Precursor conversion method preparation process of ZrB2-SiC ceramic composite powder

A technology of ceramic composite and preparation process, which is applied in the preparation process of ZrB2-SiC ceramic composite powder precursor conversion method and the field of preparation of ultra-high temperature ceramic raw material powder, which can solve the problems of high impurity content of products, poor powder dispersion High cost and other issues, to achieve the effect of low raw material cost, low cost and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] a ZrB 2 -Precursor conversion method preparation process of SiC ceramic composite powder, the specific process is as follows:

[0016] (1) Step 1: According to the amount ratio of substances, it is boric acid: zirconium oxychloride octahydrate: ethyl orthosilicate=100:9:40, glucose is calculated according to the carbon obtained after pyrolysis is complete, that is, C / (Zr+Si )=4, respectively weigh zirconium oxychloride octahydrate, boric acid, ethyl orthosilicate, and glucose for subsequent use.

[0017] (2) Step 2: Under the condition of continuous magnetic stirring, dissolve zirconium oxychloride in absolute ethanol, add a small amount of hydrogen peroxide and acetylacetone dropwise, and prepare a uniform and transparent solution, namely zirconium precursor solution. Dissolve boric acid in absolute ethanol, heat in a water bath until completely dissolved, and prepare boric acid solution. Dissolve ethyl orthosilicate in absolute ethanol to prepare ethyl orthosilicate...

Embodiment 2

[0020] a ZrB 2 -The precursor conversion method preparation process of SiC ceramic composite powder, except that the following experimental raw material ratio and heat treatment temperature are different, all the other are the same as embodiment 1.

[0021] In this embodiment: the amount ratio of the raw materials taken is boric acid: zirconium oxychloride octahydrate: ethyl orthosilicate=100:15:50, glucose is calculated according to the carbon obtained after pyrolysis is complete, that is, C / (Zr +Si)=5; the heat treatment temperature is 1600°C.

Embodiment 3

[0023] a ZrB 2 -SiC ceramic composite powder precursor conversion method preparation process, except that the ratio of raw materials in the following experiments is different, all the other are the same as in Example 1.

[0024] In this embodiment: the amount ratio of the raw materials taken is boric acid: zirconium oxychloride octahydrate: ethyl orthosilicate=100:10:60, and glucose is calculated according to the carbon obtained after pyrolysis is complete, namely C / (Zr +Si)=6.

[0025] The present invention adopts the precursor conversion method, the required raw materials are simple and easy to obtain, the prepared precursor solution can achieve the mixing of different components at the molecular level, the required pyrolysis temperature is low, and the purity of the obtained ceramic product is high, Uniform particle size.

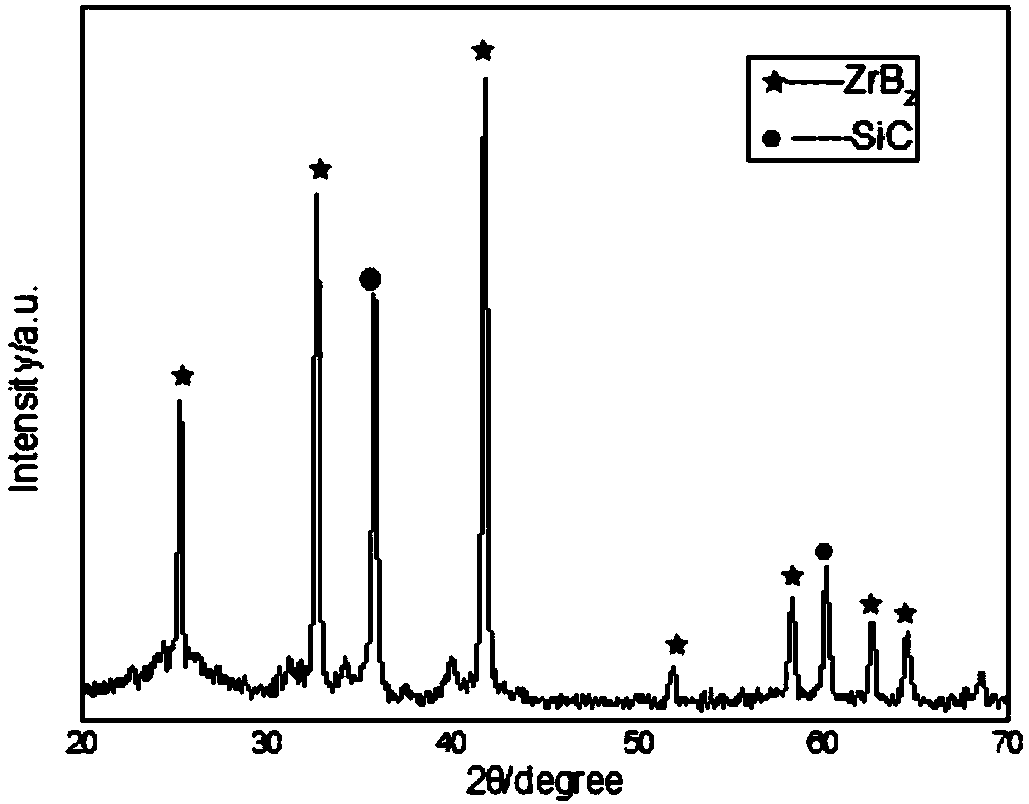

[0026] Embodiment 1 gained product, from figure 1 It can be seen that the phase composition of the composite ceramic powder prepared by the preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com