen peroxide solution with a mass fraction of 30%, and stir for 2 minutes After being mixed evenly, slowly add the water glass with a modulus of 3.2 of 5% of the quality of the solid mixture, and stir for 1 minute; , until the end of the final granulation process. After the finished fly ash ceramsite is naturally cured for 6-12 hours, it is put into an autoclave for 12 hours. The steaming condition of the autoclave is: the steaming temperature is 170°C, the pressure is 8 atmospheres,

[0041] The prepared fly ash ceramsite, ceramsite performance testing fully complies with ...

example 2

[0043] Example 2: Slowly add 1.5% of the mass of the solid mixture into a 30% hydrogen peroxide solution, and stir for 2 minutes; after mixing evenly, slowly add 5% of the mass of the solid mixture into water glass with a modulus of 3.1, and stir for 1 Minutes; after mixing evenly, continue to slowly add 8mol / L sodium hydroxide solution with 12% solid mixture mass until the final granulation process ends. Put into the autoclave and steam for 8 hours. The steaming condition of the autoclave is: steaming temperature 180 ℃, pressure is 9 atmospheres, other methods are the same as example 1.

[0044] The prepared fly ash ceramsite, ceramsite performance testing fully complies with GB / T 17431.1-2010 light aggregate performance standard, in which the cylinder compressive strength is 12Mpa, and the bulk density is 889Kg / m 3 , for Cu 2+ The adsorption capacity is 6.42mg / g.

example 3

[0045] Example 3: Slowly add 5% of the mass of the solid mixture into a 30% hydrogen peroxide solution, and stir for 2 minutes; after mixing evenly, slowly add 5% of the mass of the solid mixture into water glass with a modulus of 3.4, and stir for 1 Minutes; after mixing evenly, continue to slowly add 8mol / L sodium hydroxide solution with 15% of the mass of the solid mixture, put it into the autoclave and steam for 24 hours. The steam curing conditions of the autoclave are: the steam curing temperature is 190° C., and the pressure is 10 atmospheres. Other methods are the same as in Example 1.

[0046] The fly ash ceramsite prepared by the above implementation case, the performance test of the ceramsite fully complies with the performance standard of GB / T 17431.1-2010 light aggregate, in which the cylinder compressive strength is 14Mpa, and the bulk density is 996Kg / m 3 , for Cu 2+ The adsorption capacity is 7.85mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com