Liquid quick-setting agent and preparation method thereof

A quick-setting agent and liquid technology, applied in the field of building materials, can solve problems such as easy crystallization and precipitation, product performance failure, and inability to store for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

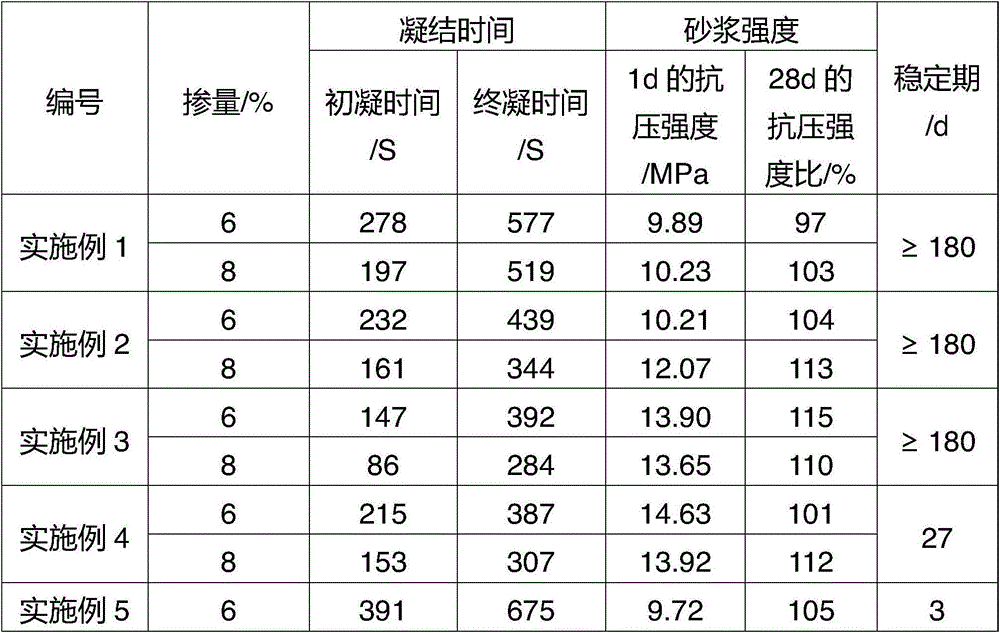

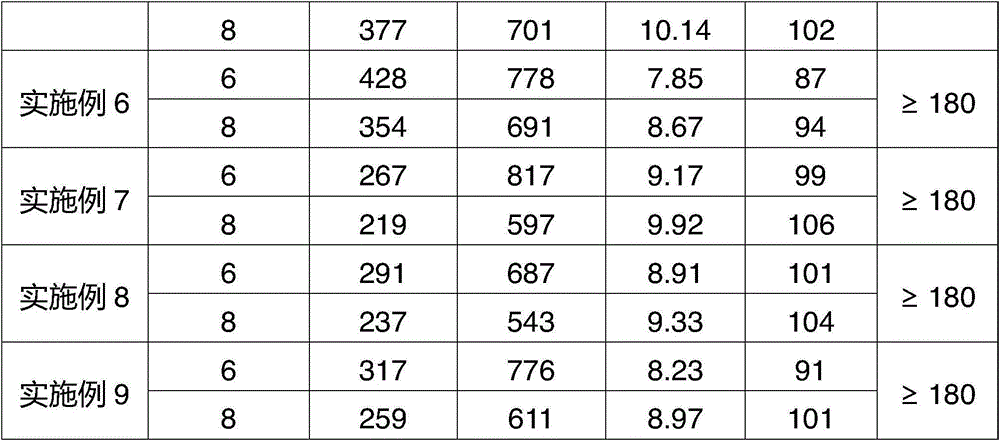

Examples

Embodiment 1

[0026] 45.5% aluminum sulfate, 8.3% diethanolamine, 1.2% phosphoric acid and 1.2% sodium fluoride can be added to 43.8% water in any order, preferably 45.5% aluminum sulfate is first added to 43.8% After that, add 8.3% diethanolamine, 1.2% phosphoric acid and 1.2% sodium fluoride in sequence. The mixed solution was heated to 50° C. and stirred with a conventional stirring device until a clear solution was obtained, and then cooled to room temperature.

Embodiment 2

[0028] 51% aluminum sulfate, 10.5% diethanolamine, 1.5% phosphoric acid and 1.5% sodium fluoride can be added to 35.5% water in any order, preferably 51% aluminum sulfate is first added to 35.5% After soaking in water, add 10.5% diethanolamine, 1.5% phosphoric acid and 1.5% sodium fluoride in sequence. The mixed solution was heated to 55° C. and stirred with a conventional stirring device until a clear solution was obtained and then cooled to room temperature.

Embodiment 3

[0030] 55% aluminum sulfate, 10.5% diethanolamine, 2% phosphoric acid and 1.5% sodium fluoride can be added to 31% water in any order, preferably 55% aluminum sulfate is added to 31% After soaking in water, add 10.5% diethanolamine, 2% phosphoric acid and 1.5% sodium fluoride in sequence. The mixed solution was heated to 60°C and stirred with a conventional stirring device until a clear solution was obtained and then cooled to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com