High stability concrete accelerator

A high-stability, quick-setting agent technology, applied in the field of high-stability quick-setting agents for concrete, can solve problems such as unfavorable storage of construction accelerators, reduction of concrete durability, and easy precipitation and precipitation, so as to facilitate popularization and use, improve The effect of stability and reasonable ratio of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

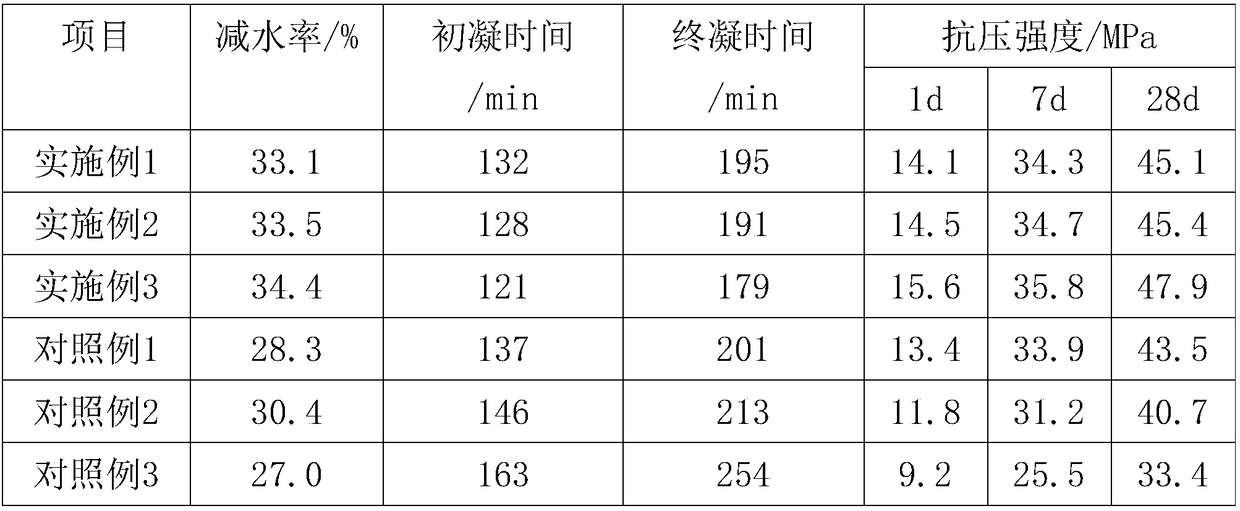

Examples

Embodiment 1

[0020] A high-stability accelerator for concrete is characterized in that it is made of the following raw materials in parts by weight: 40 parts of polyglutamic acid, 5 parts of adsorbent, 5 parts of calcium sulfate, 2 parts of polyaspartic acid, 3 parts of emulsifier, 2 parts of sodium gluconate, 1 part of crospovidone, 2 parts of aluminum oxide, 2 parts of ascorbic acid, 2 parts of potassium methyl silicate, 0.2 part of sodium lauryl sulfate.

[0021] The adsorbent is made of zeolite powder, activated carbon powder, rice straw, and alum according to the mass ratio of 1:1:1.5:0.5, and the production method is as follows: put the rice straw into a drying oven at 120° C. More than 2%, crushed into 40-mesh powder, add appropriate amount of water and stir evenly until muddy paste, then put into carbonization furnace at 400°C for carbonization for 1 hour, take it out and cool, and crush into 60-mesh powder to obtain carbonized powder; dissolve alum in Appropriate amount of water, ...

Embodiment 2

[0029] A high-stability accelerator for concrete is characterized in that it is made of the following raw materials in parts by weight: 50 parts of polyglutamic acid, 10 parts of adsorbent, 8 parts of calcium sulfate, 6 parts of polyaspartic acid, 5 parts of emulsifier, 4 parts of sodium gluconate, 3 parts of crospovidone, 4 parts of aluminum oxide, 4 parts of ascorbic acid, 4 parts of potassium methyl silicate, and 1.5 parts of sodium lauryl sulfate.

[0030] The adsorbent is made of zeolite powder, activated carbon powder, rice straw, and alum according to the mass ratio of 1:1:1.5:0.5, and the production method is as follows: put the rice straw into a drying oven at 140° C. more than 2%, crushed into 50-mesh powder, added appropriate amount of water and stirred evenly until muddy paste, then put into carbonization furnace at 500°C for carbonization for 2 hours, took it out and cooled it and crushed into 70-mesh powder to obtain carbonized powder; dissolve alum in Appropriat...

Embodiment 3

[0038] A high-stability accelerator for concrete is characterized in that it is made of the following raw materials in parts by weight: 60 parts of polyglutamic acid, 15 parts of adsorbent, 10 parts of calcium sulfate, 10 parts of polyaspartic acid, 6 parts of emulsifier, 5 parts of sodium gluconate, 5 parts of crospovidone, 5 parts of aluminum oxide, 6 parts of ascorbic acid, 5 parts of potassium methyl silicate, and 2 parts of sodium lauryl sulfate.

[0039] The adsorbent is made of zeolite powder, activated carbon powder, rice straw, and alum according to the mass ratio of 1:1:1.5:0.5, and the production method is as follows: put the rice straw into a drying oven at 150° C. more than 2%, crushed into 60-mesh powder, add appropriate amount of water and stir evenly until muddy paste, then carbonize in a carbonization furnace at 600°C for 3 hours, take it out and cool and crush into 60-80-mesh powder to obtain carbonized powder; Dissolve in an appropriate amount of water, conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com