Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81 results about "Salt fluoridation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Salt Fluoridation. Salt fluoridation is practiced as a community-based alternative to water fluoridation in many countries where there are few central water systems, water infrastructure is otherwise not appropriate, or where other factors preclude the use of water fluoridation.

Method of manufacturing refractory material by innocent treatment of secondary aluminum ash

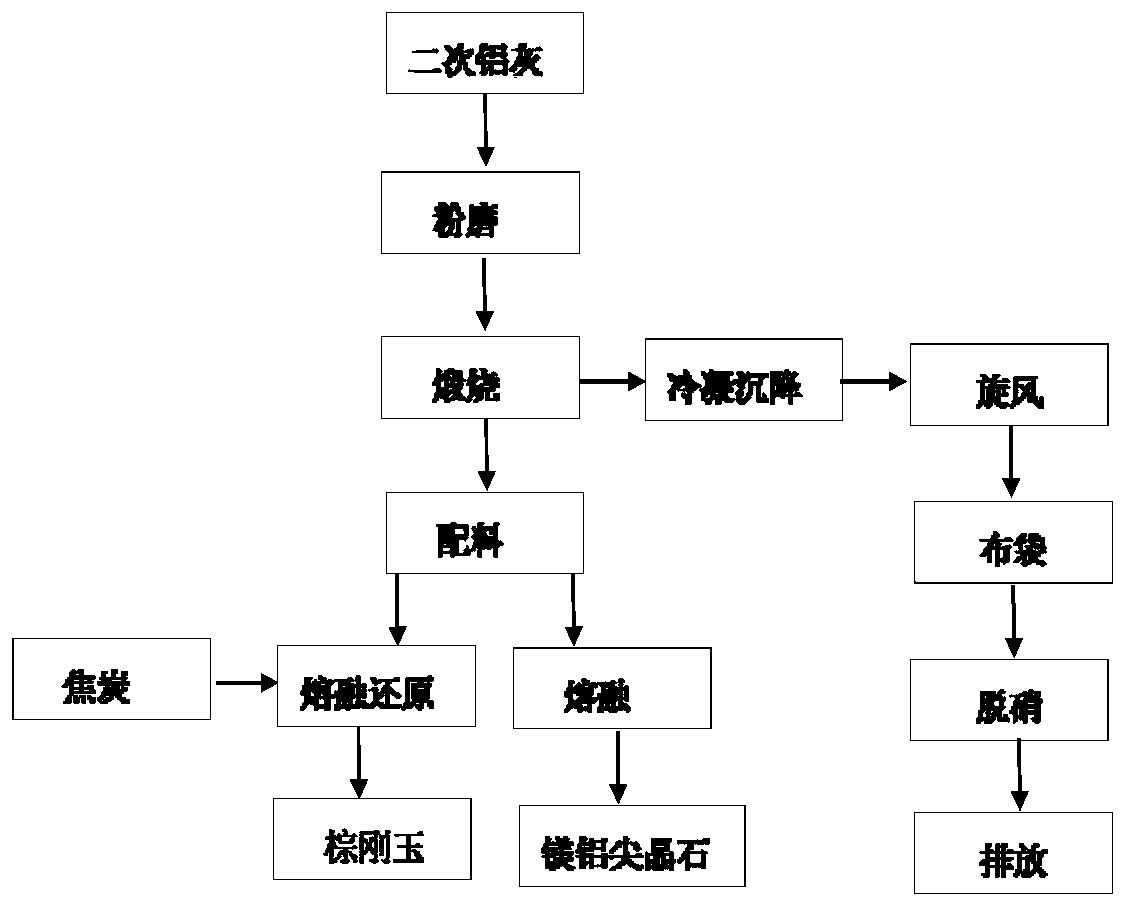

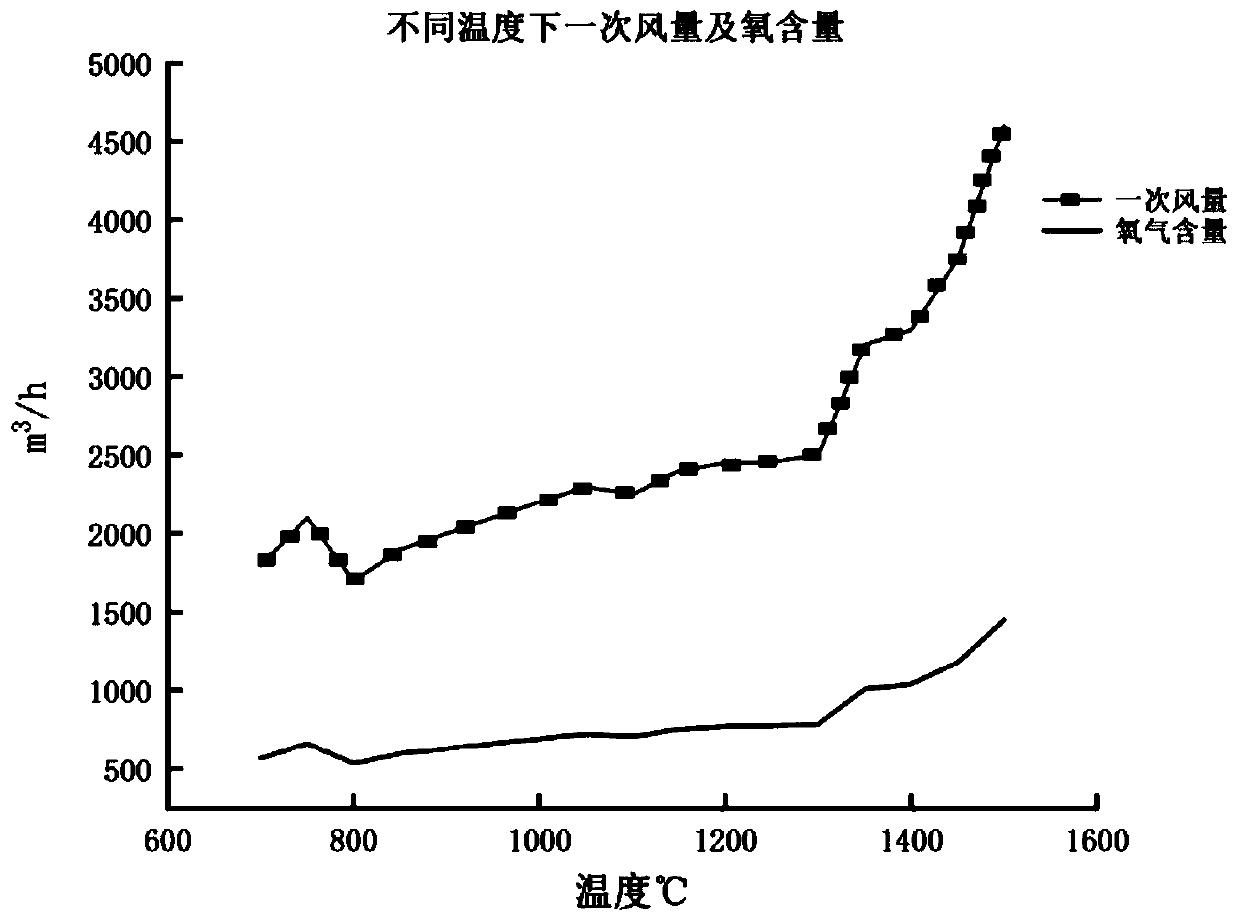

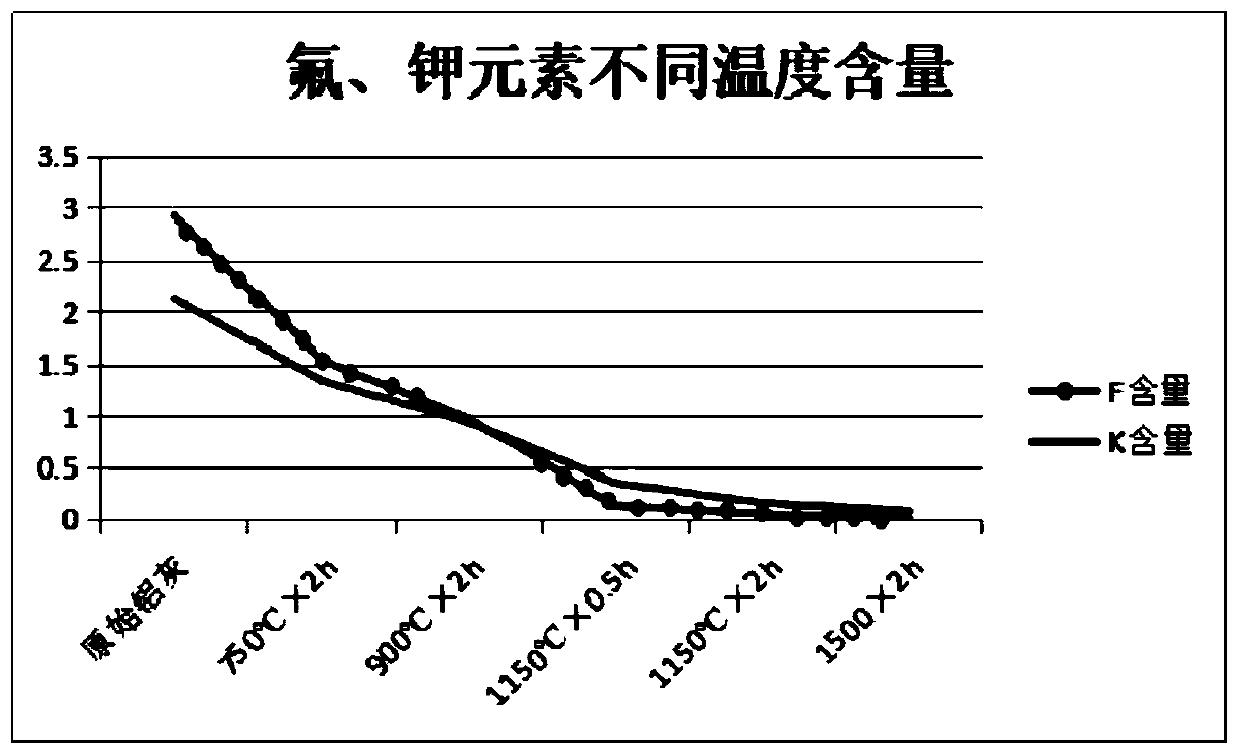

The invention discloses a method for manufacturing a refractory material by innocent treatment of secondary aluminum ash, and belongs to the field of aluminum industry. The method comprises the following steps: further grinding the secondary aluminum ash until 80% of the secondary aluminum ash passes through a screen with the pore diameter of 74 microns; and calcining the secondary aluminum ash for 0.5-4 hours at the temperature of 1150-1550 DEG C in an oxidizing atmosphere with the oxygen content of 12%-18% to convert metal aluminum, aluminum nitride and aluminum carbide in the secondary aluminum ash into aluminum oxide and volatilize the fluoride salt and chloride salt in the secondary aluminum ash, thereby producing a calcined oxide; cooling the waste flue gas containing fluoride salt and chlorate produced in the calcining process for recovery, and denitrifying and discharging the flue gas. The calcined oxide is independently prepared or mixed with an additive, and the aluminum-magnesium refractory material is prepared after electric arc melting. The preparation method can be used for preparing the refractory material with high purity.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

Method for manufacturing refined high cleanliness Al-Ti-B alloy

The invention relates to a method for manufacturing a refined high cleanliness Al-Ti-B alloy, comprising the following steps of: (1) melting an aluminum ingot, and adding potassium fluotitanate and potassium fluoborate for alloying; (2) pouring a reaction by-product floating on the surface of aluminum liquid, and neutralizing with alumina powder; (3) raising the temperature of the aluminum liquid, and scattering an alumina powder layer; (4) introducing argon or nitrogen with a pipe so that a residue solution coated in the aluminum liquid floats and is neutralized; (5) measuring the hydrogen content after the solution is treated by utilizing a small bubble rotation and degassing refining technology; (6) scattering a special high temperature anti-oxidation covering agent layer in the hot state of more than 800 DEG C; (7) raising the temperature of the aluminum liquid, introducing the aluminum liquid to a filtering box body filled with an alumina ceramic filter, and carrying out online filtering treatment on the alloy aluminum liquid; and (8) finally, reducing the temperature of the aluminum liquid, discarding scruff scum, and molding by casting to produce Al-Ti-B filaments. The method can effectively separate fluoride salt and other impurities in the Al-Ti-B alloy liquid so that the impurities in an Al-Ti-B alloy refining agent are reduced, and the cleanliness is greatly improved.

Owner:HUNAN JINLIANXING SPECIAL MATERIALS CO LTD

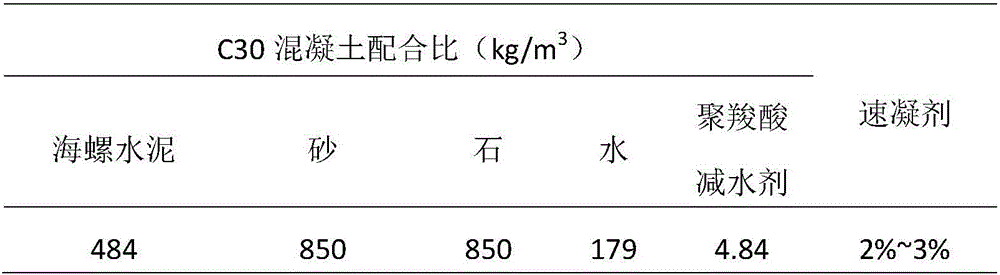

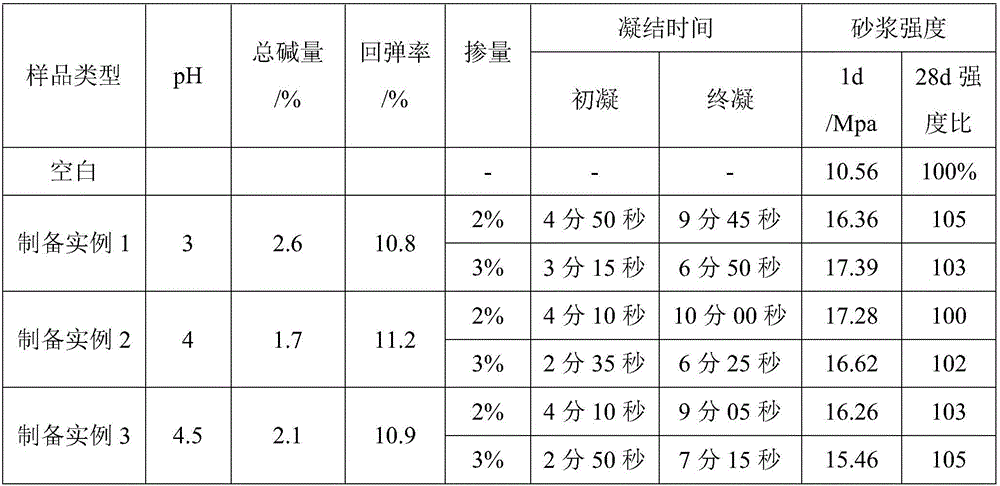

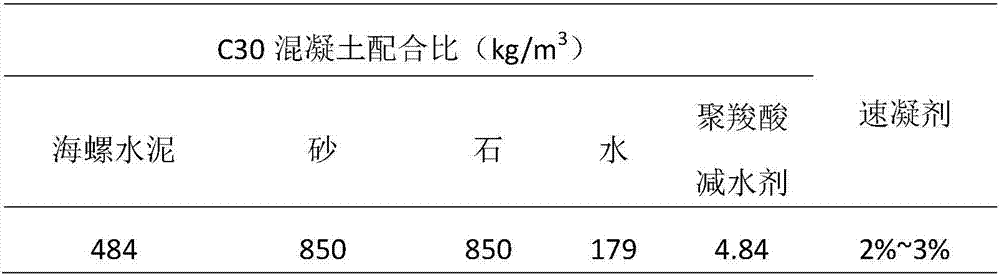

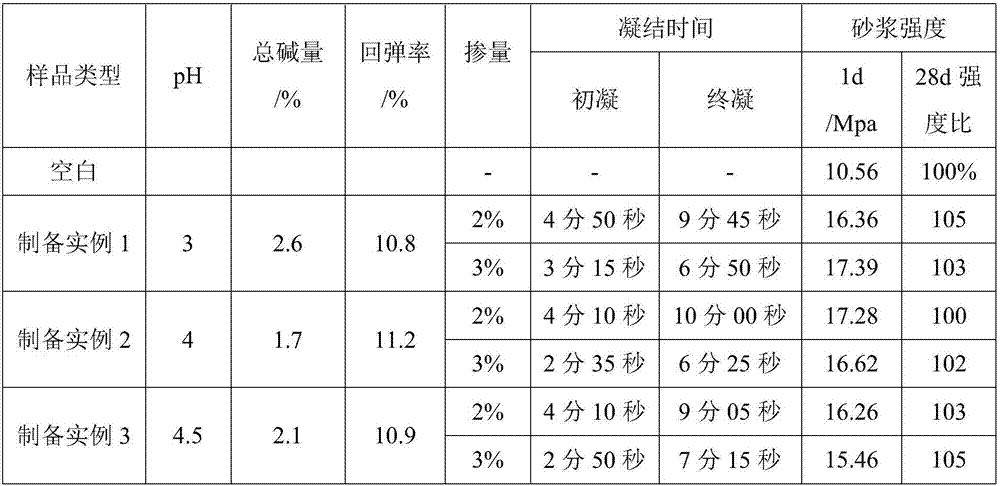

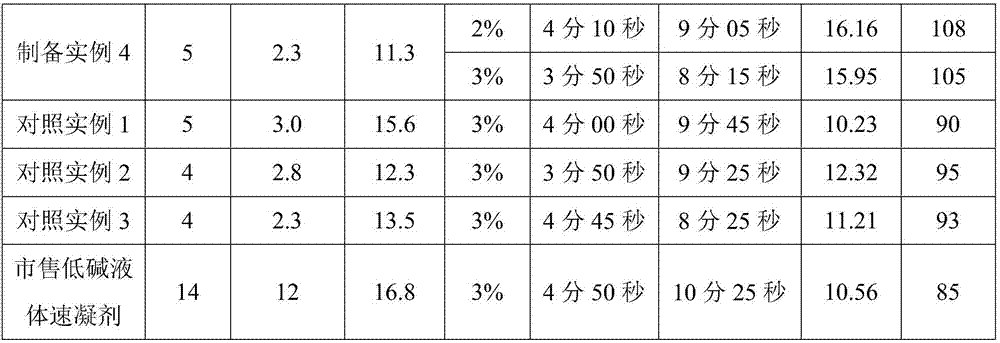

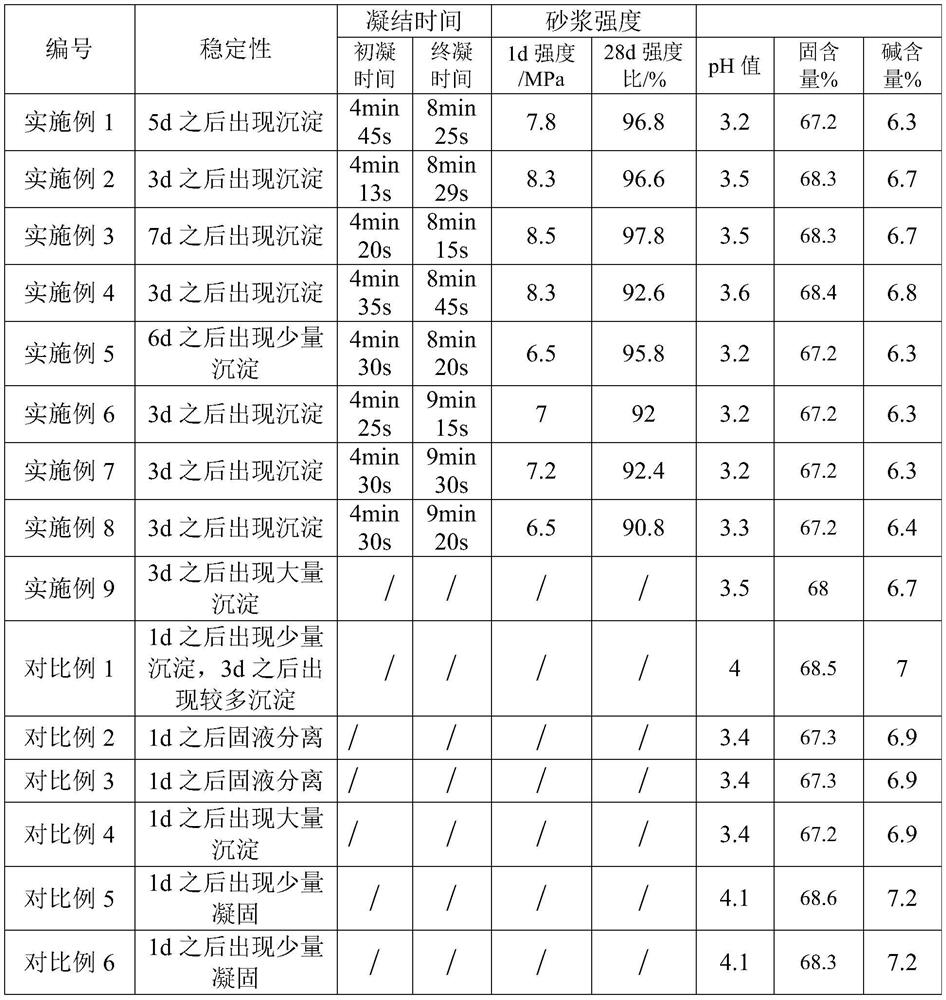

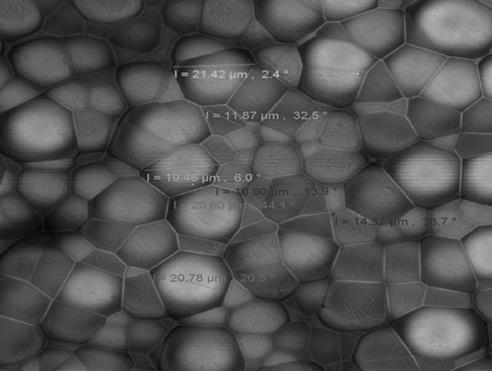

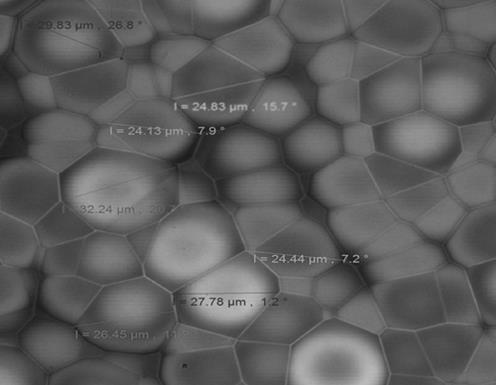

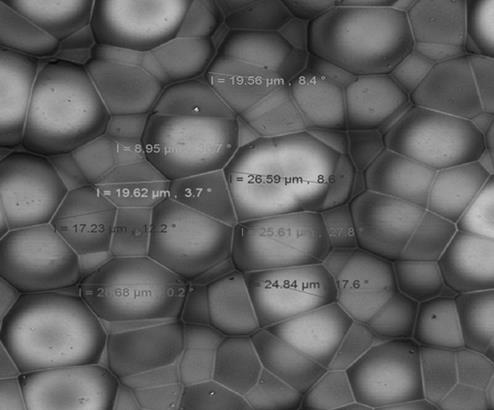

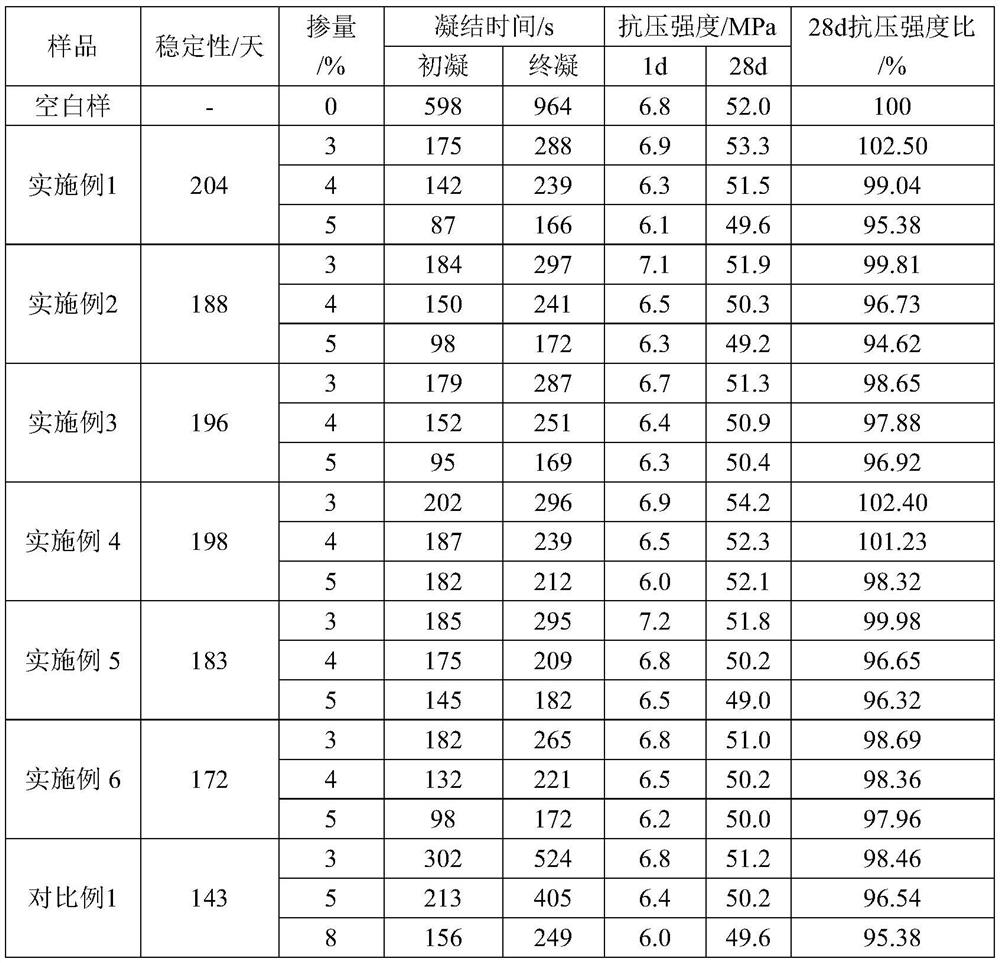

Environment-friendly low-resilience low-alkaline liquid setting accelerator and preparation method

The invention discloses an environment-friendly low-resilience low-alkaline liquid setting accelerator and a preparation method thereof. The environment-friendly low-resilience low-alkaline liquid setting accelerator is prepared from, by mass, 50-60% of a modified polyaluminium sulfate solution, 1-5% of modified fluoride salt, 1-4% of modified alcohol amine, 1-3% of a dispersant and 30-42% of water. The preparation method specifically includes the following steps that 1, the a modified polyaluminium sulfate solution is prepared; 2, modified fluoride salt is prepared; 3, modified alcohol amine is prepared; 4, the dispersant and the balance water are added, stirring is carried out for 1-4 h at 40-70 DEG C, and the finished product is obtained. As for the total alkali amount of the prepared low-alkaline liquid setting accelerator, Na2O+K2O<3%, the pH ranges from 3 to 5, and harm to the skin is small; when applied to spraying concrete, the low-alkaline liquid setting accelerator guarantees construction safety and has the advantages of being low in resilience, capable of significantly improving later-stage strength and the like.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

Method for preparing white carbon black from silicon slags containing fluorine

The invention discloses a method for preparing white carbon black from silicon slag containing fluorine. The method comprises the steps of: adding silicon slag containing fluoride and measured alkaline solution according to the proportion into a reaction kettle provided with a stirrer and a heating device; heating the mixture to 40-80 DEG C under fully stirring condition for maintaining for 20-50 min, so that the fluosilicic acid in the silicon slag containing fluoride is reacted completely to prepare a mixed solution of silicon dioxide and fluoride salt; heating or cooling the prepared liquid-solid mixture of silicon dioxide and fluoride salt to 50 DEG C or less, then filtering or centrifuging the mixture for liquid-solid separation so as to prepare a wet cake of silica and a filtrate of fluoride salt; backwashing the prepared wet cake of silica for 4-6 times, merging the first washing solution with fluoride salt to prepare a fluoride salt solution for other uses, and putting the second to the sixth washing solution into the first to the fifth washing solution tank respectively for the next first to fifth washing; drying the wet filter cake of silica to obtain white carbon black products. The method has the advantages of simplicity in processing, less equipment, simplicity and convenience in operation, and low production cost, and is convenient to realize industrial production.

Owner:WENGFU (GRP) CO LTD +1

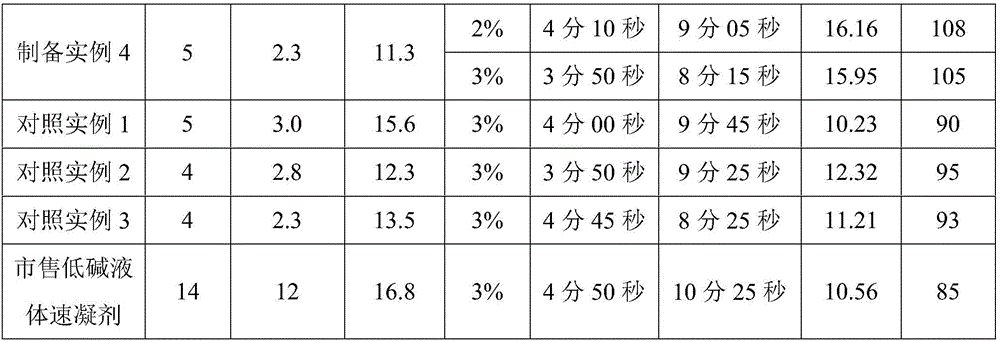

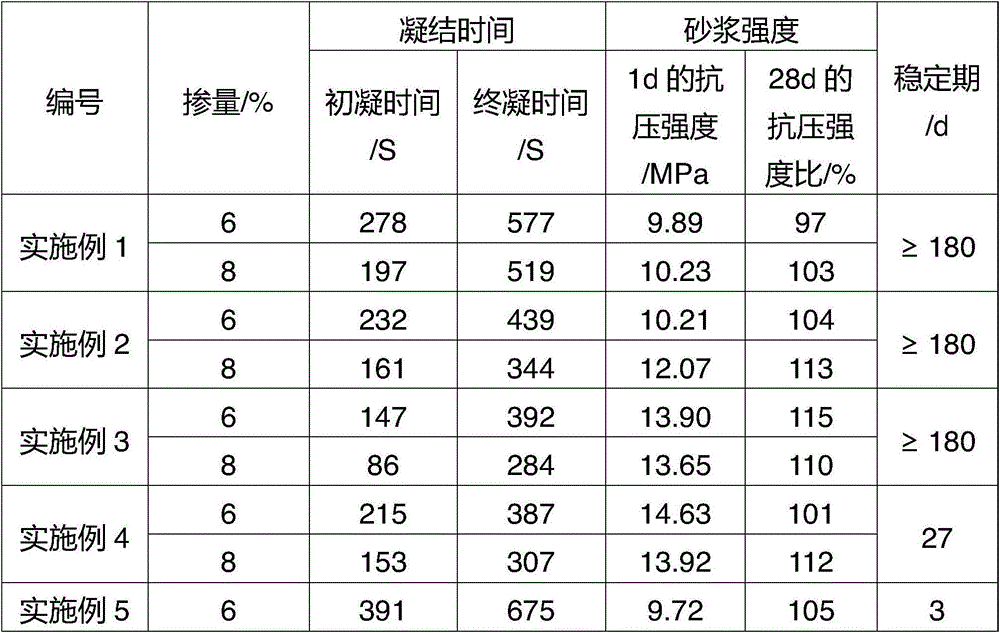

Liquid quick-setting agent and preparation method thereof

The invention provides a liquid quick-setting agent and a preparation method thereof. The liquid quick-setting agent adopts aluminum sulfate as a main material, and is low in alkaline content, good in quick-setting effect and high in stability. The preparation method comprises the following steps of: uniformly mixing the following materials in percent by weight: 45%-60% of aluminium sulfate, 5%-15% of alcohol amine, 0.5%-5% of solubilizing agent, 0-5% of setting accelerator and the balance of water, thus obtaining the liquid quick-setting agent; the content of Al2O3 of the aluminium sulfate is 14%-17%; the solubilizing agent is phosphoric acid and / or hydroxy carboxylic acid with the number of carbon atoms being not more than 6; the setting accelerator is at least one of water-soluble nitrate, nitrite, sulfate, fluoride salt, carbonate and carboxylate-sulfonate-nonionic terpolymer. The liquid quick-setting agent obtained by the preparation method is used for jetting concrete, the doping amount is generally 5%-8% of the mass of cement, the quick setting effect is good, the stability is high and the stable period reaches more than 180 days.

Owner:XINJIANG UNIVERSITY

Fluorine gas purifying filler and preparation method and application thereof

ActiveCN107337180AHigh porosityWidely used valueDispersed particle separationFluorineHydrofluoric acidPorosity

Owner:洛阳森蓝化工材料科技有限公司

Method for recovering fluoride salt from aluminum electrolysis overhaul slag through pressurized alkaline leaching

ActiveCN113426808AImprove leaching rateHigh reactivitySolid waste disposalProcess efficiency improvementAluminium electrolysisSlag

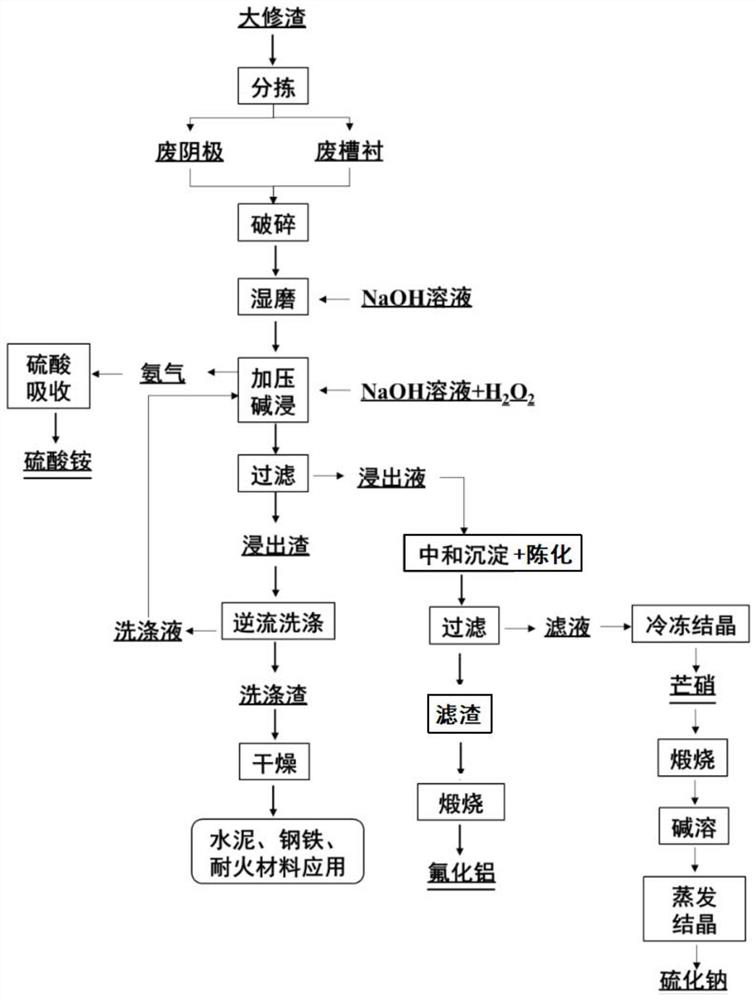

A method for recovering fluoride salt from aluminum electrolysis overhaul slag through pressurized alkaline leaching comprises the steps that waste cathodes and waste tank linings are subjected to two-stage crushing, NaOH solutions are added for wet ball milling, and waste cathode slurry and waste tank lining slurry are obtained; the waste cathode slurry and the waste tank lining slurry are respectively added into NaOH solutions to carry out pressurized alkaline leaching, and a cyanide breaking agent H2O2 which is 0.2-0.4% of the volume of a leaching solution is added in the pressurized alkaline leaching process to carry out cyanide breaking treatment; the pressure is released after pressurized alkaline leaching is completed, and the discharged ammonia gas is washed with sulfuric acid to form ammonium sulfate which can be used as a chemical fertilizer; the extract is filtered to obtain a leaching solution and leaching residues, countercurrent washing is connducted on the leaching residues, and then the leaching residues are dried to be used as an additive for smelting iron and steel, preparing cement and preparing a refractory material; the leaching solution is filtered after neutralized and precipitated, and filter residues are calcinated to form aluminum fluoride; and a filtrate is frozen and crystallized to obtain mirabilite. According to the method, the waste cathode carbon blocks and the waste tank linings can be subjected to harmless treatment and comprehensive resource utilization, and fluoride salt is obtained through recovery.

Owner:YUNNAN RUNXIN ALUMINUM

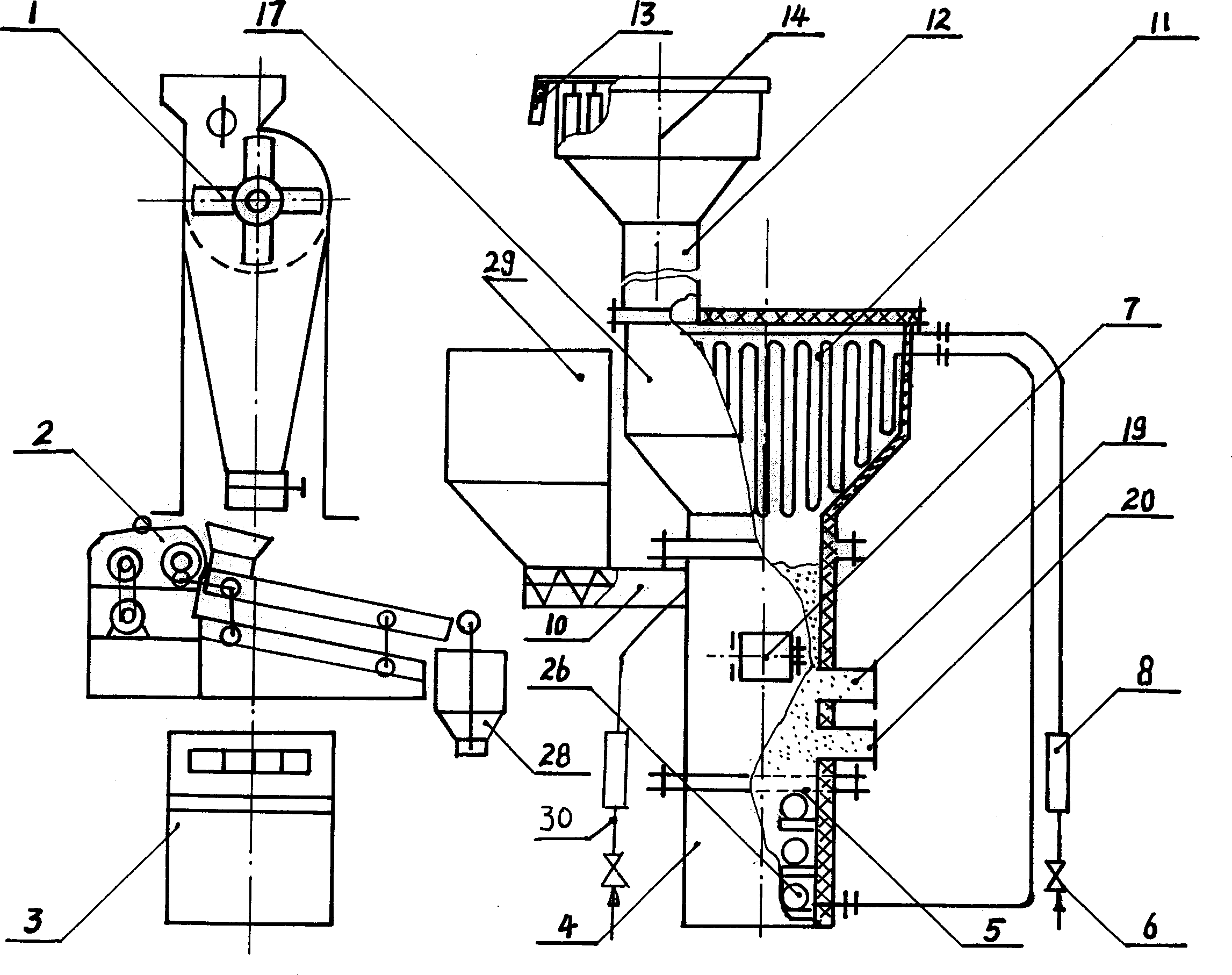

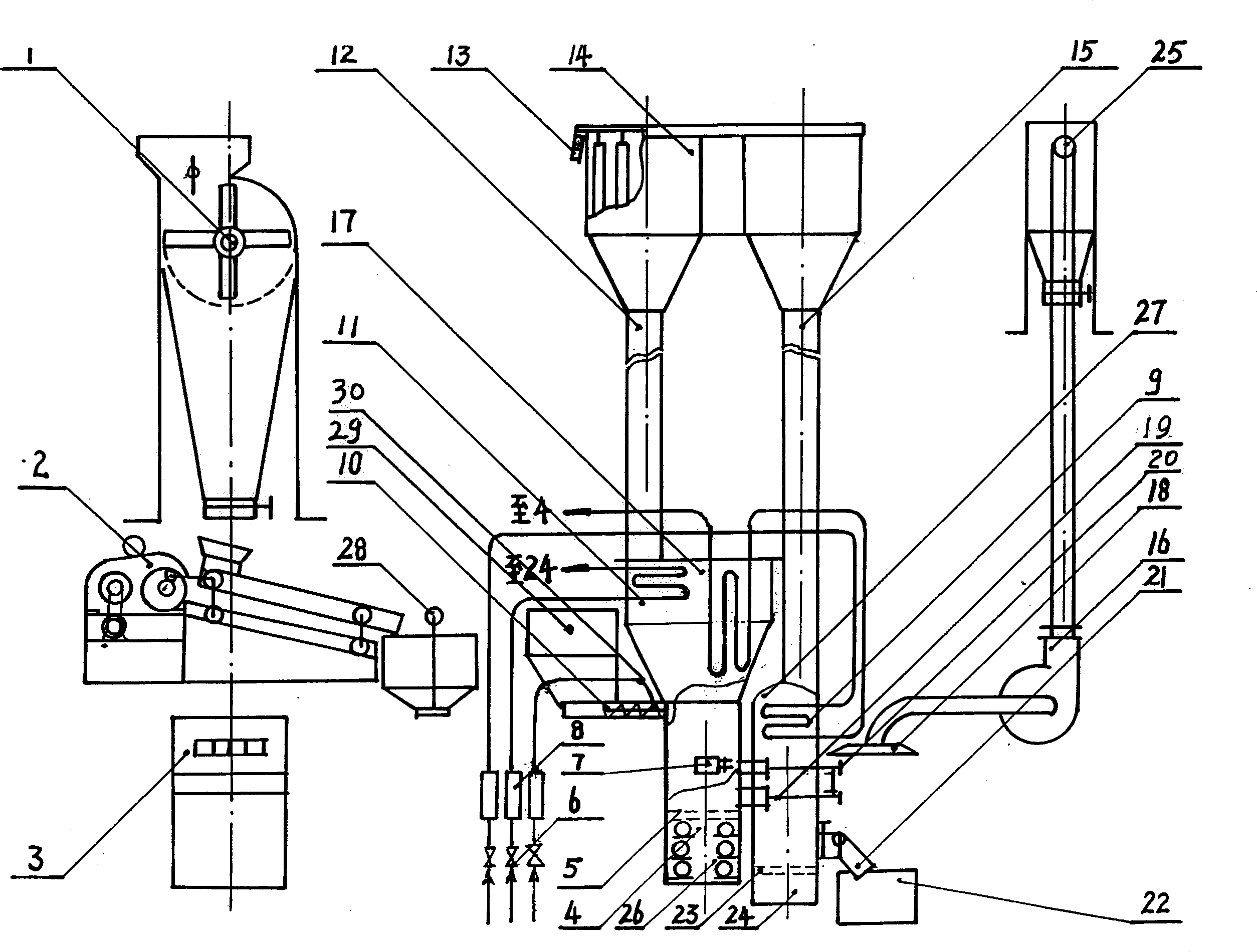

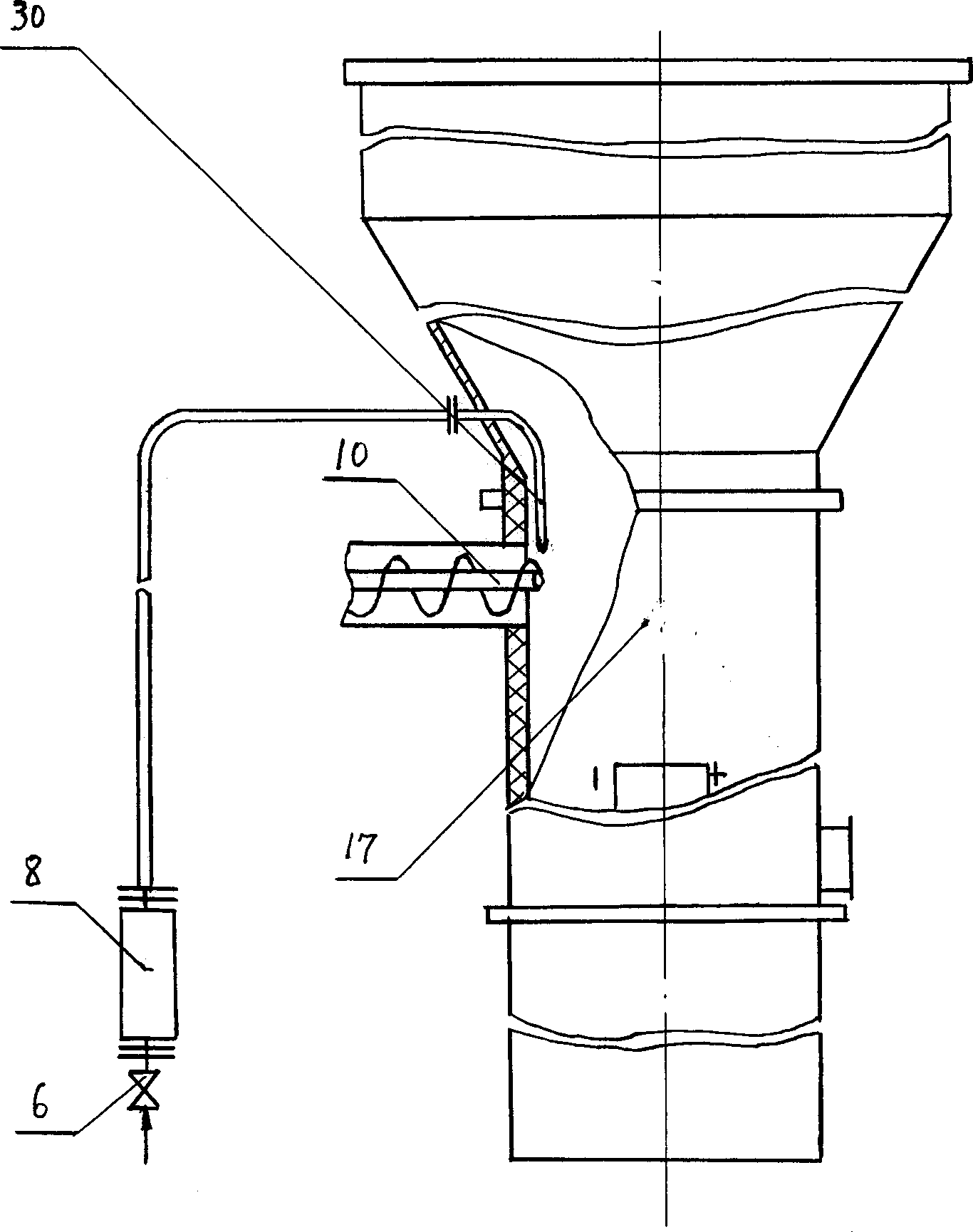

Equipment for preparing regenerated fluoride salt or alumina from waste of aluminium electrolysis

InactiveCN1396282AImprove product qualityHigh recovery rateFluoride preparationProcess efficiency improvementAluminium electrolysisCrusher

An apparatus for prepairng the regenerated fluoride salt and alumina from the waste generated by aluminium electrolysis is an improvement to the patent ZL96115111.0, and features that an additional crush-screen system composed hammer crusher and sieve set is used in the front of the said apparatus. Its advantages are low consumption of electric energy, no secondary pollution, high recovery rate and high quality of products.

Owner:抚顺铝厂科学研究所

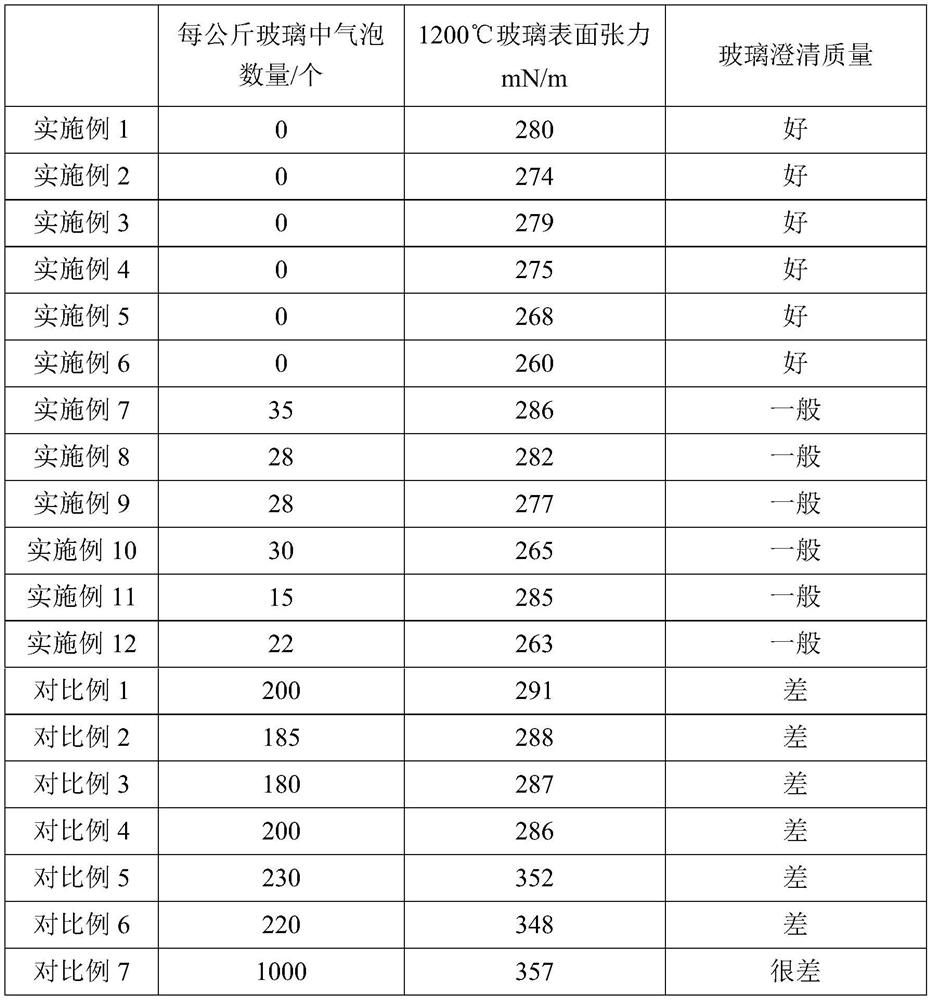

Composite clarifying agent, composition for neutral borosilicate medicinal glass as well as glass prepared from composition, and applications

The invention relates to the field of glass manufacturing, and discloses a composite clarifying agent, a composition for neutral borosilicate medicinal glass as well as glass prepared from composition, and applications. The clarifying agent comprises chlorate, fluoride salt and valence-variable oxide, wherein the chlorate is selected from one or more of sodium chloride, calcium chloride, potassium chloride, barium chloride and ammonium chloride, the fluoride salt is sodium fluosilicate and / or calcium fluoride, and the variable valence oxide is tin oxide and / or cerium oxide. When the composite clarifying agent provided by the invention is applied to neutral borosilicate medicinal glass, the surface tension of molten glass can be remarkably reduced, and a good clarifying effect is achieved by utilizing the discharge of bubbles in the molten glass.

Owner:东旭药玻(北京)科技有限公司 +1

Method for recovering fluoride salt from complex aluminum electrolyte

ActiveCN114314625AConducive to stable productionThe process is simple and greenAlkali metal fluoridesAluminium fluoridesEngineeringWaste recycling

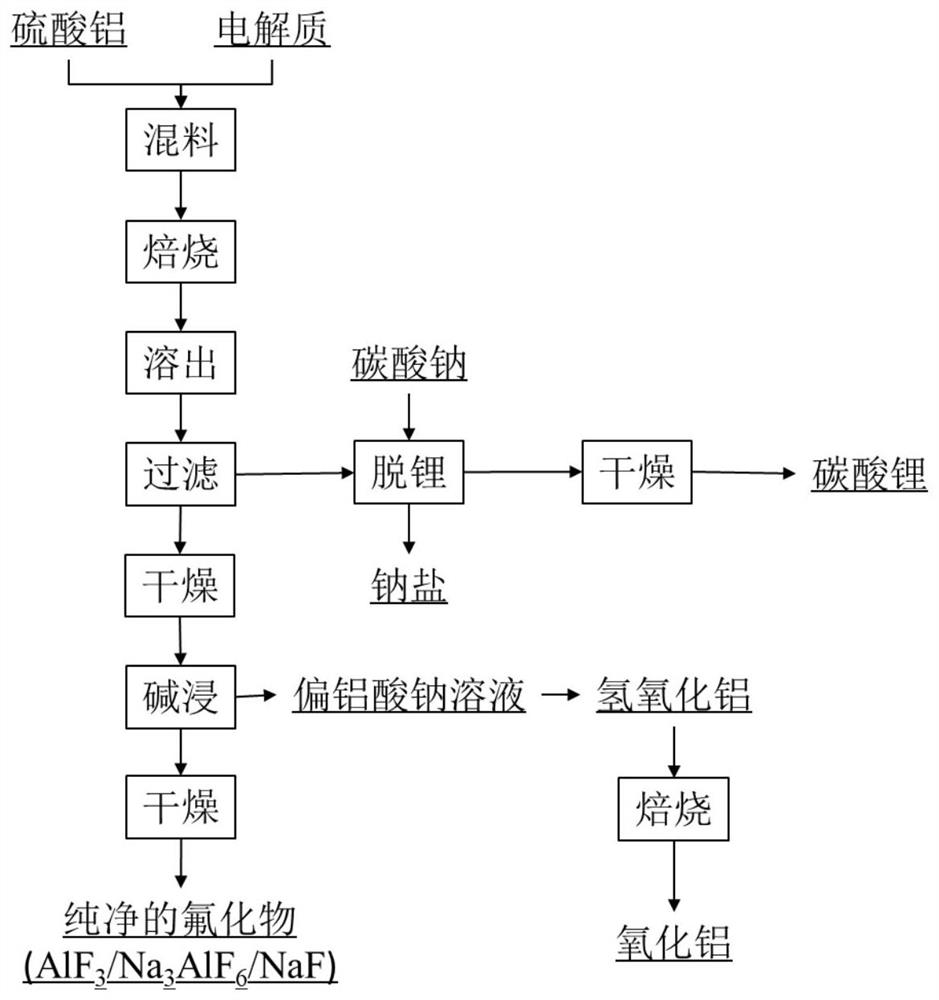

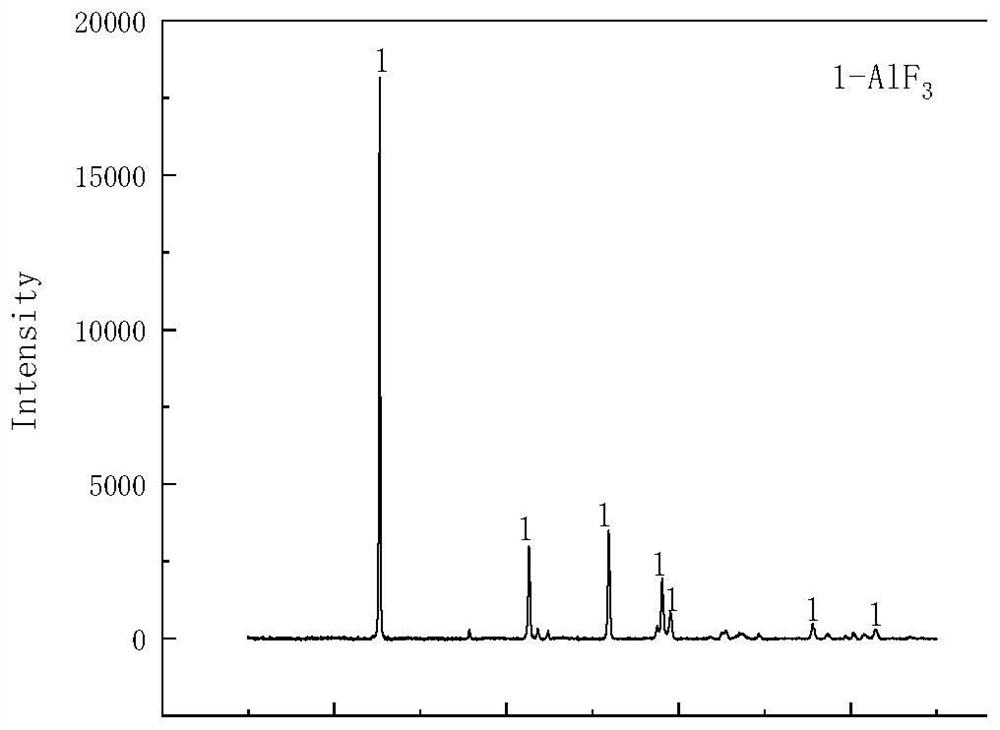

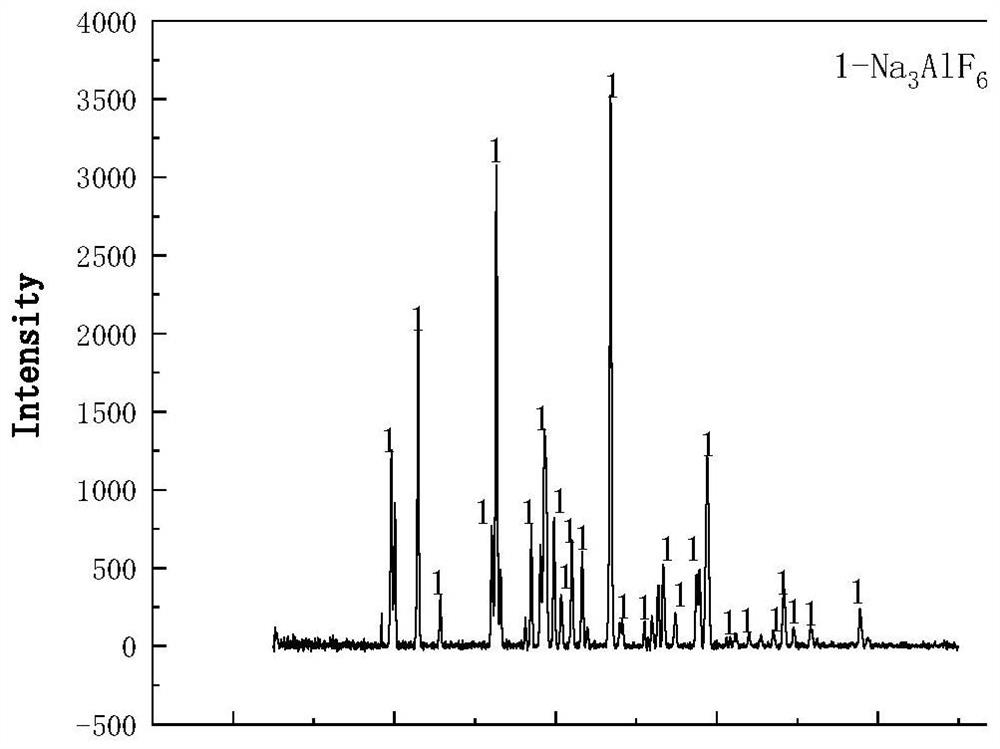

The invention belongs to the technical field of aluminum smelting solid waste recycling and reusing, and particularly relates to a method for recycling fluoride salt from complex aluminum electrolyte. According to the method for recovering the fluoride salt from the complex aluminum electrolyte, the complex aluminum electrolyte and the aluminum sulfate are used as raw materials, the processes of roasting, acid pickling dissolution, alkaline leaching, lithium removal, potassium removal, sodium removal and the like are sequentially carried out, a pure fluoride product (aluminum fluoride / sodium fluoride) is prepared, the whole process flow is simple and green, and the yield is high. According to the method, the fluorine element, the lithium element and the like in the complex aluminum electrolyte are recycled at the same time, HF is not generated, the resource utilization efficiency and economic benefits are improved, and stable production of electrolytic aluminum enterprises is promoted.

Owner:NORTHEASTERN UNIV

Environment-friendly recycling method for abandoned cathode carbon blocks of aluminum electrolysis cell

InactiveCN105401169AReduce storage costsSignificant comprehensive benefitsEnvironmental engineeringFluorine containing

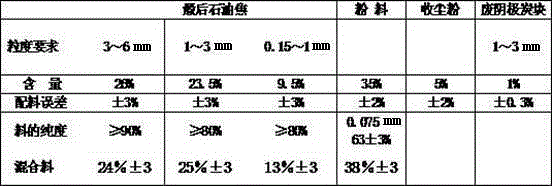

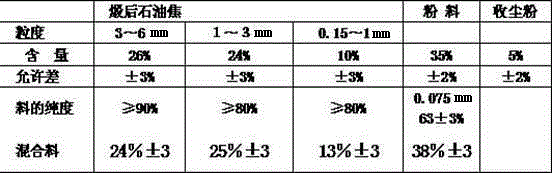

The invention discloses an environment-friendly recycling method for abandoned cathode carbon blocks of an aluminum electrolysis cell. The abandoned cathode carbon blocks are cleaned and crushed and then blended into an aluminum electrolysis carbon anode production system, and fluoride salt in the abandoned cathode carbon blocks is made to enter anode carbon bodies for aluminum electrolysis to be used as a production raw material for anode carbon for aluminum electrolysis. By means of the environment-friendly recycling method for the abandoned cathode carbon blocks of the aluminum electrolysis cell, the abandoned fluorine-containing cathode carbon blocks are successfully disposed, and original storage cost is lowered to zero; meanwhile, useful components such as carbon, Na, Mg, Al, K, Ca and Fe in the original abandoned cathode carbon blocks are successfully recycled in aluminum electrolysis production, waste is turned into wealth, and direct and indirect economic benefits and environmental protection benefits are remarkable.

Owner:新疆生产建设兵团第八师天山铝业有限公司

Method for preparing aluminum fluoride and aluminum oxide by decarburization and sodium removal of electrolytic aluminum carbon slag

PendingCN112551566ARealize full recyclingWide variety of sourcesAluminium oxide/hydroxide preparationAluminium hydroxide preparationAluminum fluorideSlag

The invention belongs to the technical field of electrolytic aluminum burner carbon slag recycling, and discloses a method for preparing aluminum fluoride and aluminum oxide by decarburization and sodium removal of electrolytic aluminum carbon slag. The method comprises the following steps: crushing electrolytic aluminum carbon slag into fine particles with the particle size of less than 3 mm, adding a decarburization agent into the carbon slag, uniformly mixing to obtain a 1# mixture, adding the 1# mixture into a high-temperature furnace, and carrying out I-section heating treatment in an airatmosphere to obtain crude fluoride salt A; adding a sodium removal agent into the crude fluoride salt A, uniformly mixing to obtain a 2# mixture, adding the 2# mixture into a high-temperature furnace, and carrying out II-stage heating treatment to obtain crude fluoride salt B; adding the crude fluoride salt B into a stirring tank, adding industrial pure water to fully dissolve sodium salt into water, and carrying out solid-liquid separation to obtain a precipitate C and a sodium salt solution D; and drying the precipitate C to obtain aluminum fluoride and aluminum oxide products. According to the invention, the whole technological process is free of waste residues and waste water, the decarburization agent and the sodium removal agent are wide in source, the production cost is low, and industrial implementation is easy.

Owner:ZHENGZHOU UNIV

Preparation method of adsorbent for fluorine gas purification

PendingCN114054007AHigh porosityImprove adsorption capacityGas treatmentOther chemical processesSorbentPhysical chemistry

The invention discloses a preparation method of an adsorbent for fluorine gas purification. The method comprises the following steps: proportionally mixing a fluoride salt raw material with a binder and a solvent, and performing concentrating, granulating, sintering and post-treatment to obtain the adsorbent for fluorine gas purification. The post-treatment method comprises the following steps: mixing a product obtained after sintering with fluorine gas or fluorine-nitrogen mixed gas with the volume fraction of 5%-10%, standing and reacting, wherein the use amount of the fluorine gas with the volume fraction of 5%-10% is 0.5-1.0 wt% of the adsorbent. The adsorbent for fluorine gas purification prepared by the method is large in porosity, strong in adsorption capacity, remarkably improved in mechanical property and good in use stability, can improve the fluorine gas purification efficiency in the fluorine preparation process, and has good practicability and wide utilization value. The preparation method disclosed by the invention is simple in process, universal in equipment, low in corrosivity and easy to realize automatic control. The raw materials used in the preparation method are commercially available products, and are low in price and easy to obtain.

Owner:天津海嘉斯迪新材料合伙企业(有限合伙)

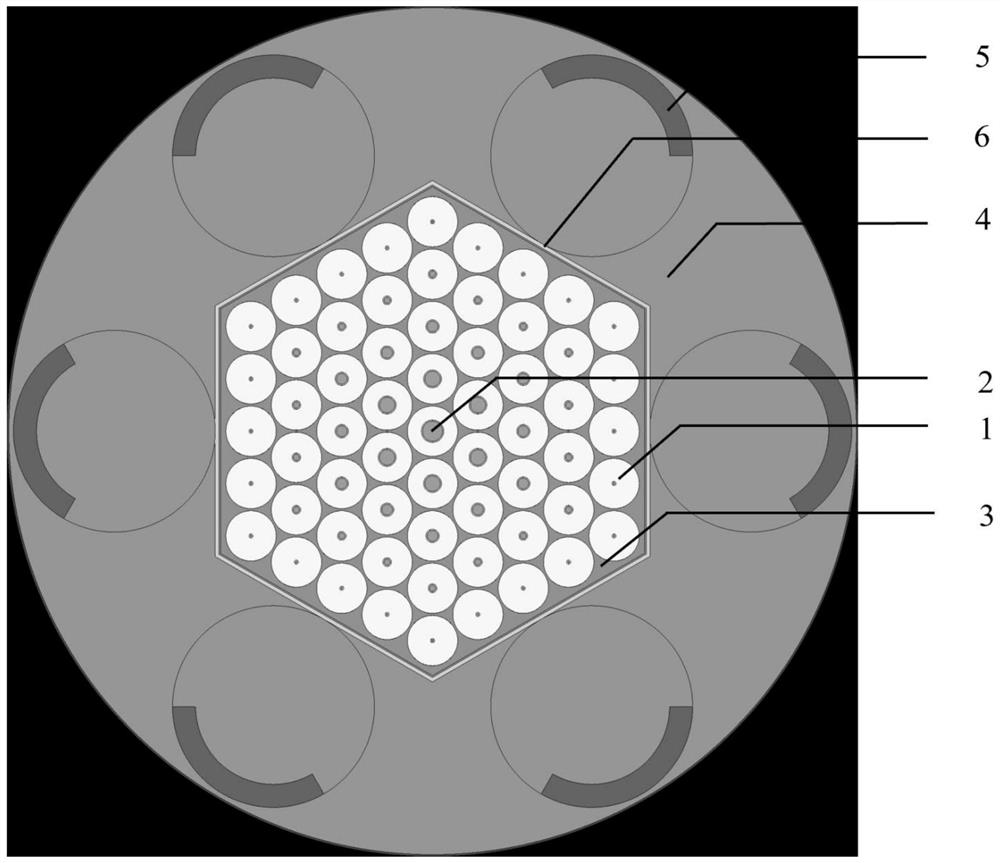

Liquid-solid dual-fuel space nuclear reactor power supply

PendingCN112669999ACompact layoutReduce quality problemsFuel elementsNuclear energy generationReactor pressure vesselNuclear reactor

The invention discloses a liquid-solid dual-fuel space nuclear reactor power supply. A reactor core comprises UC solid fuel rods, a fluoride salt coolant, a reactor core spectral shift absorber material, a reflecting layer material, a control drum and a reactor pressure vessel; the reactor core active area comprises a plurality of UC solid fuel rods, wherein coolant guide pipes are arranged in the UC solid fuel rods; a fluoride salt coolant is arranged in the coolant guide pipe, a cavity filled with helium buffer fission gas is formed in the end of the UC solid fuel rod, and the reflecting layer material and the control drum are arranged on the outer side of the reactor core active area. According to the invention, the residual reactivity, compactness and miniaturization of the reactor core are further improved while the heat of the reactor core is timely brought out, and the safety requirements of the reactor core are met in the service life operation process of the reactor core and under accident conditions.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for preparing aluminum fluoride and aluminum oxide by decarburization and sodium removal of aluminum electrolysis carbon residue

PendingUS20220144658A1High purityLow production costAluminium oxide/hydroxide preparationAluminium hydroxide preparationAir atmosphereAluminum fluoride

A method for preparing aluminum fluoride and aluminum oxide by decarburization and sodium removal of an aluminum electrolysis carbon residue is disclosed. The method includes: crushing the aluminum electrolysis carbon residue into fine particles not larger than 3 mm, adding decarburization agent into the carbon residue, mixing to obtain first mixture, adding the first mixture into a high-temperature furnace, conducting I-stage heating treatment in air atmosphere to obtain crude fluoride salt A; adding sodium removal agent into the crude fluoride salt A, mixing to obtain second mixture, adding the second mixture into high-temperature furnace, and conductingII-stage heating treatment to obtain crude fluoride salt B; adding the crude fluoride salt B into stirring tank, adding industrial pure water, dissolving a sodium salt into water, and conducting solid-liquid separation to obtain precipitate C and sodium salt solution D; drying the precipitate C to obtain aluminum fluoride and aluminum oxide.

Owner:ZHENGZHOU UNIV

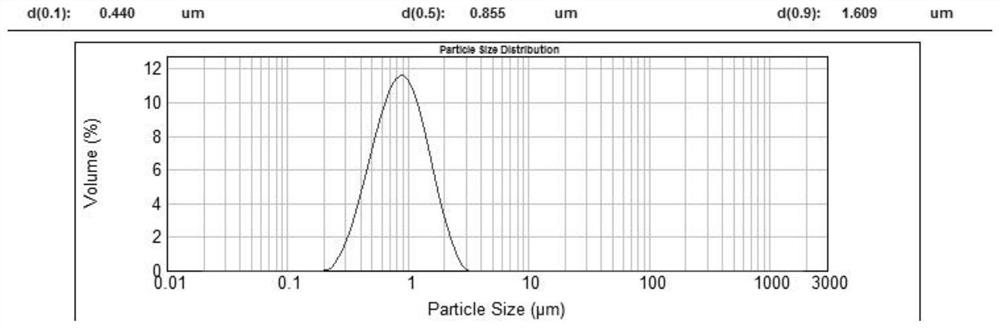

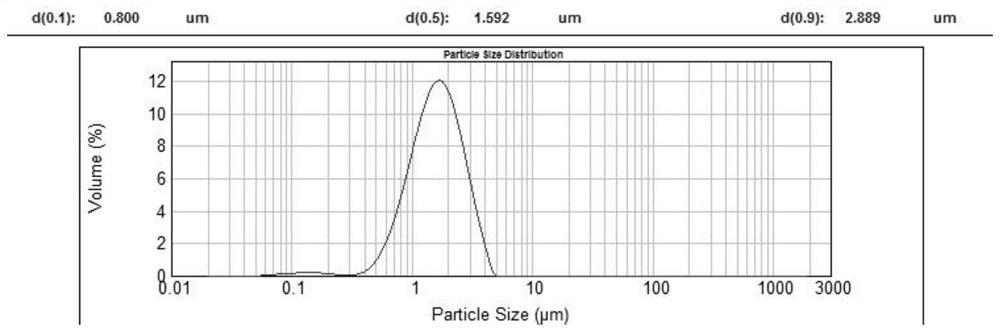

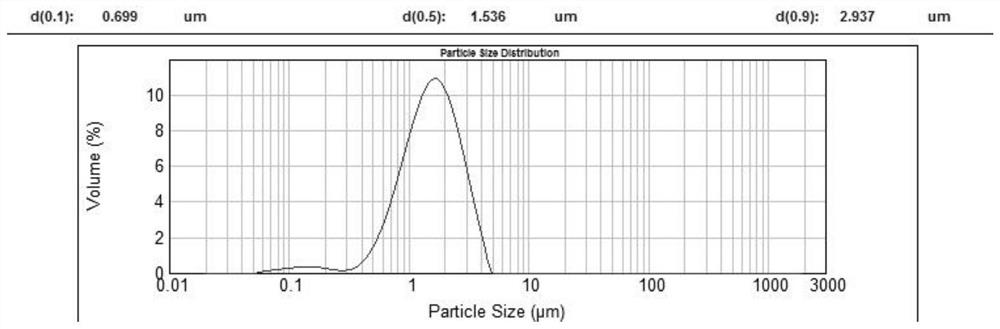

A method of ball milling pretreatment combined with chemical method to prepare ultra-fine clean coal

ActiveCN110003965BBreak down refinement bottlenecksSmall particle sizeBiofuelsSolid fuelsMetallurgyActive agent

The invention discloses a method for combining ball milling pretreatment-chemical method to prepare superfine clean coal, which comprises the following steps: (1) crushing anthracite and roasting it in a protective atmosphere to obtain coal particles; Add a dispersant, control the gradation of the balls, carry out ball milling, and then dry to obtain superfine coal powder; (2) After mixing superfine coal powder and surfactant, add it to the mixed immersion solution of acid and fluoride salt, heat After leaching, filter, wash and dry to obtain superfine clean anthracite coal powder. The present invention removes volatile matter from the crushed anthracite in a protective atmosphere and cooperates with ball milling pretreatment to obtain ultra-fine coal powder with small particle size and narrow distribution range, and then removes impurities to increase the purity of the obtained ultra-fine coal powder Not less than 99.5wt%.

Owner:CENT SOUTH UNIV

A method for preparing white carbon black from fluorine-containing silicon slag

The invention discloses a method for preparing white carbon black from fluorine-containing silicon slag. Heating the mixed material to 40~80℃ under certain conditions, maintaining the reaction for 20~50 minutes, so that the fluorosilicic acid in the fluorine-containing silicon slag reacts completely, and a mixed solution of silicon dioxide and fluoride salt is obtained; the obtained silicon dioxide and fluoride salt liquid-solid mixture while hot or cooled to ≤? 50°C, send to filter or centrifuge for liquid-solid separation to obtain silica wet cake and fluoride salt filtrate; carry out countercurrent washing on the obtained silica wet cake for 4 to 6 times, and combine the washing liquid and fluoride salt filtrate The fluoride salt solution is used for other purposes, and the second to sixth times of washing liquid are respectively entered into the first to fifth washing liquid storage tanks for the first to fifth washing of the next time; the silicon dioxide wet filter cake is dried to obtain Silica products. The invention has the advantages of simple technological process, less equipment, simple and convenient operation, low production cost and easy realization of industrialized production.

Owner:WENGFU (GRP) CO LTD +1

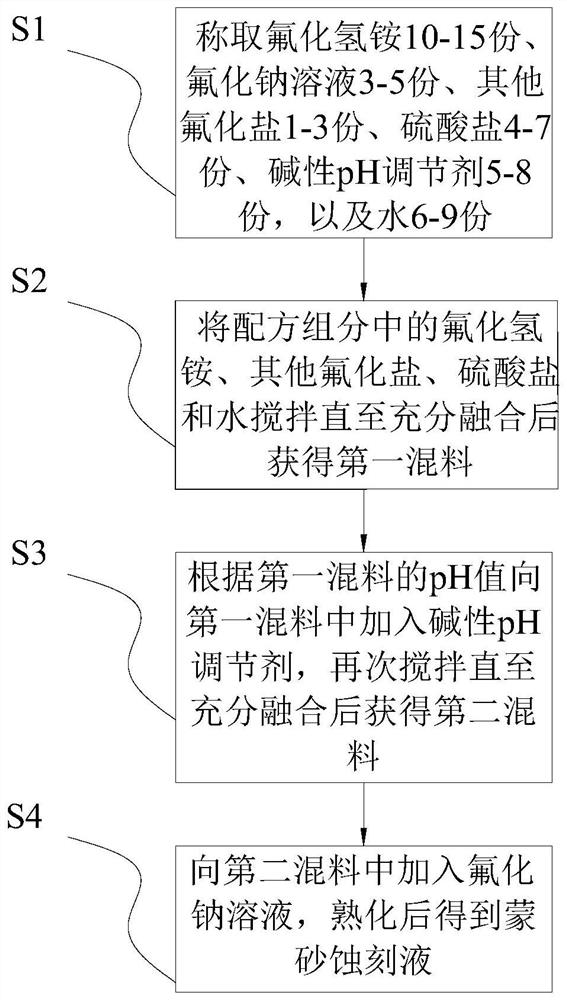

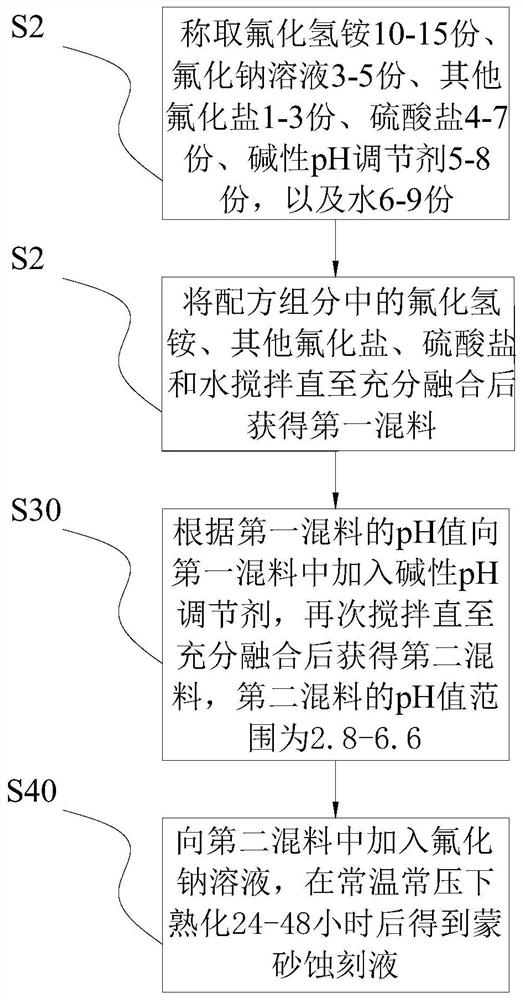

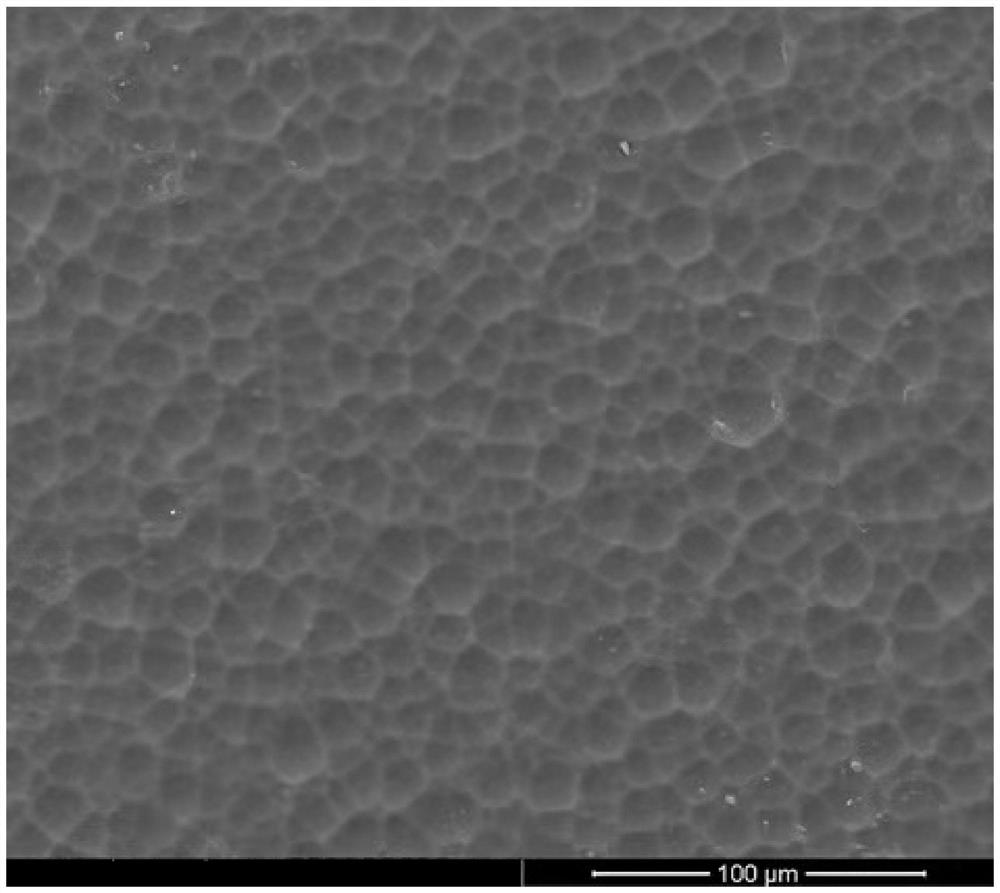

Frosting etching solution as well as preparation method and use method thereof

PendingCN112679102AEffective corrosionRegular and uniform surface morphologyEtchingDiffuse reflection

The invention is applicable to the technical field of frosting etching, and provides a frosting etching solution and a preparation method and a use method thereof. The frosting etching solution comprises the following formula components in parts by mass: 10-15 parts of ammonium bifluoride, 3-5 parts of a sodium fluoride solution, 1-3 parts of other fluoride salts, 4-7 parts of sulfate, 5-8 parts of an alkaline pH regulator, and 6-9 parts of water. The frosting etching solution provided by the invention is strong in frosting etching capability, does not need to add an additional acidic pH regulator, and can be used for many times; glass treated by the frosting etching solution has a moderate frosting effect and has a diffuse reflection or light scattering function, so that the glare effect of an electronic screen or a lamp is reduced or avoided; the width value and the depth value of pits formed in the surface of the glass are both moderate, no burr feeling or rough feeling is generated, and the flash point effect is avoided; and the etched glass also has a visual effect similar to that of paper, accords with the watching habit of human eyes, and reduces visual fatigue.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

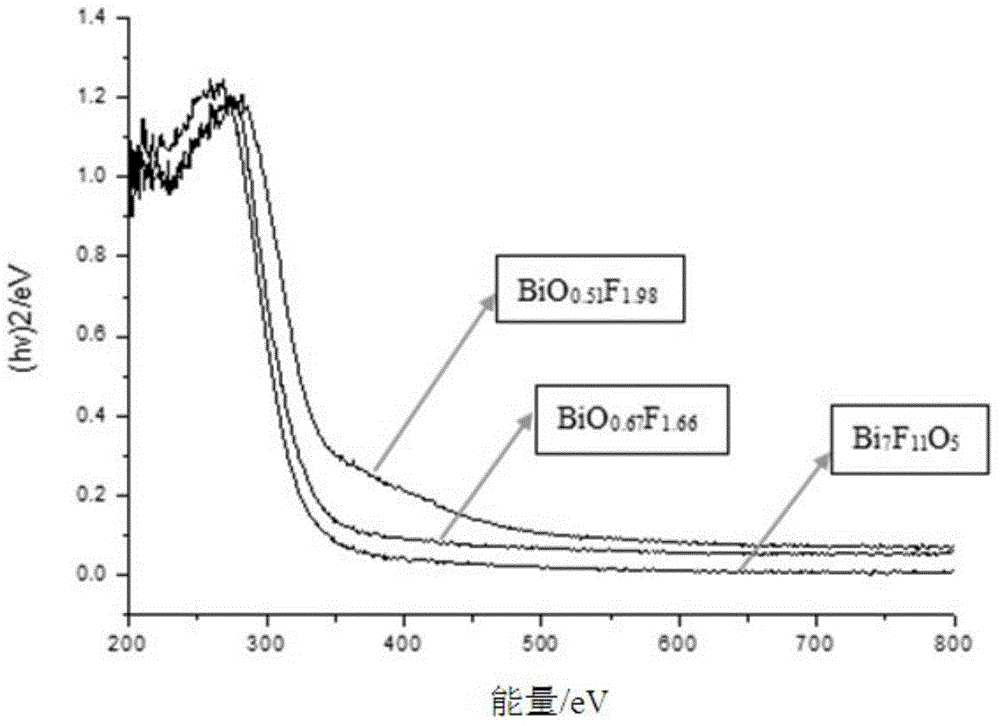

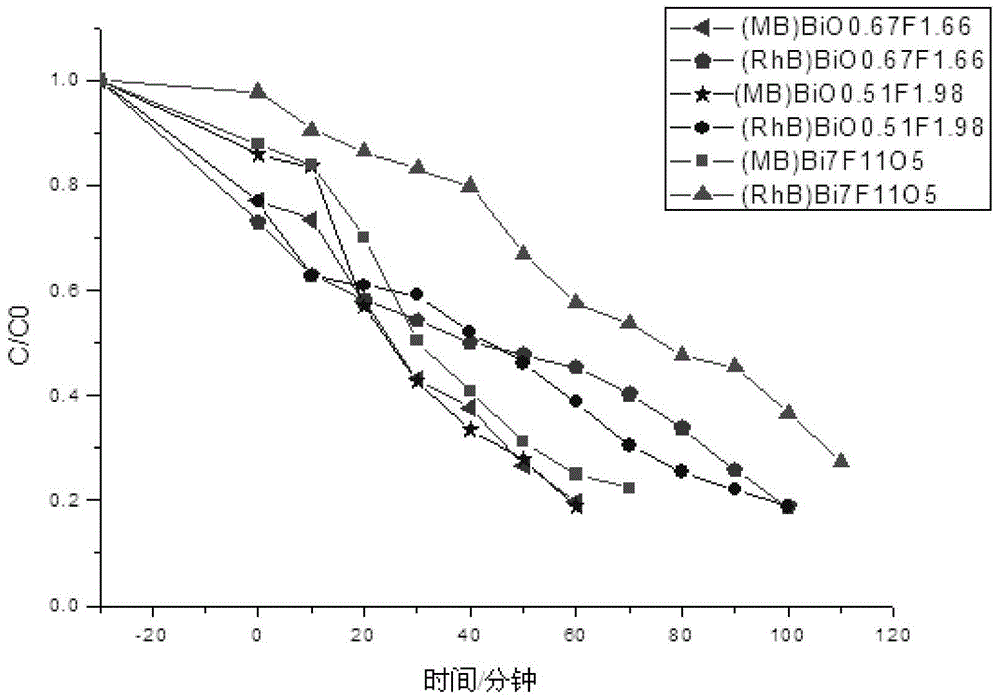

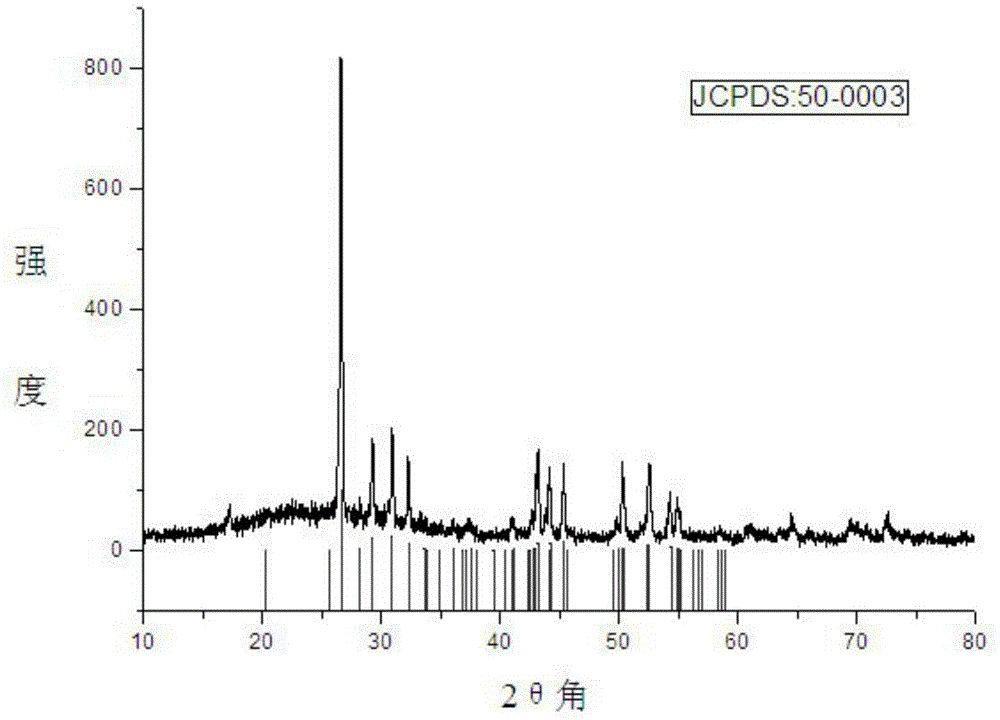

Bismuth oxyfluoride photocatalyst and preparing method of bismuth oxyfluoride photocatalyst

InactiveCN104801320ASimple methodHigh catalytic activityPhysical/chemical process catalystsWater/sewage treatment by irradiationPtru catalystPolytetrafluoroethylene

The invention discloses a bismuth oxyfluoride photocatalyst and a preparing method of the bismuth oxyfluoride photocatalyst. The preparing method comprises the following steps of adding glacial acetic acid into water, wherein the volume ratio of the glacial acetic acid to the water is 1:2-5:1, stirring the glacial acetic acid and the water, adding bismuth nitrate and soluble fluoride salt into glacial acetic acid solution, stirring in thermostatic waterbath of 75 DEG C to 85 DEG C for 20 to 40 minutes to dissolve the bismuth nitrate and the fluoride salt, making mixed solution with the bismuth nitrate concentrate as 0.95mmol / 30ml to 1.05mmol / 30ml and the mole ratio of bismuth element to fluorine element as 1:1.9 to 1:2.1, adding the mixed solution into a polytetrafluoroethylene lining to be subjected to thermal reaction for 10 to 13 hours in constant-temperature water of 120 DEG C to 160 DEG C, and obtaining the bismuth oxyfluoride photocatalyst after centrifuging, washing and drying. The preparing method is simple, practical, easy to popularize in large scale, suitable for making the bismuth oxyfluoride photocatalyst with high catalytic activity and applied to catalytic degradation of organic pollutants.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Electrolyte for aluminium electrolysis and electrolysis technology using same

The invention relates to an electrolyte for aluminium electrolysis and an electrolysis technology using the same. The electrolyte adopts a pure fluoride salt system, which comprises following components in percentage by weight: 30 to 38% of NaF, 49 to 60% of AlF3, 1 to 5% of LiF, 1 to 6% of KF, and 3 to 6% of Al2O3; wherein the mole ratio of NaF to AlF3 is 1.0 to 1.52. The electrolyte has the advantages of low liquidus temperature, good solubility of prepared alumina, and high conductivity, and has the good functions of reducing energy consumption, increasing current efficiency, and improving work environment during the electrolysis process.

Owner:北京润括未来科技有限公司

A kind of environment-friendly low-rebound low-alkali liquid quick-setting agent and preparation method thereof

The invention discloses an environment-friendly low-resilience low-alkaline liquid setting accelerator and a preparation method thereof. The environment-friendly low-resilience low-alkaline liquid setting accelerator is prepared from, by mass, 50-60% of a modified polyaluminium sulfate solution, 1-5% of modified fluoride salt, 1-4% of modified alcohol amine, 1-3% of a dispersant and 30-42% of water. The preparation method specifically includes the following steps that 1, the a modified polyaluminium sulfate solution is prepared; 2, modified fluoride salt is prepared; 3, modified alcohol amine is prepared; 4, the dispersant and the balance water are added, stirring is carried out for 1-4 h at 40-70 DEG C, and the finished product is obtained. As for the total alkali amount of the prepared low-alkaline liquid setting accelerator, Na2O+K2O<3%, the pH ranges from 3 to 5, and harm to the skin is small; when applied to spraying concrete, the low-alkaline liquid setting accelerator guarantees construction safety and has the advantages of being low in resilience, capable of significantly improving later-stage strength and the like.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

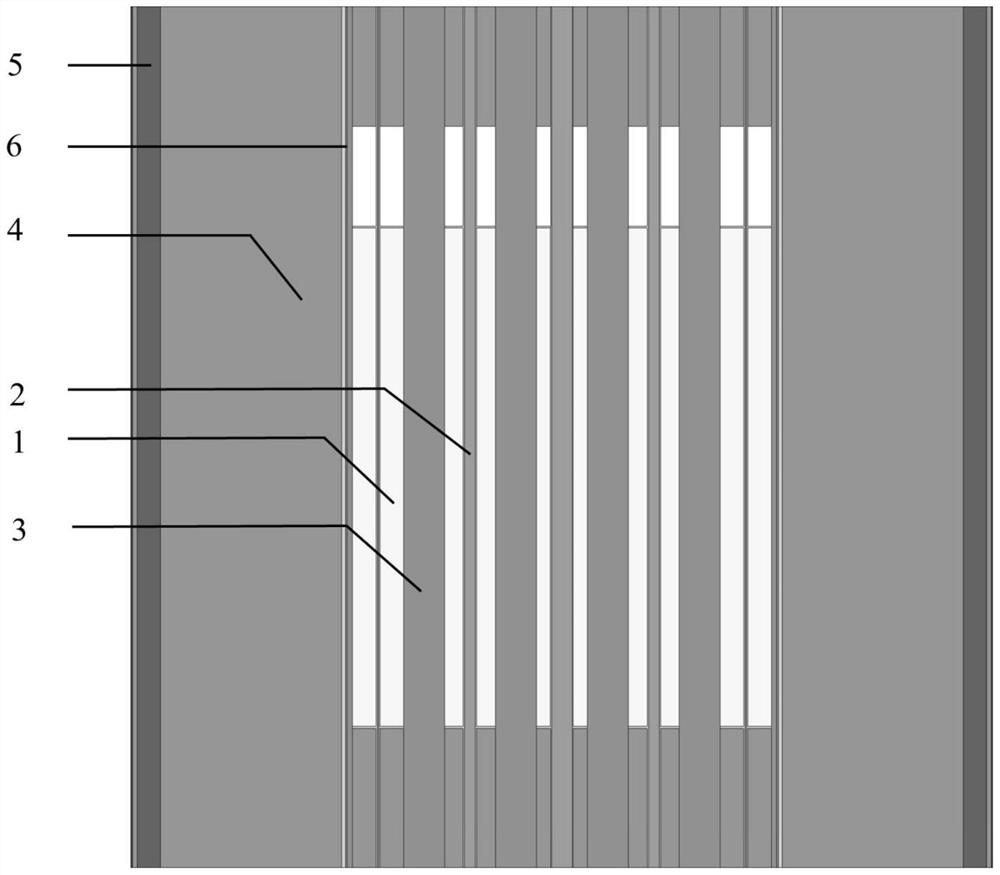

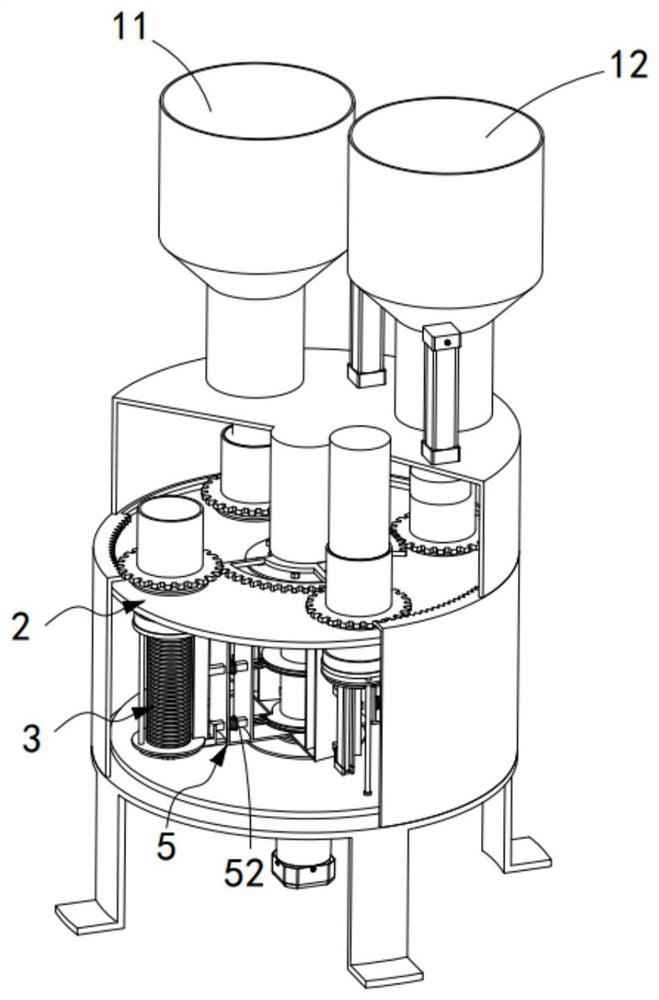

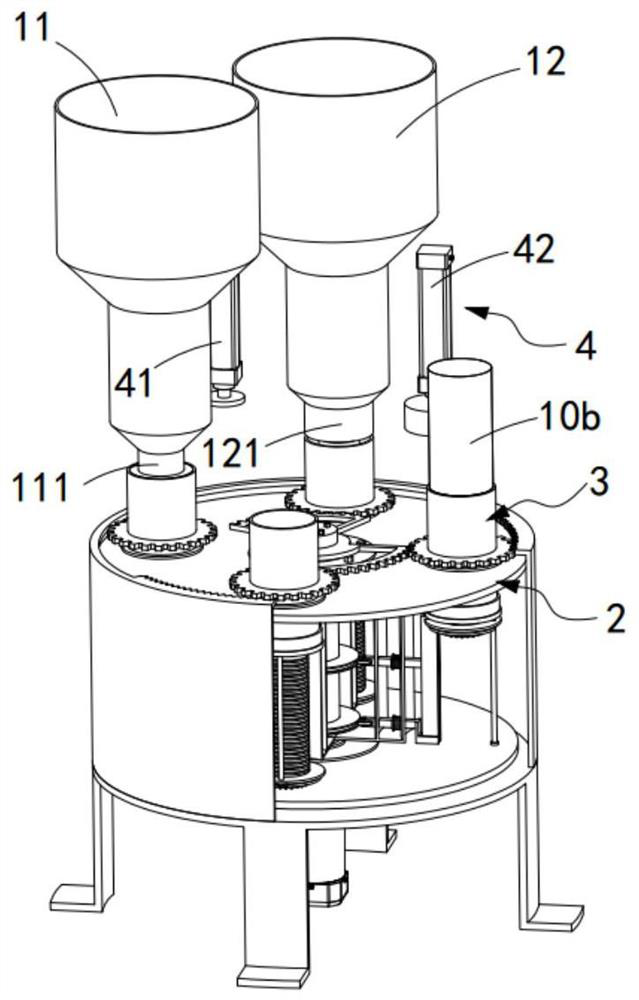

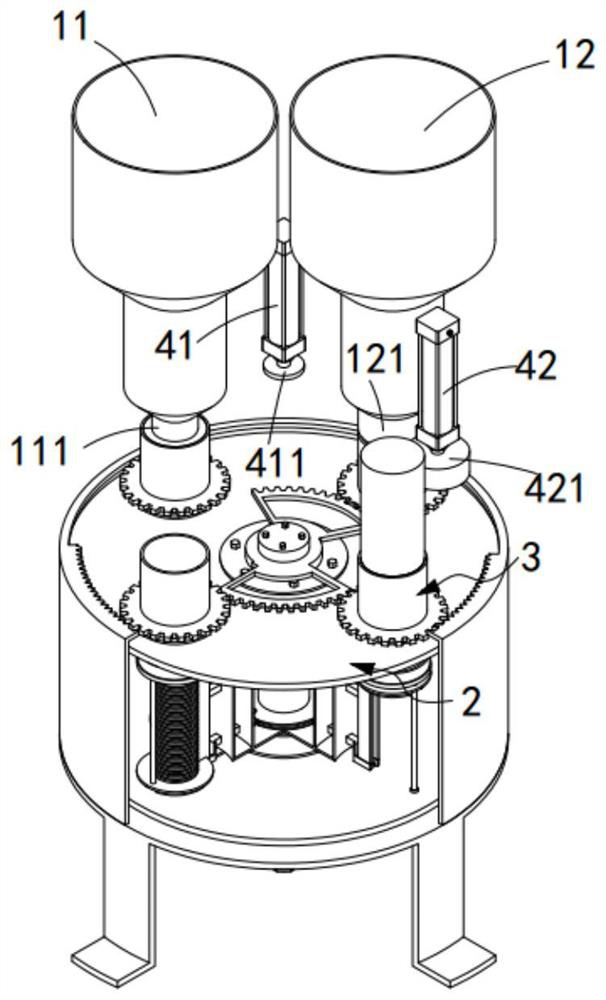

Production equipment for graphite product with gorgeous surface colors

ActiveCN112373105AIncrease roughnessGuaranteed StrengthPress ramShaping pressSurface roughnessGraphite

The invention relates to the technical field of colored graphite processing, in particular to production equipment for a graphite product with gorgeous surface colors. The production equipment comprises a first feeding bin, a second feeding bin, a turntable, forming devices and a pressing device. Through the forming devices with inner cylinders and outer cylinders, a graphite core material withoutfluoride salt is pressed by utilizing the inner cylinders, a graphite surface layer material with fluoride salt is pressed by utilizing the outer cylinders, the graphite surface layer material and the graphite core material are combined together through dipping after being pressed, the fluoride salt is decomposed in the carbonization process, and uniformly distributed pits are formed in a graphite surface layer, so that the surface roughness of the graphite product is increased, the adhesive force of a dyed coating is improved, and the technical problem that the dyed graphite product is proneto decoloring and color fading is solved.

Owner:SINOSTEEL NEW MATERIAL ZHEJIANG

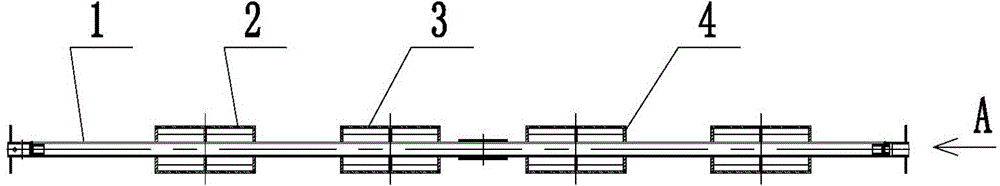

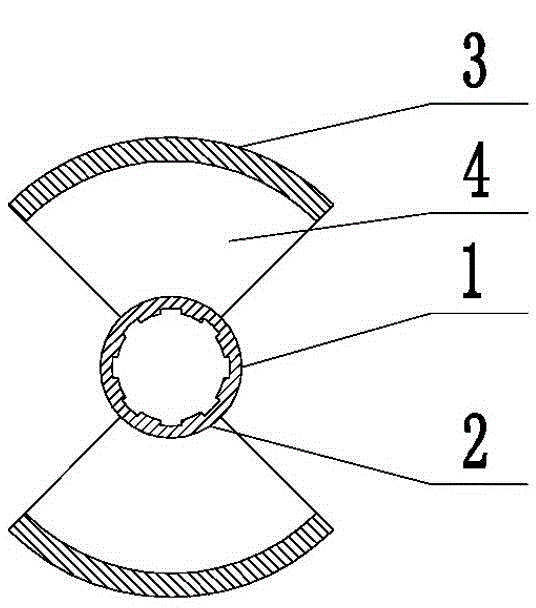

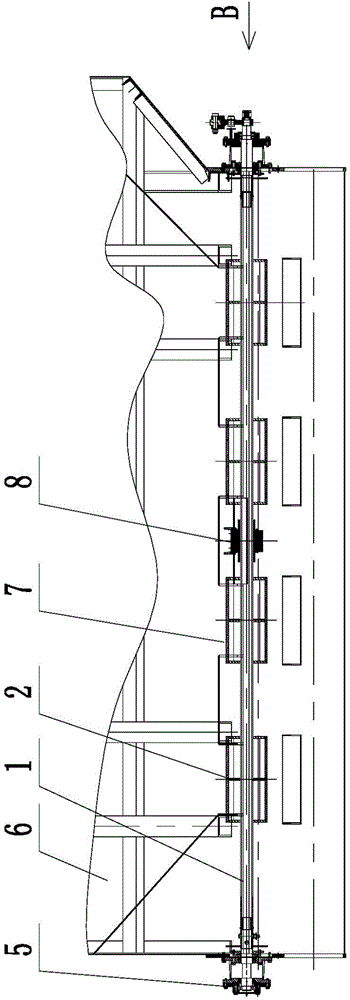

Rotary type flow-adjustable blanking valve structure and fluoride salt charging vehicle applying blanking valve

ActiveCN105987194ACompact structureEasy to manufacture and assemblePlug valvesOperating means/releasing devices for valvesEngineeringElectrical and Electronics engineering

The invention relates to a rotary type flow-adjustable blanking valve structure and a fluoride salt charging vehicle applying the blanking valve, belongs to the technical field of metallurgical machinery, and in particular relates to a rotary type flow-adjustable blanking valve structure applied to a fluoride salt charging vehicle and a fluoride salt charging vehicle applying the blanking valve. The invention provides a blanking valve structure of a fluoride salt charging vehicle with simple structure, strong reliability and convenience in flow adjustment. The blanking valve structure comprises a spindle and is characterized in that a core body is arranged on the spindle, the core body comprises supporting plates which are vertical to the spindle and are arranged at the two sides of the spindle, and arc-shaped plates are arranged at the outer edges of the supporting plates at the two sides of the spindle.

Owner:NFC (SHENYANG) METALLURGICAL MACHINERY CO LTD

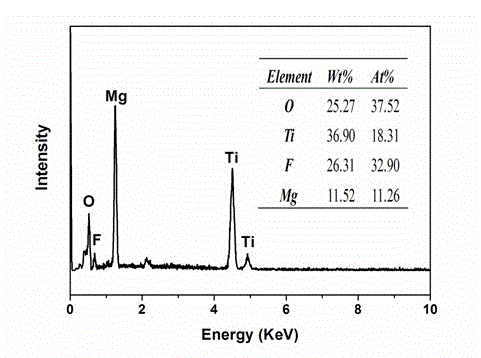

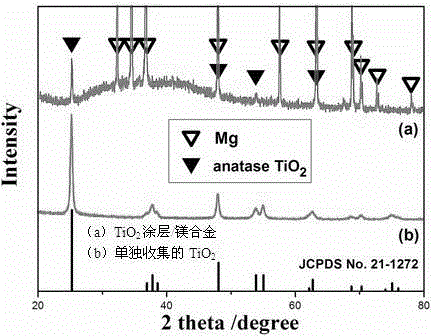

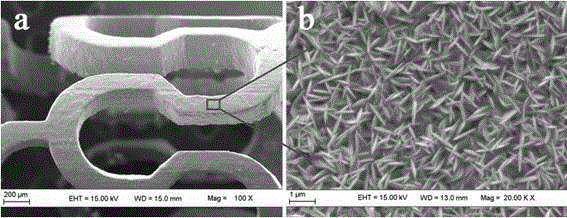

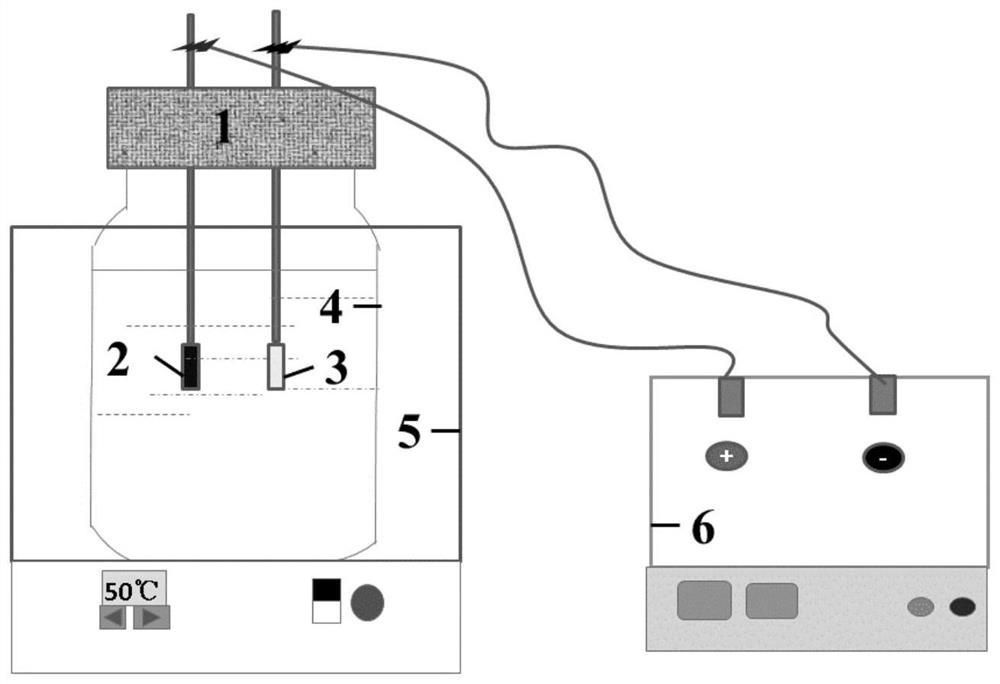

Hydrothermal preparation method of nano-titania coating on surface of magnesium alloy intravascular stent

ActiveCN103334105AEasy to handleModerate reaction temperatureMetallic material coating processesMg alloysBlood vessel

The invention discloses a hydrothermal preparation method of a nano-titania coating on surface of a magnesium alloy intravascular stent. The preparation method comprises the following steps: uniformly mixing absolute ethyl alcohol and hydrofluoric acid, and then adding tetrabutyl titanate for blending to obtain solution A, wherein the concentration of hydrofluoric acid in the solution A is 0.1-0.4 mol / L, and the concentration of tetrabutyl titanate is 0.1-0.3 mol / L; dissolving fluoride salt in deionized water to obtain solution B, wherein the concentration of fluoride salt in the solution B is 0.1-0.4 mol / L; then uniformly mixing the solution A and the solution B to obtain solution C; placing the magnesium alloy intravascular stent after processing into the solution C, and taking out after a hydrothermal reaction so as to obtain the nano-titania coating. The method has the advantages of being environment-friendly, convenient to process, easily-obtained, low in price, and the like; the bonding force of the obtained sheet nano-titania coating and the magnesium alloy intravascular stent is high, and the nano-titania coating has good corrosion resistance and blood compatibility, the coating is large in porosity and specific area, the dimensions are uniform and controllable, and the nano-titania coating is suitable for intravascular stent medicine carrying.

Owner:ZHENGZHOU UNIV

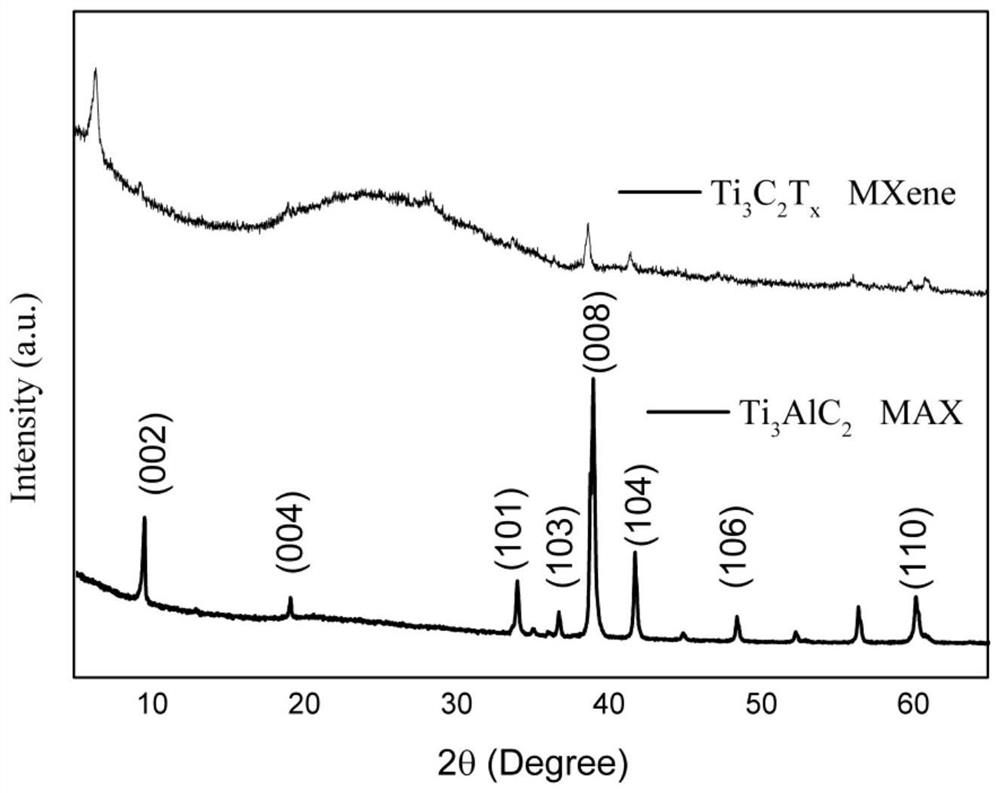

Method for etching MXene based on electrochemistry, MXene turbid liquid and application of MXene turbid liquid

PendingCN114737227AAvoid strong acids and basesThe operation process is economical and simpleCarbon compoundsNitrogen-metal/silicon/boron binary compoundsOrganic solventPhysical chemistry

The invention provides a method for etching MXene based on electrochemical etching, MXene turbid liquid and application of the MXene turbid liquid, an organic solvent of fluoride salt is used as an electric etching solution, an MAX electrode is used as a working electrode, and MXene is obtained under the action of electrochemical etching. According to the method provided by the invention, the powdery or turbid liquid MXene can be prepared according to the post-treatment step of the etching liquid. In addition, by-product metal fluoride can be removed in an environment-friendly manner through post-treatment, few-layer MXene can be directly obtained, and the technological process is simplified.

Owner:JIANGSU UNIV

Liquid setting accelerator as well as preparation method and application thereof

The invention relates to a liquid setting accelerator as well as a preparation method and application thereof. The liquid setting accelerator comprises aluminum salt, fluoride salt, fluosilicate, a first stabilizer, a complexing agent, a water solvent and optional other components; the other components comprise fluoride salt and / or a second stabilizer, the mass content of the fluosilicate is 8-12% by mass of the aluminum salt, and the mass content of the complexing agent is 6-10% by mass of the aluminum salt. The liquid setting accelerator provided by the invention can achieve good rapid setting effects under the condition of low mixing amount, wherein the good rapid setting effects comprise faster initial setting time and final setting time, higher compressive strength and the like.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

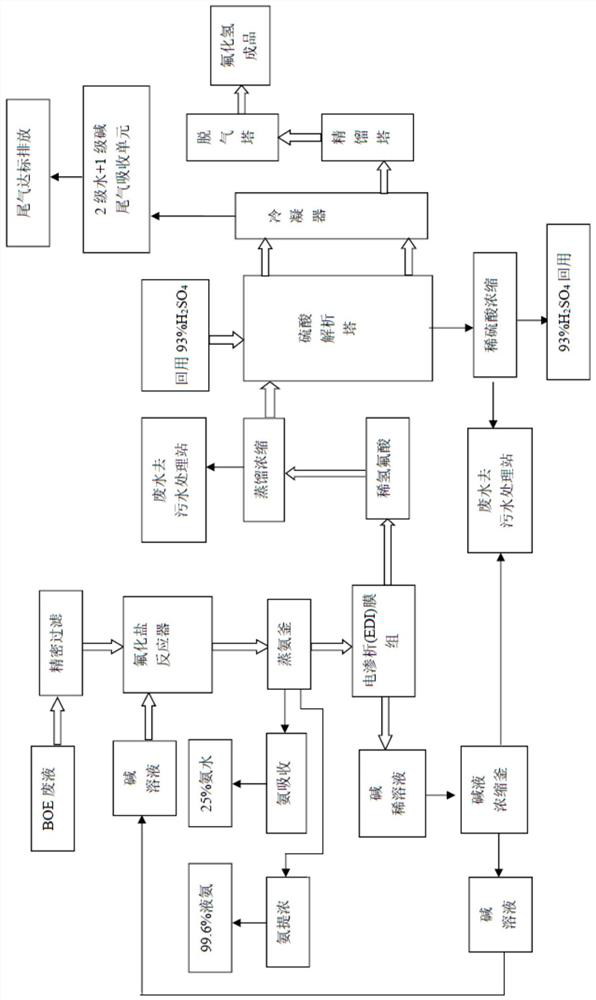

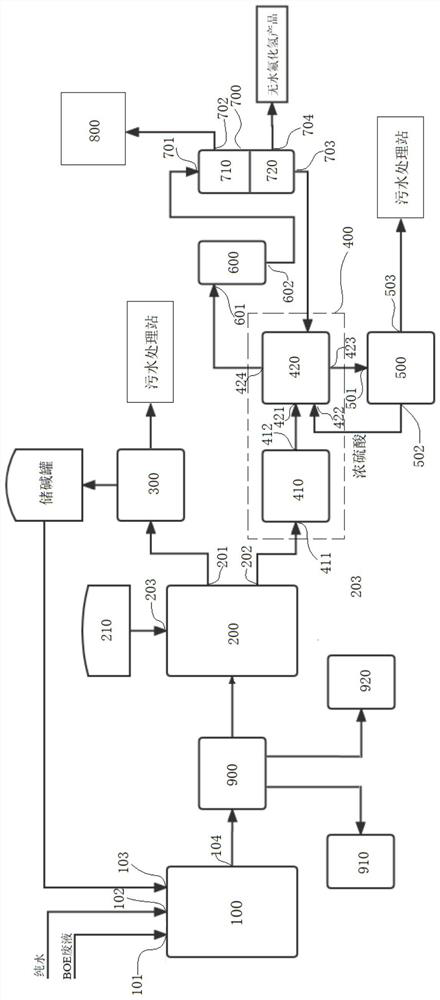

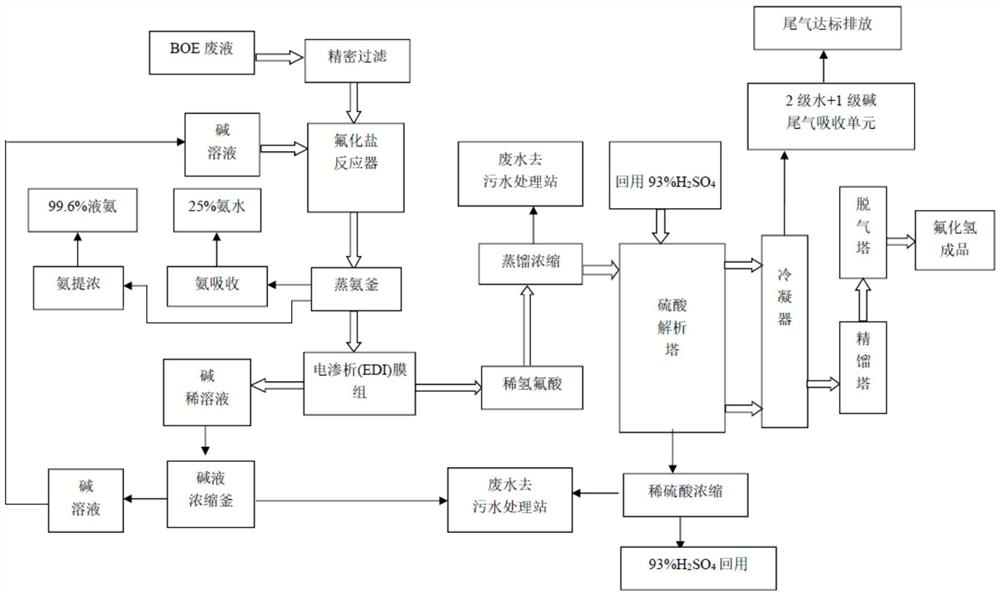

Method and device for preparing hydrogen fluoride from BOE waste liquid

PendingCN113955720ATurn waste into treasureReasonable process designHydrogen fluorideAmmonia preparation/separationHydrogen fluoridePhysical chemistry

The invention provides a method and a device for preparing hydrogen fluoride from BOE waste liquid, and the method comprises the following steps: reacting the BOE waste liquid with alkali to generate a fluoride salt solution and ammonia water; carrying out steam stripping to evaporate out ammonia gas; decomposing the fluoride salt solution into hydrofluoric acid dilute liquor and dilute alkali liquor through bipolar membrane electrodialysis; heating and concentrating the dilute alkali liquor into concentrated alkali liquor and wastewater, and recycling the concentrated alkali liquor; heating, distilling and concentrating the hydrofluoric acid dilute liquor into concentrated hydrofluoric acid and wastewater; mixing the concentrated hydrofluoric acid with concentrated sulfuric acid to obtain hydrogen fluoride gas and dilute sulfuric acid; heating and concentrating the dilute sulfuric acid into concentrated sulfuric acid and wastewater, and recycling the concentrated sulfuric acid. According to the method, the chip etching BOE waste liquid is used as the raw material, the hydrogen fluoride product is obtained after a series of treatment, alkali liquor and concentrated sulfuric acid are recycled in the process, a closed loop is achieved in the whole reaction process, value orientation of turning waste into wealth, circular economy and environmental protection is truly achieved, and the method is suitable for industrial application and popularization.

Owner:浙江容跃环保科技有限公司

Forming process with anti-fingerprint, anti-scratch and wear-resistant glass substrate etching effect

The invention relates to the technical field of glass deep processing, and particularly discloses a forming process with an anti-fingerprint, anti-scratch and wear-resistant glass substrate etching effect, which is mainly applied to chemical etching of a glass mobile phone back cover. A honeycomb-like particle layer is formed on the surface of the glass mobile phone back cover to disperse lines of fingerprints as much as possible, so that an anti-fingerprint effect is achieved; meanwhile, the honeycomb-like particle layer is good in wear resistance and can be used for a long time without falling off. Besides, organic acid such as p-toluenesulfonic acid and methanesulfonic acid is adopted as acid in the etching solution and combined with fluoride salt (ammonium hydrogen fluoride and sodium fluoride) to form effective components in the etching solution, production is stable during frosting, and waste liquid obtained after frosting is environmentally friendly; in addition, the etching liquid is low in price, the etching process is easy to control, the production yield is high, and the product quality is stable.

Owner:佛山犀马精细化工有限公司

Metal surface silver plating method

InactiveCN110670053AGood restorativeUniform filmLiquid/solution decomposition chemical coatingChemical reactionPhysical chemistry

The invention relates to a metal surface silver plating method. According to the method, a non-silver-plated portion is in contact with repair liquid to make a chemical reaction. The heating temperature during the chemical reaction is 30 DEG C to 40 DEG C. After the non-silver-plated portion is reacted with the repair liquid, water washing and drying are carried out, wherein a solute of the repairliquid is silver nitrate, urea and fluoride salt, and a solvent of the repair liquid is water. The new method can achieve rapid silver plating, a film is uniform, bright and smooth, and the good conductivity is achieved.

Owner:BEIJING SHUGUANG AERO ELECTRICAL

Accelerating agent as well as preparation method and application thereof

The invention belongs to the field of building materials, and particularly relates to an accelerator as well as a preparation method and an application thereof. The accelerator is mainly prepared by mixing water and the following raw materials in parts by mass: 35-50 parts of aluminum salt, 1-3 parts of silicate, 3-10 parts of fluoride salt, 5-10 parts of a neutralizer and 5-10 parts of a stabilizer. The aluminum salt, the silicate, the fluoride salt, the neutralizer and the stabilizer are introduced into the accelerator, so that the accelerating effect is remarkable, and the stability of the accelerator can be obviously enhanced.

Owner:DO FLUORIDE CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com