Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

175 results about "Paraldehyde" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Paraldehyde is the cyclic trimer of acetaldehyde molecules. Formally, it is a derivative of 1,3,5-trioxane. The corresponding tetramer is metaldehyde. A colourless liquid, it is sparingly soluble in water and highly soluble in ethanol. Paraldehyde slowly oxidizes in air, turning brown and producing an odour of acetic acid. It quickly reacts with most plastics and rubber.

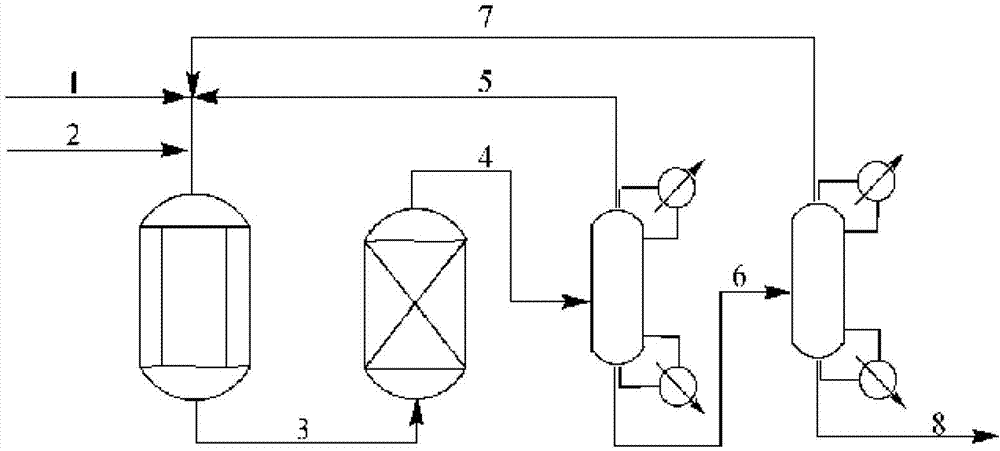

Method for continuous production of polyformaldehyde dimethyl ether

InactiveCN102786397ARealize industrial productionImprove stabilityOrganic chemistryOrganic compound preparationPtru catalystDistillation

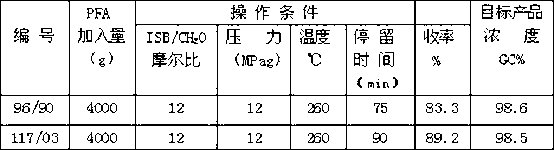

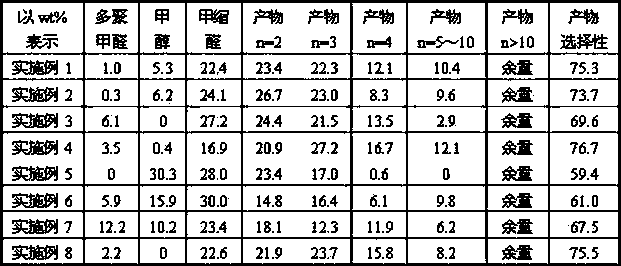

The invention provides a method for continuous production of polyformaldehyde dimethyl ether. The method is characterized by comprising the following steps: a) feeding dimethoxymethane and hot-melted paraformaldehyde into a fixed bed reactor and adopting an acidic resin catalyst, so as to prepare polyformaldehyde dimethyl ether (DMM3-8), wherein the reaction temperature is 120-180 DEG C and the pressure is 0.1-10 MPa; b) cooling the reaction product, and then performing adsorptive separation through a dehydrating tower, so as to obtain polyformaldehyde dimethyl ether of which most water, cytidine glycol and hemiacetal are desorbed; c) feeding the polyformaldehyde dimethyl ether subjected to desorption into a distillation tower for separation, wherein most of a low-boiling component (dimethoxymethane (DMM)), poly-di-formaldehyde dimethyl ether (DMM2), a by-product (methanol) and triformol are extracted first, and then the materials in a tower kettle are fed into a rectifying tower in the next step, so as to extract the rest of the DMM2 and the triformol; and d) returning the low-boiling component (dimethoxymethane (DMM)), the methanol, the DMM2 and the triformol, which are evaporated out by the distillation tower and the rectifying tower in the last step, into the fixed bed reactor to continue to react to prepare polyformaldehyde dimethyl ether.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Modified coal tar, and producing method

InactiveCN1760331AIncrease electrode contentHigh strengthWorking-up pitch/asphalt/bitumen by chemical meansSmall footprintPhenol

A modified coal asphalt with linear resin molecule structure and adjustable softening point is prepared from one or more of coal tar, antracene oil, phenol oil, naphthelene oil and the coal asphalt with softening point lower than 130 deg.C through using acid to regulate pH value, and polymerizing reaction on formaldehyde or tripolyformaldehyde or polyformaldehyde which controlling temp, pressure and time.

Owner:任利华

Catalyst for synthesizing methyl acrylate by trioxymethylene or paraformaldehyde and acetic acid and acetic acid aqueous solution, its preparation and its application method

InactiveCN103638956AProcess raw materials are cheapGentle production processPhysical/chemical process catalystsOrganic compound preparationAlkali metal oxidePhosphoric acid

The invention discloses a catalyst for synthesizing methyl acrylate by trioxymethylene or paraformaldehyde and acetic acid and acetic acid aqueous solution, its preparation and its application method. The catalyst uses lactic acid to dissolve ammonium metavanadate, one or more than one alkali metal salt and phosphoric acid can be added for preparing a dipping liquid, a step of roasting is carried out to form the compound catalyst which takes silicon dioxide, alumina, active carbon or molecular sieve as carriers and is loaded with a vanadic anhydride-phosphoric pentoxide-alkali metal oxide. The load capacity of the vanadium element accounts for 5-20% of total mass of the catalyst, the mass ratio of phosphor to vanadium is 0.5-4, and the alkali metal element accounts for 1-5% of total mass of the catalyst. The preparation step of the catalyst comprises the steps of configuring the dipping liquid, dipping the carriers, drying, and heating and roasting the dipping body. According to the invention, a fixed bed reactor is employed, methyl acrylate is continuously produced under suitable reaction condition, one way conversion rate of formaldehyde can reach 40%, and the selectivity of methyl acrylate can reach 55%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Benzoxazine resin based on furfuryl amine, composition and preparation method thereof

The invention relates to a benzoxazine resin based on furfuryl amine, a composition and a preparation method thereof. The benzoxazine resin is prepared from phenol derived from renewable resources (for example, eugenol, guaiacol and cardanol), primary amine derived from renewable resources (for example, furfuryl amine) and an aqueous solution of paraformaldehyde or trioxymethylene or formaldehyde; and the relevant composition is a composition prepared from the benzoxazine resin and other thermosetting resins. The benzoxazine resin based on furfuryl amine and the composition thereof can be used in multiple fields of matrix resins of paint, thermosetting plastic, composite material and the like.

Owner:BEIJING UNIV OF CHEM TECH

Method of treating high-concentration metaformaldehyde waste water into reuse water

InactiveCN101671098AIncrease the amount of waterImprove impact resistanceGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisActivated sludgeHigh concentration

The invention discloses a method of treating high-concentration metaformaldehyde waste water into reuse water, relating to a treatment technology of high-concentration metaformaldehyde waste water. The pH of metaformaldehyde waste water of which the formaldehyde content is 4000mg / L into 3.0-4.0, then metaformaldehyde waste water is sent into an anaerobic hydrolysis composite reactor combining activated sludge with biomembrane and an aerobic composite reactor; at last, a double-membrane method is adopted to treat to ensure that effluent reaches the standard of urban wastewater recycling industrial water quality, thus serving as recirculated cooling water. The invention strengthens removal of high-concentration formaldehyde, COD, trioxymethylene, divinylene oxide and other pollutants in high-concentration metaformaldehyde waste water by biological treatment, can effectively resist impact from violent water yield and water quality, and has the advantages of high system starting speed, small foam of the aerobic composite reactor, low operation cost, stable and effective treatment and zero discharge of waste water.

Owner:上海中耀环保实业有限公司

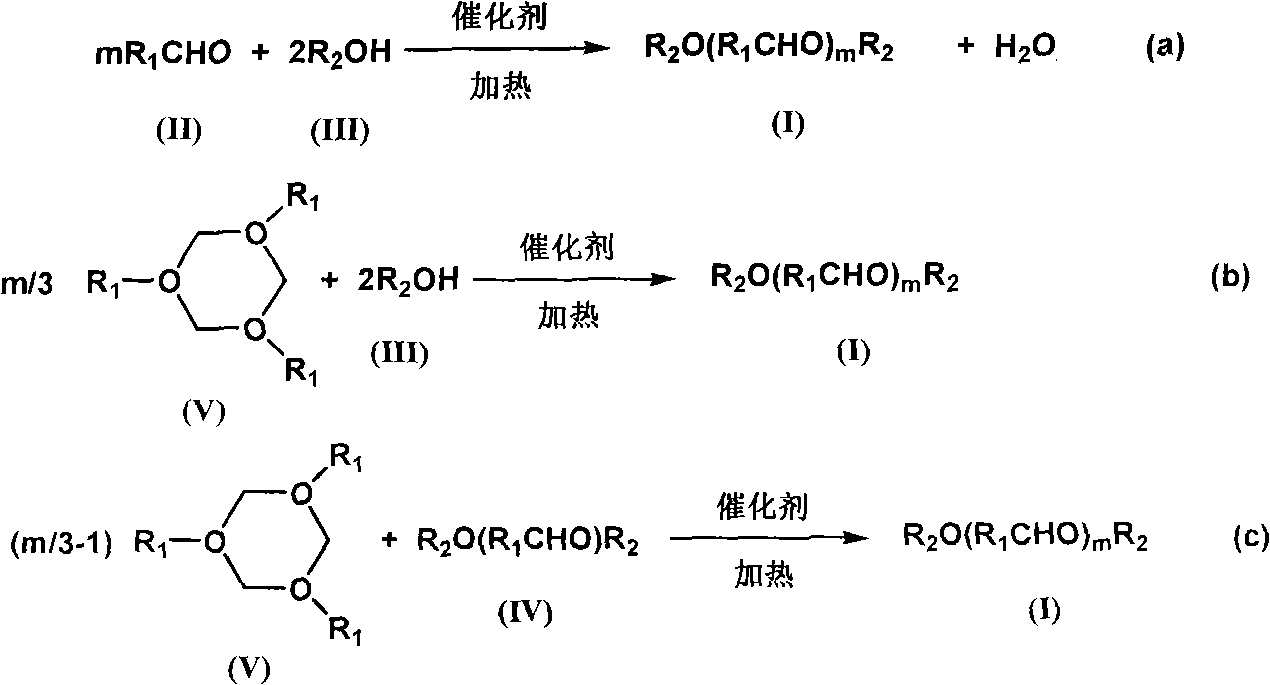

Method for preparing alkoxy ether compounds

ActiveCN102757323AEfficient synthesisSimple processOrganic chemistryOrganic compound preparationHeteropoly acidHigh activity

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

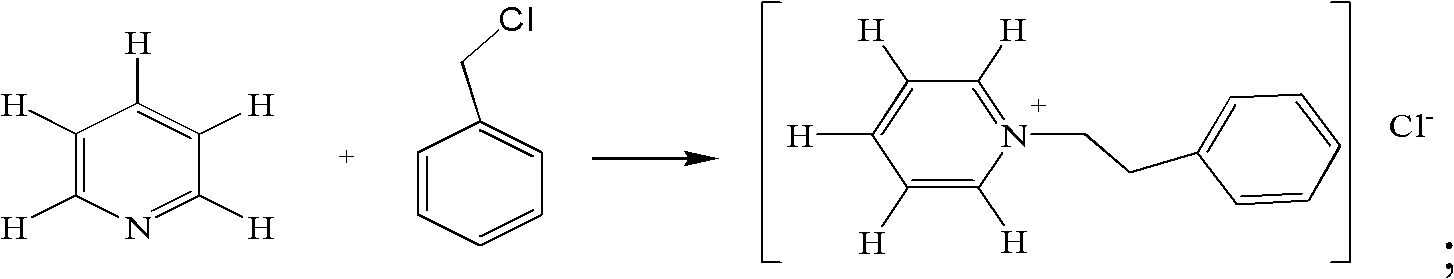

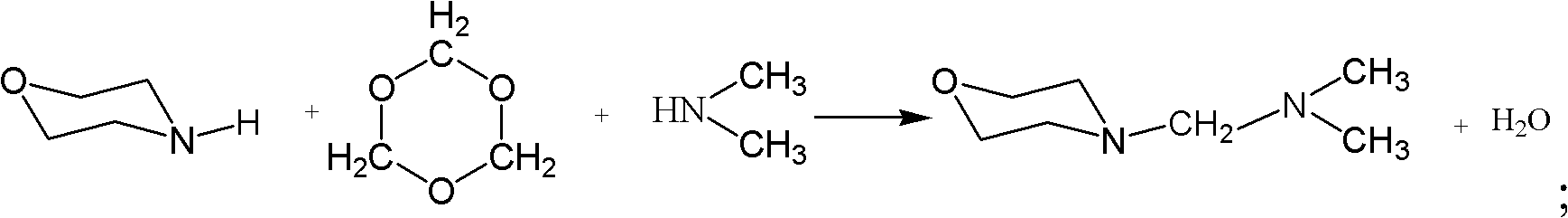

High-temperature O2/CO2 corrosion inhibitor for coiled tubing and preparation method of agent B of high-temperature O2/CO2 corrosion inhibitor

ActiveCN102627955AEnsure safe operationAvoid corrosionBorehole/well accessoriesSulfite saltMannich reaction

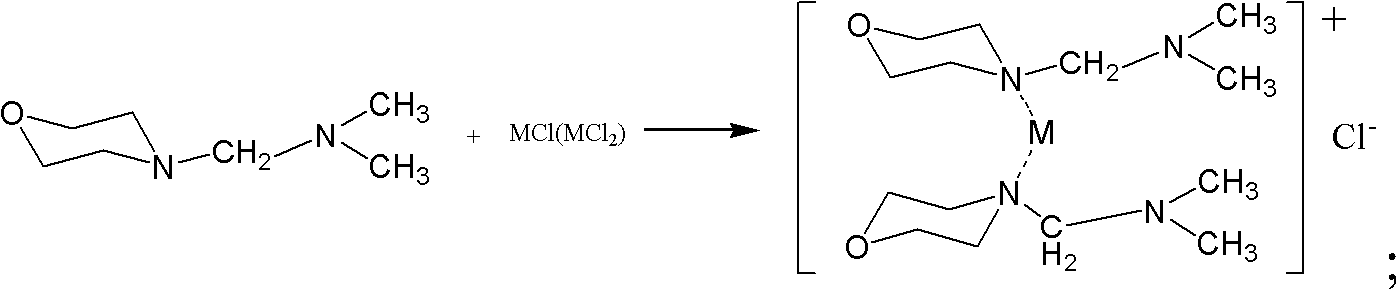

The invention discloses a high-temperature O2 / CO2 corrosion inhibitor for coiled tubing. The high-temperature O2 / CO2 corrosion inhibitor for the coiled tubing is used by matching an agent A mainly used for deoxidizing and an agent B mainly used for resisting corrosion of carbon dioxide, wherein the agent A is acetone oxime, D-ascorbic acid, sodium sulfite or ferrous sulphate; and the agent B is formed by mixing the components in percentage by weight: 20-30 percent of quaternary pyridine salt, 10-15 percent of mannich base chelate, 3-7 percent of surfactant and 48-67 percent of solvent. The quaternary pyridine salt is obtained by reacting pyridine with benzyl chloride; and the mannich base chelate is obtained by aldehyde ketone amine condensate generated by morpholine, trioxymethylene and dimethylamine through a mannich reaction with metal chloride. The corrosion inhibitor provided by the invention has use temperature up to 170DEG C, is suitable for a water-corrosive medium in which oxygen and carbon dioxde coexist and can be used for effectively inhibiting the corrosion of media such as the oxygen and the carbon dioxide and ensuring safe operation of the coiled tubing in the production process.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Preparation method of partially methylated amino resin

The invention relates to a preparation method of partially methylated amino resin. The method comprises the following steps: carrying out a hydroxylation reaction on melamine and paraform, and adding methanol to generate the methylated amino resin. The preparation method has the advantages of high conversion rate, safe reaction and production, simple process, low energy consumption, simple post-treatment, low cost, small environmental pollution, good product quality and easy condition control.

Owner:ZHEJIANG XINHUA NEW MATERIAL TECH CO LTD

Primary concentration and purification method for trioxymethylene after synthesizing

InactiveCN101121709AShort operating timeIncrease productionOrganic chemistryLiquid wastePurification methods

The invention discloses a new method for preliminary concentration and purification of paraformaldehyde after synthesis, which belongs to the technical field of concentration and purification of crude paraformaldehyde. The mixture is sent to the rectification tower for rectification; the top product obtained after rectification enters the condenser, and enters the absorption tower after cooling; the rectification tower still liquid returns to the paraformaldehyde synthesis reactor; after being absorbed by the absorption tower, the absorption tower The top gas and the bottom product enter the pre-concentration tower together for rectification treatment, and the solution obtained at the bottom of the pre-concentration tower is used as the reflux of the synthesis rectification tower and the absorption liquid of the absorption tower; The top product is sent to the concentration tower for concentration, and formaldehyde solution is obtained at the bottom of the concentration tower; the top product obtained from the concentration tower enters the light component removal tower, and the top of the light component removal tower obtains combustible waste liquid, and the bottom of the tower obtains 30-90% aqueous solution of paraformaldehyde. The invention has large output and low operation cost.

Owner:ZHEJIANG SANPO POLYMER

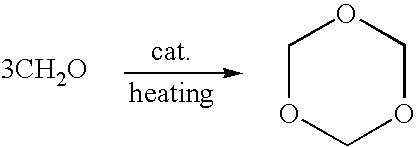

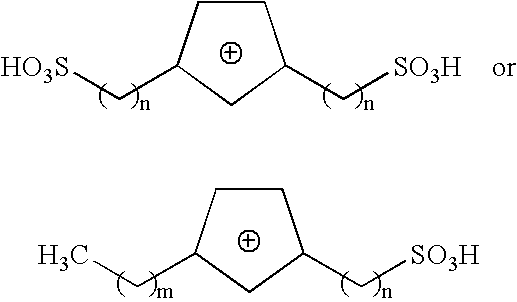

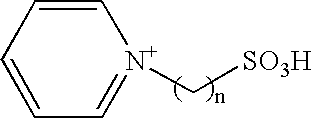

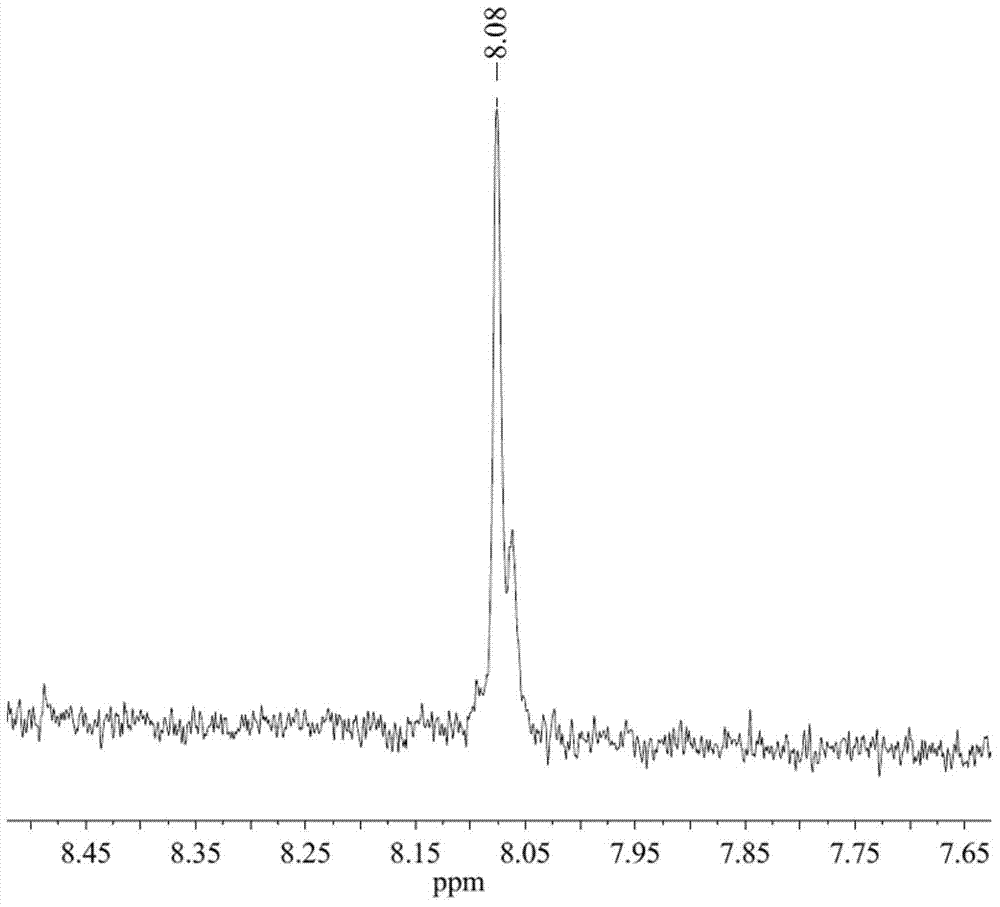

Method of synthesizing trioxymethylene from formaldehyde by the catalytic action of an ionic liquid

The present invention relates to a method of synthesizing trioxymethylene from formaldehyde by the catalytic action of an acidic ionic liquid. In the method, formaldehyde solution with a concentration of 30˜80 wt % is used as reactant, and an ionic liquid is used as catalyst. The cation moiety of the catalyst is selected from either imidazoles cation or pyridines cation, and the anion moiety of the catalyst is selected from one of p-tolyl benzene sulfonate, trifluoromethyl sulfonate, and hydrogen sulfate. In the present invention, ionic liquid is used, for the first time, as a catalyst to synthesize trioxymethylene from formaldehyde. The catalyst can be circularly used for continuous sampling.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

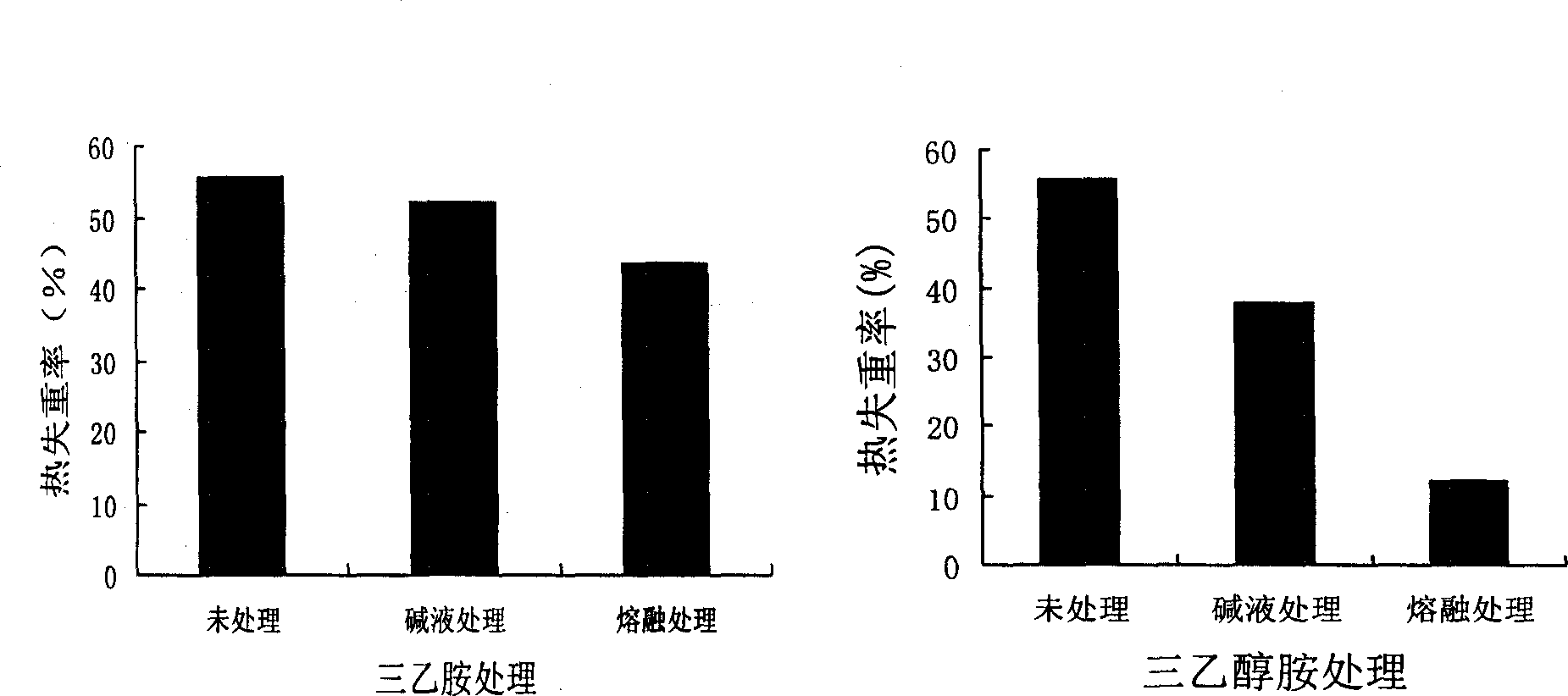

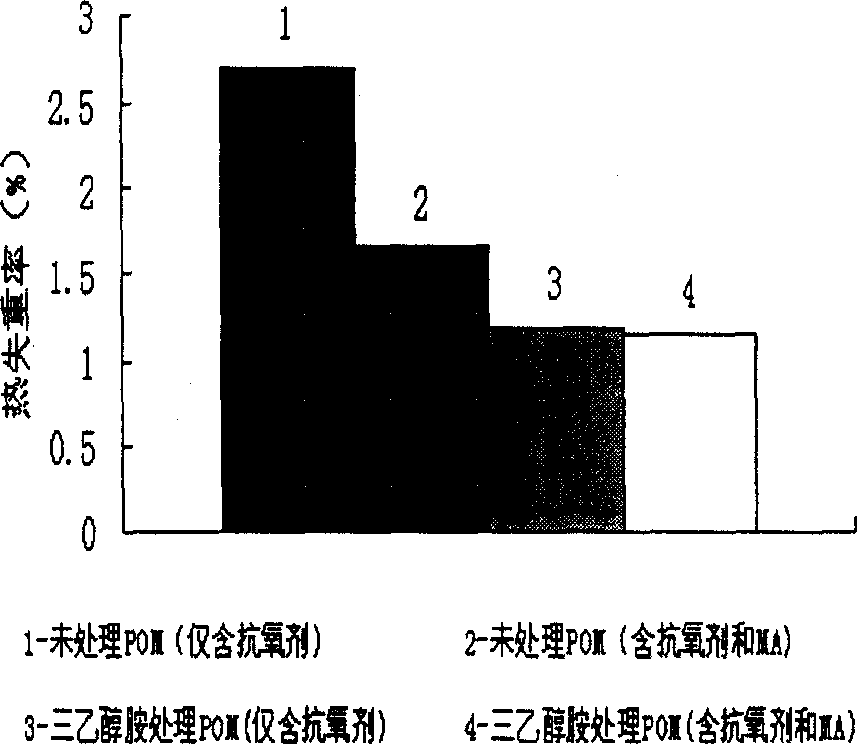

Polyformamine treatment thermal stabilizing method

InactiveCN1891753AImprove thermal stabilityFacilitate the removal of hydrolysisPolymer scienceAntioxidant

This invention relates to a thermal-stabilizing method for paraformaldehyde-amine including: mixing paraformaldehyde with the melt index 9~27g / 10min of 100 amounts by weight, antioxidants 0.1~0.5 of amounts by weight, formic acid absorber of 367 amounts by weight, lubricant of 367 amounts by weight, amine compounds of 0.05 amounts by weight and water of 1-10 amounts by weight, then melt-mixing the mixture in the exhaust twin-screw extruder, extruding the materials in the form of granulation and the temperature of the barrel extruder is set at 140~220 deg. C, screw speed is set at 30 - 180 rpm, the materials are dried for 3~5h at 80-90deg.C or mixing the paraformaldehyde, antioxidants, formic acid absorber and lubricant, then extruding the materials in the form of granulation, feeding amide solution in the feeding throat of the extruder at the same time and the melt temperature, screw speed, drying process are the same with the former.

Owner:YUNNAN YUNTIANHUA +1

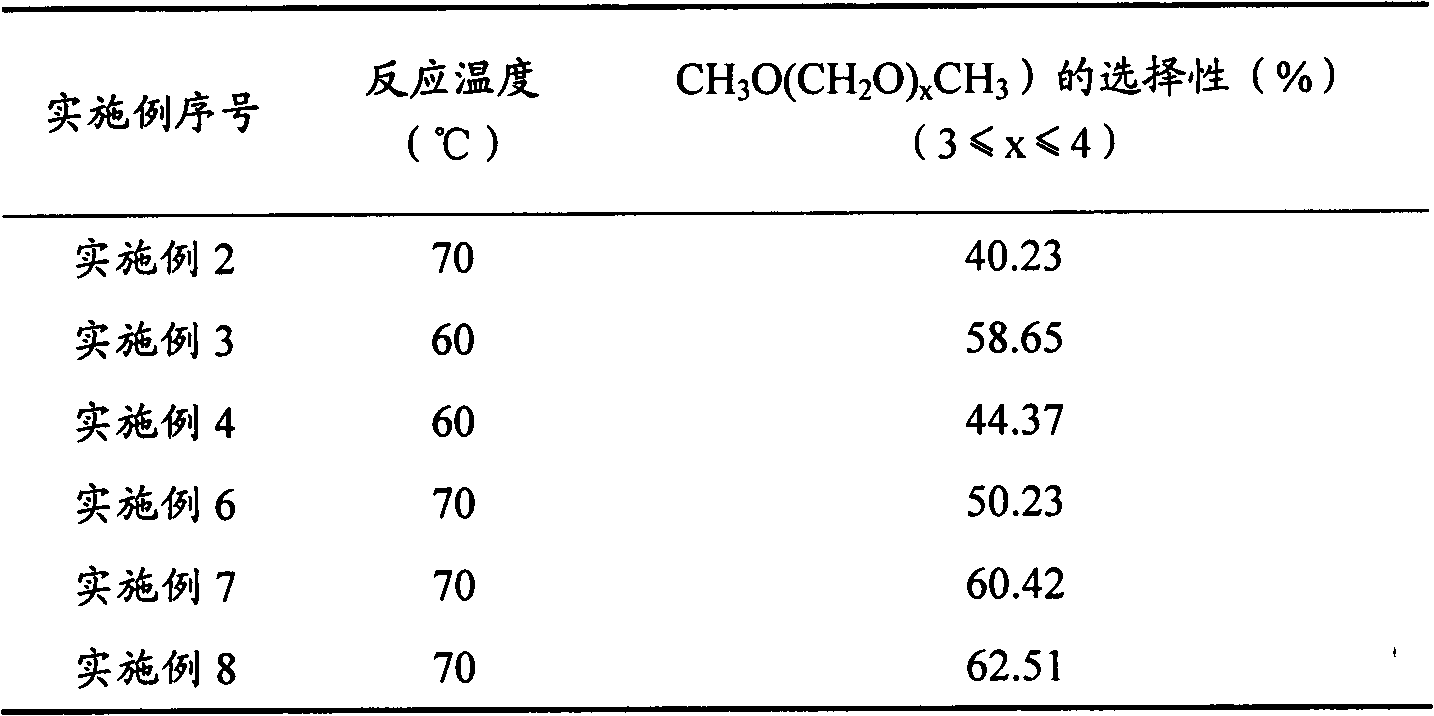

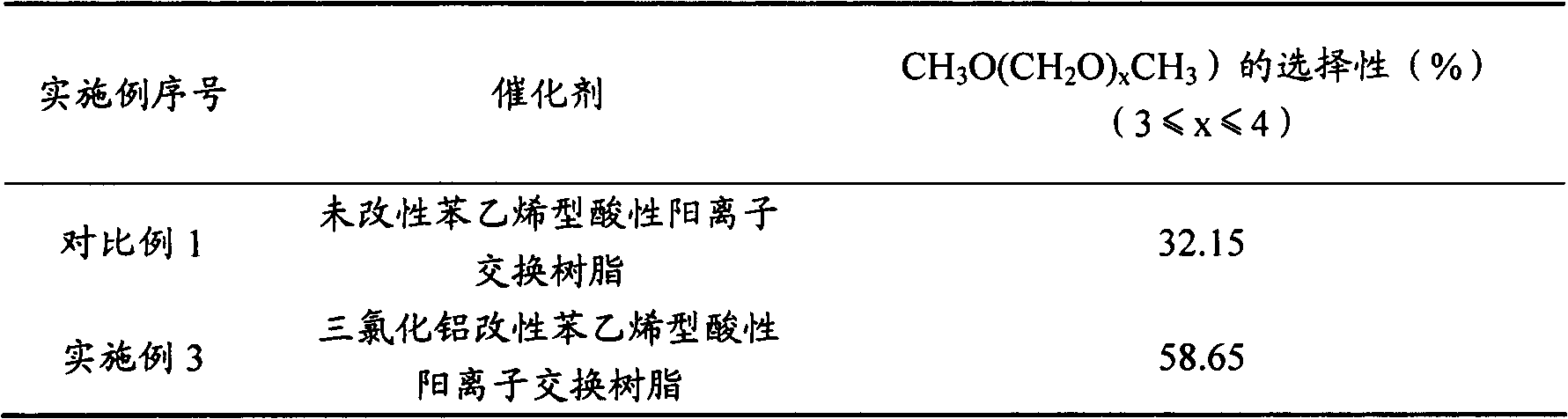

Modified acidic cation exchange resin and applications thereof

The invention relates to a modified acidic cation exchange resin and applications thereof A modified styrene type acidic cation exchange resin is prepared by carrying an inorganic acid, an organic acidity and / or Lewis acid with a styrene type acidic cation exchange resin, wherein according to total weight of the styrene type acidic cation exchange resin and carried substances being 100%, the content of the inorganic acid, the organic acidity and / or Lewis acid is 0.1-30% by weight. The invention provides applications of the modified styrene type acidic cation exchange resin for preparing PODE in a reaction of methanol with formaldehyde, a reaction of methylal with trioxymethylene, a reaction of methylal with paraformaldehyde, a reaction of methanol with a mixture of formaldehyde and paraformaldehyde, a reaction of methanol with a mixture of formaldehyde and trioxymethylene, and a reaction of methylal with a mixture of trioxymethylene and paraformaldehyde.

Owner:EAST CHINA UNIV OF SCI & TECH

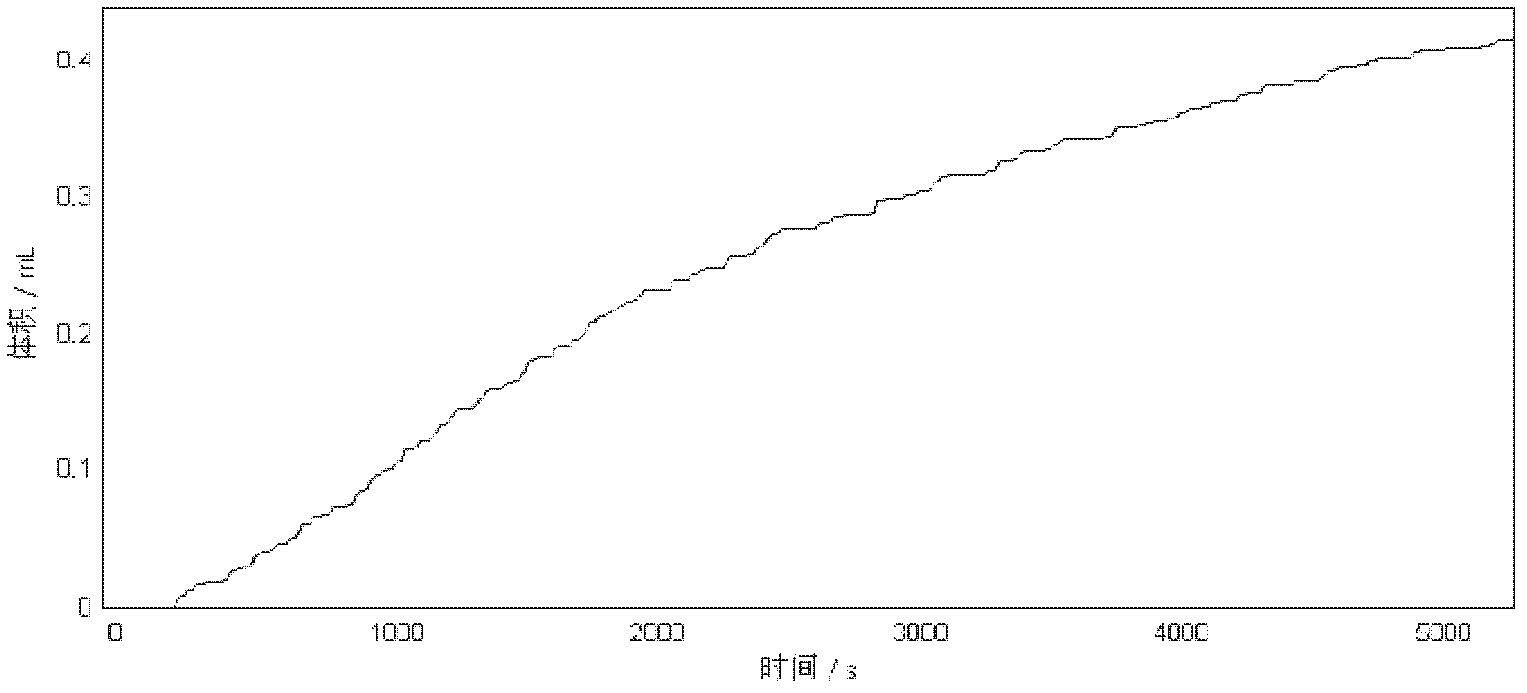

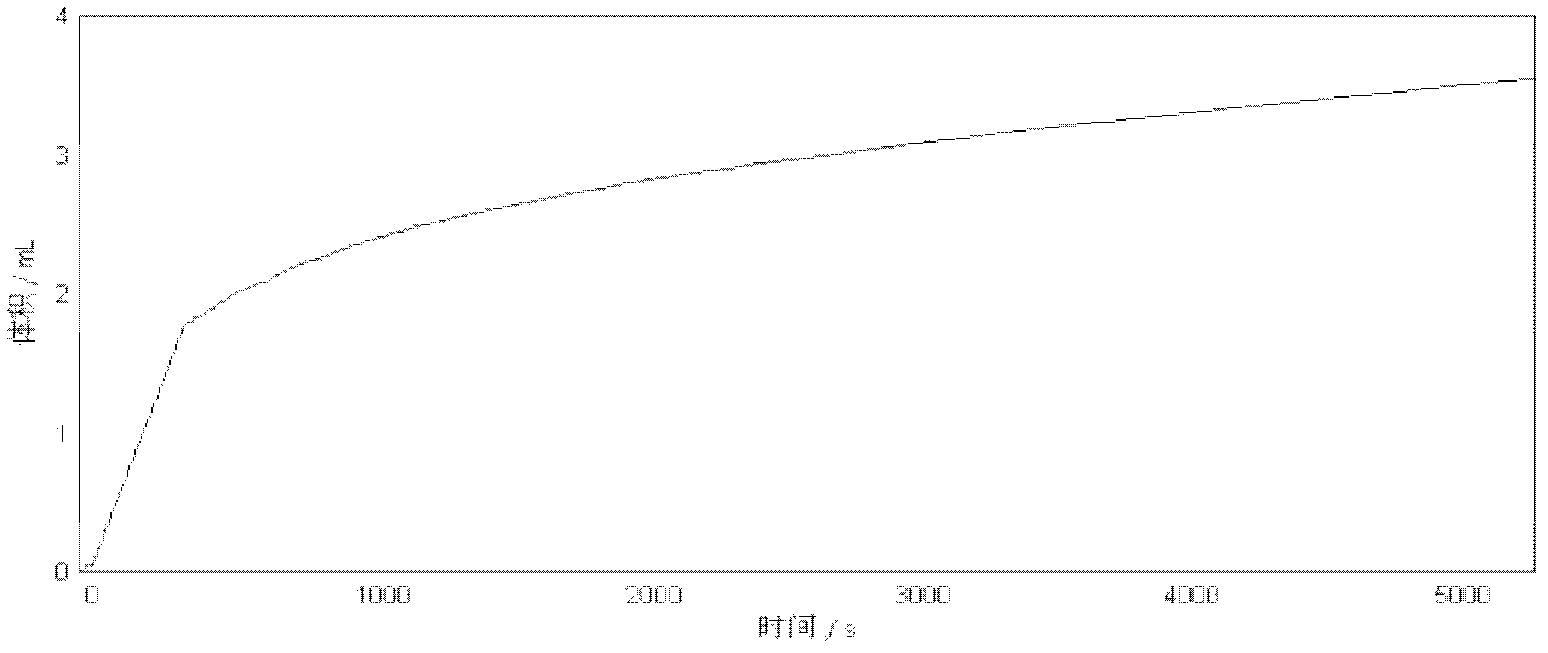

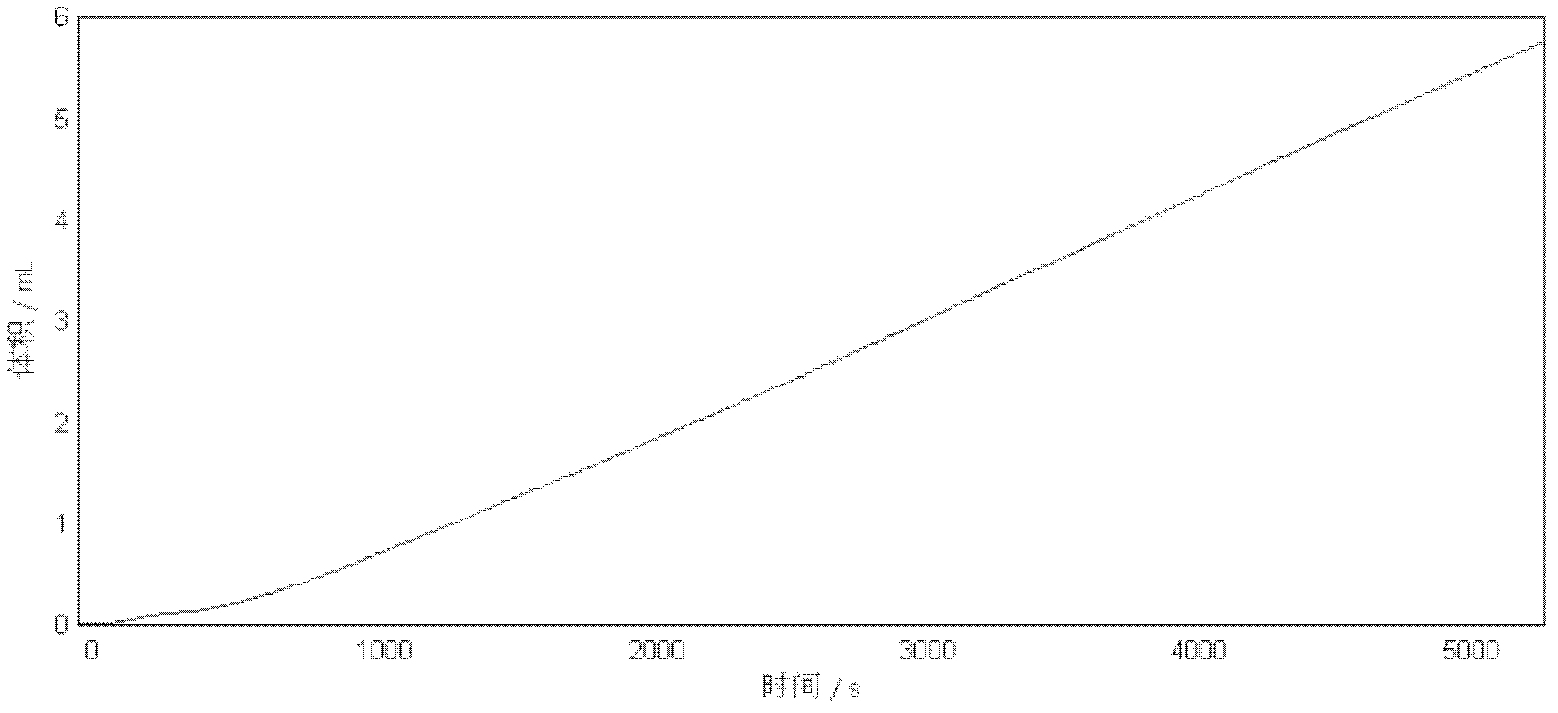

Method for measuring thermal stability of polyformaldehyde

InactiveCN102539624AAccurate thermal stabilityChemical analysis using titrationParaldehydeTime range

The invention relates to a method for measuring thermal stability of polyformaldehyde, which includes the following steps: the polyformaldehyde is heated and smelted; the formaldehyde gas generated by resolving is brought out by the fed-in inertia carrier gas, so as to be fed in the sodium sulfite solution; the formaldehyde gas is absorbed by the sodium sulfite solution to generate sodium hydroxide, and sodium hydroxide is generated by titration reaction of sulfuric acid titration liquid; and the quantity of formaldehyde gas can be calculated through conversion as per the consumption amount of sulfuric acid, so as to analyze the thermal stability of polyformaldehyde. The technical scheme provided by the invention provides the simple, convenient and feasible method for measuring thermal stability of polyformaldehyde, can be used for confirming the formaldehyde content generated after the pyrolysis of polyformaldehyde through titration, and can visually reflect the resolving rate of polyformaldehyde and the specific condition of resolving at different time ranges, thereby obtaining more accurate thermal stability of the polyformaldehyde, and providing accurate reference to the follow-up processing.

Owner:上海蓝星聚甲醛有限公司

5,6-dihydropyrane and preparation method for derivative thereof

InactiveCN101143860ALess corrosivePrevent self-aggregationOrganic chemistryDepolymerizationPresent method

The invention discloses a preparation method of a 5, 6-dihydrogen-pyran and the derivatives of the 5, 6-dihydrogen-pyran. In the present methods, the self-polymerization of conjugate dienes is easily happened in a synthesis reaction, and as a result, the yield rate of products is low. In the invention, under the catalysis of lewis acid, the conjugate dienes and anhydrous formaldehyde synthesize the 5, 6-dihydrogen-pyran and the derivatives by the Diels-Alder reaction; after being depolymerized by paraformaldehyde, trioxymethylene or polyoxymethylene in another reaction kettle, the anhydrous formaldehyde in the form of gas enters into the reaction kettle of synthesis reaction which is carried out under the temperature between 30 DEG C and 100 DEG C. Because the invention separates the depolymerization from the synthesis, the synthesis reaction does not have to be carried out under a high temperature, the self-polymerization of conjugate dienes is avoided, and therefore the yield rate of reaction is increased.

Owner:ZHEJIANG NHU CO LTD

Method and apparatus for synthesizing of chloromethylether of ethylamine intermediate product

InactiveCN101302144AHighlight substantiveSignificant progressEther preparation by organic exchangeAlcoholChloromethyl ethyl ether

The invention discloses a method and a device for synthesizing chloromethyl ethyl ether, an immediate of acetochlor. Polyformaldehyde and alcohol with the needed amount are added into an A kettle and a B kettle; through circulating ejection systems of the A kettle and the B kettle, hydrochloric acid gas enters the A kettle to react, escaped hydrochloric acid gas continues to be etherified in an ejector of the A kettle and the A kettle, and the unreacted hydrochloric acid gas enters an ejector of the B kettle and the B kettle and continues to react; and uncondensed gas enters a condenser and an absorbing tank. When a product in the A kettle is qualified, the product is discharged; the operation is switched to feed fillings into the A kettle; the hydrochloric acid gas enters the B kettle for etherification, the escaped hydrochloric acid gas continues to be etherified in the B kettle and the ejector of the B kettle, the unreacted hydrochloric acid gas enters the A kettle and the ejector of the A kettle and continues to react, and unreacted light component gas enters the condenser and the absorbing tank; when a product in the B kettle is qualified, the product is discharged, and one-time switching operation of the A kettle and the B kettle is finished. The utilization rate of the hydrochloric acid gas is improved by 30 percent or so, no waste water exists during the etherification, and the cost of the product is apparently reduced.

Owner:CNPC JILIN CHEM GROUP CORP

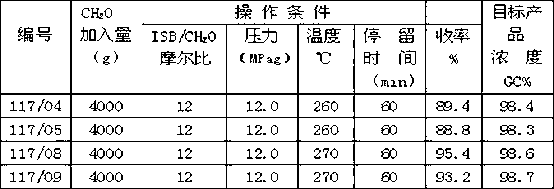

Method for gaseous-phase catalysis-free continuous synthesizing of 3-methyl-3-butenyl-1-alcohol

The invention discloses a method for the gaseous-phase catalysis-free continuous synthesizing of 3-methyl-3-butenyl-1-alcohol. According to the method, no paraformaldehyde serving as a main related raw material is used for pulping in isobutylene liquid, so that when the suspension liquid of the paraformaldehyde is heated to depolymerize, the escaped formaldehyde cannot automatically polymerize again to form solid paraformaldehyde and delink to generate trioxymethylene, and thus, heat exchangers and pipelines cannot be blocked. The method comprises the steps of: pre-depolymerizing the paraformaldehyde (allowed to be above 96wt%) in methanol to form formaldehyde dissolved in the methanol, and thus obtaining a pre-depolymerizing liquid; and pressurizing to continuously feed the formaldehyde to a reactor to be subjected to a synthetic reaction with isobutylene at the temperature of 270-290 DEG C and pressure of 10.0MPag-16MPag according to an olefine aldehyde molar ratio of 8-15 for a retention time of 50-100 minutes. The product yield can reach 93-95%.

Owner:吉林众鑫化工集团有限公司

Novel high-temperature resistant acidification corrosion inhibitor

InactiveCN103642480ANo three wastes pollutionLow costDrilling compositionBorehole/well accessoriesThioureaChemical products

Belonging to the technical field of oilfield chemical products, the invention in particular relates to a novel high-temperature resistant acidification corrosion inhibitor. The corrosion inhibitor is prepared by: reacting acetophenone, trioxymethylene, cyclohexylamine, hydrochloric acid with oleic acid to generate a ketone aldehyde amine condensate, and then compounding the condensate with nonylphenol polyoxyethylene ether, ethanol (methanol), thiourea, propargyl alcohol and potassium iodide. The high-temperature resistant acidification corrosion inhibitor has the advantages of no pollution of three wastes, low cost, easily available raw materials, simple process, convenient use and the like, and can effectively resist high temperature (204DEG C).

Owner:钱程

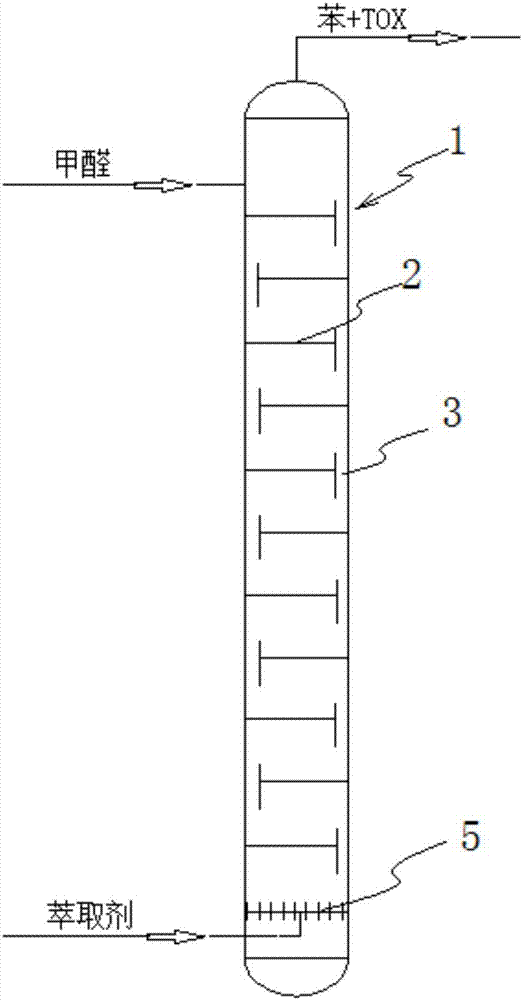

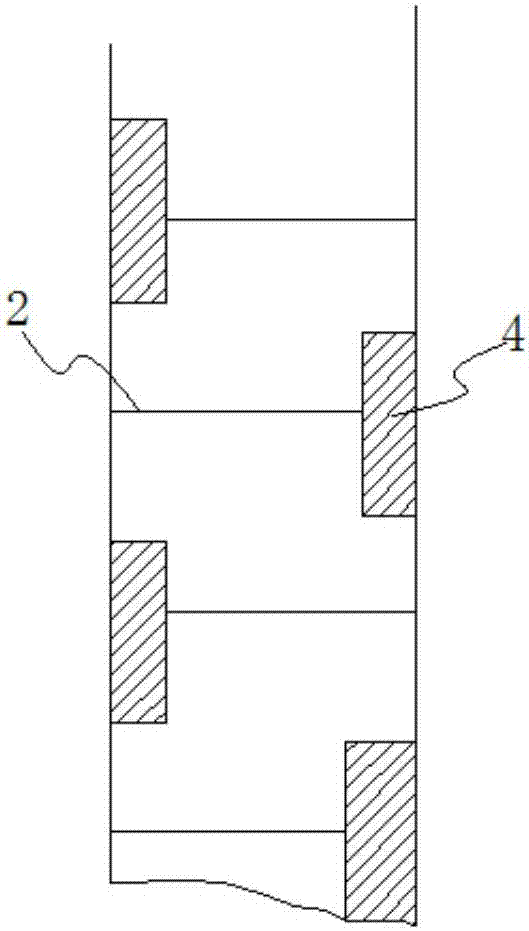

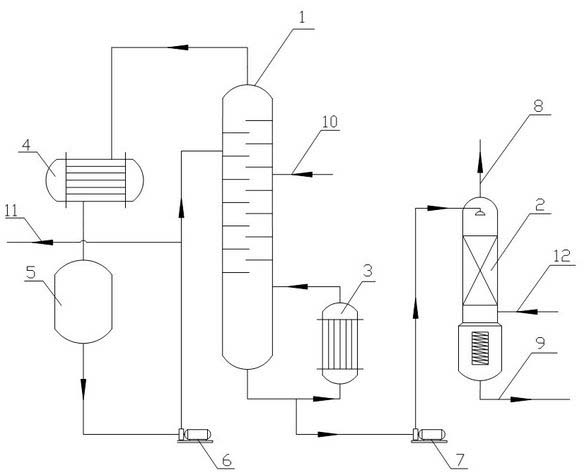

Production process for s-trioxane and extraction reaction tower

PendingCN107474036AImprove conversion rateReduce energy consumptionOrganic chemistryLiquid solutions solvent extractionPolyoxymethylenePtru catalyst

The invention discloses a production process for s-trioxane and an extraction reaction tower. Specifically, the extraction reaction tower includes an extraction agent inlet disposed at the bottom, a reactant recovery port arranged at the top, and multiple stages of extraction reaction units arranged sequentially from the bottom up. Adjacent extraction reaction units are separated by perforated tower plates, also downcomers are disposed between adjacent extraction reaction units, and the extraction reaction units are internally provided with a solid acid catalyst. The production process for s-trioxane and the extraction reaction tower provided by the invention can reach a formaldehyde conversion rate of more than 45%, and also have the characteristics of small steam consumption in the reaction process, and low equipment investment and the like.

Owner:湖北三里枫香科技有限公司

Method for preparing polymethoxy dimethyl ether by virtue of slurry bed in combination with fixed bed

ActiveCN104119210AImprove distributionIncrease profitOrganic chemistryOrganic compound preparationSlurry reactorProduct system

The invention provides a method for preparing polymethoxy dimethyl ether by virtue of a slurry bed in combination with a fixed bed. According to the method, conventional methanol and / or methyl acetal, formaldehyde and / or trioxymethylene in the prior art are taken as synthetic raw materials, by the steps of firstly reacting reaction raw materials in the slurry bed to balance and then moving the obtained product to the fixed-bed reactor and reacting, the original balance of the balanced material system obtained by reacting in the slurry reactor is broken in the fixed bed, and the reaction is further carried out towards the direction capable of forming polymethoxy dimethyl ether so that the distribution of effective polymethoxy dimethyl ether with a low degree of polymerization in a product system containing polymethoxy dimethyl ether is preferable, the content of DMM2-8 component reaches 60%, the utilization rate of raw materials is effectively improved and the production cost is decreased.

Owner:DONGFANG HONGSHENG NEW ENERGY APPL TECH RES INST +1

Prepn process of standard acetaldehyde gas

The preparation process of standard acetaldehyde gas includes the following steps: feeding acetaldehyde solution into vacuumized bottle, gasifying acetaldehyde, heating to depolymerize paraldehyde in the acetaldehyde solution into acetaldehyde gas, cooling to room temperature, and diluting with inert gas to normal pressure to obtain standard acetaldehyde gas. Compared with available technology, the present invention has the advantages of being simple, fast and accurate, low cost, etc. The prepared standard acetaldehyde gas may be set stably for over 24 hr, and is used in environment atmosphere detection and acetaldehyde detection in industrial waste gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

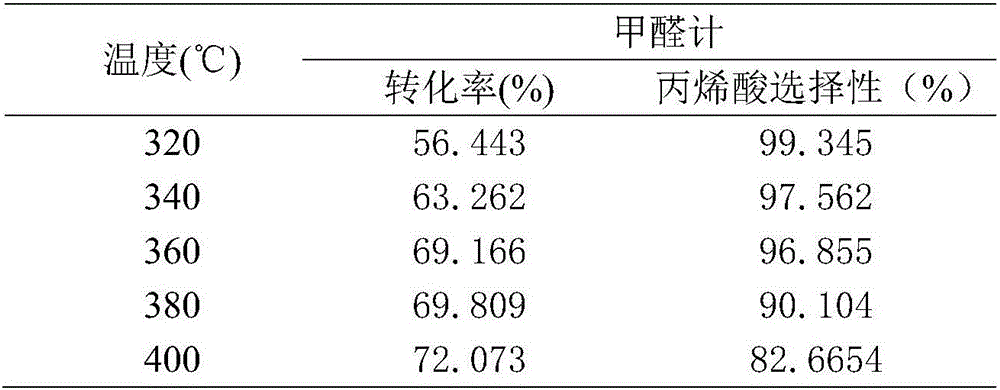

Cs-VPO/SiO2 catalyst, preparation method therefor and use of Cs-VPO/SiO2 catalyst in preparation of acrylic acid through catalyzing condensation of acetic acid and trioxymethylene

InactiveCN106582749AHigh catalytic activityImprove catalytic stabilityPhysical/chemical process catalystsOrganic compound preparationIsobutanolFiltration

The invention provides a Cs-VPO / SiO2 catalyst, a preparation method therefor and use of the Cs-VPO / SiO2 catalyst in preparation of acrylic acid through catalyzing condensation of acetic acid and trioxymethylene. The preparation method comprises the steps: (1) firstly, weighing vanadium pentoxide, adding the weighed vanadium pentoxide into a three-mouthed flask, then, adding isobutanol and benzyl alcohol into the three-mouthed flask, and carrying out constant-temperature stirring refluxing until the vanadium pentoxide is completely dissolved; and weighing phosphoric acid, slowly adding the weighed phosphoric acid into the flask, and then, continuing to carry out a constant-temperature refluxing reaction until the solution is dark blue, so as to obtain a vanadium-phosphorus oxide, i.e., VPO; and (2) adding SiO2 into the three-mouthed flask in the step (1), then, adding an aqueous solution of cesium carbonate into the three-mouthed flask, and carrying out a stirring reaction; and taking out a sample after the reaction is completed, carrying out suction filtration, carrying out washing with isobutanol and acetone, then, carrying out drying, grinding and roasting, tabletting the sample, and carrying out screening, thereby preparing the Cs-VPO / SiO2 catalyst. The Cs-VPO / SiO2 catalyst provided by the invention has the remarkable characteristic of having good catalytic activity and stability in a reaction process.

Owner:JIANGSU UNIV

Method for preparing polyformaldehyde dimethyl ether from paraformaldehyde

ActiveCN103664543AStrong acidHigh selectivityOrganic chemistryOrganic compound preparationPolyoxymethylenePtru catalyst

The invention relates to a method for preparing polyformaldehyde dimethyl ether from paraformaldehyde, which is mainly used for solving the problems that the conventional method for synthesizing the polyformaldehyde dimethyl ether by taking trioxymethylene as a material is high in cost and not high in catalyst reaction selectivity. In order to solve the problems betters, a following technical scheme is as follows: methanol, methylal and polyformaldehyde are taken as materials in a mass ratio of (0-10):(0-10):1 to contact with a catalyst for reaction to generate polyformaldehyde dimethyl ether CH3O(CH2O)nCH3 under conditions with a reaction temperature of 70 DEG C-200 DEG C and reaction pressure of 0.2 MPa-0.6 MPa, wherein the dosages of the methanol and the methylal cannot be 0 at the same time, and the used catalyst comprises the following components in parts by weight: 30-80 parts of an oxide carrier and 20-70 parts of heteropoly acid. And therefore, the method can be used for industrial production of polyformaldehyde dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

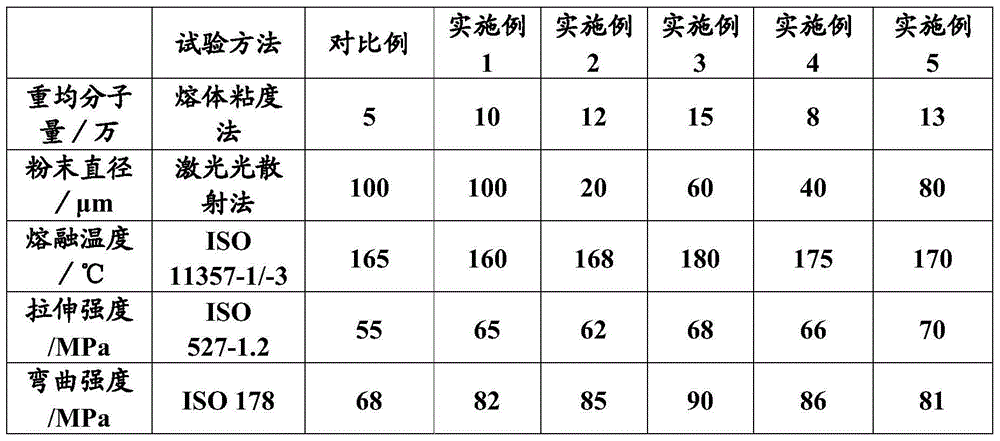

3D printing high-molecular polyformaldehyde powder and preparation method

The invention provides a 3D printing high-molecular polyformaldehyde powder which is characterized in that raw materials comprise, by weight, 100 parts of trioxymethylene, 2-5 parts of a comonomer, 0.005-1 part of an initiator, 0.1-0.5 part of a molecular weight modifier, 0.1-0.5 part of an antioxidant, 0.1-0.5 part of a formaldehyde absorbent, and 0.1-0.5 part of a formic acid absorbent. The polyformaldehyde powder provided by the invention has the following characteristics: weight-average molecular weight can reach 80-150 thousand; melting temperature is 160-180 DEG C; and partical size is 20-100 microns. The polyformaldehyde powder can be used in 3D printing molding, and a product has better integrated performance than a product prepared from a common polyformaldehyde powder.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Synthesis method of N, N-diisopropylethylamine

InactiveCN102875385AAtom utilization is highSimple processPreparation by reductive alkylationSynthesis methodsDiisopropylamine

The invention discloses a synthesis method of N, N-diisopropylethylamine. The synthesis method comprises the following steps of: (1) reacting paraldehyde serving as a raw material in a solvent under normal pressure and at the temperature of 22-28 DEG C under the action of an acidic catalyst for 20-40 minutes; (2) adding diisopropylamine and metal hydride serving as a reducing agent into a reaction product obtained by the step (1), preserving heat and reacting for 10-30 minutes to obtain the N, N-diisopropylethylamine, wherein the molar ratio of the diisopropylamine to the paraldehyde is 1:0.34-0.4, the molar ratio of the diisopropylamine to the metal hydride is 1:1-1.2, and the mass ratio of the acidic catalyst to the diisopropylamine is 1-5 percent; and (3) after removing the solvent under reduced pressure from reaction solution obtained by the step (2), adjusting pH (Potential of Hydrogen) to be 13, and then separating and rectifying to obtain the N, N-diisopropylethylamine.

Owner:ZHEJIANG UNIV

Preparation method of polyacetal resin

The invention provides a preparation method of polyacetal resin. The preparation method comprises the following steps: trioxymethylene, comonomer cyclic ether and / or cyclic acetal, glycidyl ether withat least two epoxy groups and an acetal chain transfer agent initiate a polymerization reaction through a heteropolyacid catalyst, and then react with an inactivator sulfur-containing functional group oxazole derivative and are extruded to obtain a product. The effective access of glycidyl ether to a polyacetal main chain can be realized by adding cyclic ether and / or a mixture of cyclic acetal and glycidyl ether with at least two epoxy groups in a specific stage of a polymerization reaction through a simple process; in addition, by improving the inactivation process, the material is mixed with an inactivator sulfur-containing functional group oxazole derivative and then subjected to reactive extrusion, so that the thermal stability and various mechanical properties of the polyacetal resinare improved.

Owner:WANHUA CHEM GRP CO LTD

Low-corrosion and low-formaldehyde-release polyformaldehyde composition and preparation method and application thereof

The invention discloses a low-corrosion and low-formaldehyde-release polyformaldehyde composition and a preparation method and an application thereof. The composition includes copolymerized polyformaldehyde resin, an organic formaldehyde absorbent, an inorganic formaldehyde and formic acid absorbent, an antioxidant, a lubricant and a crystallization nucleating agent. The composition can be used in application occasions having extremely harsh requirements on the formaldehyde release amount and corrosivity, avoids the problems of discoloration, volatilization and emigration brought by a traditional formaldehyde absorbent, and besides, also has an excellent effect on absorbing formic acid; and the preparation method is simple and convenient to operate, and is quite easily applied to the polyformaldehyde technical field.

Owner:CHINA NAT OFFSHORE OIL CORP +4

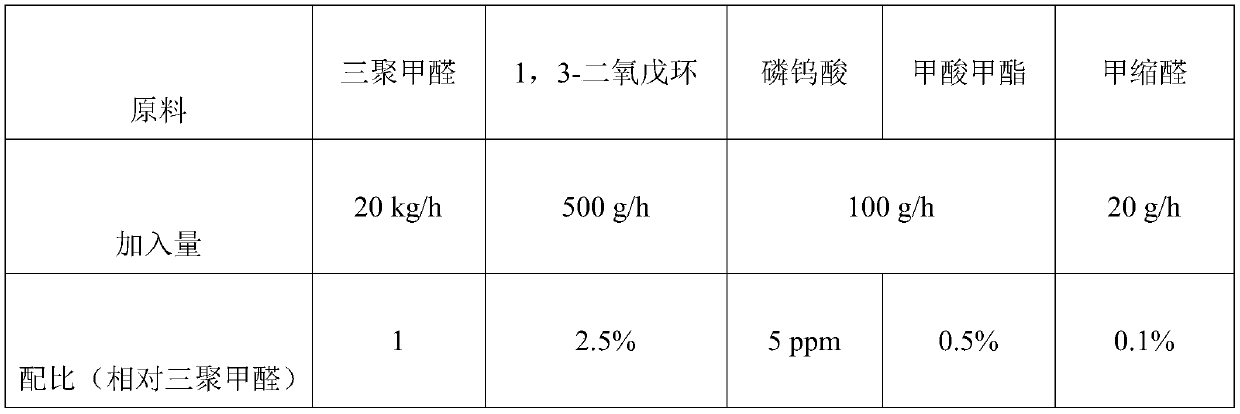

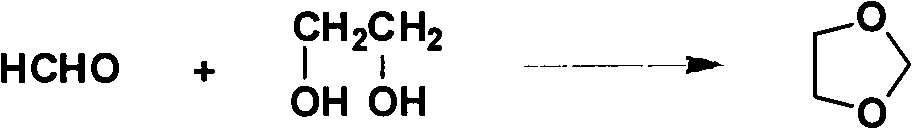

New method for preparing 1,3-dioxolane by catalytic condensation

The invention relates to a new method for preparing 1,3-dioxolane by catalytic condensation, which comprises the following step of: enabling glycol and formaldehyde (trioxymethylene, paraformaldehyde or 37% formalin) to be subjected to condensation reaction under the catalysis of silica gel-supported phosphotungstic acid. The 1,3-dioxolane prepared by the method provided by the invention can be used as a solvent of grease, polymers, coatings and bonding agents, an extracting agent of wax and medicaments (vitamins and the like), a solvent for lithium battery electrolytes, a chlorine-based solvent stabilizing agent, a medicament intermediate or the like. The invention has the advantages that the process is simple, the catalytic efficiency is high, the catalyst dose is little, the reaction rate is high, the yield is high, the equipment requirement is low, a catalyst can be easily recovered and can be reused, and large-scale commercialized preparation and production can be realized, thereby meeting the currently increased market demand.

Owner:TIANJIN JIULIAN TECH CO LTD

Process for producing 2-methyl-8-nitryl quinoline

The invention provides a method for preparing 2-methyl-8-nitroquinoline. The method comprises the following steps: o-nitroaniline reacts in hydrochloric acid and benzene solution to form hydrochloride of the o-nitroaniline; the o-nitroaniline hydrochloride and aldehyde are subjected to cyclization at a temperature between 10 and 100 DEG C; oxidation reaction is performed by use of oxidant at a temperature between 10 and 100 DEG C; and finally the 2-methyl-8-nitroquinoline with high purity is obtained through separation, neutralization, washing and drying. The method has the advantages that the method uses low-toxicity paraldehyde as a raw material to replace virulent crotonaldehyde, and uses iodine as the oxidant to replace virulent arsenic acid so as to reduce toxic effects on human and environment; inorganic acid and inorganic base used in the reaction are common acid and base; and the method is low in cost, little in pollution and high in product purity, and reaches the yield of 80 percent.

Owner:CINIC CHEM SHANGHAI

Method and device for removing light components in trioxymethylene

ActiveCN102633770AReduce partial pressureEfficient removalOrganic chemistryFractional distillationPolyoxymethylenePhysical chemistry

Owner:XINGTAI RISUN COAL CHEM IND

Injection forming feed for superfine hard alloy and preparation method thereof

ActiveCN109226742ANo defects such as swelling and bubblingShort degreasing timeTransportation and packagingMetal-working apparatusOXALIC ACID DIHYDRATEPolyethylene glycol

The invention discloses injection forming feed for superfine hard alloy and a preparation method thereof, and relates to the field of powder metallurgy. The feed is prepared from, by mass, 92-94.5% ofsuperfine hard alloy powder and 5.5-8% of a binding agent, wherein the binding agent is prepared from 59.0-69.0% of polyformaldehyde (POM), 23.0-35.0% of polyethylene glycol (PEG), 3.0-4.0% of high density polyethylene (HDPE), 2.0-2.5% of an ethylene-vinyl acetate copolymer (EVA) and 1.0-1.5% of stearic acid (SA). The PEG is added after the superfine hard alloy powder is preheated, after the PEDand the superfine hard alloy powder are mixed uniformly, the POM, HDPE, EVA and SA are added for mixing, and the preparation is completed. The feed adopts oxalic acid for catalyzing degreasing, so that the degreasing time can be reduced obviously, the production efficiency can be improved obviously, the use of acid catalysts and toxic solvents which are harmful to the environment is avoided, and the injection forming feed is economical and environmentally friendly and has a broad application prospect.

Owner:GUANGDONG INST OF NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com