Preparation method of graphene modified temperature-indicating thermal barrier coating

A graphene modification, graphene technology, applied in coatings, chemical instruments and methods, metal material coating processes, etc., to achieve the effect of highly sensitive response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

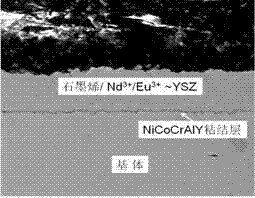

[0040] The invention provides a method for preparing a graphene-modified temperature-indicating thermal barrier coating, comprising step 1: weighing 2400g of zirconia octahydrate (ZrOCl 2 ·8H 2 O) Dissolve in 5000ml deionized water and stir to mix.

[0041] Step 2: Weigh 80g of yttrium oxide (Y 2 o 3 ), 2g europium oxide (Eu 2 o 3 ) and 1g neodymium oxide (Nd 2 o 3 ) solid powder, dissolved in 1000ml of dilute hydrochloric acid with a concentration of 1 mol / L, at a rate of 500rpm / min, stirred evenly for 30min and then mixed.

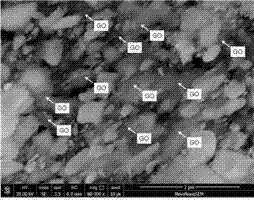

[0042] Step 3: Weigh 2 g of graphene oxide and disperse it in 500 ml of absolute ethanol with ultrasonic vibration to prepare a graphene oxide dispersion. The ultrasonic dispersion time is 120min, and the ultrasonic frequency is 15Hz.

[0043] Step 4: Mix the two solutions obtained in Step 2 and Step 3. Under vacuum conditions, keep the temperature at 350° C., and stir evenly for 30 minutes with a high-speed mixer at a speed of 500 rpm / min.

[0...

Embodiment 2

[0053] On the basis of the above examples, this example provides a method for preparing a graphene-modified temperature-indicating thermal barrier coating, including step 1: weighing 4800g of zirconia octahydrate (ZrOCl 2 ·8H 2 O) Dissolve in 10000ml deionized water and stir to mix.

[0054] Step 2: Weigh 160g of yttrium oxide (Y 2 o 3 ), 4g europium oxide (Eu 2 o 3 ) and 2g neodymium oxide (Nd 2 o 3 ) solid powder, dissolved in 2000ml of dilute hydrochloric acid with a concentration of 1 mol / L, at a rate of 500rpm / min, stirring evenly for 50min for mixing.

[0055] Step 3: Weigh 4 g of graphene oxide and disperse it in 1000 ml of absolute ethanol with ultrasonic vibration to prepare graphene oxide dispersion. The ultrasonic dispersion time is 150min, and the ultrasonic frequency is 15Hz.

[0056] Step 4: Mix the two solutions obtained in Step 2 and Step 3. Under vacuum conditions, the temperature is kept at 360° C., and the speed of a high-speed mixer is 500 rpm / min, ...

Embodiment 3

[0062] On the basis of the above examples, this example provides a method for preparing a graphene-modified temperature-indicating thermal barrier coating, including step 1: weighing 1200g of zirconia octahydrate (ZrOCl 2 ·8H 2 O) Dissolve in 2500ml deionized water and stir to mix.

[0063] Step 2: Weigh 40g of yttrium oxide (Y 2 o 3 ), 1g europium oxide (Eu 2 o 3 ) and 0.5g neodymium oxide (Nd 2 o 3 ) solid powder, dissolved in 500ml of dilute hydrochloric acid with a concentration of 1 mol / L, at a rate of 500rpm / min, stirring evenly for 30min for mixing.

[0064] Step 3: Weigh 2 g of graphene oxide and disperse it in 500 ml of absolute ethanol with ultrasonic vibration to prepare a graphene oxide dispersion. The ultrasonic dispersion time is 120min, and the ultrasonic frequency is 15Hz.

[0065] Step 4: Mix the two solutions obtained in Step 2 and Step 3. Under vacuum conditions, keep the temperature at 350° C., and stir evenly for 30 minutes with a high-speed mixer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com