Technology for preparing spherical ultrafine zirconium boride powder by adopting liquid phase method and prepared zirconium boride powder

A kind of spherical, liquid-phase method, applied in the direction of boron/boride, metal boride, etc., can solve the problems of wide powder particle size distribution, high reaction temperature, etc., and achieve easy reaction process, high powder purity, and reaction process control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

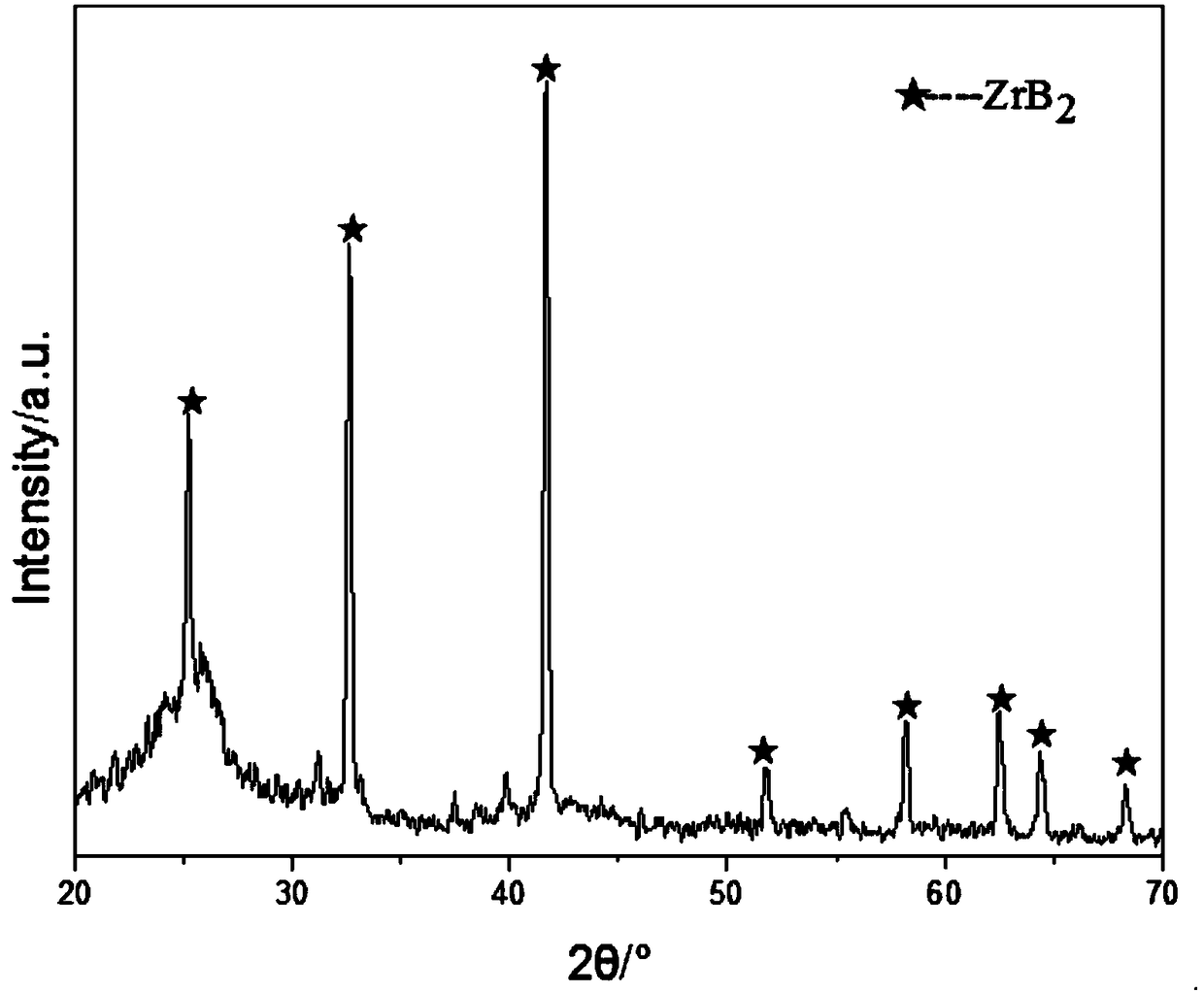

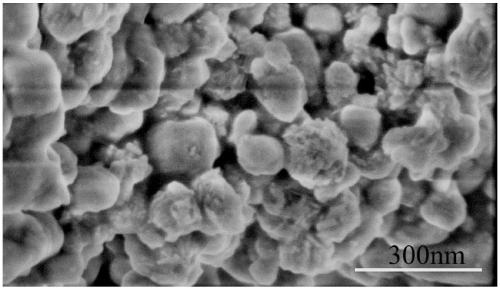

[0026] a ZrB 2 The preparation process of the precursor conversion method of ceramic powder, the specific process is as follows:

[0027] (1) Step 1: According to the amount ratio of substances, it is boric acid: zirconium oxychloride octahydrate=3:1, glucose is calculated according to the carbon obtained after pyrolysis is complete, that is, C / (Zr+B)=6, take 1.6 respectively g zirconium oxychloride octahydrate, 4g boric acid, and 10g glucose for subsequent use.

[0028] (2) Step 2: Dissolve 1.6g of zirconium oxychloride in 20ml of absolute ethanol, add dropwise 2ml of hydrogen peroxide and 5ml of acetylacetone, and continue stirring for 1 hour to obtain a uniform and transparent solution, namely zirconium sol. Dissolve 4g of boric acid in 30g of absolute ethanol, heat in a water bath at 40°C until completely dissolved, and prepare a boric acid solution. Dissolve 10 g of glucose in 20 g of deionized water to prepare a glucose solution. In the case of continuous magnetic sti...

Embodiment 2

[0033] A single-component ZrB 2 The preparation process of the precursor conversion method of ceramic powder is the same as in Example 1 except that the following experimental raw material ratios are different.

[0034] In this embodiment: the amount ratio of the raw materials weighed is boric acid: zirconium oxychloride octahydrate=4:1, glucose is calculated according to the carbon obtained after pyrolysis is complete, that is, C / (Zr+B)=6.

Embodiment 3

[0036] a ZrB 2 The preparation process of the precursor conversion method of the ceramic powder is the same as in Example 1 except that the ratio of the following experimental raw materials and the heat treatment temperature are different.

[0037] In the present embodiment: the amount ratio of the raw material that weighs is boric acid: zirconium oxychloride octahydrate=3:1, and glucose calculates namely C / (Zr+B)=6 according to the carbon that obtains after pyrolysis is complete, heat treatment temperature It is 1600°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com