Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

137 results about "Zirconium oxychloride octahydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

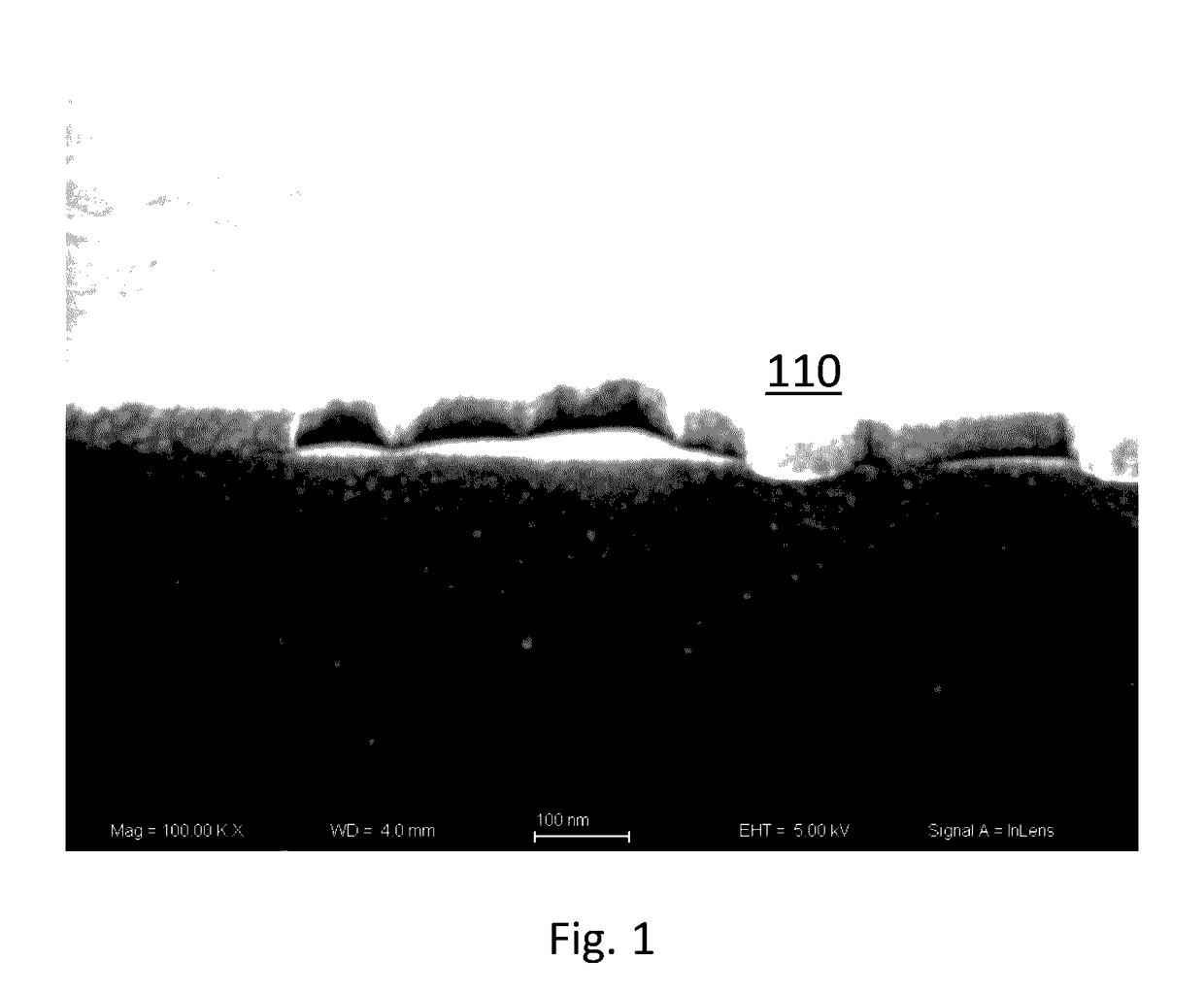

Scratch-resistant liquid based coatings for glass

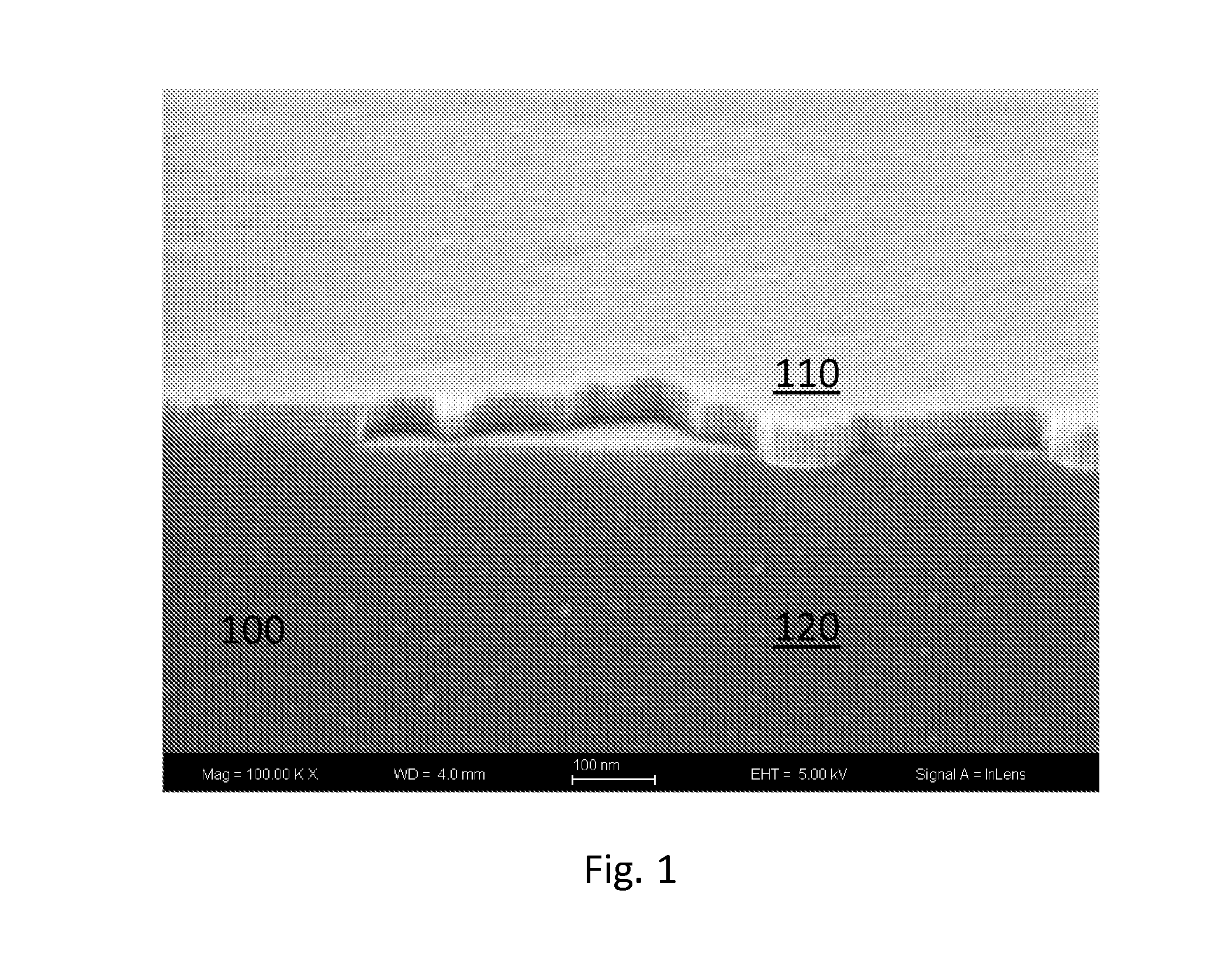

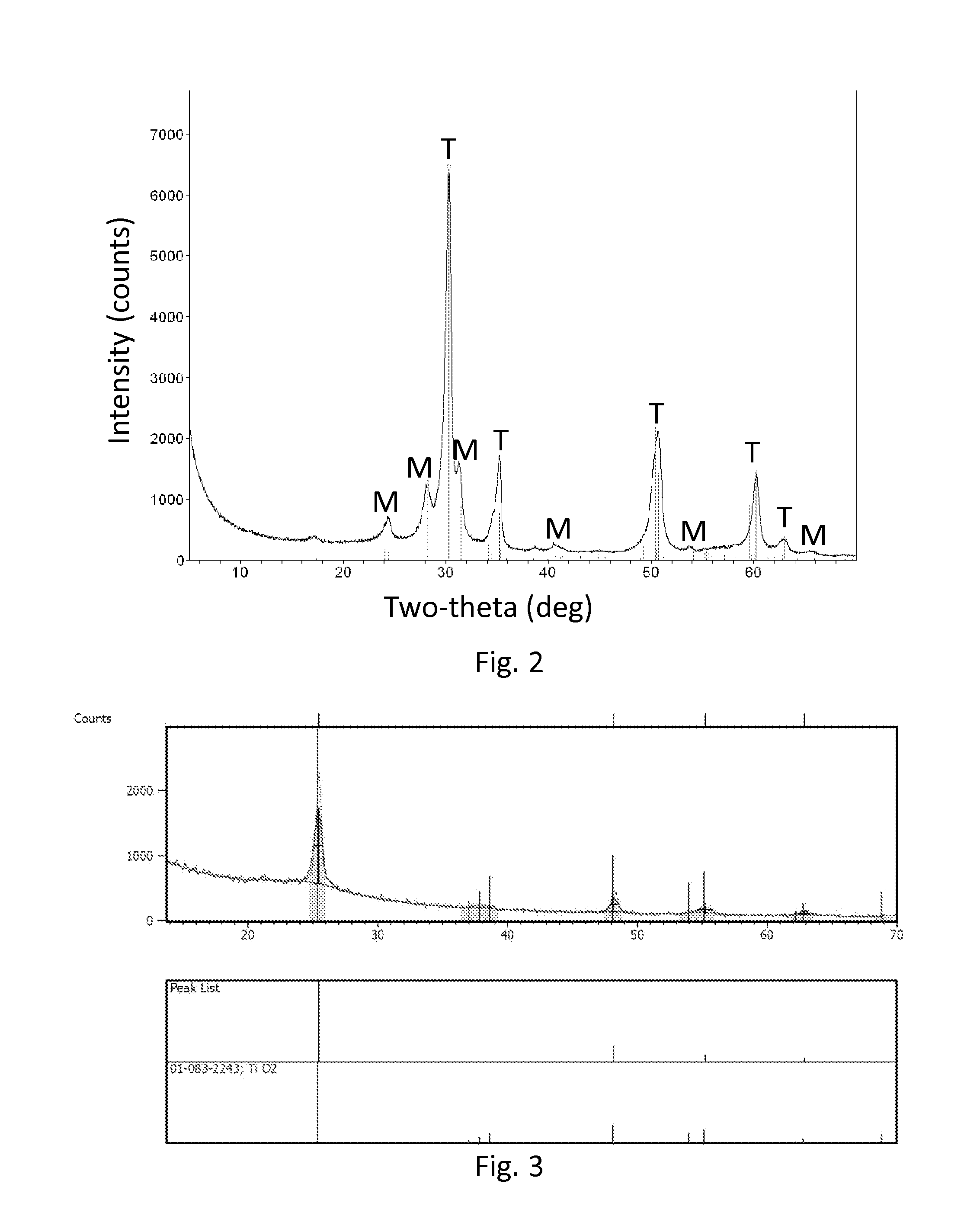

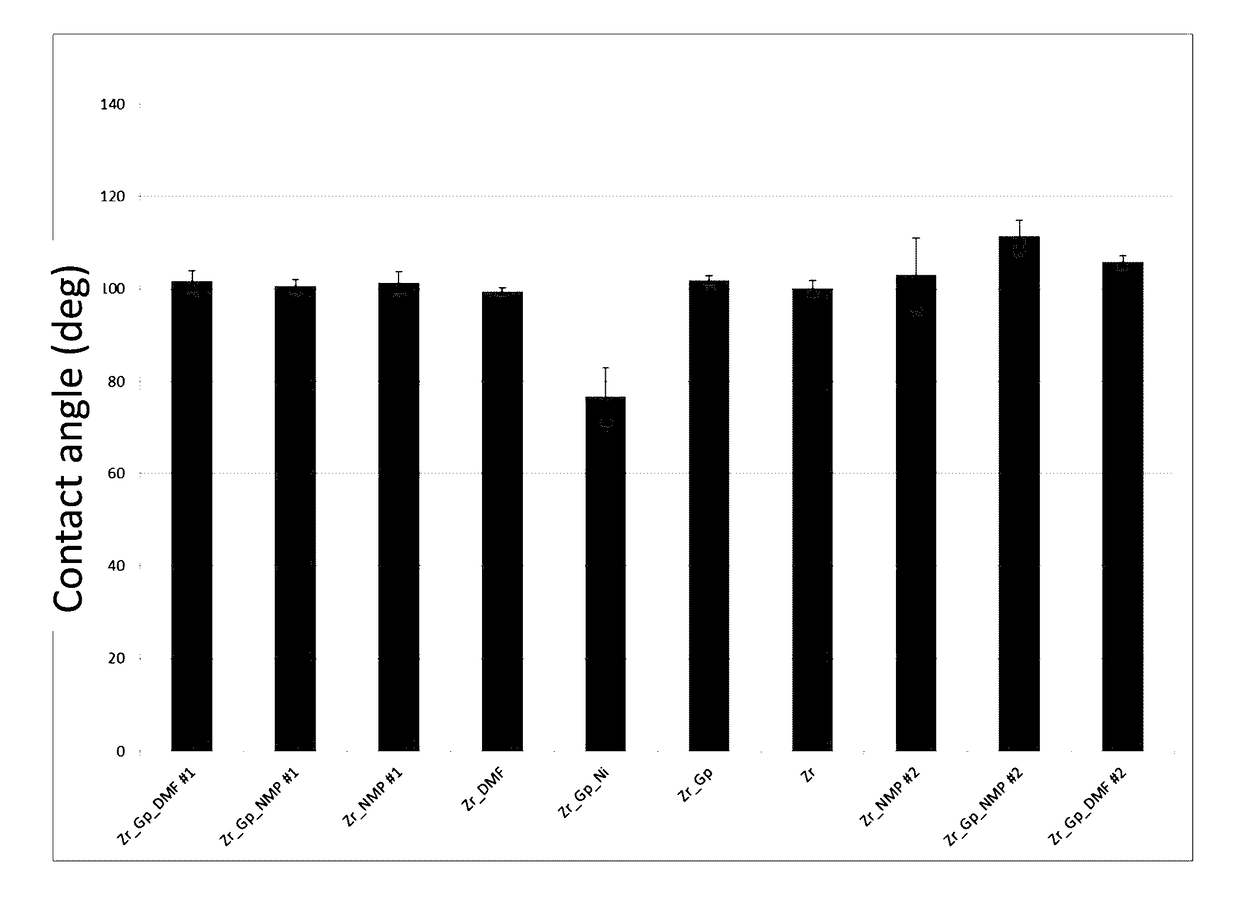

ActiveUS20150132563A1High hardnessIncreased durabilityPretreated surfacesLiquid/solution decomposition chemical coatingMetallurgyZirconia coating

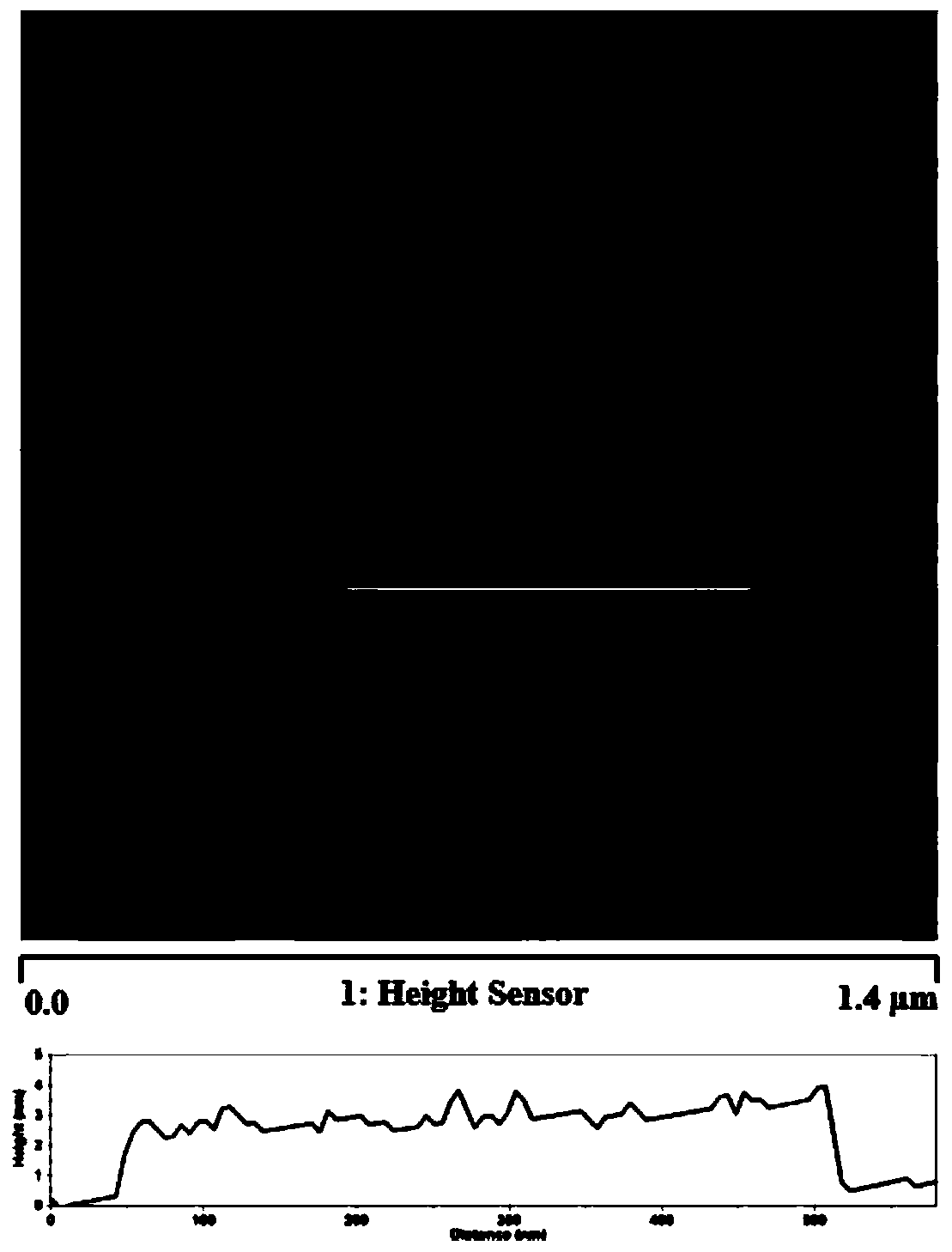

A sol-gel method for forming durable, scratch-resistant coatings on glass substrates. Zirconia coatings, for example, are formed from a solution of zirconium oxychloride octahydrate in an organic, polar, aprotic solvent such as dimethylformamide. Annealed coatings, which optionally include an additive such as graphene, have a low coefficient of friction and can exhibit high hardness and hydrophobicity.

Owner:CORNING INC

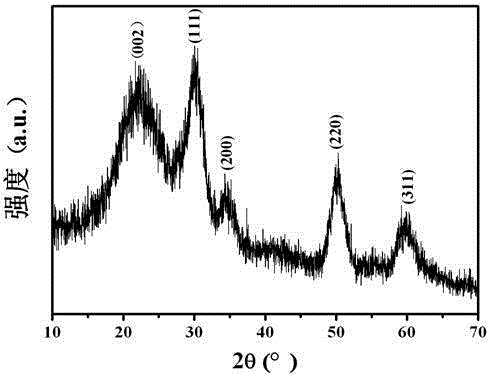

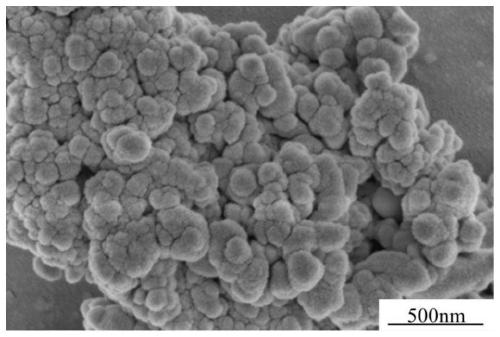

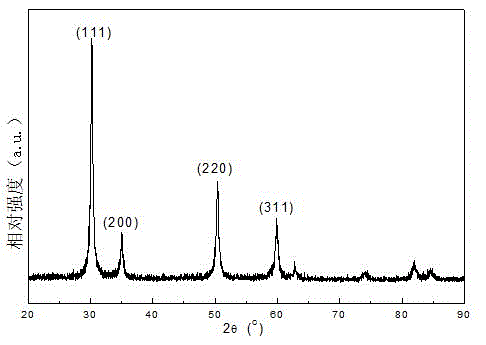

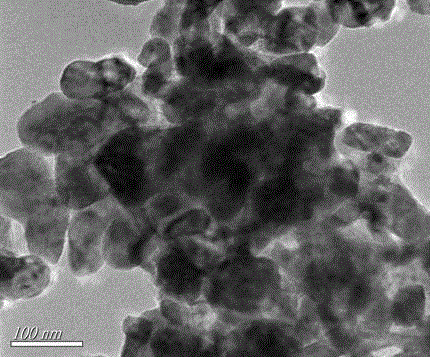

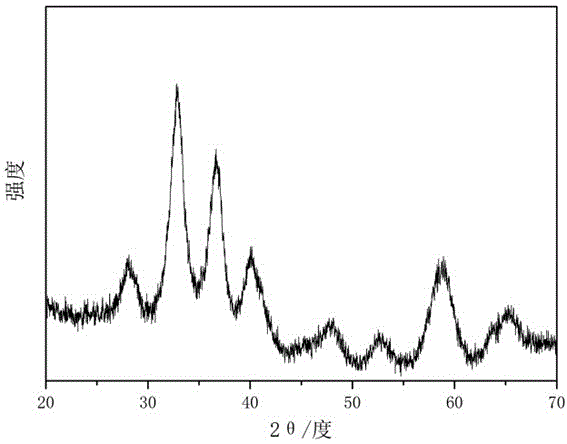

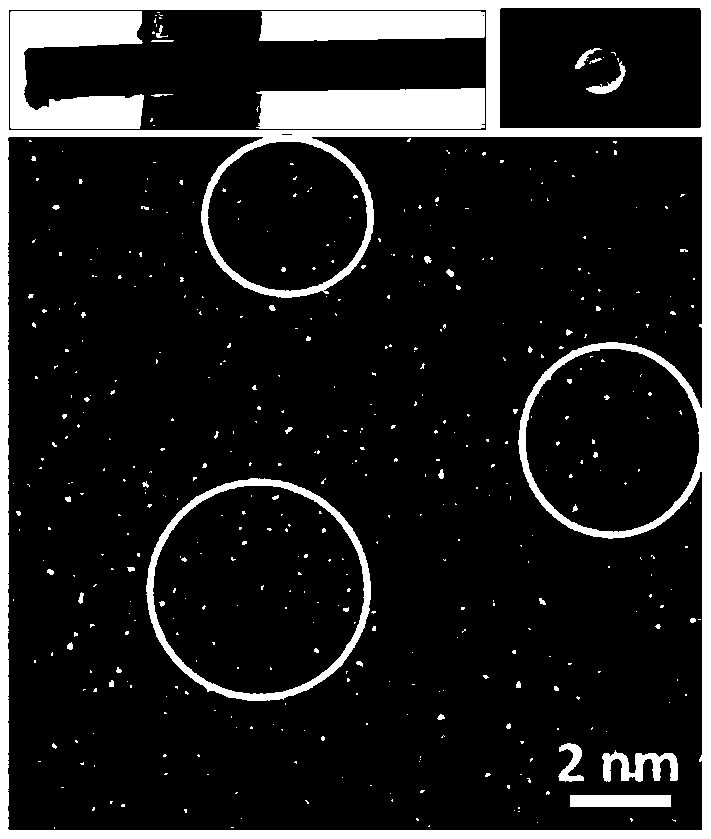

Preparation method of yttria-stabilized zirconia tetragonal nano powder with high specific surface area

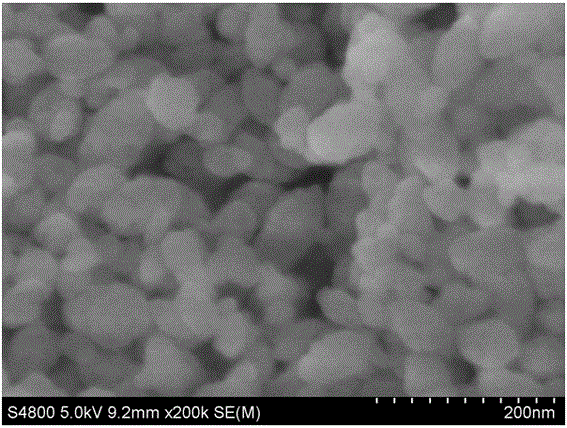

ActiveCN103524128ASolve serious sintering and agglomerationSolution areaMaterial nanotechnologyZirconium hydrideSolution combustion

A preparation method of an yttria-stabilized zirconia tetragonal nano powder with high specific surface area. The method is characterized by comprising the following steps: (1) respectively weighing zirconium oxychloride octahydrate?and an yttrium raw material according to a stoichiometric ratio of zirconium and yttrium in (Y2O3)x(ZrO2) 1-2x (0.005<=x<=0.150), according to the amount of a target product, converting the yttrium raw material into an yttrium nitrate solution by dissolving, and then completely dissolving the zirconium oxychloride octahydrate; (2) respectively adding a soluble salt and organic fuel to the solution obtained in the step (1), heating for dissolving, continuing heating and concentrating to a sticky state, igniting in a heating furnace chamber at 400-1000 DEG C, and taking out the powder after complete combustion; and (3) washing, filtering and drying the powder obtained in the step (2). The invention effectively solves the problems of serious particle sintering agglomeration and small specific area in the process of solution combustion for synthesis of zirconium oxide; the powder has specific surface area as high as 378 m<2> / g and particle size about 2.8 nm; and the materials are more accessible and cheaper, so as to facilitate industrialized preparation.

Owner:赣州点金新材料科技有限公司

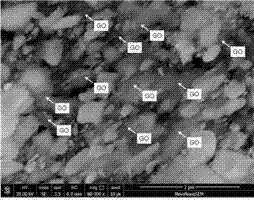

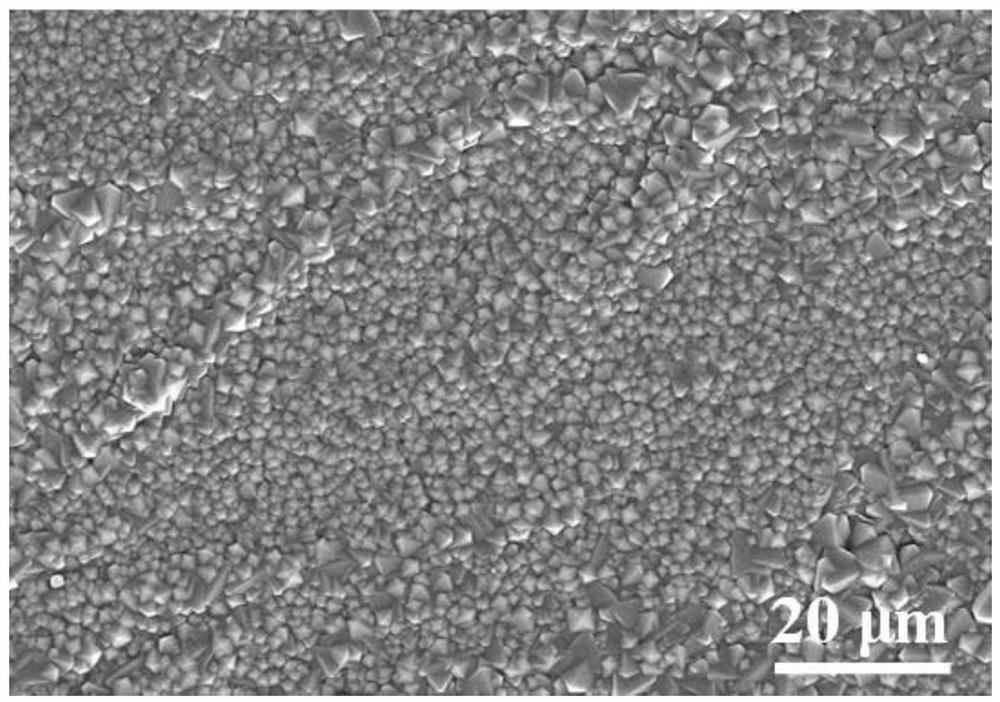

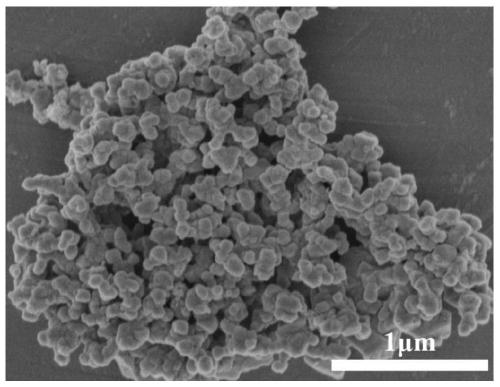

Preparation method of graphene/zirconium oxide nano-grade composite lubricating material

InactiveCN105219478ASimple processShorten the production cycleBase-materialsFreeze-dryingZirconium oxychloride

The invention discloses a preparation method of a graphene / zirconium oxide nano-grade composite lubricating material. The method comprises the following steps: a graphite oxide solution is subjected to ultrasonic treatment for 1-2h, such that a uniformly dispersed graphene oxide suspension liquid with thickness of 1-2 layers is obtained; the suspension liquid is diluted with ultrapure water; zirconium oxychloride octahydrate is dissolved in ultrapure water, such that a zirconium oxychloride solution is prepared; the diluted graphene oxide suspension liquid is mixed with the zirconium oxychloride solution, and the mixture is uniformly mixed by stirring; the mixture is subjected to ultrasonic treatment for 10-30min; hydrazine hydrate is added into the mixed liquid, and a reaction is carried out under a hydrothermal condition, wherein a reaction temperature is 150-220 DEG C and a reaction time is 18-24h; a black solid product obtained after the reaction is repeatedly washed with ultrapure water, and is subjected to freeze drying for 6-12h, such that the graphene / zirconium oxide nano-grade composite lubricating material with zirconium oxide nano-particles uniformly distributed on graphene surface is obtained. The preparation method provided by the invention has the advantages of simple process, easy operation, low cost, high product purity, and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Scratch-resistant liquid based coatings for glass

ActiveUS9663400B2Improve durability and lifetimeHigh hardnessPretreated surfacesLiquid/solution decomposition chemical coatingHardnessZirconia coating

A sol-gel method for forming durable, scratch-resistant coatings on glass substrates. Zirconia coatings, for example, are formed from a solution of zirconium oxychloride octahydrate in an organic, polar, aprotic solvent such as dimethylformamide. Annealed coatings, which optionally include an additive such as graphene, have a low coefficient of friction and can exhibit high hardness and hydrophobicity.

Owner:CORNING INC

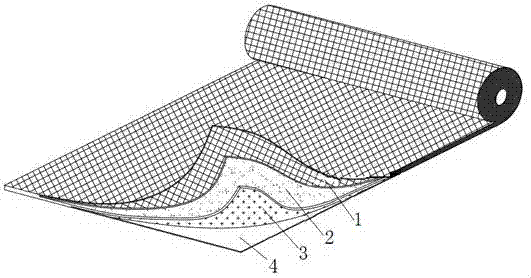

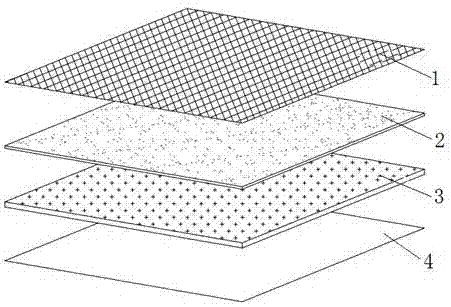

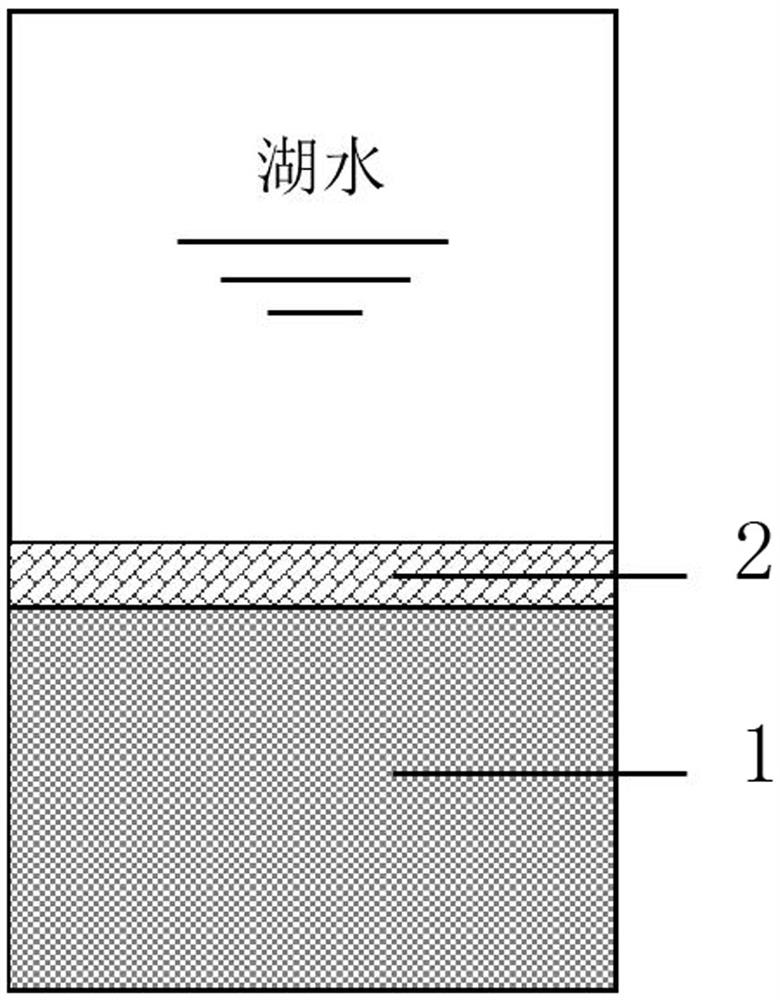

Covering carpet for repairing degradation-resistant organic substance contaminated sediment in situ and laying method of covering carpet

ActiveCN107445423APromote degradationPromote expansionSludge treatmentOther chemical processesSodium BentoniteSurface layer

The invention discloses a covering carpet for repairing degradation-resistant organic substance contaminated sediment in situ and a laying method of the covering carpet. The covering carpet comprises a bottom layer, a lower layer, an upper layer and a surface layer from bottom to top in sequence, wherein the bottom layer is made of nonwoven geotextile, the lower layer is a solubilizing layer, the upper layer is an adsorption filler layer, the surface layer is woven geotextile, the solubilizing layer adopts filler mixed by rhamnolipid-modified montmorillonite and active carbon, the adsorption filler layer adopts a quaternary ammonium salt type surfactant and organic bentonite modified by zirconium oxychloride octahydrate. The laying method of the covering carpet comprises the following steps: directly laying the covering carpet on contaminated sediment, connecting adjacent covering carpet units through stubble, and additionally arranging a fine sand layer on the covering carpet. The filler is mixed by the rhamnolipid-modified montmorillonite and the active carbon, so that degradation of degradation-resistant organic substances is promoted; modified organic bentonite is adopted as the adsorption filler layer, so that adsorption capacity on organic pollutants in water is relatively strong; and the laying mode is flexible, construction is simple and convenient, and the living environment of bentonic organisms is not damaged.

Owner:SHANDONG JIANZHU UNIV

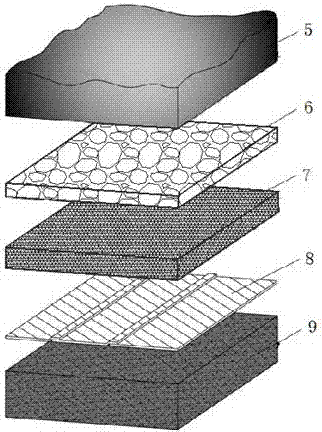

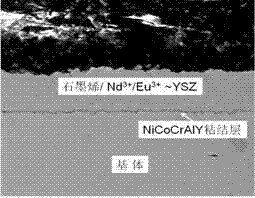

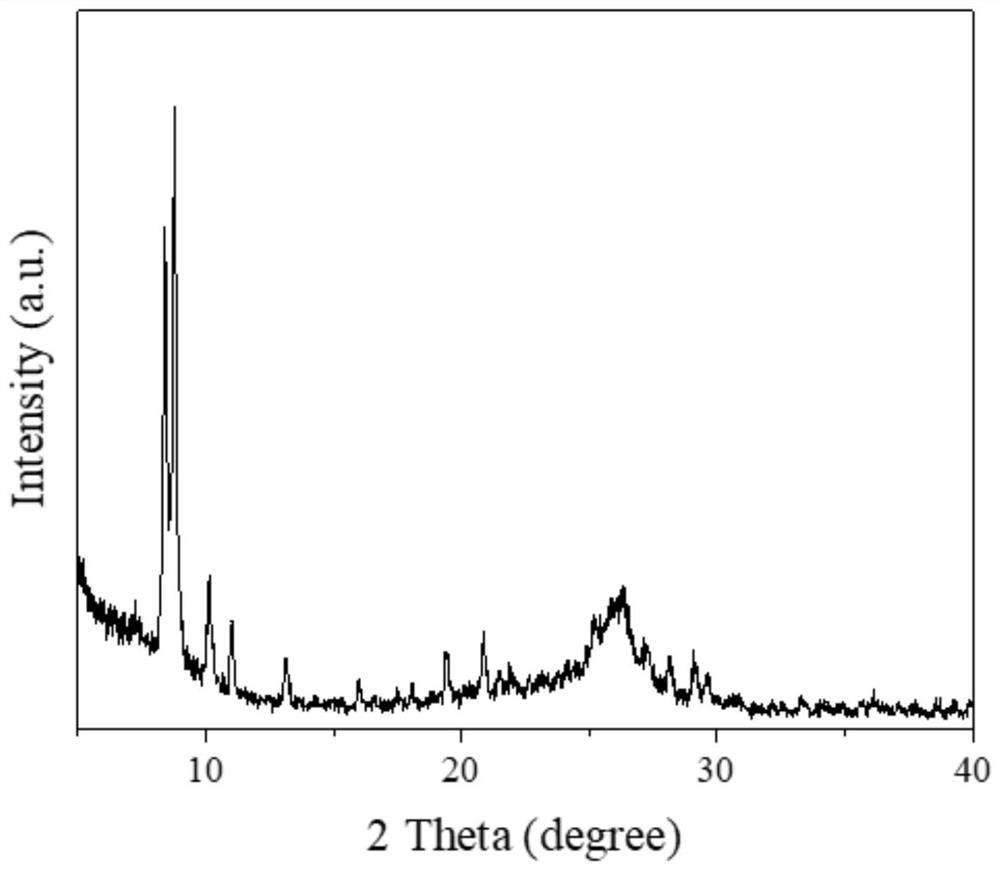

Preparation method of graphene modified temperature-indicating thermal barrier coating

ActiveCN107400846ATo achieve the purpose of failure warningMonitor IntegrityMolten spray coatingLuminescent compositionsThermal sprayingPolyethylene glycol

The invention provides a preparation method of a graphene modified temperature-indicating thermal barrier coating. The preparation method comprises steps as follows: S1, zirconium oxychloride octahydrate is dissolved in deionized water; S2, solid powder of yttrium oxide, europium oxide and neodymium oxide is dissolved in diluted hydrochloric acid; S3, graphene oxide is dispersed in absolute ethanol; S4, the two solutions obtained in S2 and S3 are mixed; S5, the mixed solution in S1 and the solution obtained in S4 are stirred and mixed with a polyethylene glycol dispersant; S6, an ammonium hydroxide reaction base solution with PH being 10 is prepared and heated, and yttria-stabilized zirconia precursor sol is obtained; S7, graphene modified Nd<3+> / Eu<3+> yttria-stabilized zirconia sol containing no Cl- is obtained; S8, the graphene modified temperature-indicating thermal barrier coating is obtained through liquid-phase plasma spraying. The problems of burning loss, blowing loss and agglomeration of nano-scale graphene in preparation of a coating with the hot spraying technique are avoided.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

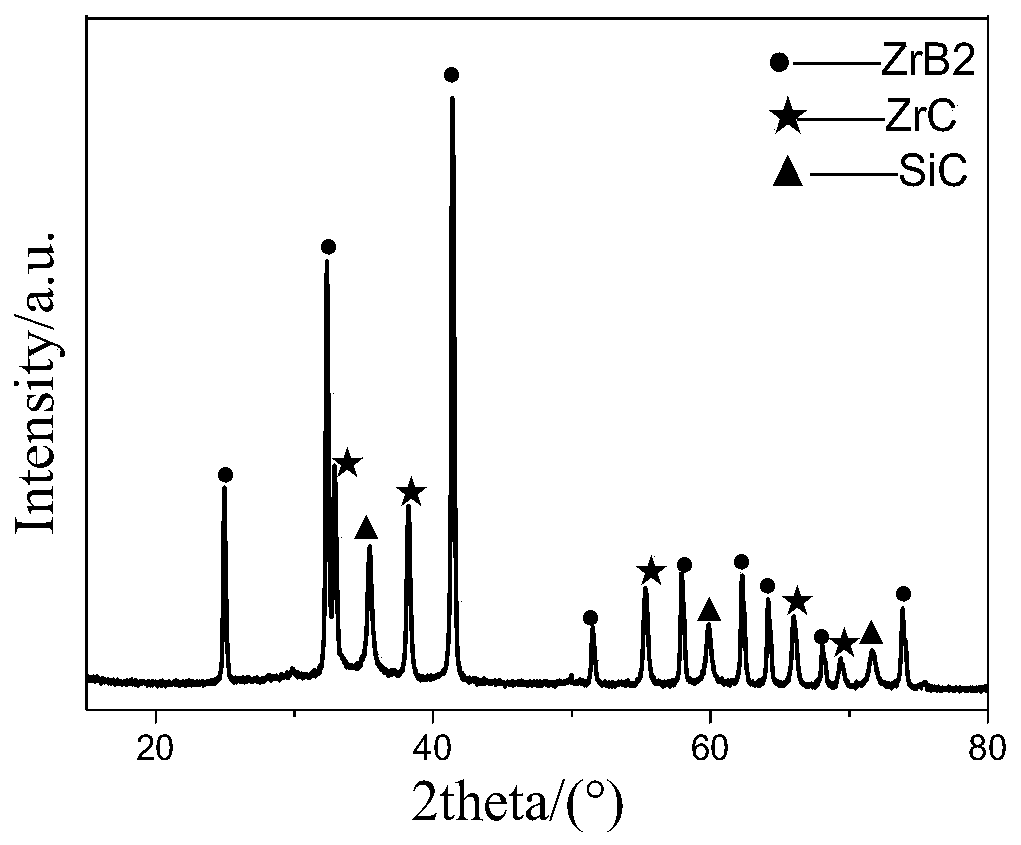

Preparation process of ZrC-ZrB2-SiC ceramic composite powder by precursor conversion method

The invention discloses a preparation process of ZrC-ZrB2-SiC ceramic composite powder by a precursor conversion method. Zirconium oxychloride octahydrate, boric acid, ethyl orthosilicate and glucoseare used as starting raw materials, and absolute ethyl alcohol and deionized water are used as solvents, wherein the molar ratio of the boric acid to the zirconium oxychloride octahydrate to the ethylorthosilicate is (1-5):1:(0.5-5), and the mass ratio of the glucose to the ethyl orthosilicate is (1-4):1. A zirconium precursor solution, a boric acid solution, an ethyl orthosilicate solution and aglucose solution are prepared separately, the solutions are uniformly mixed to obtain a boron-silicon-zirconium precursor solution, the boron-silicon-zirconium precursor solution is dried, and heat treatment is carried out at 1450-1600 DEG C for 1-2 hours under the protection of an argon atmosphere to obtain the ZrC-ZrB2-SiC ceramic powder. The prepared ceramic powder is uniform in particle sizeand the average particle size is about 150 nm. The preparation process has the characteristics of simple process, short period, low energy consumption and low cost, and the obtained ceramic phase is uniform and fine in particle size and high in purity.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

Preparation method and application of metal organic framework MOF-808 film-based functional sandwich material

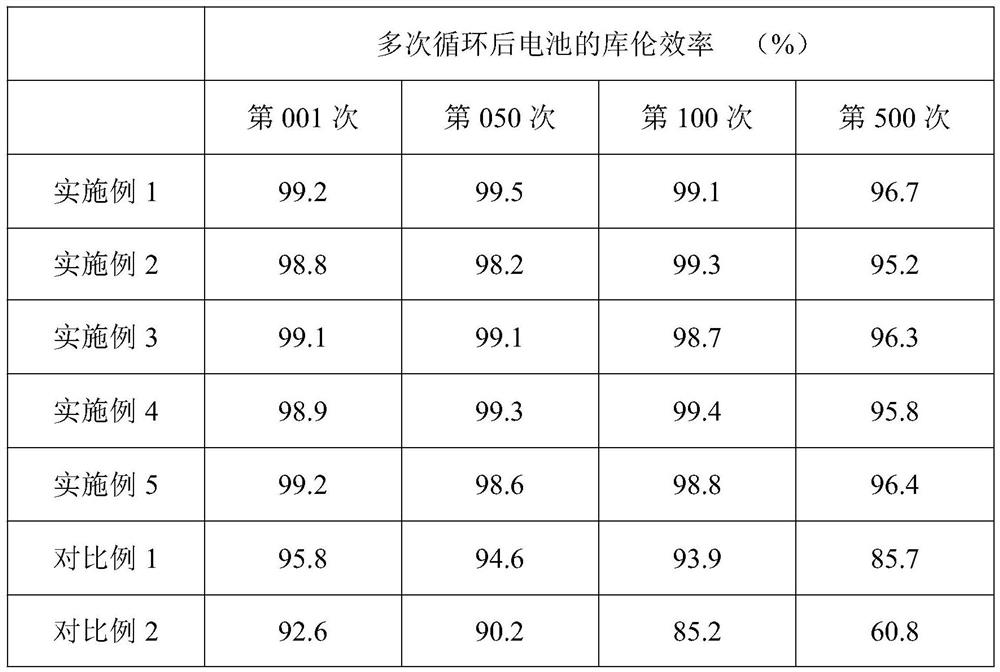

ActiveCN112688021AHigh specific capacityImprove cycle stabilityElectrode carriers/collectorsLi-accumulatorsLithium–sulfur batteryPerfluoroacetic Acid

The invention relates to a preparation method and application of a metal organic framework MOF-808 film-based functional interlayer material. The method comprises the following steps: dissolving zirconium oxychloride octahydrate and trimesic acid in deionized water, performing magnetic stirring for 30-60 minutes at normal temperature, then adding trifluoroacetic acid, and carrying out ultrasonic treatment for 30-60 minutes to obtain a synthetic solution; and then vertically immersing a carbon nanotube (CNT) film wafer in the synthetic liquid, and growing for 3-5 hours at the temperature of 110-130 DEG C to obtain the MOF-808 / CNT film. The MOF-808 / CNT film interlayer material obtained by the invention is simple to operate, easy to amplify and suitable for industrial production; when the material is used as an interlayer material between a positive electrode and a diaphragm in a lithium-sulfur battery, the performance of the lithium-sulfur battery can be remarkably improved, the reversible capacity of the lithium-sulfur battery can reach 1292mAh g <-1 >, and the cycle performance is stable.

Owner:HEBEI UNIV OF TECH

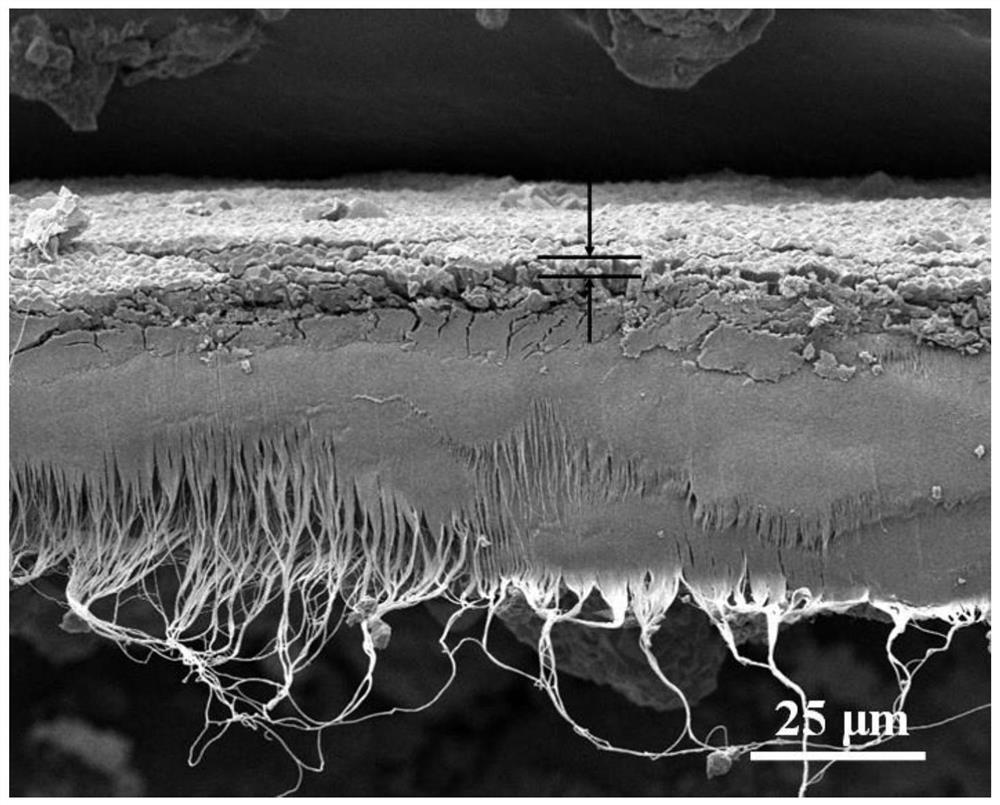

Method for preparing organic poly-zirconium precursor or silk-thrawn liquor thereof for zirconia fiber production by one-step solvent method

InactiveCN102766154ASimple production processImprove efficiencyGroup 4/14 element organic compoundsEthyl acetateMaterials science

The invention relates to a method for preparing organic poly-zirconium precursor or silk-thrawn liquor thereof for zirconia fiber production by one-step solvent method. The method includes proportioning zirconium oxychloride octahydrate, ligand acetyl acetone, ethyl acetoacetate or alcohol ether, precipitation separation agent C1-C5 which is straight-chain diamine or branched-chaine diamine, triethanolamine, ornithine or ammonia gas, phase stabilizer which is yttrium, calcium, magnesium or cerium chloride and the like according a certain ratio, adding solvent C1-C4 alcohol or mixture solvent thereof to sufficiently react with stirring at the temperature of 0-50 DEG C, filtering to remove hydrochloride, subjecting the obtained solution to pressure reduction and concentration at the temperature of 20-50 DEG C to obtain organic poly-zirconium precursor or silk-thrawn liquor; and obtaining high-quality zirconia crystal fibers by centrifugal silk throwing and fiber thermal treatment. Compared with the conventional zirconia fiber preparation technology, the method for preparing organic poly-zirconium precursor has the advantages of simple process, low cost, high yield, environment-friendliness, and product obtained is high in quality and the like.

Owner:SHANDONG UNIV +1

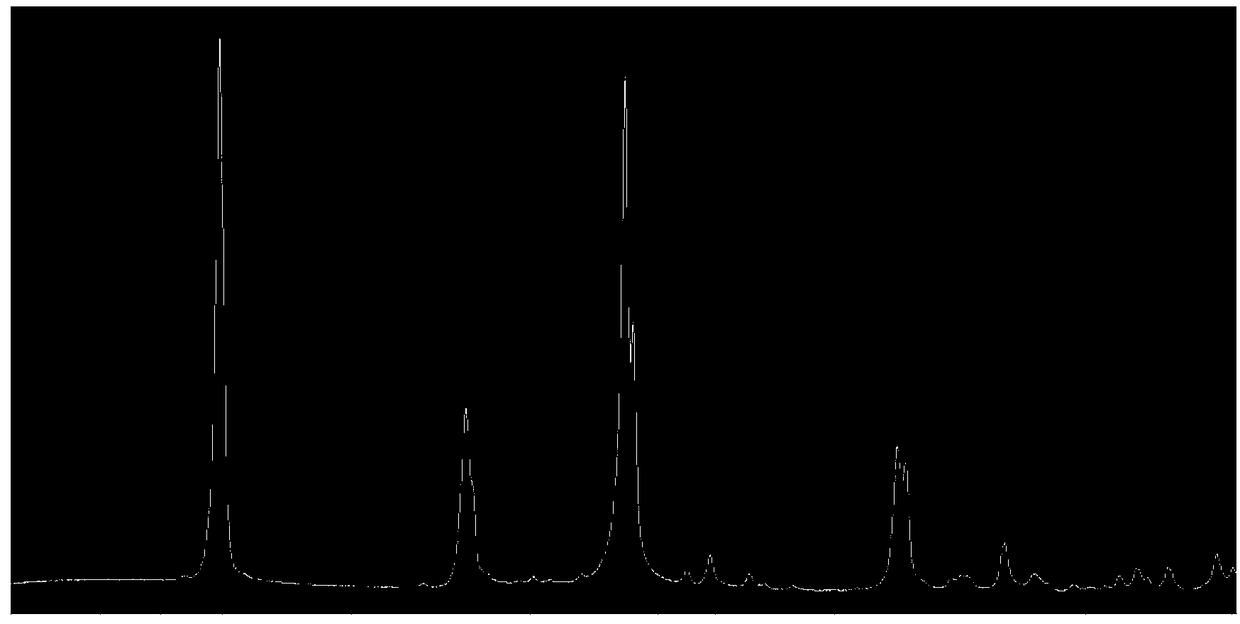

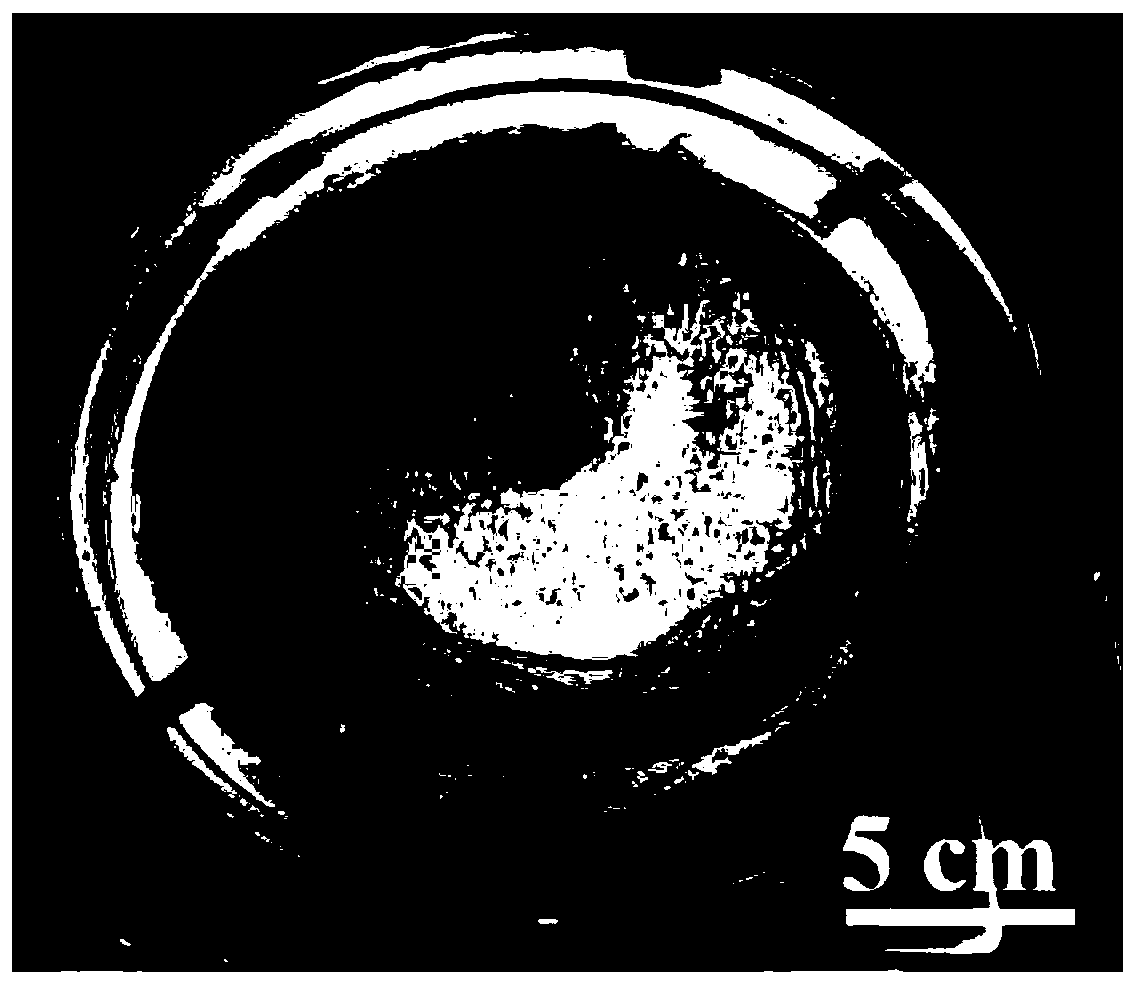

Application of zirconium dioxide microspheres prepared by using microchannel injection auxiliary method to adsorptive enrichment of organophosphorus pesticide

InactiveCN103084138ASimple processEasy to controlOther chemical processesMicroballoon preparationDesorptionMicrosphere

The invention discloses an application of zirconium dioxide microspheres prepared by using a microchannel injection auxiliary method to adsorptive enrichment of organophosphorus pesticide. According to the application, the zirconium dioxide microspheres are obtained by forming a support substance by taking a chitosan material as an intermediate product, taking zirconium oxychloride octahydrate, acetic acid and sodium hydroxide as raw materials and adopting a microchannel auxiliary method under the room temperature. Each zirconium dioxide microsphere is of a mesoporous structure and can be used for carrying out adsorptive enrichment on the organophosphorus pesticide within a shorter time and is free of secondary pollution; and the zirconium dioxide microspheres subjected to adsorption are easy to be successfully separated from a solution so as to carry out effective desorption on the pesticide, so that detection of pesticide residues in vegetables, such as brassicae chinensis and cucumbers are successfully achieved. The application disclosed by the invention has the advantages of capability of obtaining raw materials easily, simple process, environmental friendliness and low cost; and the zirconium dioxide microspheres are large in adsorbing capacity to multiple organophosphorus pesticides and good in separating effect and the like, not only can be used for environment detection of a trace amount of residues of organophosphorus pesticides of agricultural produces, but also can be used for adsorptive treatment to waste liquor of organophosphorus pesticides and accords with the demands of practical production.

Owner:HUAZHONG NORMAL UNIV

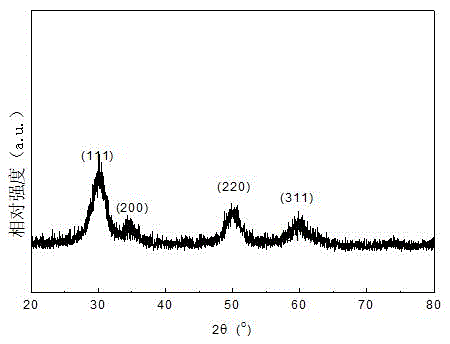

Preparation method for ivory color-imitating yttrium oxide and praseodymium oxide co-stabilized tetragonal zirconia nano ceramic powder

ActiveCN103553598ALarge specific surface areaLarge granularityYttriumZirconium oxychloride octahydrate

The invention provides a preparation method for ivory color-imitating yttrium oxide and praseodymium oxide co-stabilized tetragonal zirconia nano ceramic powder. The preparation method is characterized by comprising the following steps of (1) weighing zirconium oxychloride octahydrate barium hydroxide octahydrate, a praseodymium raw material and a yttrium raw material respectively according to stoichiometric ratio of various metal elements in (Pr6O11)x(Y2O3)y(ZrO2)1-6x-2y (wherein 0.0020 <= x+ y <= 0.1500,10<-6> <= x <= 0.0200), dissolving the praseodymium raw material and the yttrium raw material and transferring the praseodymium raw material and the yttrium raw material into a mixed solution of nitrate, and dissolving the zirconium oxychloride octahydrate in the mixed solution; (2) adding a soluble salt and an organic fuel into the mixed solution obtained by the step (1), heating to dissolve the soluble salt and the organic fuel, heating and concentrating the solution into a sticky state and adding the concentrated material into a heating furnace cavity at a temperature of 400-1,000 DEG C and igniting; and (3) washing, filtering and drying a product. The powder particles prepared by the invention are spheres which are uniform in size and good in dispersion. The particle size is 2-6 nm; and a specific surface area can reach 318 m<2>.g<-1>. The preparation method is simple in process, low in equipment requirements and short in synthesis time, can form the phase in one step; and is low in energy consumption and low in cost.

Owner:NANCHANG UNIV

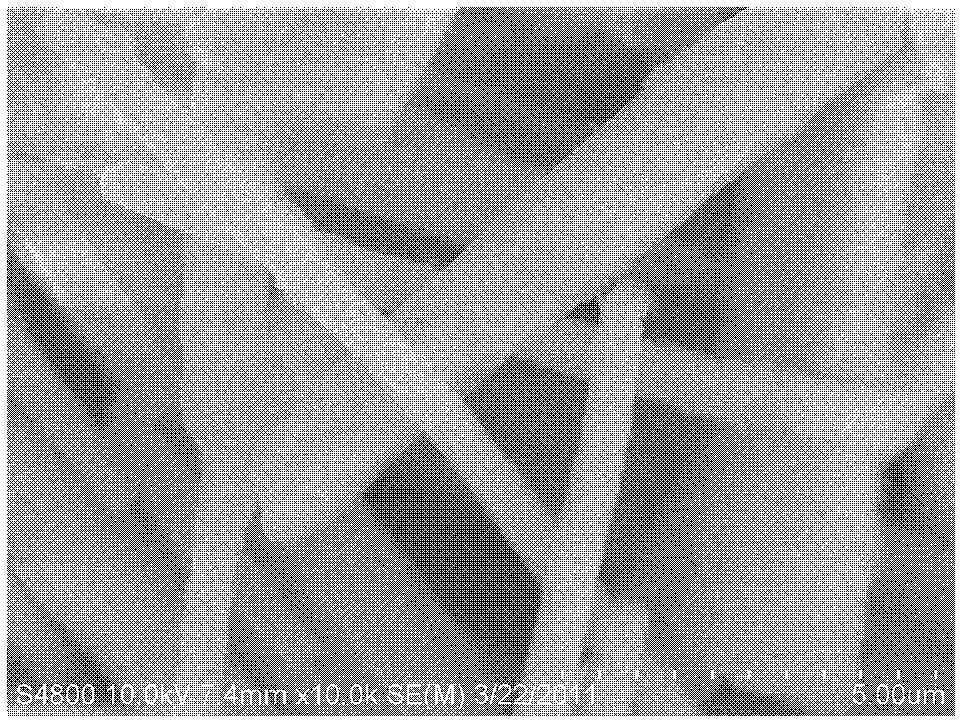

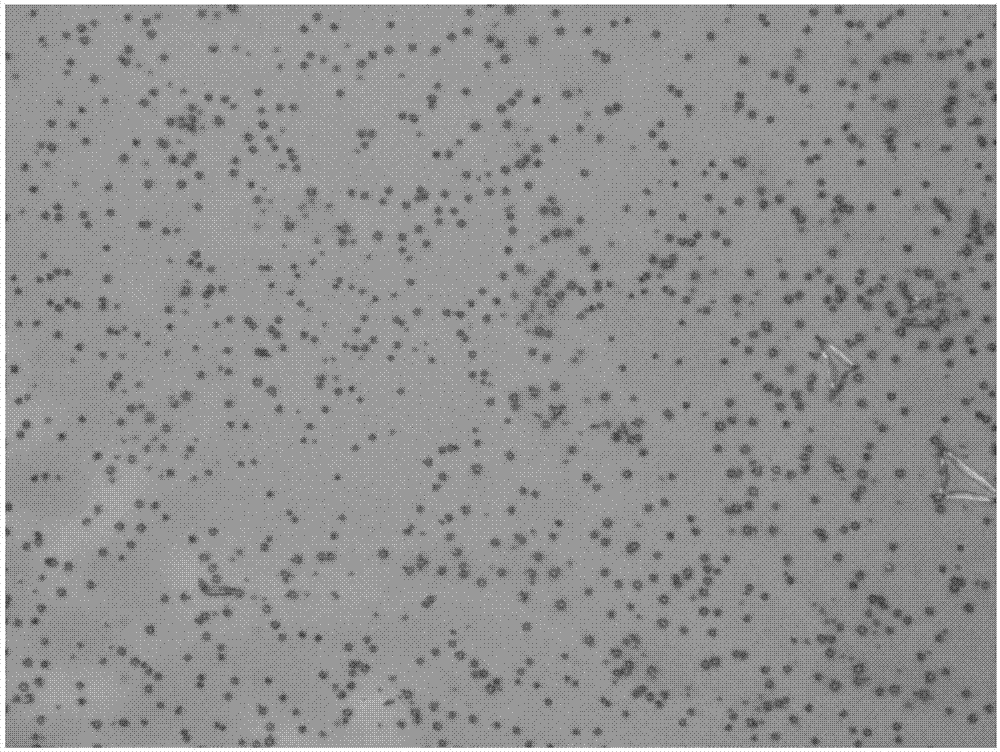

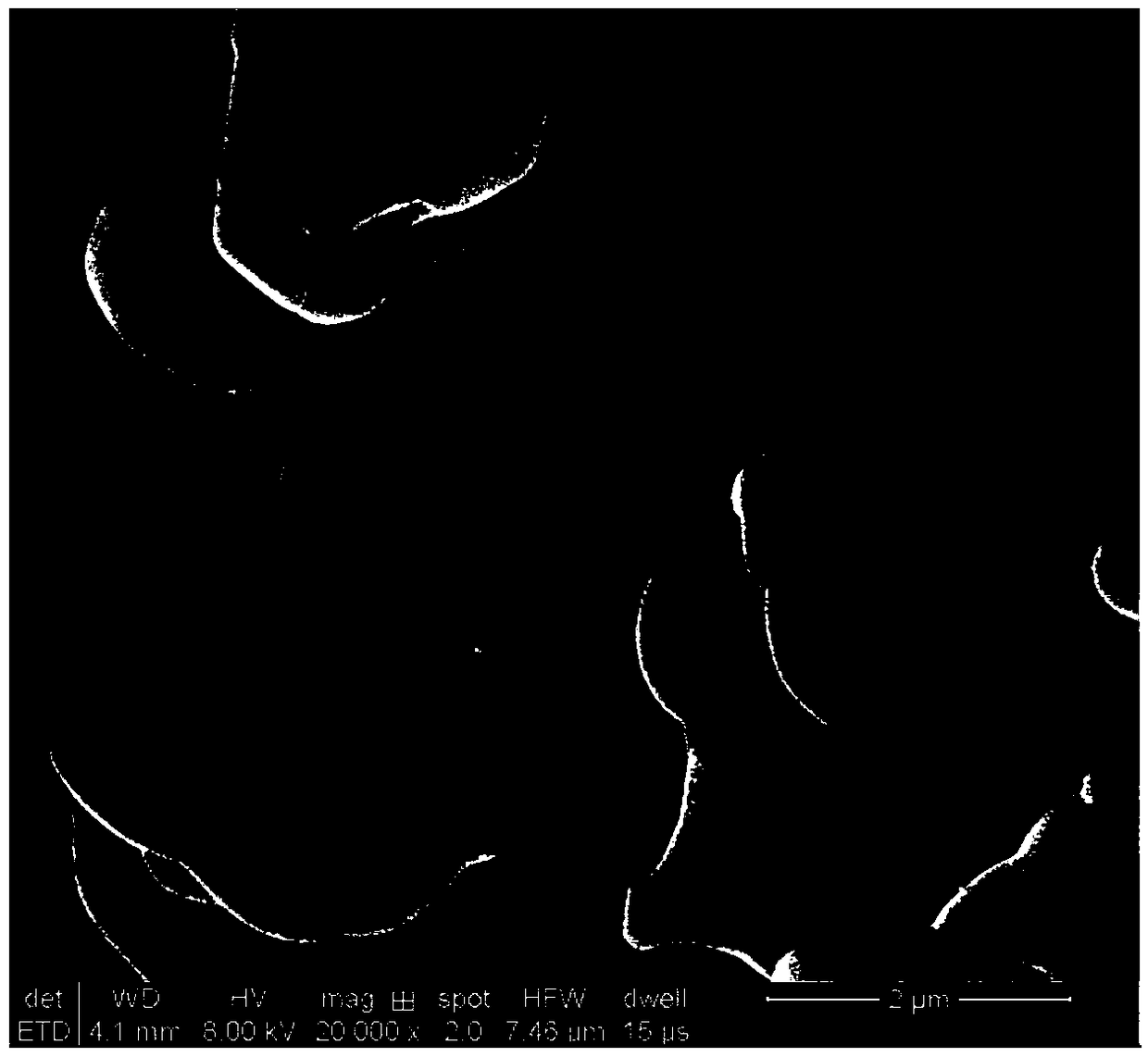

Rod-shaped zirconium phosphate and preparation method thereof

The invention relates to a rod-shaped zirconium phosphate and a preparation method thereof. The diameter of the rod-shaped zirconium phosphate is 0.4-1.0mum, and a length-diameter ratio is 5-20. The preparation method comprises the specific steps that: certain amounts of zirconium oxychloride octahydrate, oxalic acid, phosphoric acid and ethylenediamine are sequentially added in deionized water; a reaction is carried out under stirring; and pump-filtration, washing, and drying are carried out, such that the rod-shaped zirconium phosphate is obtained. a molar ratio of zirconium oxychloride octahydrate to oxalic acid to phosphoric acid to ethylenediamine is 1: a: 1: b. a corresponds to a molar ratio of oxalic acid, and is 3-5. b corresponds to a molar ratio of ethylenediamine, and is 3-5. a and b are integers or non-integers. The preparation method has the advantage of simple process, and uniform sizes of prepared rod-shaped zirconium phosphate. The rod-shaped zirconium phosphate can be applied in fields such that catalysis, ion exchange, and the like, and can be used as an antibacterial agent carrier.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

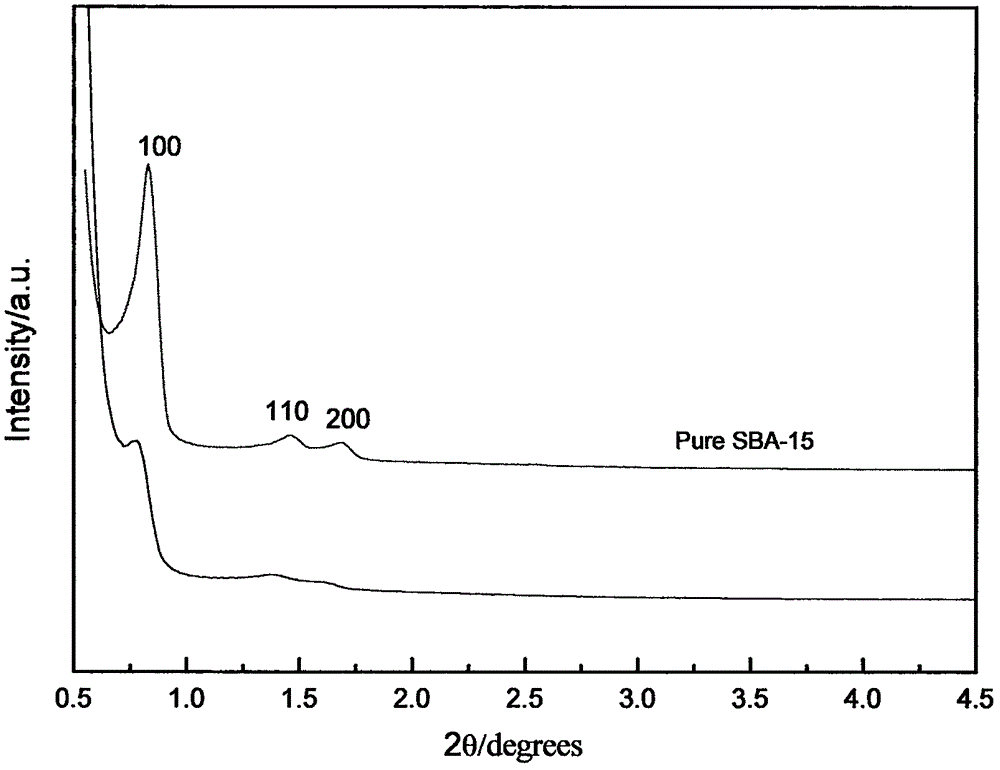

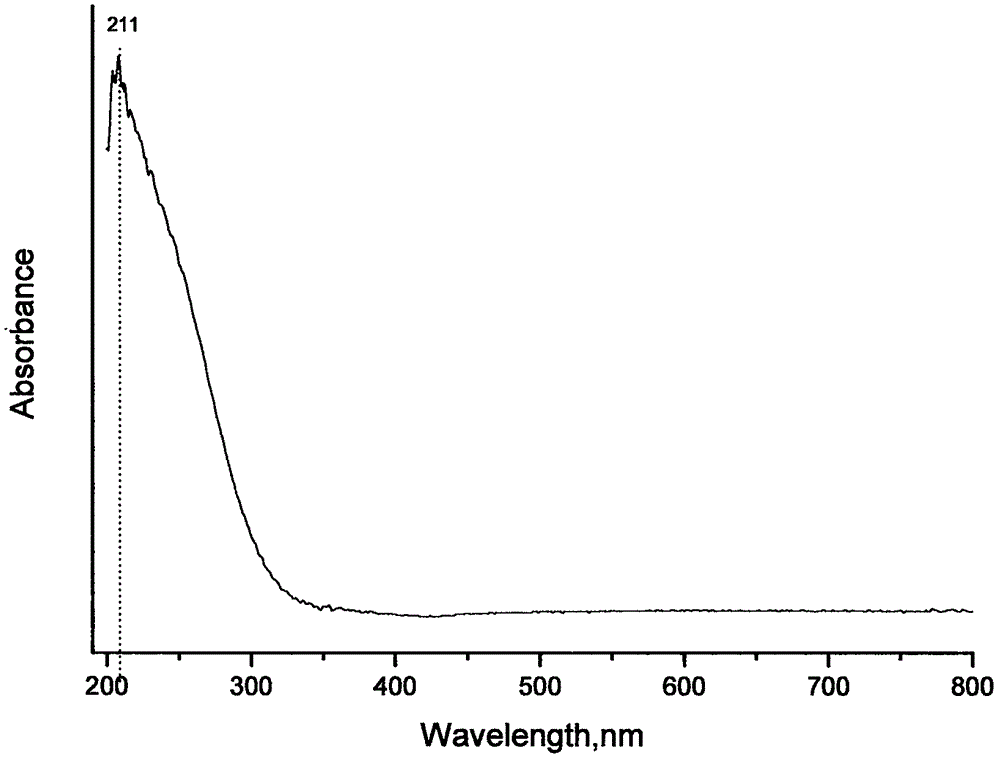

Sn-Zr/SBA-15 mesoporous molecular sieve catalyst, and preparation method and application thereof

InactiveCN106582776AImprove water resistanceImprove thermal stabilityOrganic chemistryMolecular sieve catalystsPolyethylene oxideSolvent

The invention discloses a Sn-Zr / SBA-15 mesoporous molecular sieve catalyst, and a preparation method and application thereof. The Sn-Zr / SBA-15 mesoporous molecular sieve catalyst is prepared from a polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer, stannic chloride pentahydrate, zirconium oxychloride octahydrate and ethyl orthosilicate through hydrothermal crystallization consisting of successive step-by-step hydrolysis and mixing under a weakly acidic condition. The prepared Sn-Zr / SBA-15 mesoporous molecular sieve catalyst is used for catalyzing alkylation of phenol and formaldehyde for synthesis of bisphenol F and has high catalytic activity. Sn is effectively doped into SBA-15 without destroying the mesoporous structure of the SBA-15; SnO2 aggregate is prevented from formation and blocking of the channels of the molecular sieve; a weakly acidic aqueous solution solvent is used for synthesis, so the method is green, environment-friendly and low in preparation cost; and the catalyst is easy to separate, recover and reuse.

Owner:XIANGTAN UNIV

Inkjet printing ink and method for preparing metal oxide film from inkjet printing ink

ActiveCN107955459ALimit migrationInhibitory loop effectDuplicating/marking methodsInksEngineeringSolvent

The invention belongs to the field of printing electronics and discloses inkjet printing ink and a method for preparing a metal oxide film from the inkjet printing ink. The inkjet printing ink is prepared from a glycol solvent, 0.3-5wt.% polyacrylamide and 0.1-0.6M zirconium oxychloride octahydrate. The method comprises the following steps: pre-treating a substrate, then setting the temperature ofa base plate of an inkjet printer to be 25-30 DEG C, the voltage of a nozzle to be 30-40V, the temperature of the nozzle to be 55-65 DEG C and the ink droplet interval to be 30-45mu m, and performinginkjet printing on the substrate; after the printing is completed, raising the temperature of the base plate to 40-60 DEG C, and performing standing for 10-15min; and after a liquid membrane completely gels, performing heating treatment at the temperature of 250-500 DEG C so as to obtain a zirconium oxide film. The added water-soluble polymer polyacrylamide containing polar groups has chelation on metal ions, enables the system to quickly gel after temperature rise, limits solute-solvent migration and inhibits the coffee-ring stain effect.

Owner:SOUTH CHINA UNIV OF TECH

Zirconium oxide inkjet printing ink as well as preparation method and application thereof

The invention belongs to the technical field of printed electronics, and discloses zirconium oxide inkjet printing ink as well as a preparation method and application thereof. The zirconium oxide inkjet printing ink comprises zirconium oxychloride octahydrate, polyethylene glycol, ethylene glycol and deionized water. The zirconium oxide inkjet printing ink is added into an inkjet printer, ink jetprinting is performed on a 50-60 DEG C glass substrate to obtain a film, and then the film is heated to 300-400 DEG C for heat treatment for 1-2 hours to obtain a porous zirconium oxide film. According to the invention, through selection and collocation of a solvent and a polymer, the zirconium oxide inkjet printing ink has proper viscosity and surface tension and can better meet inkjet printing requirements.

Owner:SOUTH CHINA UNIV OF TECH

Large surface area porous ZrO2 mesoscopic crystal

ActiveCN106622199AHigh mesogenic yieldGood monodispersityCatalyst carriersHydrogenMaterials preparationAmmonium bromide

The invention discloses a large surface area porous ZrO2 mesoscopic crystal, and a preparation method and an application thereof, and belongs to the metal oxide function material preparation field. The preparation method of the large surface area porous ZrO2 mesoscopic crystal includes: dissolving cetyl trimethyl ammonium bromide, zirconium oxychloride octahydrate and urea in water in proportion to obtain a mixed solution; keeping hydrothermal reaction for 3-48h at 130-200 DEG C to obtain the ZrO2 mesoscopic crystal. The preparation method of the large surface area porous ZrO2 mesoscopic crystal is simple and easy to implement, low in cost, and high in mesoscopic crystal yield, and prepares the ZrO2 mesoscopic crystal which is good in monodispersion, in granule shape, and porous inside, has the BET specific surface area up to 126-15m<2> / g, and is an excellent water-gas shift catalyst carrier.

Owner:MINJIANG UNIV

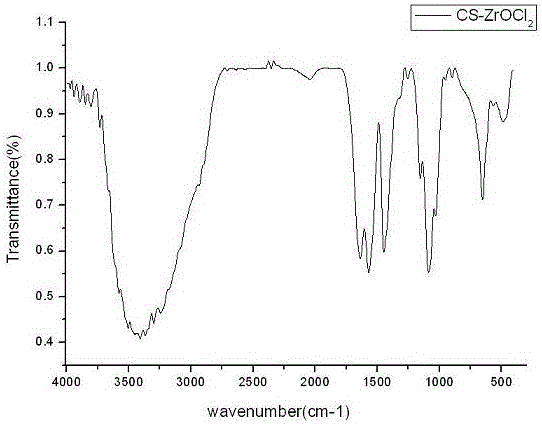

Zr/chitosan composite adsorbent for adsorbing Pb<2+> in water body and preparation method thereof

InactiveCN106378118ASimple preparation processWide variety of sourcesOther chemical processesWater contaminantsSorbentColloid

The invention discloses a preparation method of a Zr / chitosan composite adsorbent for adsorbing Pb<2+> in a water body. The method comprises the following steps: (1) dissolving chitosan in an acetic acid solution, stirring, and carrying out ultrasonic treatment to obtain a chitosan colloid; (2) dissolving zirconium oxychloride octahydrate in deionized water to prepare a zirconium oxychloride solution; (3) mixing the chitosan colloid with the zirconium oxychloride solution, stirring, and carrying out ultrasonic treatment to obtain a uniformly dispersed mixed solution; and (4) finally, adding aldehydes into the mixed solution, stirring, drying and grinding to obtain the Zr / chitosan composite adsorbent. The preparation method disclosed by the invention has the advantages of wide raw material sources, low cost and simple preparation technique, and can be easily industrialized and popularized. The composite adsorbent has favorable adsorption effects on Pb<2+> in the water body.

Owner:NANCHANG HANGKONG UNIVERSITY

Platinum-ruthenium bimetal loaded zirconia nanotube composite material and preparation method thereof and application in low-temperature thermocatalytic treatment of toluene

ActiveCN110694619ALarge specific surface areaOptimal Control StructureGas treatmentDispersed particle separationEtchingBimetallic nanoparticle

The invention discloses a platinum-ruthenium bimetal loaded zirconia nanotube composite material and a preparation method thereof and application in a thermocatalytic treatment of toluene. A SBA-15-OHmolecular sieve is taken as a template, zirconium oxychloride octahydrate is taken as a metal precursor, and a zirconia nanotube material is prepared through aging, calcination and etching; a certainamount of zirconia is taken as a carrier, and a certain amount of metal precursors such as chloroplatinic acid and ruthenium trichloride are added, and through ultrasonic stirring, a solvent is stirred for thermal evaporation and hydrogen reduction calcination is carried out to obtain a certain proportion of the platinum-ruthenium bimetal loaded zirconia nanotube composite material. The platinum-ruthenium bimetal loaded zirconia nanotube composite material synthesized through a series of steps has a good thermal catalytic effect on toluene gas, complete catalysis of low-concentration tolueneat a lower temperature can be achieved, and great research significance and certain application prospects for solving the toluene pollution gas in the air environment are achieved

Owner:苏州远尚环保有限公司

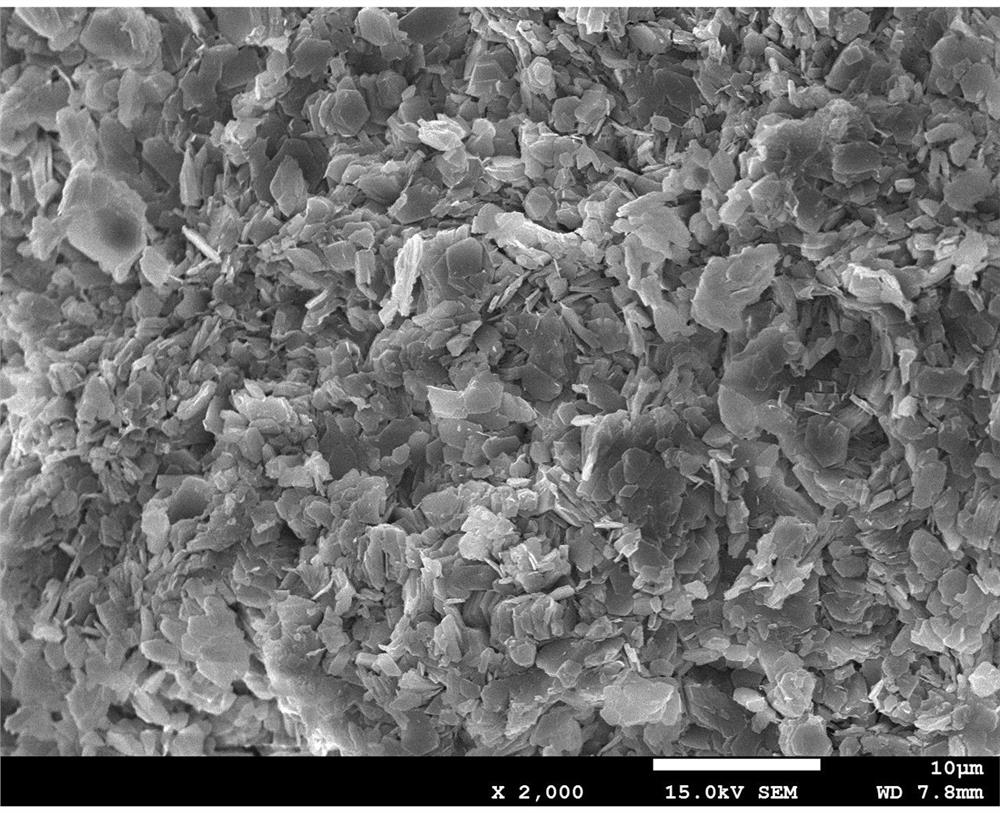

Micron-scale lamellar zirconium phosphate and preparation method thereof

InactiveCN108910854AHighly corrosiveImprove permeabilityPhosphorus compoundsHydrofluoric acidMicron scale

The invention relates to the technical field of zirconium phosphate and preparation thereof, particularly to micron-scale lamellar zirconium phosphate and a preparation method thereof, wherein the zirconium phosphate is alpha-Zr(HPO4)2.H2O, and the average particle size of the alpha-Zr(HPO4)2.H2O is 1.0-2.0 [mu]m. The preparation method comprises: adding zirconium oxychloride octahydrate to deionized water, stirring, adding a fluoride salt, stirring, adding phosphoric acid or / and phosphate, stirring, carrying out a reaction, carrying out thermal insulation standing, carrying out suction filtering, washing, and drying to obtain the micron-scale lamellar zirconium phosphate. According to the present invention, the disadvantages of use of a lot of concentrated phosphoric acid or strong corrosive hydrofluoric acid, high reaction temperature, long reaction time, harsh reaction conditions and the like of the zirconium phosphate preparation technology in the prior art are solved, and the method using the fluoride salt as the reaction catalyst is provided, and has advantages of low reaction temperature, short time, short cycle and wide application range.

Owner:绵竹耀隆化工有限公司

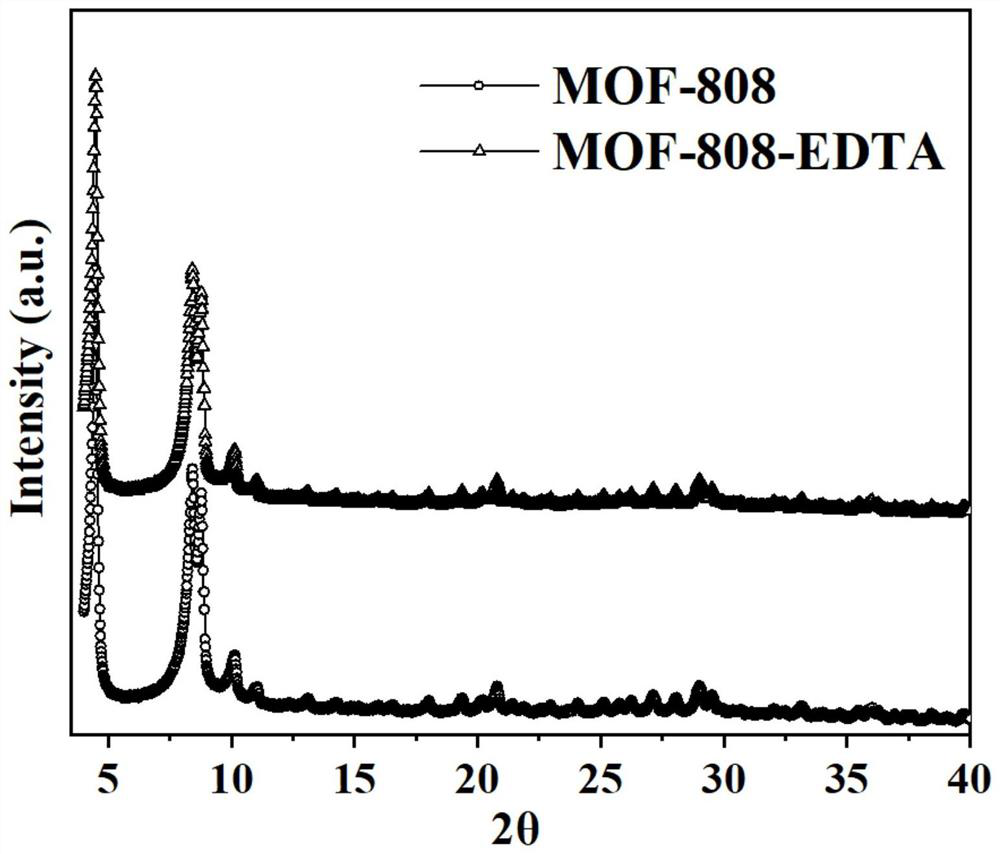

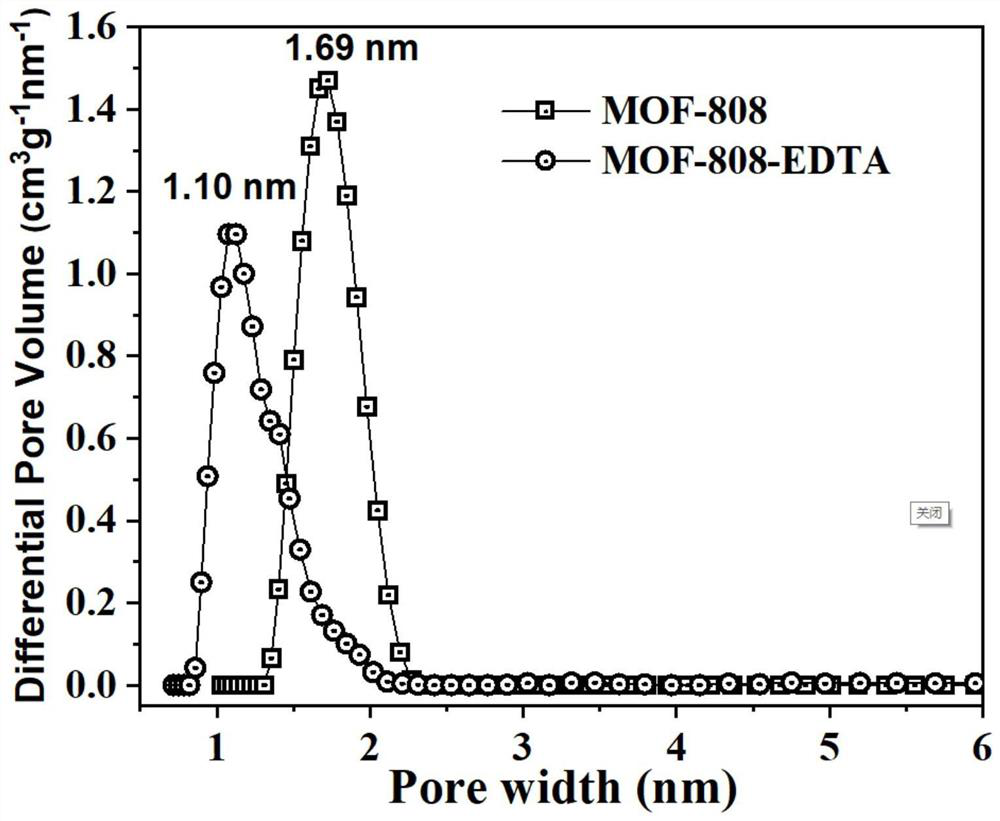

Porous material adsorbent as well as preparation method and application thereof

PendingCN113385144AEfficient removalEfficient selective adsorption capacityOther chemical processesWater contaminantsSorbentPerfluorocaprylic acid

The invention discloses a porous material adsorbent and a preparation method and application thereof. The preparation method comprises the steps of dissolving 1,3,5-benzenetricarboxylic acid and zirconium oxychloride octahydrate in a mixed solvent of formic acid and N,N-dimethylformamide (DMF), conducting heating to obtain white precipitate, and conducting washing to obtain a porous material; and dissolving the porous material into an ethylene diamine tetraacetic acid (EDTA) disodium solution, and conducting heating, filtering and washing to obtain the EDTA modified MOF-808 with the carboxyl functional group. The MOF-808-EDTA porous adsorbent disclosed by the invention can be used for efficiently removing perfluoroalkyl substances in water, wherein the perfluoroalkyl substances mainly comprise perfluorooctanoic acid (PFOA) and perfluorooctane sulfonic acid (PFOS). Meanwhile, heavy metal ion pollutants, mainly heavy metal ions such as Hg<2+>, As<2+>, Cd<2+> and Pb<2+>, in water can be efficiently removed, so that the water quality of drinking water meets the set standard and requirement of domestic drinking water.

Owner:XI AN JIAOTONG UNIV

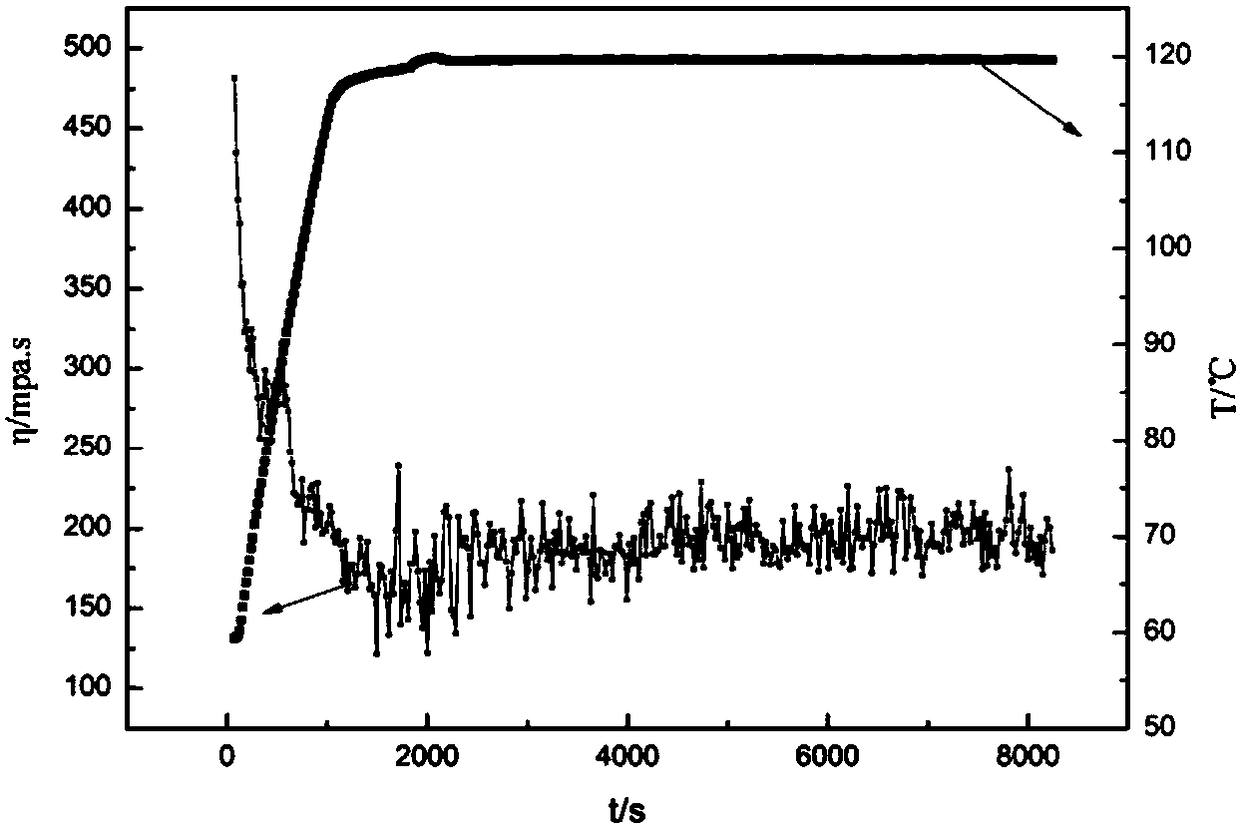

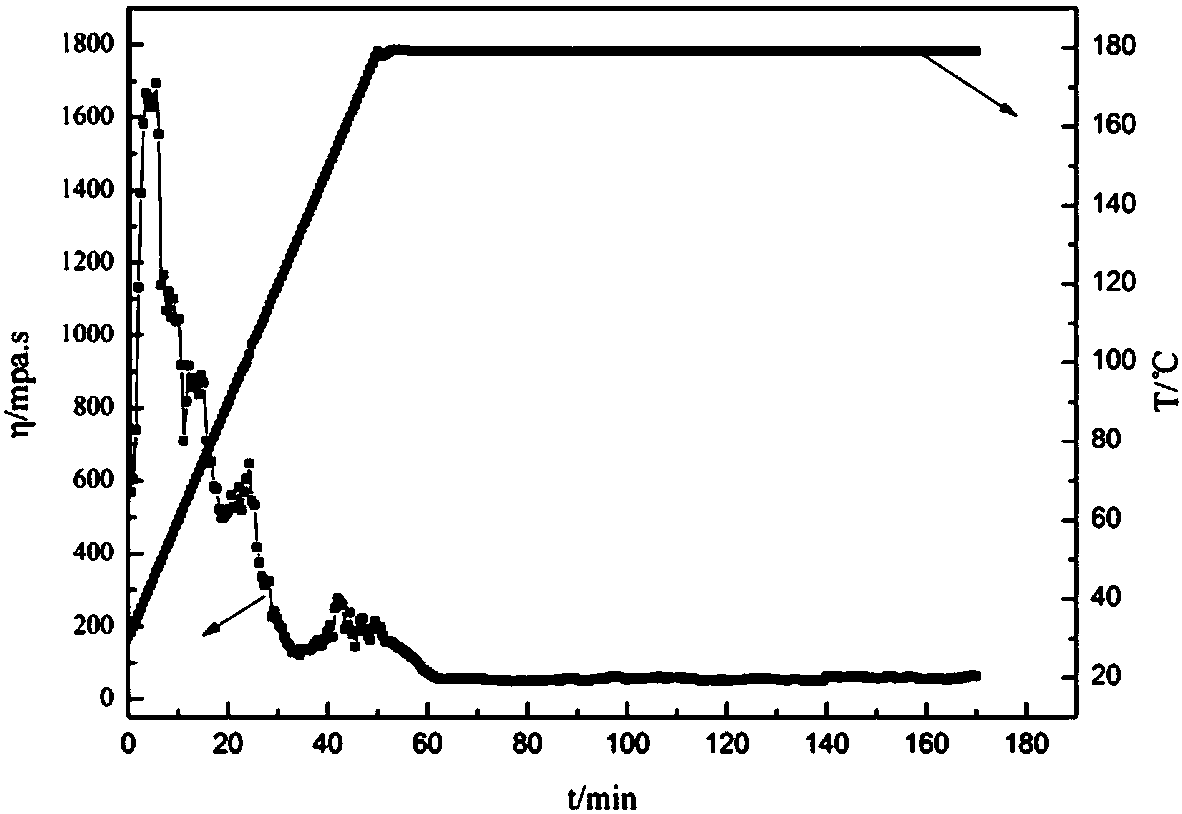

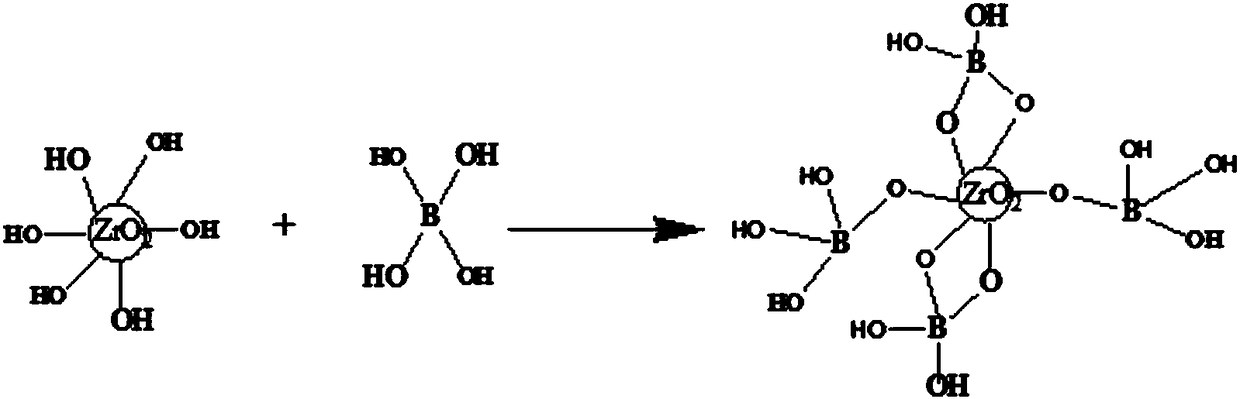

High temperature resistant nanometer zirconium boron cross-linking agent and preparation method thereof

ActiveCN108485636AEasy to operateHarm reductionOrganic chemistryDrilling compositionCross-linkGlycerol

The invention discloses a high temperature resistant nanometer zirconium boron cross-linking agent and a preparation method thereof. The preparation method of the cross-linking agent is characterizedin that (1) a lauryl sodium sulfate solution and a zirconium oxychloride octahydrate solution are respectively prepared; (2) the zirconium oxychloride octahydrate solution is dropwise added into the lauryl sodium sulfate solution; then, cyclohexane is added; next, the mixed solution is put into a reaction kettle; a sodium hydroxide solution is added; reaction is performed for 24h to obtain a nanometer zirconium dioxide emulsion; (3) glycerol, borax, beta-diketone and triethanolamine are sequentially added into the nanometer zirconium dioxide emulsion; reaction is performed under the conditionthat the pH value is 10, so that the nanometer zirconium boron cross-linking agent is prepared. The nanometer zirconium boron cross-linking agent prepared by the method has excellent temperature resistant and shearing resistant performance; the cost is low; the gel breaking and flowback are easy.

Owner:SOUTHWEST PETROLEUM UNIV

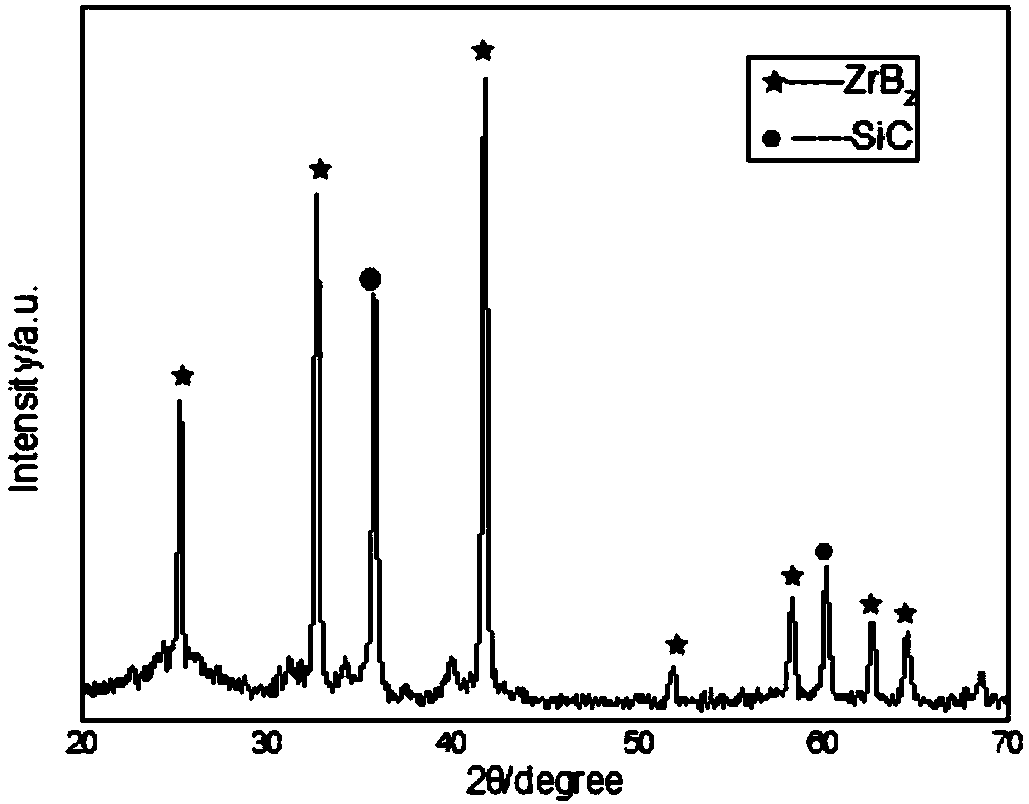

Precursor conversion method preparation process of ZrB2-SiC ceramic composite powder

The invention discloses a precursor conversion method preparation process of ZrB2-SiC ceramic composite powder. According to the process, zirconium oxychloride octahydrate, boracic acid, ethyl orthosilicate and glucose are used as starting materials; absolute ethyl alcohol and deionized water are used as solvents; the mass ratio of raw material substances of the boracic acid to the zirconium oxychloride octahydrate to the ethyl orthosilicate is 100:(9 to 20):(18 to 60); the carbon sources are excessive; a zirconium precursor solution, a boracic acid solution, an ethyl orthosilicate solution and a glucose solution are respectively prepared; all solutions are uniformly mixed to obtain a boron silicon zirconium precursor solution; after the boron silicon zirconium precursor solution is dried,heat treatment is performed for 1 to 2h at 1450 to 1600 DEG C under the argon gas atmosphere protection; the ZrB2-SiC ceramic powder is obtained. The preparation process has the characteristics of simple process, short period, low energy consumption and low cost; the obtained ceramic phase has uniform granularity and high activity; no impurity phases exist.

Owner:SHAANXI UNIV OF SCI & TECH

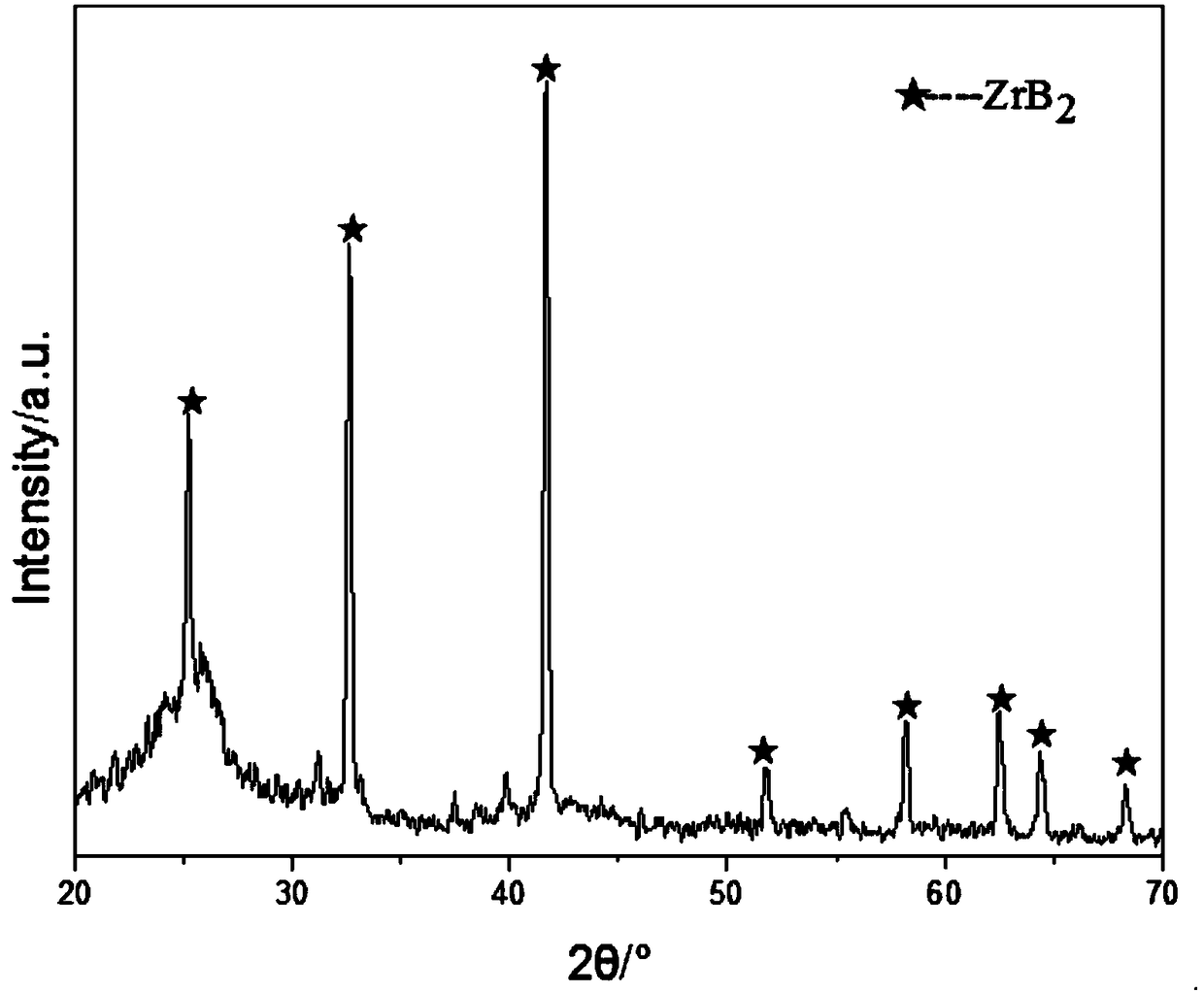

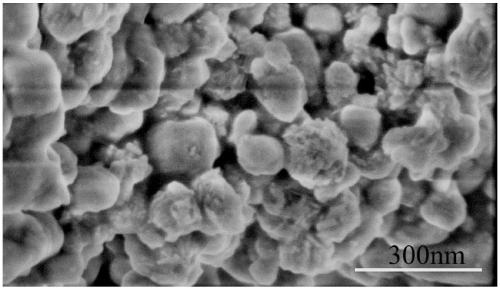

Technology for preparing spherical ultrafine zirconium boride powder by adopting liquid phase method and prepared zirconium boride powder

The invention provides a technology for preparing spherical ultrafine zirconium boride powder by adopting a liquid phase method. The technology is specifically charaterized in that ultrafine zirconiumboride powder is prepared through a sol-gel and heat treatment process, and the zirconium boride powder with controllable size can be obtained by regulating and controlling the process parameters inthe method. The technology comprises the following steps that zirconium oxychloride octahydrate, boric acid and glucose serve as starting materials, absolute ethyl alcohol and deionized water serve assolvents, a zirconium precursor solution, a boric acid solution and a glucose solution are prepared separately and are uniformly mixed so as to obtain boron-zirconium precursor sol, and in the process, acetylacetone and hydrogen peroxide are added so as to promote the formation of the precursor sol; and then drying is carried out, and calcining is carried out at high temperature in an argon atmosphere so as to prepare the ZrB2 ceramic powder with high purity and fine and uniform particle size. The technology is simple, the reaction raw material cost is low, the reaction process is easy to control, the synthesis temperature is low, and the prepared powder is high in purity, uniform and fine in particle size and less in agglomeration and can conveniently become a preferred material of a ceramic composite material and a ceramic coating.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of bionic high-strength high-flexibility nano composite fiber

ActiveCN110396731ASimple processRaw materials are easy to obtainInorganic material artificial filamentsWet spinning methodsFiberNanoscopic scale

Owner:BEIHANG UNIV

Preparation method of high-strength high-toughness zirconia nano-fiber

ActiveCN109576820ANo pollution in the processSimple processInorganic material artificial filamentsFiberAir atmosphere

The invention belongs to the technical field of light-weight high-strength nano-material preparation, and relates to a preparation method of a high-strength high-toughness zirconia nano-fiber material. According to the method, an ultrasonic-assisted liquid-phase reaction method is utilized, zirconium oxychloride octahydrate, polyvinylpyrrolidone and the like are adopted as raw materials, and the high-strength high-toughness zirconia nano-fiber material is prepared controllably. The method particularly comprises the steps that 1, an alcohol-water solution is prepared at room temperature, an appropriate amount of polyvinylpyrrolidone and zirconium oxychloride octahydrate are added, stirring is conducted to achieve uniform dispersion; 2, the mixed solution is subjected to ultrasonic treatmentfor 30 min, then constant temperature of 20-60 DEG C is kept, under the continuous stirring conduction, a reaction conducted for 2-6 hours, natural cooling and centrifugal washing are conducted, andfreeze-drying is conducted to obtain powder products; 3, powder products are placed in a muffle furnace, under the air atmosphere, calcining is conducted at 100-700 DEG C for 2 h, and finally a high-strength high-toughness zirconia nano-fiber material is obtained.

Owner:BEIHANG UNIV

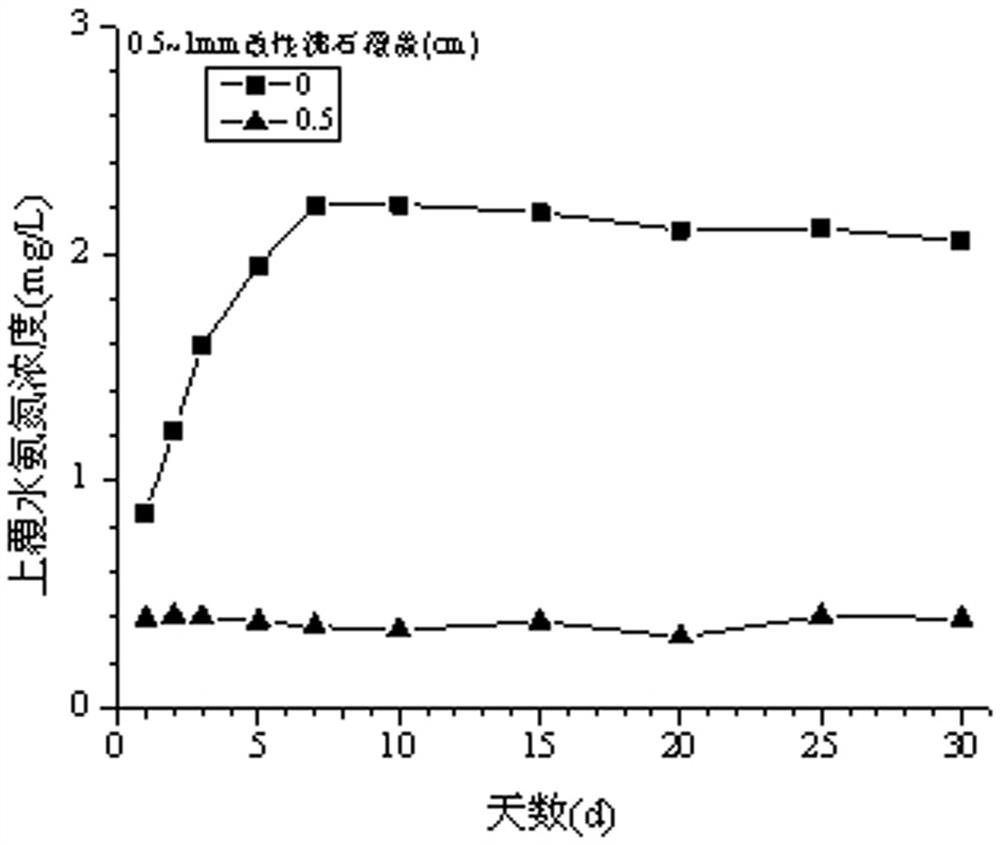

Aluminum-zirconium modified zeolite, preparation method and method for controlling release of nitrogen and phosphorus in polluted bottom mud

ActiveCN111871365ALow costSimple processSludge treatmentOther chemical processesWater chlorinationPhysical chemistry

The invention relates to and provides aluminum-zirconium modified zeolite, a preparation method and a method for controlling release of nitrogen and phosphorus in polluted bottom mud . According to the technical scheme, the aluminum-zirconium modified zeolite is characterized by being prepared by combining natural zeolite with anhydrous aluminum trichloride and zirconium oxychloride octahydrate. The aluminum-zirconium modified zeolite comprises the following components in parts by weight: 5 to 15 parts of natural zeolite; 1 to 5 parts of anhydrous aluminum trichloride; 0.4 to 1.6 parts of zirconium oxychloride octahydrate. The aluminum-zirconium modified zeolite perferably comprises the following components in parts by weight: 10 parts of natural zeolite; 3 parts of anhydrous aluminum trichloride; and 1 part of zirconium oxychloride octahydrate. The product is suitable for the field of water environment treatment.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Precursor-conversion-method preparation process of self-dispersion superfine ZrC-SiC ceramic composite powder

The invention discloses a precursor-conversion-method preparation process of self-dispersion superfine ZrC-SiC ceramic composite powder. Zirconium oxychloride octahydrate and tetraethoxysilane are used as a zirconium source and a silicon source; glucose is adopted as a carbon source and a carbonization product dispersing agent in a pyrolysis process, hydrogen peroxide is adopted as a hydrolysis accelerant and absolute ethyl alcohol and deionized water are adopted as composite solvents, and the process comprises respectively preparing a zirconium precursor solution, a tetraethoxysilane solutionand a glucose solution and uniformly mixing the solutions to obtain a silicon-zirconium precursor solution; and drying the silicon-zirconium precursor solution, and carrying out heat treatment at 1450-1600 DEG C for 1-2 hours under argon atmosphere protection to obtain the ZrC-SiC ceramic powder with favorable dispersity, a narrow particle size distribution range and an average particle size of less than 100 nm. The raw materials are safe and non-toxic, the cost is low, the process is simple, the reaction process is easy to control, the synthesis temperature is low, and the prepared ceramic powder is fine and uniform in particle size, good in dispersity and suitable for large-scale production.

Owner:SHAANXI UNIV OF SCI & TECH

Method for improving ink deposition uniformity of inkjet printing

InactiveCN109130493ASolve the problem of uneven depositionShorten the timeInksPrintingEtherEngineering

The invention belongs to the field of printing electronics, relates to the inkjet printing preparation process of an oxide film, and particularly relates to a method for improving ink deposition uniformity of inkjet printing. The method comprises the following steps: a printer substrate is kept at 50-60 DEG C, the ink droplet speed is 10m / s, the nozzles are not heated, the ink droplet spacing is 30-40 mum, multi-nozzle inkjet printing is performed on the substrate, and the number of the nozzles is 3-4; annealing is performed for 1h after printing; the ink solvent used in inkjet printing is ethylene glycol and ethylene glycol methyl ether mixed in the volume ratio of 1 / 2-2 / 1, and the ink contains polyvinylpyrrolidone equivalent to 3-5% by mass of the solvent and zirconium oxychloride octahydrate with the concentration of 0.1-1.0 M. Compared with the conventional gel template method, the problem of non-uniform deposition of the non-Newtonian fluid ink in the quick drying printing processcan be solved through simple improvement of the printer parameters.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method and application of sulfur-doped g-C3N4/alpha-ZrP-carbonized ZIF-8 positive electrode material

InactiveCN112201790AImprove conductivityEasy to fixPositive electrodesLi-accumulatorsO-Phosphoric AcidElectrical battery

The invention belongs to the technical field of lithium-sulfur batteries, and particularly relates to a preparation method and application of a sulfur-doped g-C3N4 / alpha-ZrP-carbonized ZIF-8 positiveelectrode material. The preparation method comprises the following steps: firstly, preparing mesoporous g-C3N4 by taking SBA-15 as a template agent and melamine and urea as raw materials; and using zinc nitrate, zirconium oxychloride octahydrate, 2-methylimidazole and phosphoric acid as raw materials to load carbonized ZIF-8 and alpha-ZrP nanosheets on g-C3N4, and finally doping elemental sulfur to prepare the positive electrode material. According to the prepared positive electrode material, the capacity of the lithium-sulfur battery is improved, large volume expansion of the elemental sulfurpositive electrode is avoided, and the shuttle effect caused by long-chain polysulfide is reduced.

Owner:程信强

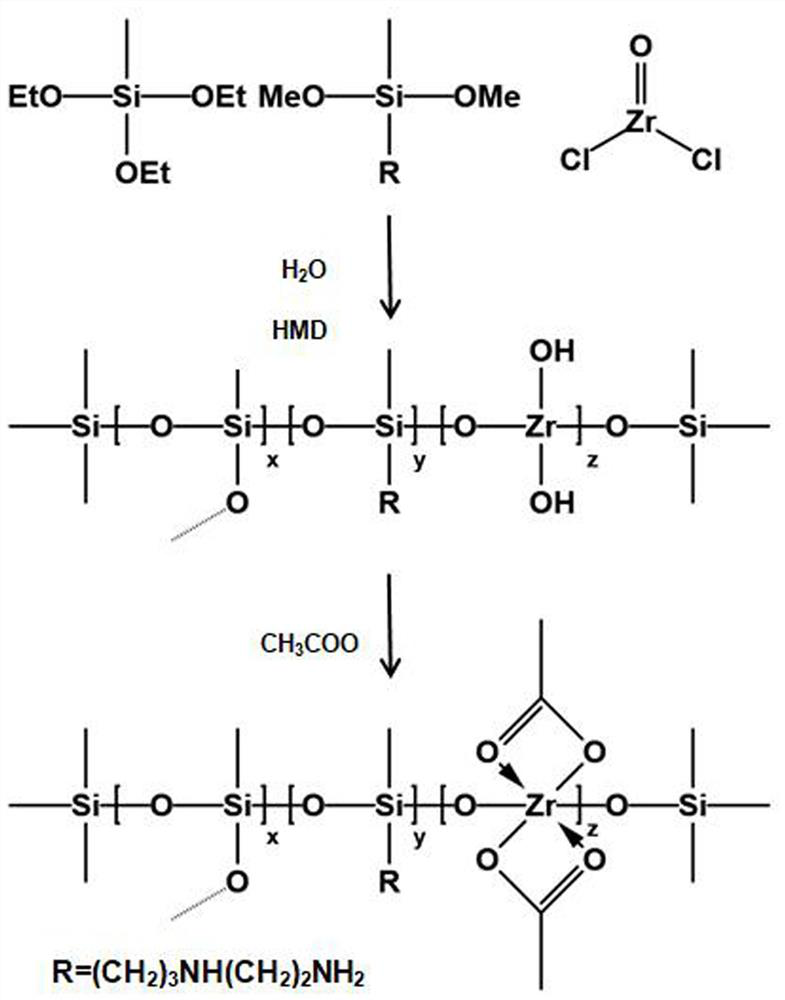

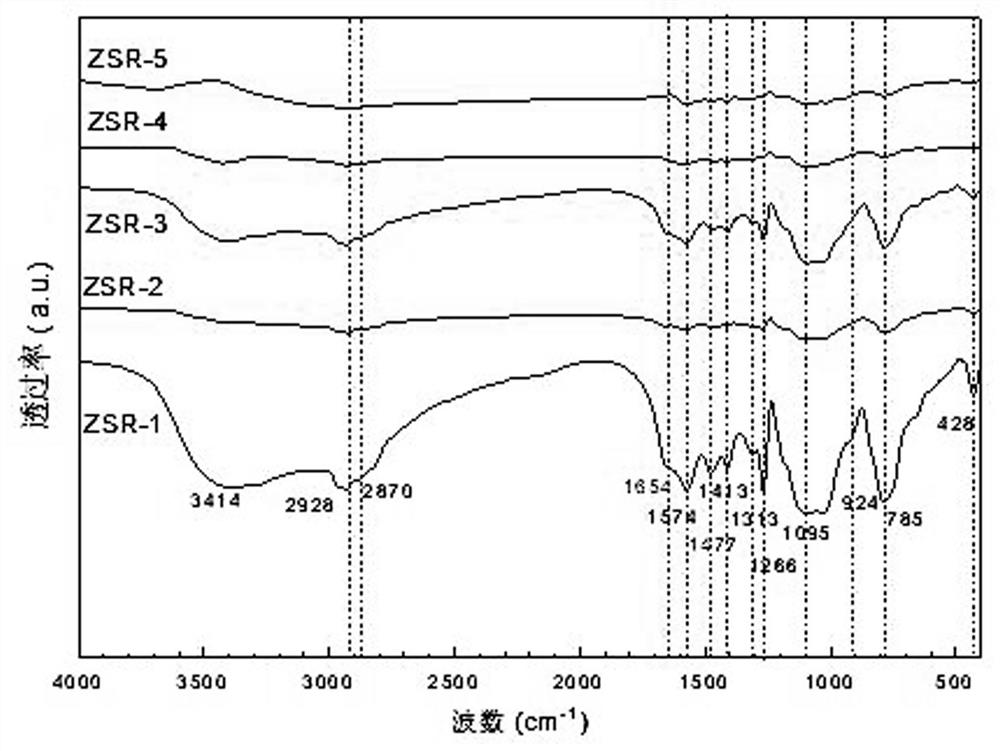

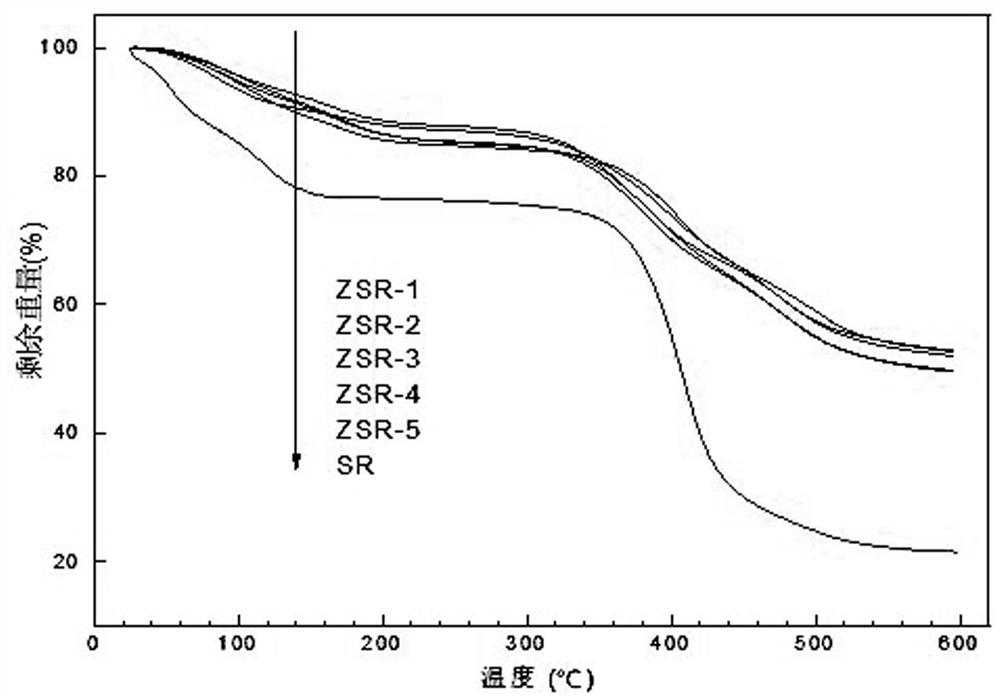

Zirconium modified silicon resin impregnating compound as well as preparation method and application thereof

The invention belongs to the technical field of sizing agents, and particularly relates to a zirconium modified silicon resin impregnating compound as well as a preparation method and application thereof. The invention relates to a zirconium modified silicon resin impregnating compound which comprises the following components: zirconium oxychloride octahydrate (ZrOCl2. 8H2O), silicate ester, amino silane, organic acid and an end-capping reagent, the preparation method comprises the following steps: carrying out hydrolysis-copolymerization reaction on zirconium oxychloride octahydrate (ZrOCl2. 8H2O), silicate ester and amino silane, and adding organic acid and an end-capping reagent to finally obtain the zirconium modified silicon resin impregnating compound. The mechanical property test result of the basalt fiber single yarn shows that after heat treatment at 300 DEG C, the breaking strength of the ZRBF-2 group fiber is 376 N, and the breaking strength retention rate is 86.3%; the breaking strength of the BF fiber which is not subjected to infiltration treatment is 287.8 N and is far lower than that of ZRBF-2, so that the zirconium modified silicon resin impregnating compound can effectively improve the temperature resistance of the basalt fiber.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com