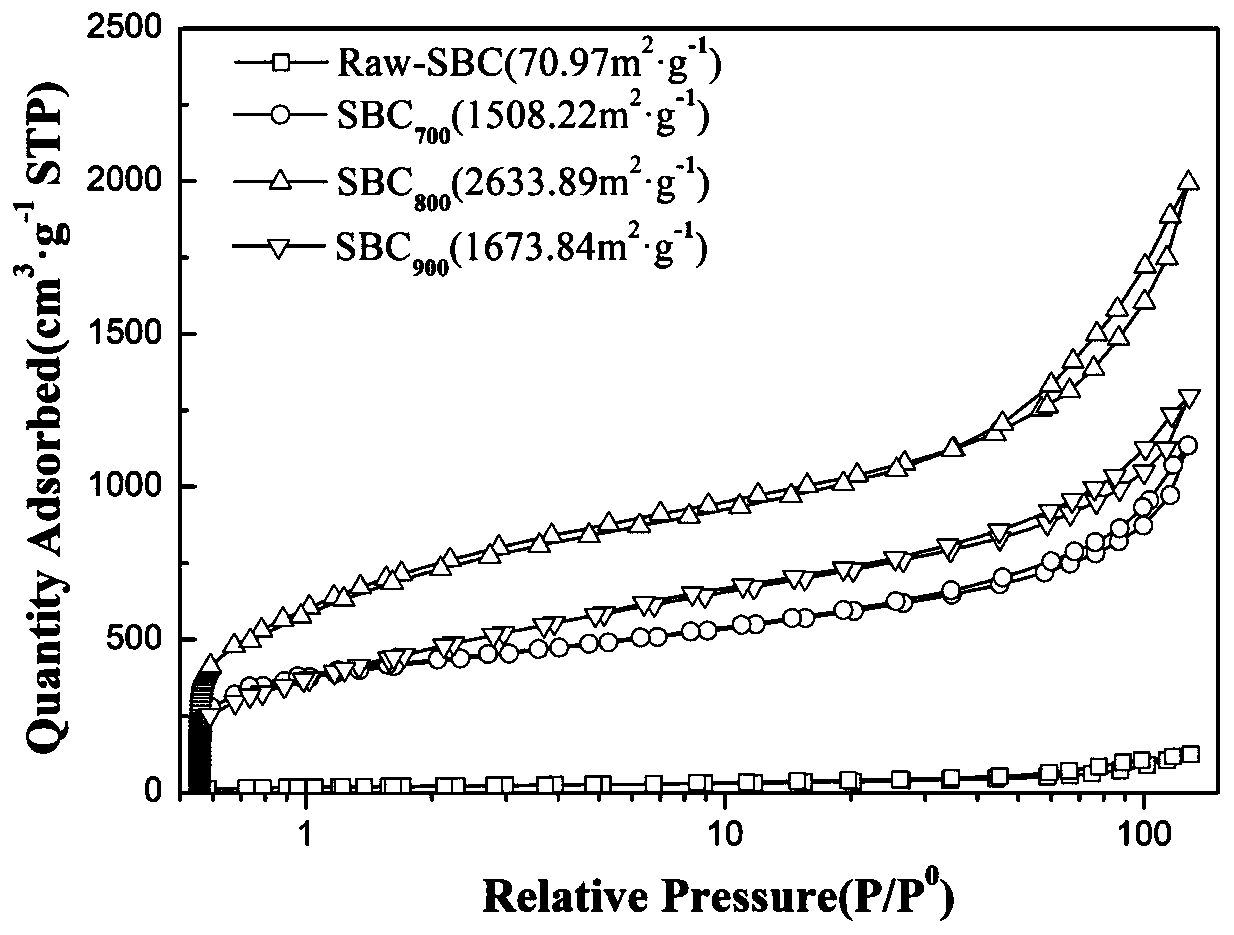

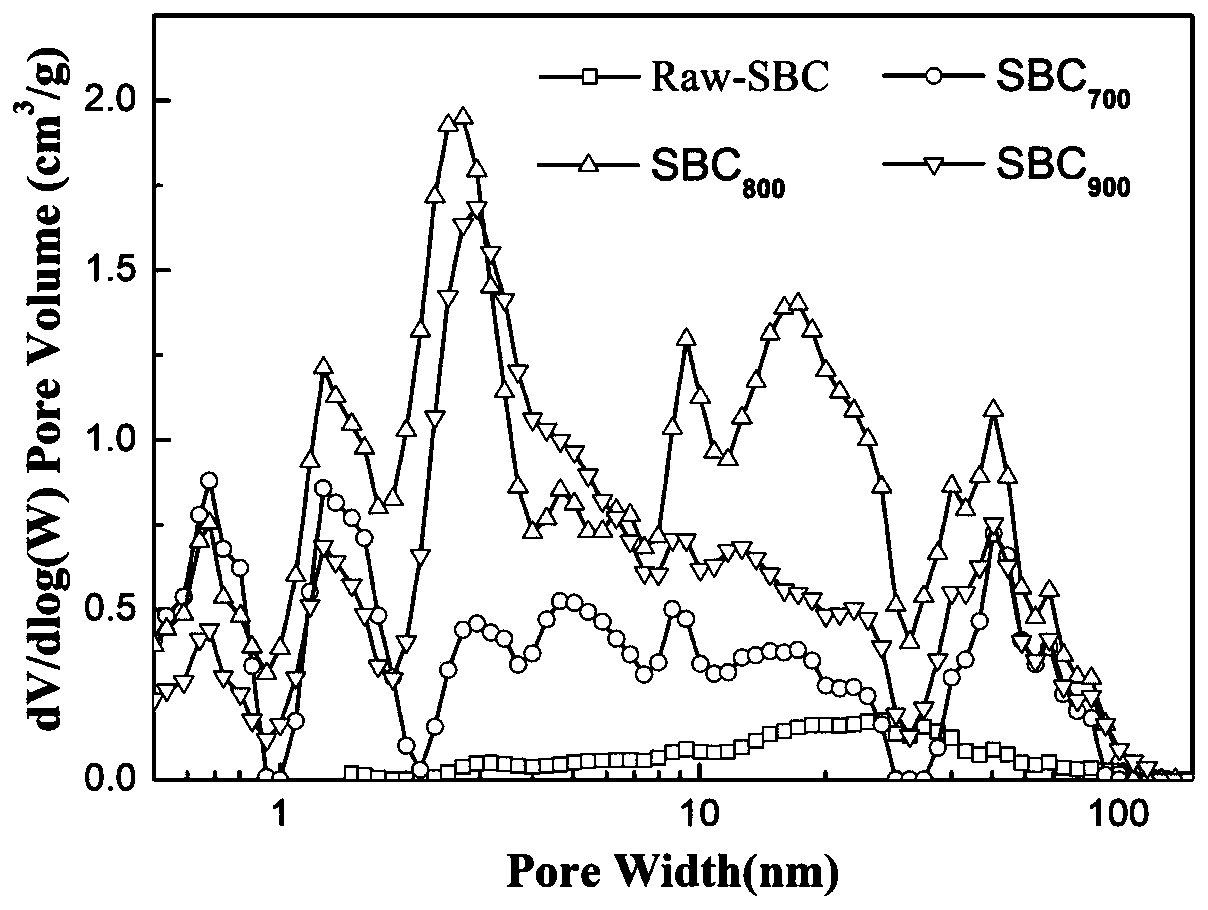

Super-high specific surface area carbon-based functional material and preparation method and application thereof

A technology of ultra-high specific surface area and carbon-based functional materials, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problem of not too high specific surface area, and achieve simple steps and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Use KOH solution to alkali-treat 4L of raw mud, slowly drop the concentrated KOH solution prepared in advance into the raw mud (simultaneously drop the solution and stir), and fully mix and adjust to pH=13. After subpackaging, use a six-way agitator, adjust the rotation speed to 200r / min, and stir for 30 minutes to initially destroy the cell body structure. The sludge after alkali treatment is extracted by centrifugation, and the centrifuge is guaranteed to run for 10 minutes under the centrifugal force of 3000g (speed 5320r / min). Use a syringe filter (0.45 μm, Millex, Millipore) to filter the supernatant into a beaker, which is SEPS. The solid phase is discarded, and the process of separating and extracting SEPS from the sludge is completed. Then put it into an electric blast drying oven and bake at 105°C for 24 hours until the water is evaporated to dryness. Grind SEPS into a powder with an agate mortar and put it in a porcelain crucible.

[0036] SEPS carbon-based...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com