Alkali-free liquid accelerator and production process thereof

A production process and technology of quick-setting agent, applied in the field of alkali-free liquid quick-setting agent and production technology, can solve the problem of large dosage affecting concrete performance, etc., and achieve the effect of good quick-setting effect, improved stability and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

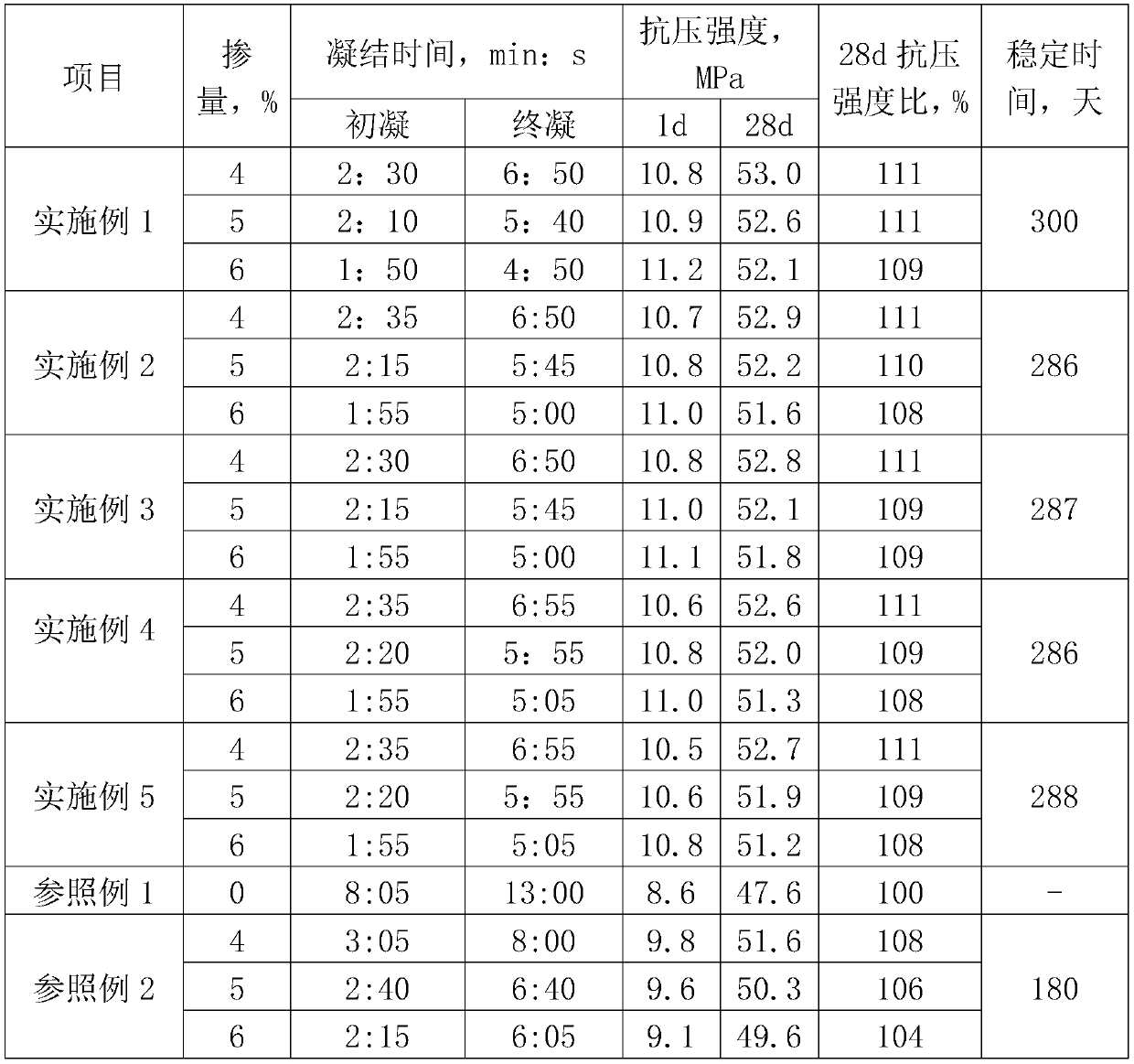

Examples

Embodiment 1

[0027] Preparation of alkali-free liquid accelerator:

[0028] 1.1 Raw materials (in parts by weight):

[0029] 60 parts of polyaluminum sulfate; 4.5 parts of sodium fluoride; 10 parts of aluminum n-butoxide; 1.5 parts of triethanolamine; 1.5 parts of diethanolamine; 0.7 parts of magnesium silicate; 2 parts of glycerol; 2 parts of hydroxyethyl cellulose; 3 parts of phosphoric acid ; 35 parts of deionized water.

[0030] 1.2 Preparation method:

[0031] It includes the following steps:

[0032] (1) Weigh each raw material according to the proportion;

[0033] (2) Add sodium fluoride and deionized water into the reaction vessel, after the temperature is raised to 60°C, add mineral acid, and stir at a speed of 1800r / min for 25min; obtain solution A;

[0034] (3) Add polyaluminum sulfate to solution A; stir for 40 minutes at a speed of 1800r / min; obtain solution B;

[0035] (4) After heating to 75°C, add aluminum n-butoxide, triethanolamine, diethanolamine, magnesium silicate and thickener to...

Embodiment 2

[0038] Preparation of alkali-free liquid accelerator:

[0039] 2.1 Raw materials (in parts by weight):

[0040] 50 parts of polyaluminum sulfate; 3 parts of sodium fluoride; 8 parts of aluminum isooctanolate; 3 parts of triethanolamine; 1 part of diethanolamine; 0.5 parts of magnesium silicate; 3 parts of glycerol; 1 part of hydroxyethyl cellulose; 5 parts of phosphoric acid ; 30 parts of deionized water.

[0041] 2.2 Preparation method:

[0042] It includes the following steps:

[0043] (1) Weigh each raw material according to the proportion;

[0044] (2) Add sodium fluoride and deionized water into the reaction vessel, heat up to 55°C, add mineral acid, and stir for 30 minutes at a speed of 1000r / min; to obtain solution A;

[0045] (3) Add polyaluminum sulfate to solution A; stir for 50 minutes at a speed of 2000r / min; obtain solution B;

[0046] (4) After heating to 70°C, add aluminum isooctanolate, triethanolamine, diethanolamine, magnesium silicate and thickener to solution B; stir f...

Embodiment 3

[0049] Preparation of alkali-free liquid accelerator:

[0050] 3.1 Raw materials (in parts by weight):

[0051] 70 parts of polyaluminum sulfate; 6 parts of sodium fluoride; 12 parts of aluminum n-octanoxide; 1 part of triethanolamine; 3 parts of diethanolamine; 1 part of magnesium silicate; 1 part of glycerol; 3 parts of hydroxyethyl cellulose; 1 part of phosphoric acid ; 40 parts of deionized water.

[0052] 3.2 Preparation method:

[0053] It includes the following steps:

[0054] (1) Weigh each raw material according to the proportion;

[0055] (2) Add sodium fluoride and deionized water into the reaction vessel, heat up to 65°C, add mineral acid, and stir at 2000r / min for 20min; obtain solution A;

[0056] (3) Add polyaluminum sulfate to solution A; stir for 30 minutes at a speed of 1500r / min; obtain solution B;

[0057] (4) After the temperature is raised to 80°C, add aluminum n-octanoxide, triethanolamine, diethanolamine, magnesium silicate and thickener to solution B; stir at 1500...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com