Method of manufacturing refractory material by innocent treatment of secondary aluminum ash

A technology for harmless treatment and refractory materials, which is applied in the field of manufacturing refractory materials and can solve problems such as polluting groundwater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

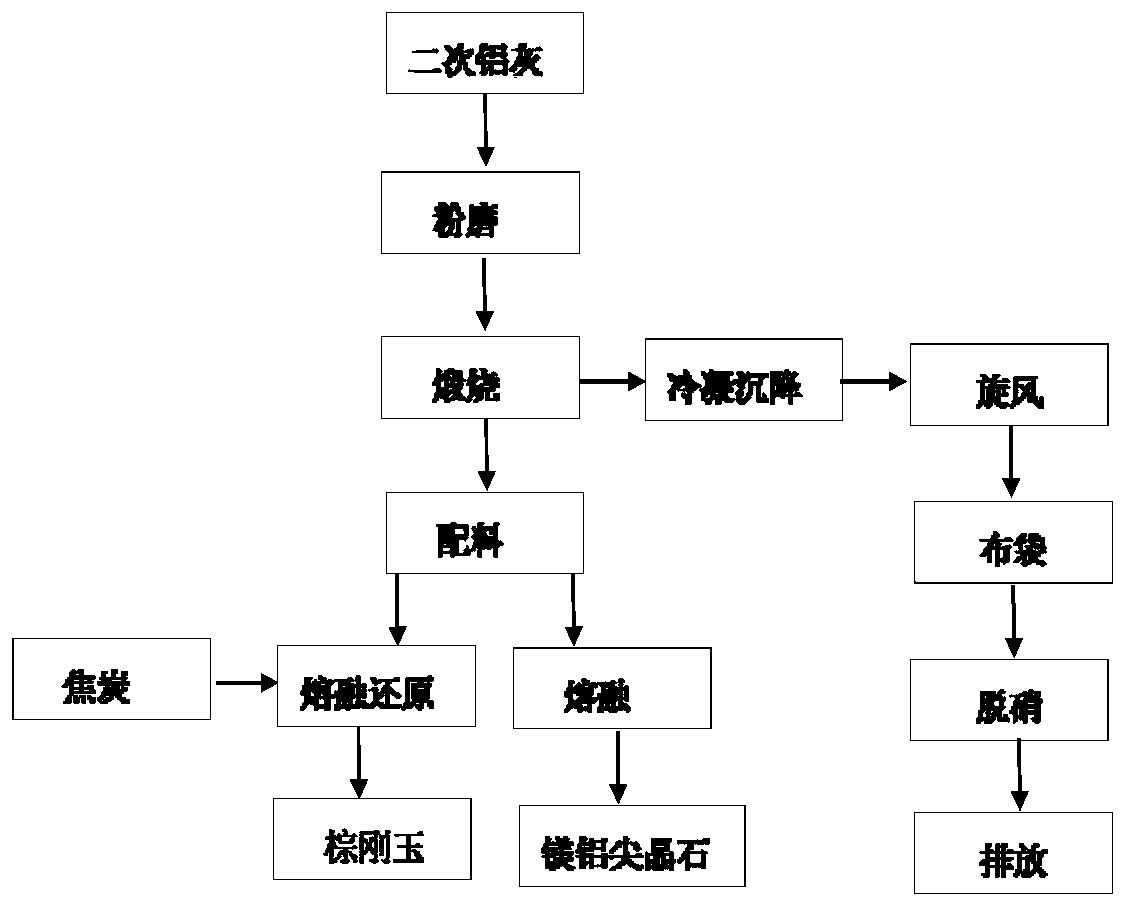

Method used

Image

Examples

no. 1 example

[0124] In this example, the object of process treatment is the secondary aluminum ash produced by the metal aluminum melting and casting process, and the secondary aluminum ash includes the following components by mass percentage: 4% Al, 42% Al 2 o 3 , 30% AlN, 7% MgO, 10% fluoride salt, and the rest are impurities. The main impurity is Na 2 O, K 2 O, Fe 2 o 3 , SiO 2 .

[0125] 1. The secondary aluminum ash is ball milled until 80% of the particle size passes through a 74μm sieve;

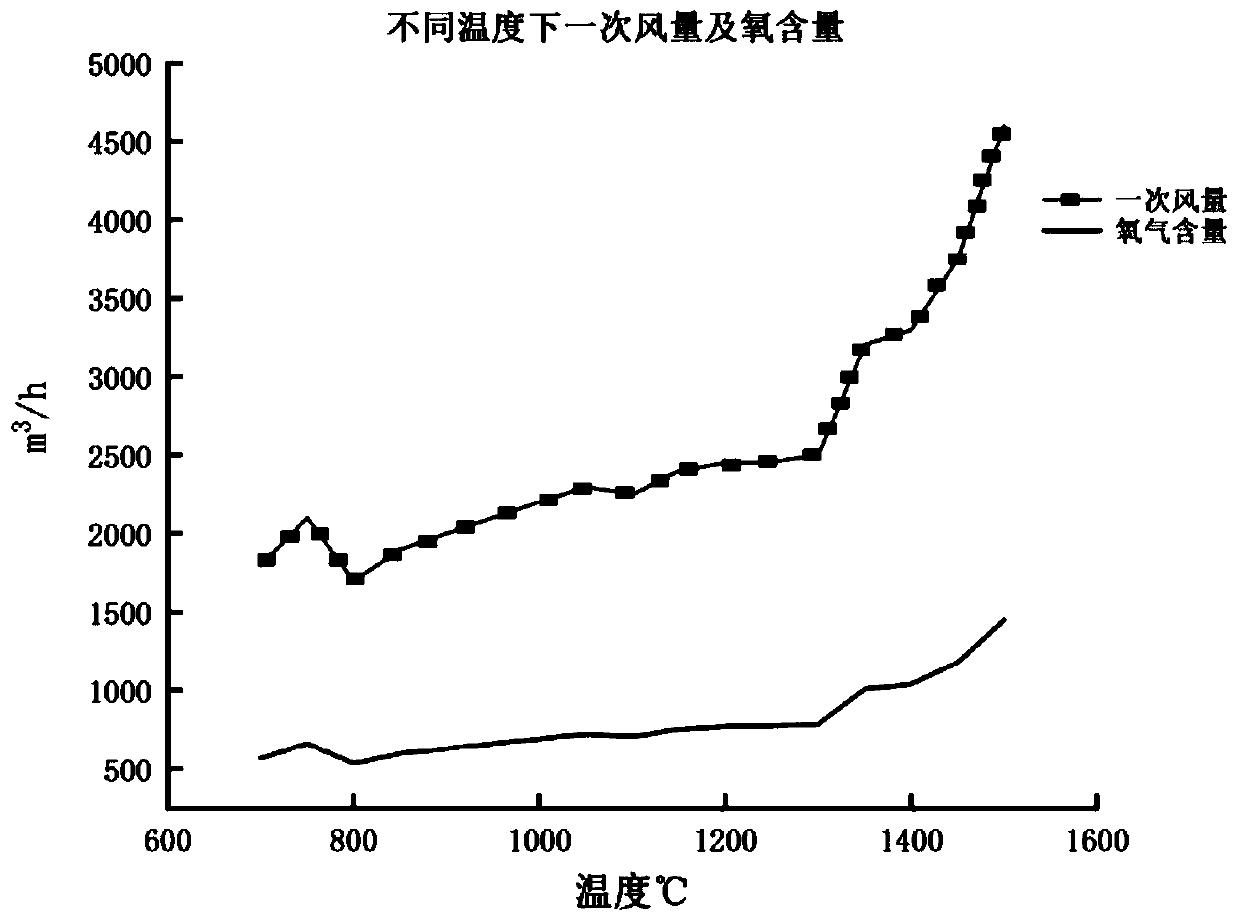

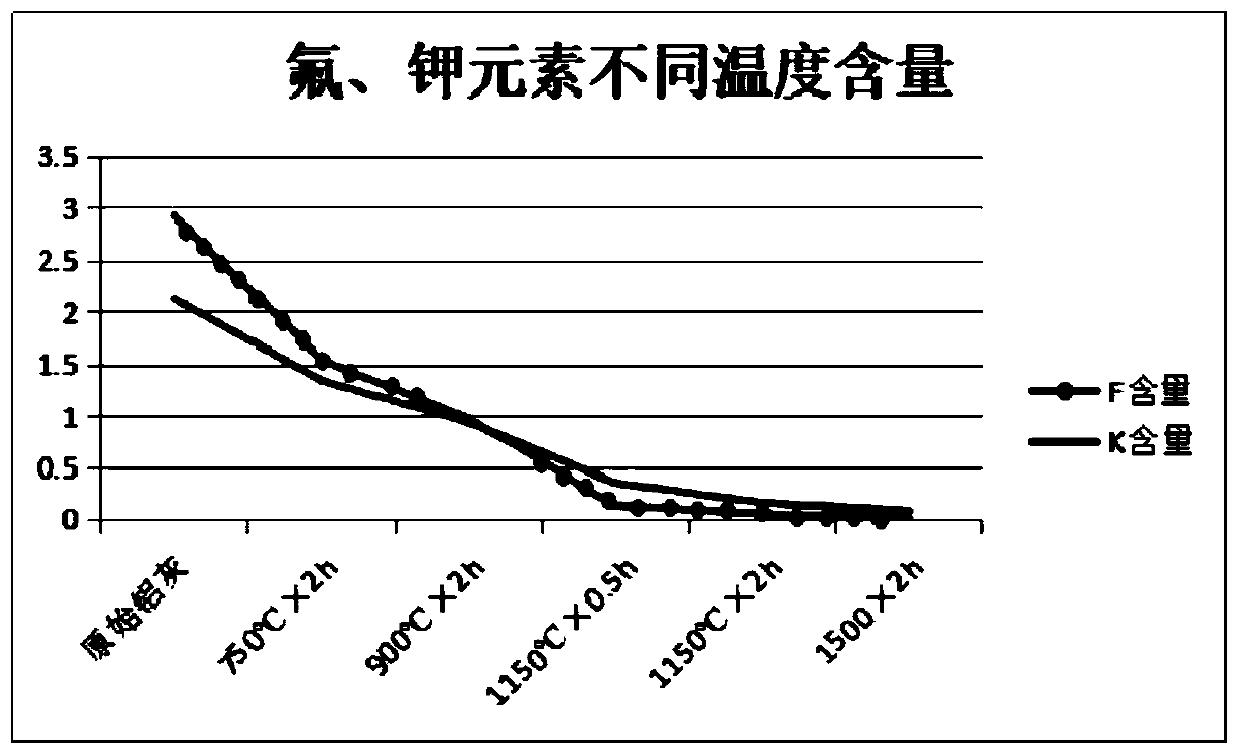

[0126] 2. The secondary aluminum ash enters the middle chamber of the kiln head through the bucket elevator, and blows the secondary aluminum ash into the rotary kiln through the Roots blower below the kiln head chamber. The secondary aluminum ash is calcined at an oxygen content of 14-18% and a temperature of 1150°C for 2 hours, and cooled to normal temperature by a cooler; the main component of the obtained calcined oxide is Al by mass percentage 2 o 3 88.3%, MgO 7.8%, SiO 2 1.6%, TiO ...

no. 2 example

[0136] Manufacturing method is the same as embodiment 1, and difference is:

[0137] 1. In this example, the secondary aluminum ash as the object of process treatment includes the following components by mass percentage: 5% Al, 44% Al 2 o 3 , 30% AlN, 3% MgO, 8% fluoride, 3.5% K 2 O, the rest is Na 2 O, Fe 2 o 3 , SiO 2 , CaO, TiO 2 and other impurities.

[0138] 2. The main composition of the oxide after calcination is Al by mass percentage 2 o 3 92.7%, MgO 3.5%, SiO 2 1.4%, TiO 2 0.47%, K 2 O 0.19%, CaO 0.17%, Na2O 0.19%, TFe 0.62%, fluoride <0.1%, and other trace impurities.

[0139] 3. Add the above-mentioned calcined oxide to coke with a mass percentage of 3%, the C of the coke is ≥ 95%, and the particle size is less than 10mm;

[0140] 4. Put the above-mentioned calcined oxides into the electric arc furnace for melting and reduction layer by layer. When the charge is basically melted, control the temperature at 2050-2150°C and refine for 0.5 hours, then p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com