Method for measuring thermal stability of polyformaldehyde

A measurement method and thermal stability technology, applied in chemical analysis by titration, etc., can solve problems such as inability to directly reflect the decomposition of polyoxymethylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

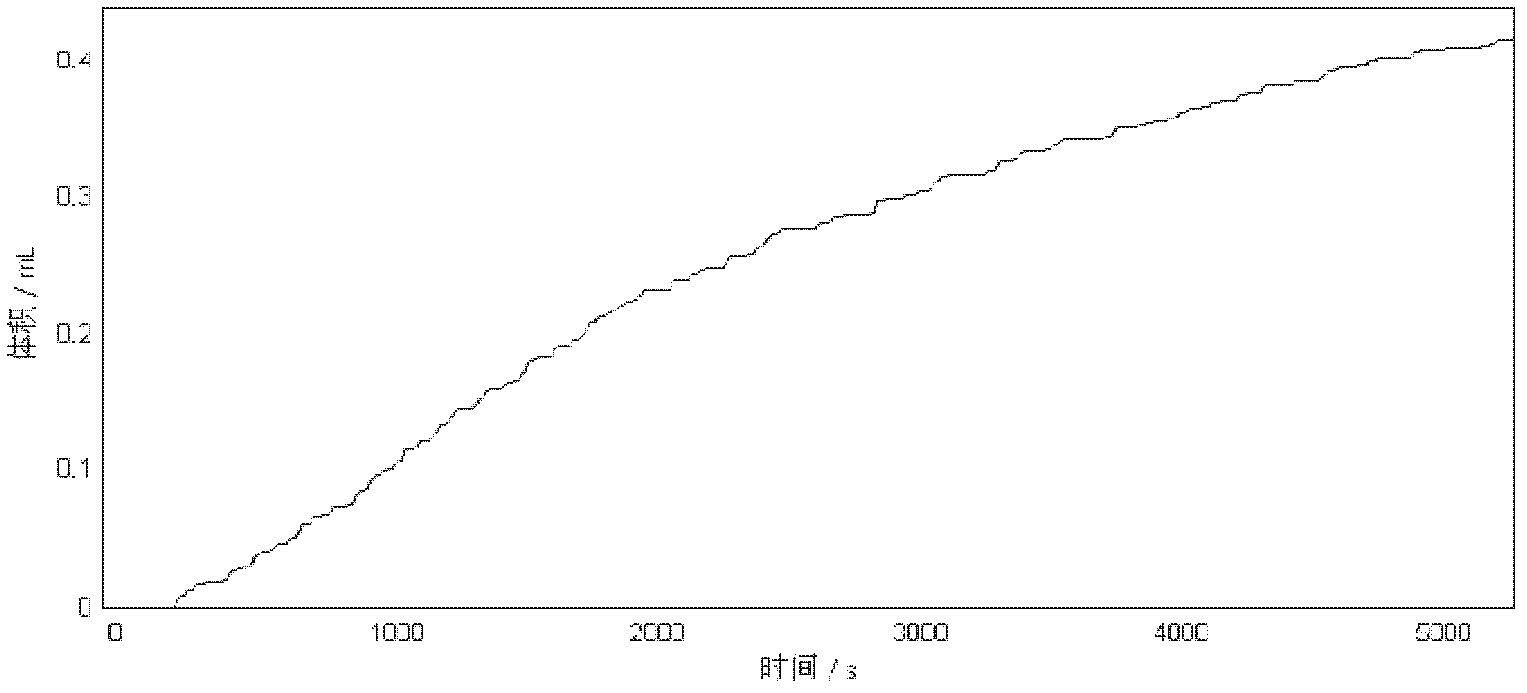

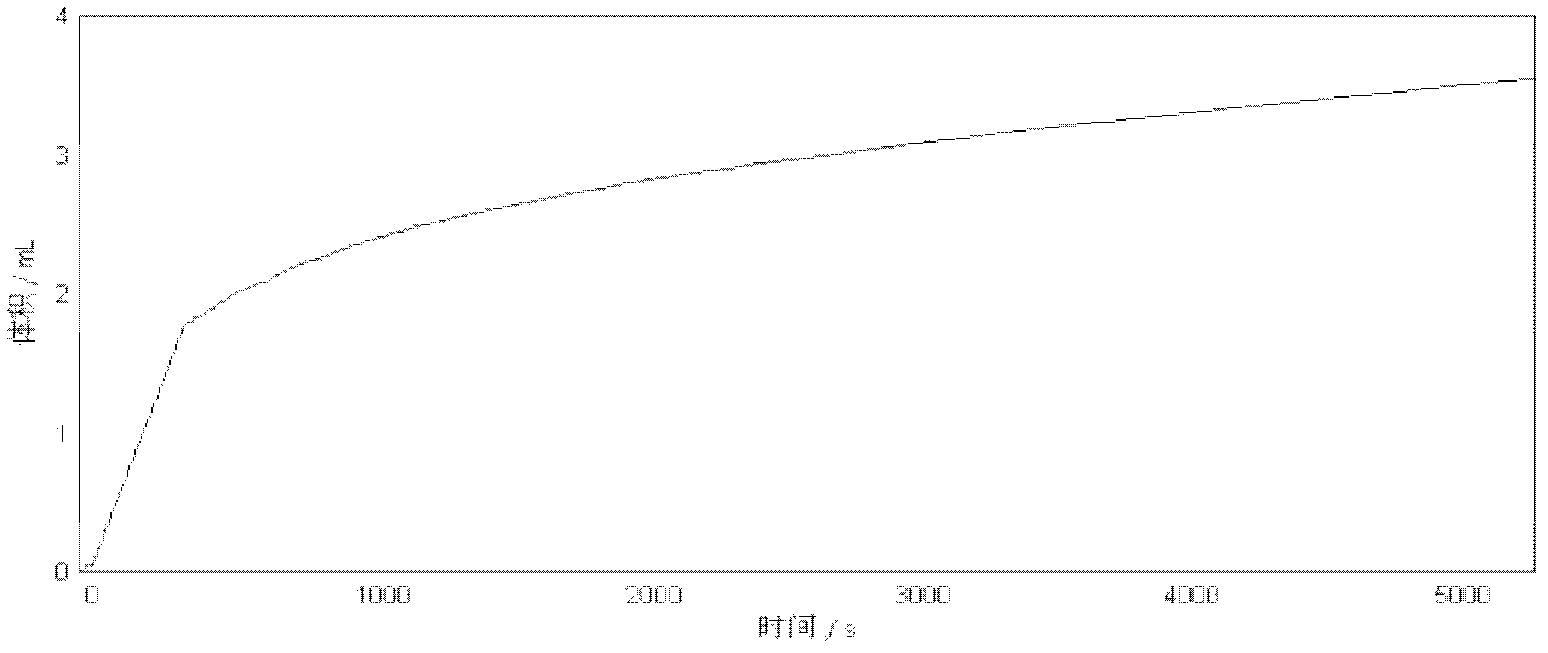

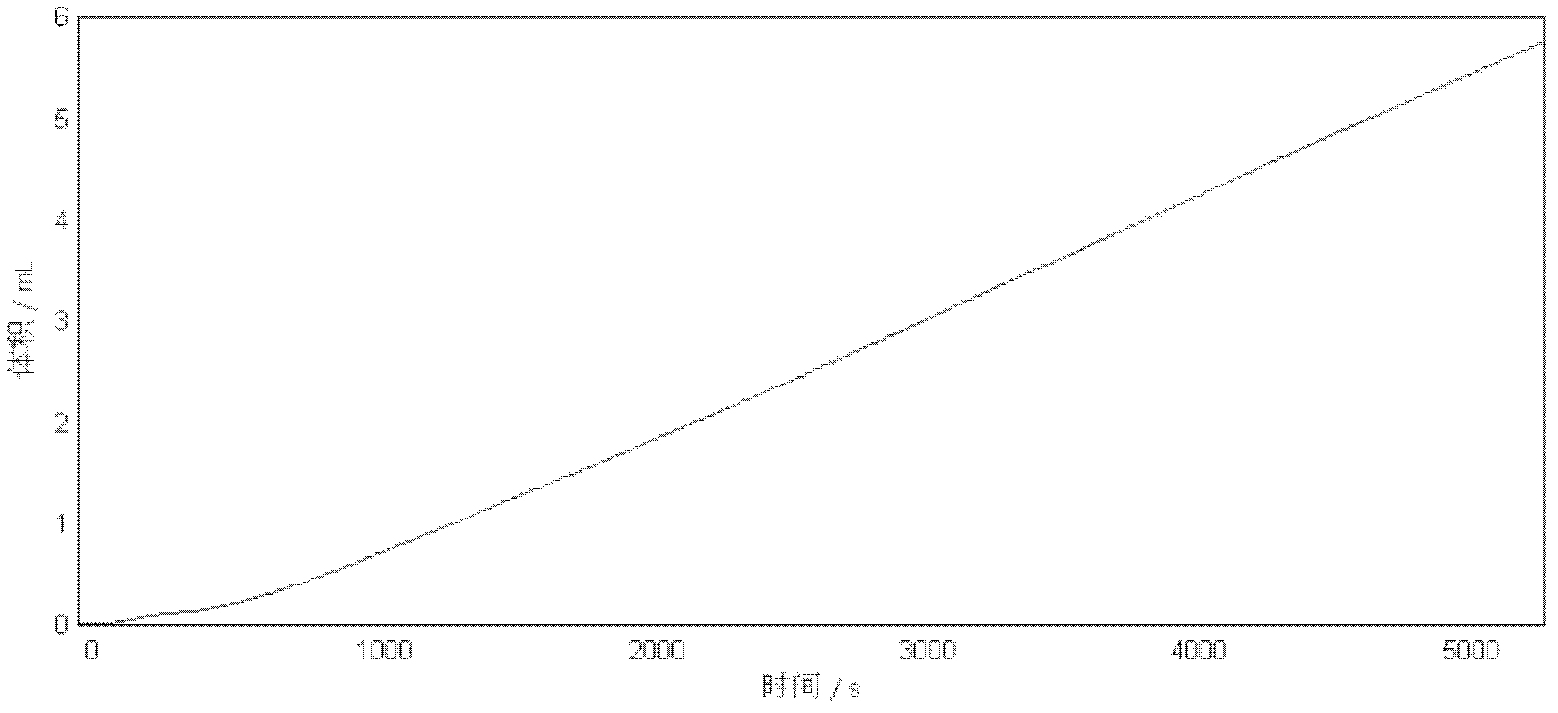

Image

Examples

Embodiment

[0035] 1. Heat up the heating oil bath of the reaction device. The temperature of the oil bath is strictly controlled at 223±2°C. Before putting in the test sample, it needs to be kept warm for 20 minutes until the temperature is stable before the test can be started. When the heat preservation is started, the nitrogen valve is opened, and the nitrogen flow rate Control it at 1000±2ml / min to completely discharge the air in the reaction device.

[0036] 2. Prepare a sodium sulfite solution with a concentration of 0.05N and a sulfuric acid standard titration solution with a concentration of 0.05N. Take 200ml of sodium sulfite solution with a 250ml beaker, add a small amount of formaldehyde solution therein, because sodium sulfite and formaldehyde generate sodium hydroxide, the pH value of the sodium sulfite solution rises to more than 10 (rough test), then use sulfuric acid titration solution to titrate, finally The pH of the sodium sulfite solution was adjusted to 9.20.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com