Application of zirconium dioxide microspheres prepared by using microchannel injection auxiliary method to adsorptive enrichment of organophosphorus pesticide

A technology of organophosphorus pesticides and zirconia, which is applied in the direction of zirconia, microsphere preparation, microcapsule preparation, etc., can solve the problem of complex preparation process of magnetic materials, the effective adsorption and removal of high-concentration organophosphorus pesticide pollutants, and the adsorption capacity Not very strong and other problems, to achieve the effect of simple and easy control of the process, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

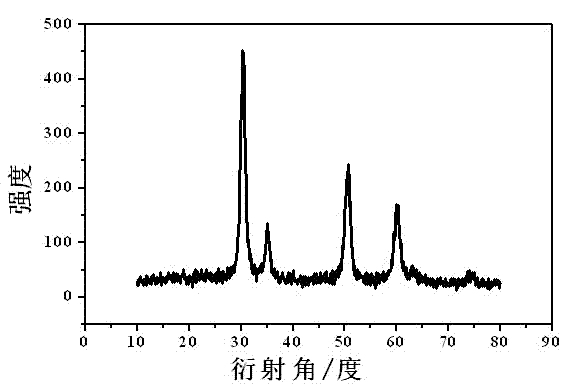

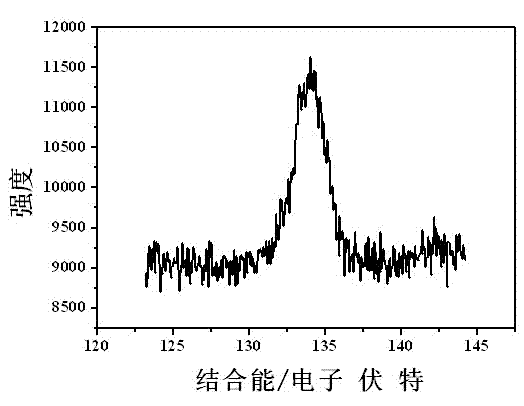

[0029] Preparation of Zirconium Dioxide Microspheres

[0030] The preparation steps are as follows:

[0031] 1) Add 3.0 grams of chitosan to 100 mL of acetic acid aqueous solution with a volume concentration of 3%, and form a homogeneous solution under magnetic stirring; add 0.3 g of zirconium oxychloride octahydrate solid to chitosan under magnetic stirring In the acetic acid solution, continue magnetic stirring to mix into a homogeneous solution;

[0032] 2) Use a 2 mL syringe with a needle diameter of 0.5 mm to draw a full tube of homogeneous solution (2 mL), drop by drop at a height of about 6 cm to a volume of 55 mL of 3 mol / L sodium hydroxide In the petri dish of the solution, wherein the diameter of the petri dish is 8.7 cm, the volume of the sodium hydroxide solution installed at this time accounts for more than 2 / 3 of the volume of the petri dish. At this time, the sodium hydroxide solution will be greatly excessive. A spherical product is formed immediately. ...

Embodiment 2

[0036]Organophosphorus pesticide dichlorvos experiment in the zirconia microsphere material adsorption solution prepared in Example 1

[0037] 1. Weigh 30 mg of the obtained zirconia microsphere material adsorbent;

[0038] 2. Weigh the solid dichlorvos pesticide and dissolve it in methanol solution to prepare a concentration of 1000 mg L -1 Dichlorvos (DDVP) standard solution:

[0039] 3. Pipette the standard solution in step 2 and dilute it into 50 ml each of 150, 200, 270 and 300 mg / L simulated contamination solutions for later use:

[0040] 4. Adsorption experiment of dichlorvos in contaminated solution. The experiment was carried out at room temperature without adjusting the pH value of the sewage. The concentration of the zirconia material was 0.6 g / L. The timing was started after the adsorbent was evenly dispersed in the sewage. During the entire adsorption process, the oscillator was kept at 120 rpm. Sampling was carried out at different times, and the s...

Embodiment 3

[0044] 1. Weigh 25g each of small green vegetables and cucumber slice samples as actual samples;

[0045] 2. Add the weighed samples into the mortar respectively, add 5 g NaCl each and grind them;

[0046] 3. Transfer the ground sample to a conical flask, add 30 ml of acetonitrile, ultrasonic for 15 minutes, after cooling, centrifuge with a centrifuge and let it stand; transfer the organic phase to a 100 ml volumetric flask; continue to use acetonitrile for the remaining mother liquor Extract twice, and continue to transfer the organic phase solution to a volumetric flask. After the extraction is finished, add acetonitrile to the volumetric flask containing the acetonitrile solution to the mark;

[0047] 4. Transfer the acetonitrile solution obtained in the previous step to a 150 ml Erlenmeyer flask, add 0.1 g of the zirconia microspheres prepared in Example 1, and oscillate and adsorb for 90 minutes;

[0048] 5. After the adsorption is completed, take ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com