Modified acidic cation exchange resin and applications thereof

A technology of acidic cation and exchange resin, which is applied in the direction of cation exchange, ion exchange, organic compound/hydride/coordination complex catalyst, etc. It can solve the problems of low selectivity, complicated process, and low conversion rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In a 1-liter stainless steel stirred tank, add 400g of water, add 2.5g of methyl amyl alcohol, 15g of potassium chloride, 0.1g of sodium nitrite, raise the temperature to 80°C, add 60g of styrene (content ≥ 99%), 35g of divinyl Benzene (divinylbenzene content 50%), 72g of butanol and 1g of paraffin constitute an organic mixture, stir and heat up to 95°C, and react for 8 hours to obtain a polymer. The polymer was placed in deionized water at 95°C, boiled at normal pressure for 5 hours, and washed to obtain 100 g of white balls, among which white balls with a particle size ranging from 0.4mm to 1.25mm accounted for more than 95%;

[0022] In a 1-liter glass stirred tank, add 60 g of the above-mentioned white balls, stir, add 300 g of 20% oleum dropwise, and program the temperature to rise from room temperature to 90 °C at a heating rate of 10 °C / h, stabilize for 2 hours, and then raise the temperature to 130 °C. ℃, keep warm for 5 hours, cool, add 30% dilute sulfuric acid...

Embodiment 2

[0025] The reaction between formaldehyde and methanol is carried out in a fixed-bed reaction. A stainless steel tubular fixed-bed reactor (dimensions φ24×6×600mm) is used. Under the action of a heating furnace, there is a 45mm constant temperature zone in the reaction tube, and the catalyst is filled in the constant temperature zone. Inside, the rest is filled with quartz sand (40-60 mesh) to fix the catalyst. The temperature of the catalyst bed is controlled by the AI-708 artificial intelligence regulator. When the temperature is constant, the fluctuation of the bed temperature is controlled within ±1°C. Raw material liquid formaldehyde and methanol are metered and fed by 2PB00C advection pump. The liquid composition before and after the reaction was analyzed by gas chromatography, the chromatographic column was Agilent HP-5 capillary column (0.32mm×30m), FID detector, and the area normalization method was used for quantification.

Embodiment 3

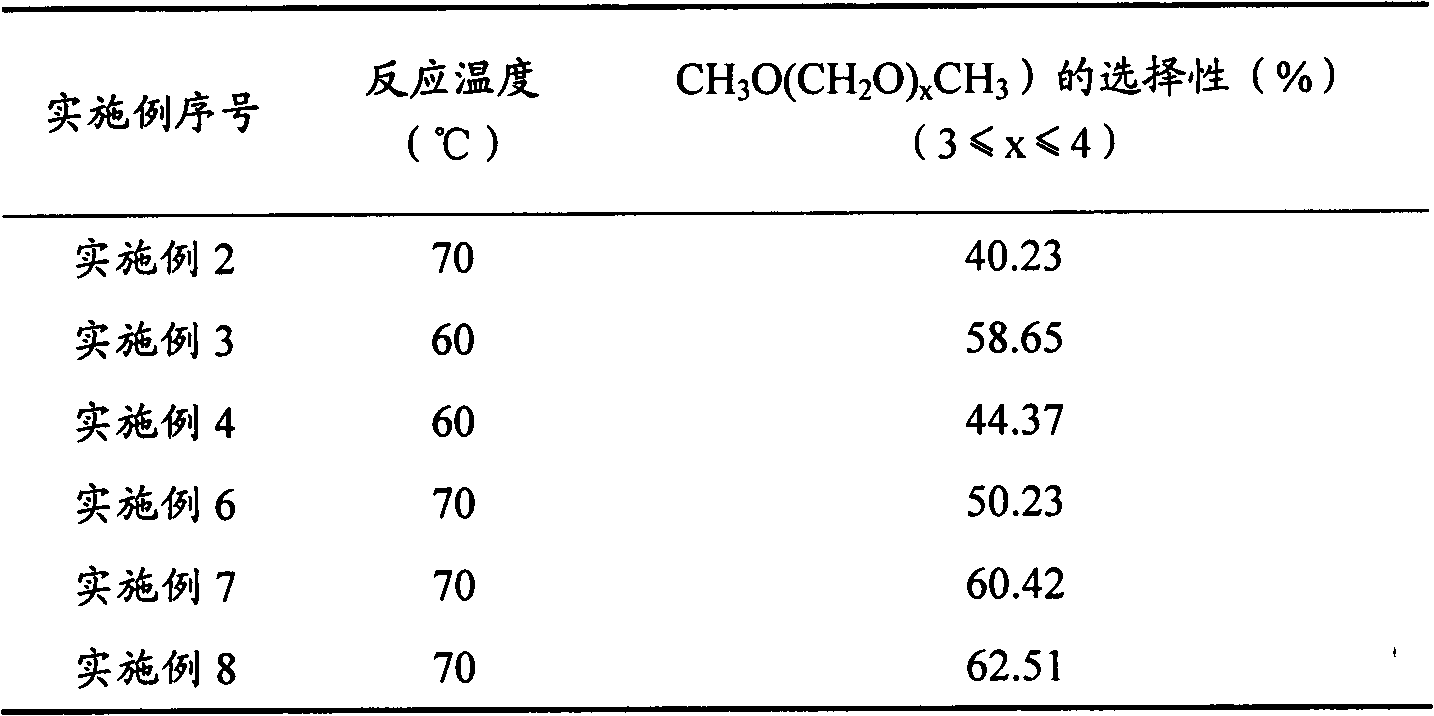

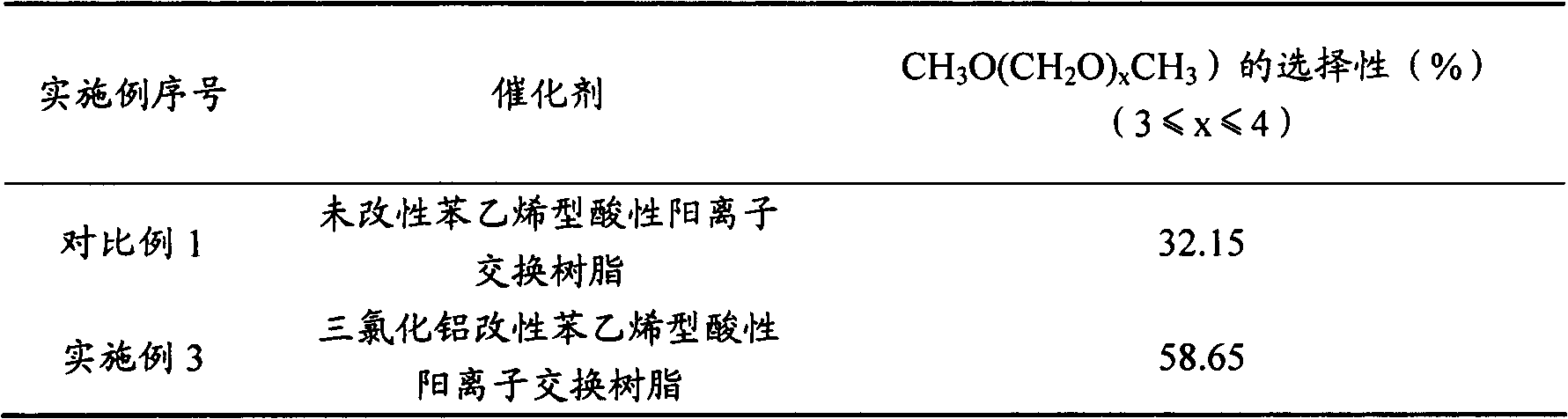

[0028] Except formaldehyde and methyl alcohol in the replacement embodiment 2 with methylal and paraformaldehyde (the mol ratio of methylal and paraformaldehyde is 3: 1) and change the temperature of reaction in embodiment 2 into 60 ℃, , other conditions are the same as in Example 2, and the reaction results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com