High temperature resistant nanometer zirconium boron cross-linking agent and preparation method thereof

A cross-linking agent and high-temperature-resistant technology, which is applied in chemical instruments and methods, drilling compositions, organic chemistry, etc., can solve the problems of high-temperature resistance and high cost of cross-linking agents, and achieve good temperature and shear resistance , low cost, low harm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

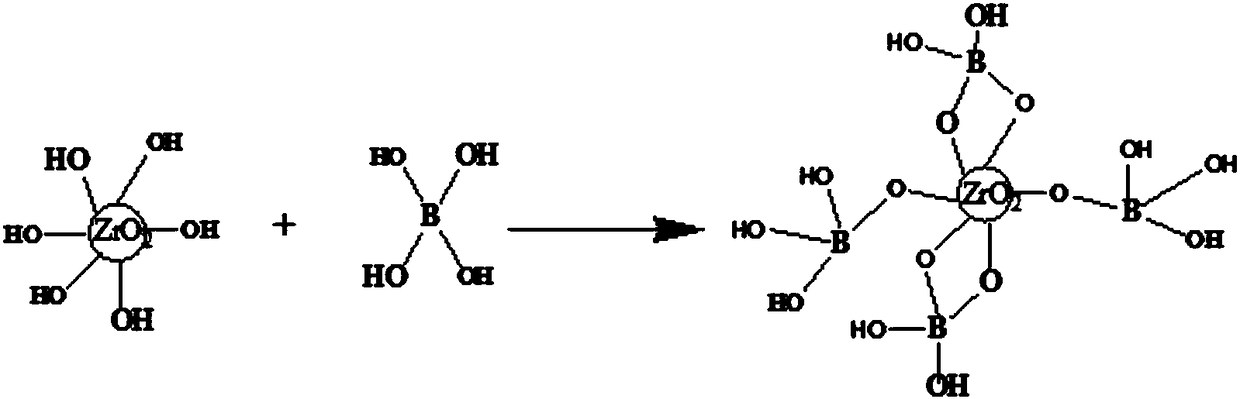

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of a high-temperature-resistant nano zirconium-boron crosslinking agent, comprising the following steps:

[0036] (1) Dissolve 8.65g of sodium lauryl sulfate in 60mL of deionized water and stir to dissolve at 45°C;

[0037] (2) Weigh 4.83g of zirconium oxychloride octahydrate and dissolve it in 30mL of deionized water, stir and dissolve at room temperature; 150mL cyclohexane, magnetically stirred for 2-3h to obtain a mixed solution;

[0038] (3) Move the obtained mixed solution to a 500mL hydrothermal reaction kettle with polytetrafluoroethylene lining, add 60mL, 4mol / l sodium hydroxide solution, react at 100°C for 24h, alternately use ethanol and deionized water After washing 3 times, according to the theoretical yield, a 0.5wt% nano zirconium dioxide emulsion was prepared, and ultrasonicated for 30 minutes to make it uniformly dispersed;

[0039] (4) Take 50ml of 0.5wt% nano-zirconia emulsion in a three-necked flask, add 25mL of glycerol therein...

Embodiment 2

[0041] A preparation method of a high-temperature-resistant nano zirconium-boron crosslinking agent, comprising the following steps:

[0042] (1) Dissolve 12g of sodium lauryl sulfate in 120mL of deionized water, stir and dissolve at 45°C;

[0043] (2) Weigh 8.4g of zirconium oxychloride octahydrate and dissolve it in 60mL of deionized water, stir and dissolve at room temperature; 300mL cyclohexane, magnetically stirred for 2-3h to obtain a mixed solution;

[0044] (3) Move the obtained mixed solution to a 500mL hydrothermal reaction kettle with polytetrafluoroethylene lining, add 60mL, 4mol / l sodium hydroxide solution, react at 100°C for 24h, alternately use ethanol and deionized water After washing 3 times, according to the theoretical yield, a 0.5wt% nano zirconium dioxide emulsion was prepared, and ultrasonicated for 30 minutes to make it uniformly dispersed;

[0045] (4) Take 60ml of 0.5wt% nano-zirconia emulsion in a three-necked flask, add 30mL of glycerol therein, st...

Embodiment 3

[0047] A preparation method of a high-temperature-resistant nano zirconium-boron crosslinking agent, comprising the following steps:

[0048] (1) Dissolve 16.2g of sodium lauryl sulfate in 90mL of deionized water and stir to dissolve at 45°C;

[0049] (2) Weigh 6.75g of zirconium oxychloride octahydrate and dissolve it in 45mL of deionized water, stir and dissolve at room temperature; 225mL cyclohexane, magnetically stirred for 2-3h to obtain a mixed solution;

[0050](3) Move the obtained mixed solution to a 500mL hydrothermal reaction kettle with polytetrafluoroethylene lining, add 60mL, 4mol / l sodium hydroxide solution, react at 100°C for 24h, alternately use ethanol and deionized water After washing 3 times, according to the theoretical yield, a 0.5wt% nano zirconium dioxide emulsion was prepared, and ultrasonicated for 30 minutes to make it uniformly dispersed;

[0051] (4) Take 50ml of 0.5wt% nano-zirconia emulsion in a three-necked flask, add 25mL of glycerol therein,...

PUM

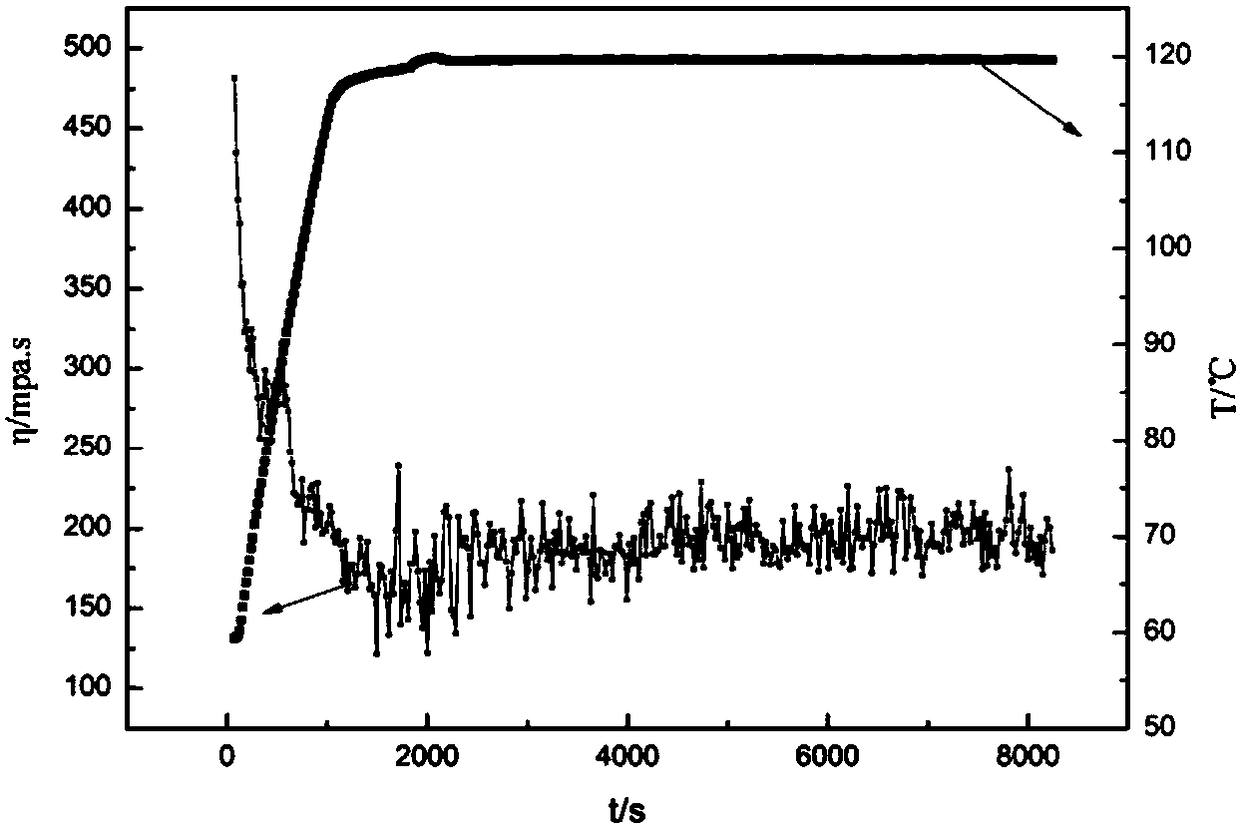

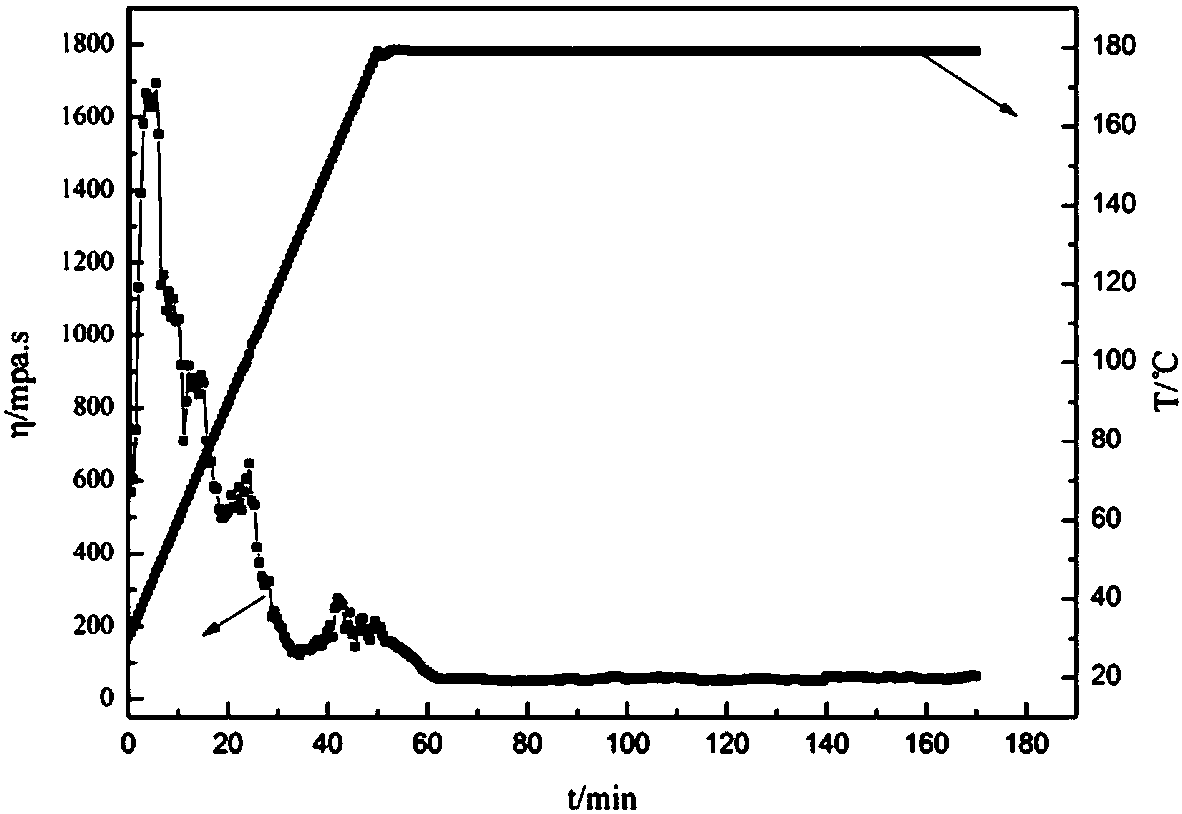

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com