Zirconium modified silicon resin impregnating compound as well as preparation method and application thereof

A technology of modified silicon and sizing agent, which is applied in the field of sizing agent to improve the effect of temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

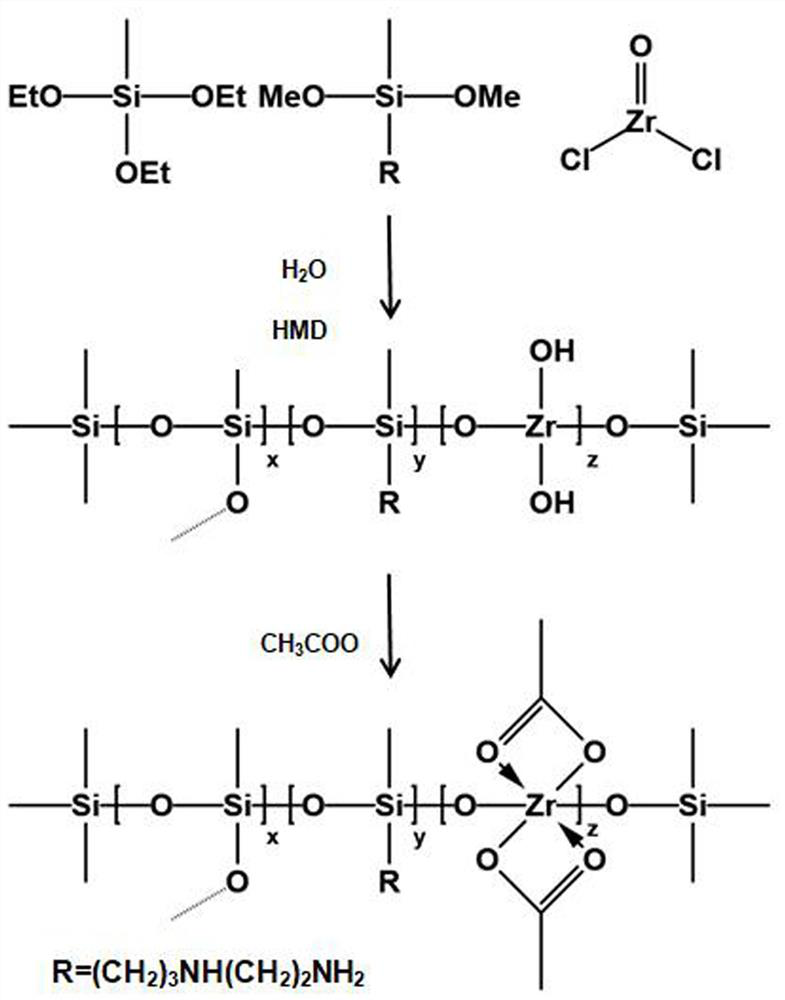

Method used

Image

Examples

Embodiment 1

[0040] The zirconium-modified silicone resin in this example is prepared by the following method: first mix 0.02mol methyltriethoxysilane (MTES) and 0.005mol zirconium oxychloride octahydrate (ZrOCl 2 ·8H 2 O) Mix and stir until the zirconium oxychloride dissolves, then add 0.03mol of N-β-(aminoethyl)-γ-aminopropylmethyldimethoxysilane (KH602); 2ml of distilled water was added dropwise to carry out the hydrolysis-copolymerization reaction. After stirring for 40 min, 0.6g of glacial acetic acid (HA) was added until the resin was water-soluble. Finally, 0.002525 mol of hexamethyldisiloxane (HMDS) was added to the beaker as an end-capping agent, and the reaction was completed after stirring for 30 min. The synthesized zirconium-modified silicone resin sizing agent was named ZSR-1, and then diluted into a solution with a solid content of 0.7%, infiltrated and coated with basalt fibers, and the infiltrated fibers were designated as ZRBF-1.

Embodiment 2

[0042] The zirconium-modified silicone resin in this example is prepared by the following method: first mix 0.02mol methyltriethoxysilane (MTES) and 0.001mol zirconium oxychloride octahydrate (ZrOCl 2 ·8H 2 O) Mix and stir until the zirconium oxychloride dissolves, then add 0.03mol of N-β-(aminoethyl)-γ-aminopropylmethyldimethoxysilane (KH602); 2ml of distilled water was added dropwise to carry out the hydrolysis-copolymerization reaction. After stirring for 40 min, 0.6g of glacial acetic acid (HA) was added until the resin was water-soluble. Finally, 0.00255 mol of hexamethyldisiloxane (HMDS) was added to the beaker as an end-capping agent, and the reaction was completed after stirring for 30 min. The synthesized zirconium-modified silicone resin sizing agent was named ZSR-2, and then diluted into a solution with a solid content of 0.7%, infiltrated and coated with basalt fibers, and the infiltrated fibers were designated as ZRBF-2.

Embodiment 3

[0044]The zirconium-modified silicone resin in this example is prepared by the following method: first mix 0.02mol methyltriethoxysilane (MTES) and 0.0015mol zirconium oxychloride octahydrate (ZrOCl 2 ·8H 2 O) Mix and stir until the zirconium oxychloride dissolves, then add 0.03mol of N-β-(aminoethyl)-γ-aminopropylmethyldimethoxysilane (KH602); 1.75ml of distilled water was added dropwise to carry out the hydrolysis-copolymerization reaction. After stirring for 40 min, 0.9g of glacial acetic acid (HA) was added until the resin was water-soluble. Finally, 0.002575 mol of hexamethyldisiloxane (HMDS) was added to the beaker as an end-capping agent, and the reaction was completed after stirring for 30 minutes. The synthesized zirconium-modified silicone resin sizing agent was named ZSR-3, and then diluted into a solution with a solid content of 0.7%, infiltrated and coated with basalt fibers, and the infiltrated fibers were designated as ZRBF-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com