Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Gentle production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst for synthesizing acrylic acid by aqueous formaldehyde solution and acetic acid and preparation and application method of catalyst

ActiveCN103586067AProcess raw materials are cheapGentle production processMolecular sieve catalystsOrganic compound preparationActivated carbonMolecular sieve

The invention discloses a catalyst suitable for synthesizing acrylic acid by an aqueous formaldehyde solution and acetic acid and a preparation and application method of the catalyst. The catalyst is mainly characterized by adopting one or more of activated carbon, aluminum sesquioxide, silicon dioxide or molecular sieve as carriers, and loading phosphorus pentoxide and one or more alkaline-earth metal oxides, wherein phosphorus pentoxide accounts for 1%-20% of the total mass of the catalyst, and the alkaline-earth metal oxides account for 5%-30% of the total weight of the catalyst. The catalyst is prepared by the steps of impregnation, temperature programmed calcination and the like, and a vacuum-ultrasonic impregnation technique is introduced during the preparation process. According to the invention, a fixed bed reactor is adopted for produce acrylic acid continuously under the suitable reaction conditions, the conversion per pass of formaldehyde is up to 35%, and the selectivity of acrylic acid is up to 55%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing cyclic sulfate by directly oxidizing hydrogen peroxide

PendingCN111909129ALess impuritiesHigh purityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCatalytic oxidation

The method comprises the following steps: dropwise adding hydrogen peroxide into a mixture of cyclic sulfite, an organic solvent and a solid catalyst to carry out catalytic oxidation reaction, filtering out the solid catalyst after the reaction is finished, standing filtrate for layering, taking an organic layer, and performing distilling and concentrating to obtain a cyclic sulfate product. Cheaphydrogen peroxide is used for directly catalyzing and oxidizing cyclic sulfite to prepare cyclic sulfate, so that on one hand, the reaction is mild and easy to control, and the reaction conversion rate is high; on the other hand, no waste salt is generated, the evaporation capacity of water is small, energy consumption is low, generated waste water is little, and the production process is more environmentally friendly; the used solid catalyst contains an active component, an active auxiliary agent and an oxide carrier, and can be recycled, so that the consumption of noble metals is reduced, and the production cost is greatly reduced; the cyclic sulfate prepared by the method is few in impurities, high in purity and wide in market prospect.

Owner:CHANGSHU CHANGJI CHEM +1

Profiled polylactic acid fiber and preparation method thereof

ActiveCN101608346AImprove hydrophilicityFluffy goodHollow filament manufactureFilament manufactureStretch ratioProcess conditions

The invention discloses a profiled polylactic acid fiber and a preparation method thereof. Cross section of the profiled polylactic acid fiber can be of C shape, hollow circular shape, trilobal shape, cross shape and triangular shape; and compared with common circular polylactic acid fiber, the profiled polylactic acid fiber has good hydrophilicity, bulkiness, flexibility, luster and excellent mechanical properties. The invention also discloses a preparation method of the profiled polylactic acid fiber. The profiled polylactic acid fiber with uniform structure and excellent mechanical properties is prepared by using profiled spinneret orifices in the melt spinning process at moderate spinning speed, lower heat stretching and heat treatment temperature, stretching ratio and mild melt spinning process conditions in a liquid phase thermostatic bath by improving spinning dynamics.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method for cephalosporin anti-infective drug

ActiveCN105017286ASimple preparation processReduce generationOrganic chemistry7-ACACefazedone sodium

The invention relates to a preparation method for a cephalosporin anti-infective drug-cefazedone sodium, belonging to the field of pharmaceutical synthesis. According to the invention, the method uses GCLE as a raw material to substitute 7-ACA and overcomes the defects of low yield, high pollution and the like in prior art; the preparation method with mild reaction conditions, little side reaction and simple process is provided; meanwhile, the method has the advantages of cheap and easily-available raw materials, low cost, high product yield, high product purity and applicability to industrial production.

Owner:SHANDONG LUOXIN PARMACEUTICAL GROUP STOCK CO LTD

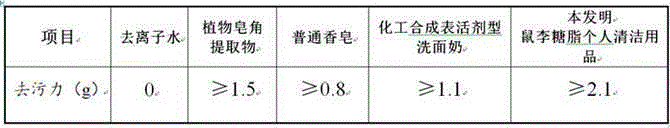

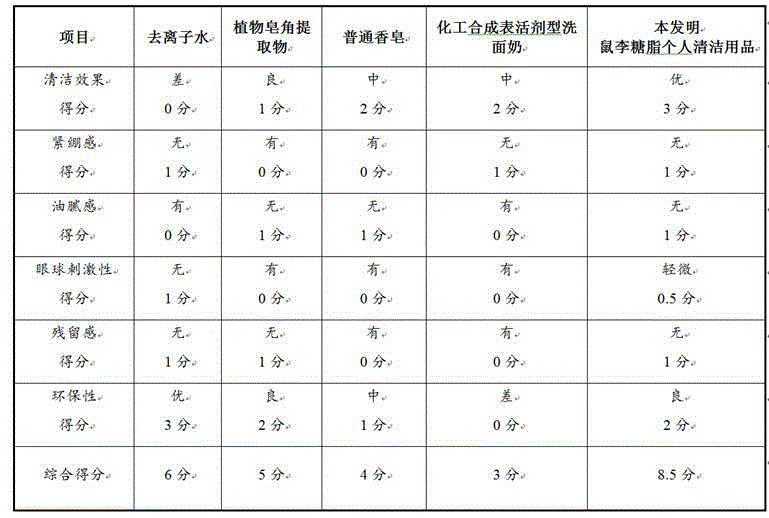

Rhamnolipid-containing personal cleaning product and preparing method thereof

ActiveCN104887539ASignificant wettingAbility to significantly emulsify fats and oilsEsterified saccharide compoundsCosmetic preparationsBiotechnologyVegetable oil

The invention discloses a rhamnolipid-containing personal cleaning product and a preparing method thereof. The preparing method includes: subjecting a bacterium, Pseudomonas aeruginosa, to fermentation cultivation via a non-vertical fermentation tank so as to convert fresh vegetable oil into rhamnolipid, performing extracting, refining and concentrating to obtain rhamnolipid concentrate containing 90% to 95% of rhamnolipid, directly adding 0.1 to 0.5 part of citric acid, as pH regulator, 0.1 to 0.5 part of peppermint water, as flavoring agent, and the balance of distilled water or deionized water, as final concentrate viscosity regulator, into the 50 to 95 parts of the rhamnolipid concentrate, performing full mixing, allowing standing, and performing degassing to obtain the personal cleaning product. The pH is adjusted to 5.0 to 10.0. The repeated trials on the personal cleaning product show that the personal cleaning product has evident technical effect on skin cleaning and post-cleaning tactile improving and is widely applicable.

Owner:陈竞

Production method of hand-tearing fabric

The invention discloses a production method of hand-tearing fabric. The production method comprises the following steps: interweaving warps and wefts to obtain gray fabric, wherein cation modified polyester fiber is adopted for the warps and the wefts; carrying out acid treatment and alkali treatment on the gray fabric obtained in step (1), then dyeing and soaping to obtain the hand-tearing fabric. According to the manner, the production method of the hand-tearing fabric is simple in operation, easy to master perfectly, safe and effective, and mild in production process; no danger can occur, and the obtained hand-tearing fabric is low in price, does not have much difference from existing hand-tearing fabric in performance, and can be popularized and applied in a wide scope.

Owner:吴江市鲲翰纺织有限公司

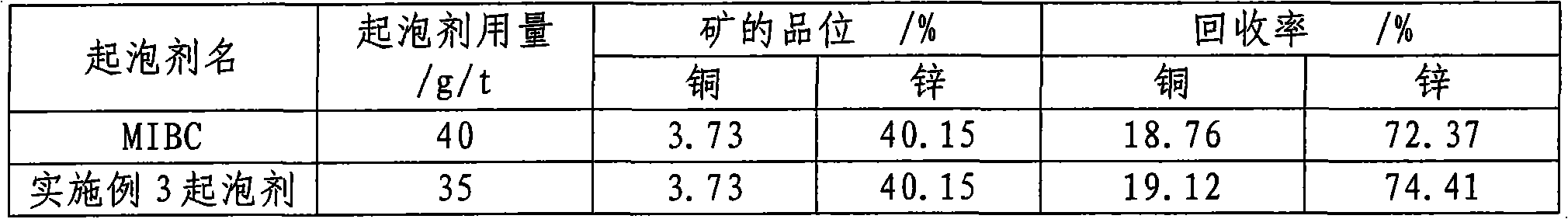

Mineral floatation foaming agent and preparation method thereof

InactiveCN102120197AExtensive sources of raw materialsThe synthesis process is simpleSulfonic acids salts preparationFlotationMineralogyCarbon atom

The invention discloses a mineral floatation foaming agent and a preparation method thereof. The mineral flotation foaming agent is prepared from the raw materials of fatty alcohol with a branch chain and epoxy chloropropane by epoxidation and sulfonation. One end of the foaming agent has polar groups of -OH and -SO3H, and the other end of the foaming agent has fatty alcohol sulfonate with straight chain alkyls or branch chain alkyls of different carbon atoms. The raw materials of the mineral flotation foaming agent are widely available and cheap, the synthesis process is simple, the synthesis conditions are mild, the reaction is easy to control, and the industrialization is easy to realize. The foaming agent has good aerophily and hydrophily as well as excellent foaming performance. The degradation speed of the foaming agent is higher than that of the terpineol with an annular structure, thereby being favorable for environmental protection. Compared with the existing product, the mineral recovery rate is increased by 0.5-2%, and the using cost is lowered by 10-20%.

Owner:KUNMING FURUITE TRADE

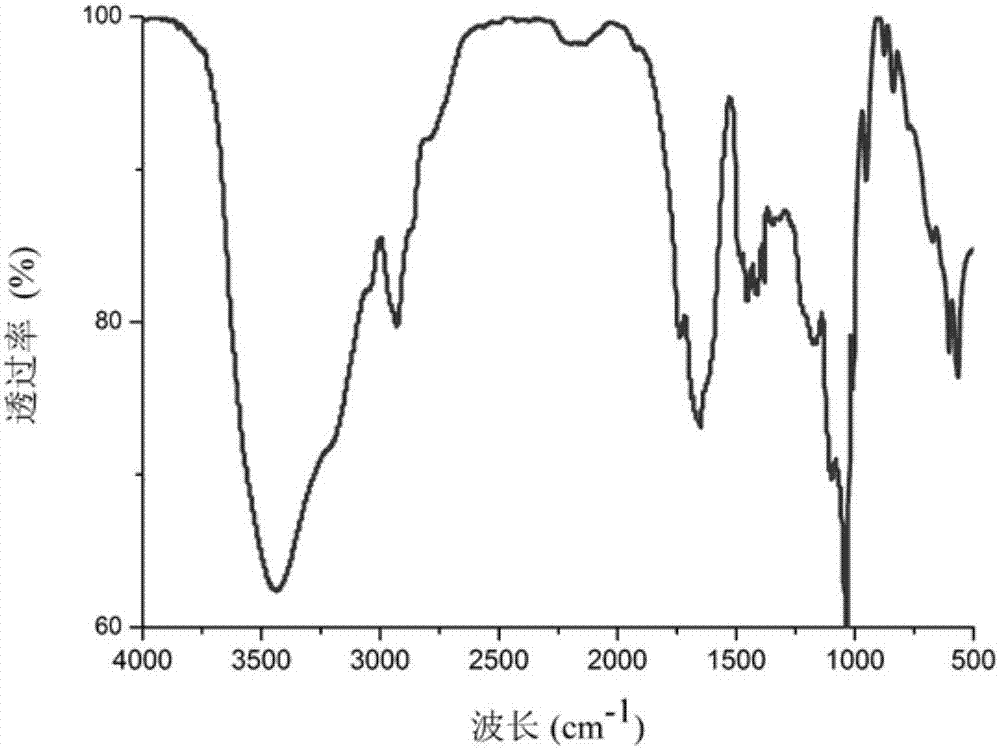

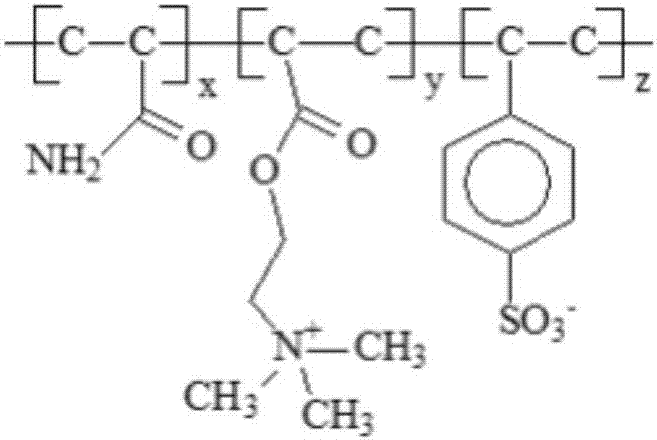

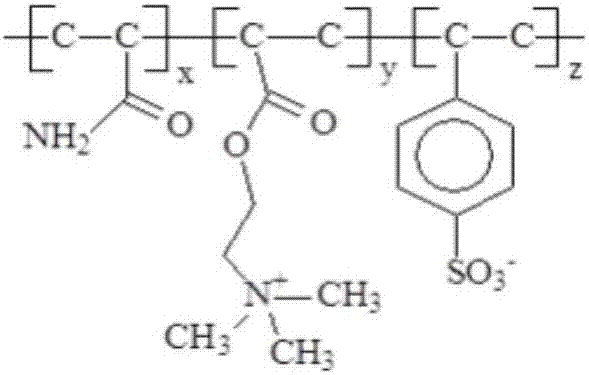

Polymeric acid solution thickener

InactiveCN106947457AGood thickeningImprove temperature resistanceDrilling compositionApparent viscosityEngineering

The purpose of the invention to provide a polymeric acid solution thickener. The thickener has excellent resistance to a high temperature and shearing, and can meet high temperature and deep well construction requirements. The ternary copolymeric acidified fracturing thickener obtained in the invention can be used for thickening an acid solution with the hydrochloric acid concentration of 5-28%, the apparent viscosity of the thickener at room temperature is 100 mPa.s or above, the viscosity retention rate at 90 DEG C still reaches 60% or above, the viscosity at 110 DEG C can still reach 30 mPa. s or above, and the thickener has good thickening and temperature resisting performances. Compared with conventional preparation technologies, a technology disclosed in the invention has the advantages of high production efficiency, simplicity, mild production conditions, easiness in control of the polymerization process, great reduction of the production cost, and easiness in industrial promotion; and the above product has the advantages of good solubility, convenience in transportation, and good application prospect.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

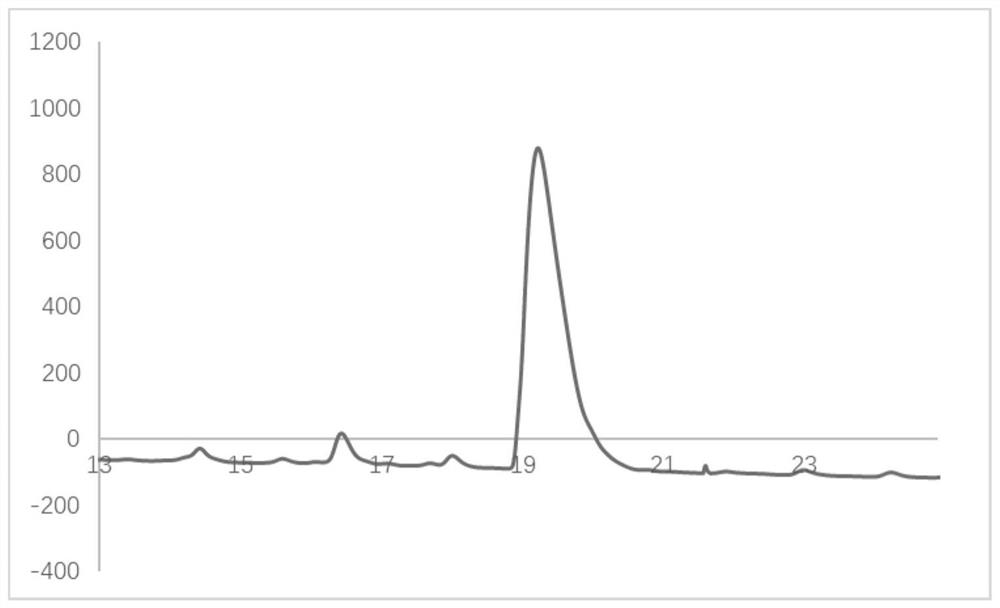

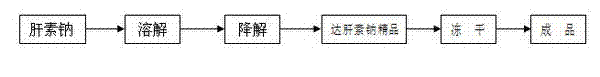

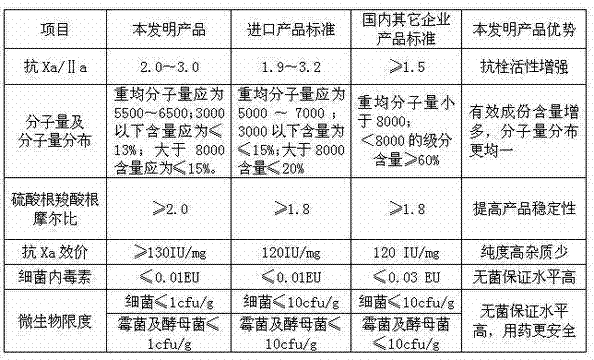

Preparation process of dalteparin sodium

ActiveCN102558393BPrevent embolismPrevent venous thromboembolismOrganic active ingredientsMetabolism disorderExtracorporeal circulationFreeze-drying

Owner:HEBEI CHANGSHAN BIOCHEM PHARMA

Deodorant for high-temperature composting process

InactiveCN104649750APracticalEasy to useBio-organic fraction processingOrganic fertiliser preparationSulfateDeodorant

The invention discloses a deodorant for a high-temperature composting process. The deodorant comprises the following materials by weight: 1-5 parts of potassium permanganate, 20-30 parts of ferrous sulfate, 20-30 parts of silicon dioxide, 15-25 parts of calcium oxide, a proper amount of sterilization agent and a proper amount of aromatic hydrocarbon. The product is mainly used as a deodorant for sterilization and disinfection in the high-temperature composting process, and is highly practical and convenient for usage. The invention has the advantages of wide sources of raw materials, mild production process, easy operation and low cost, and provides an ideal deodorant for the high-temperature composting process.

Owner:QINGDAO WATER WORLD ENVIRONMENTAL PROTECTION TECH

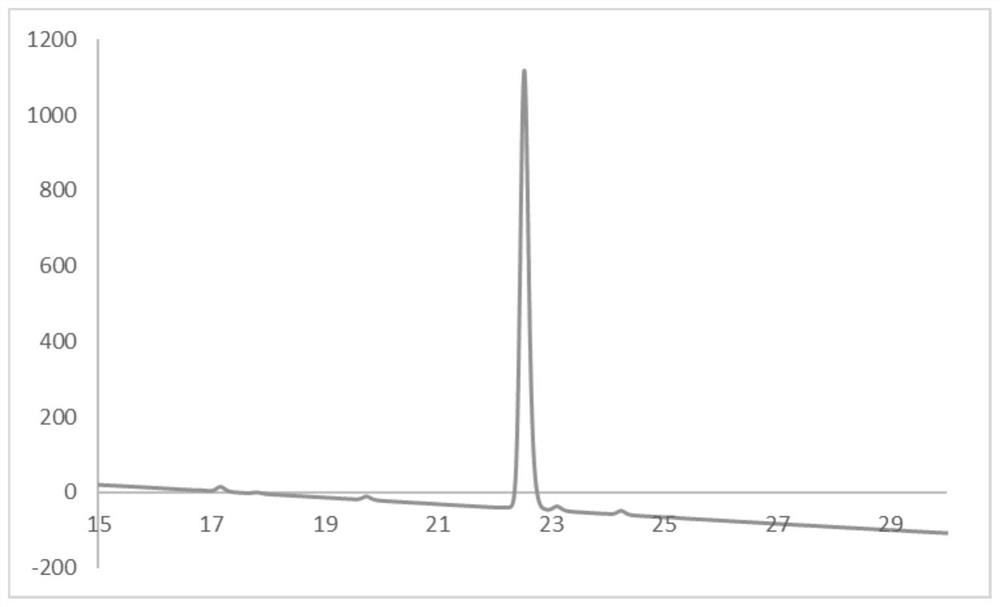

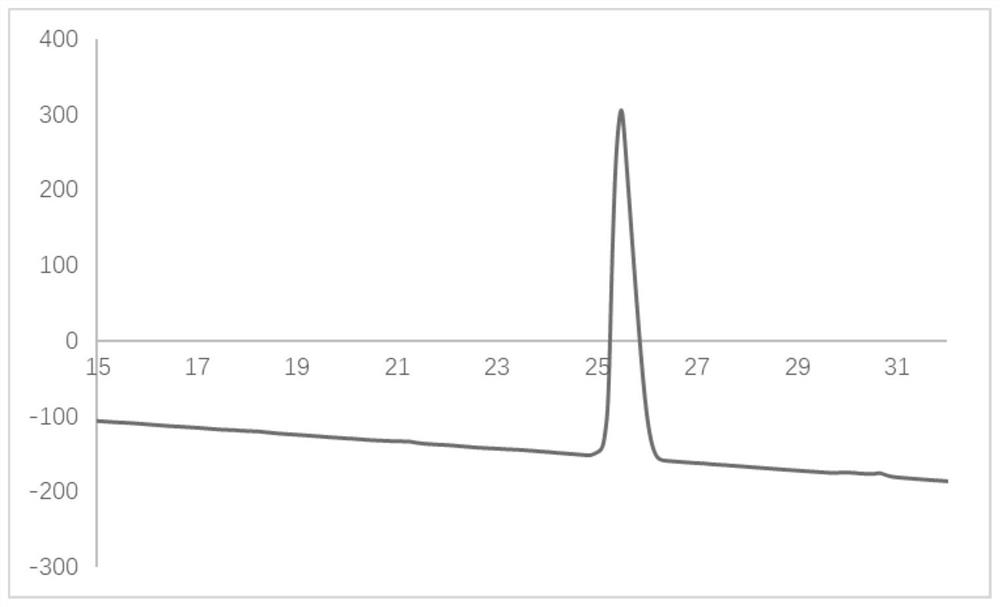

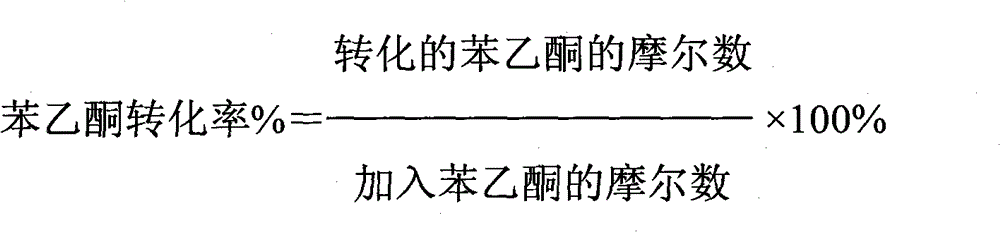

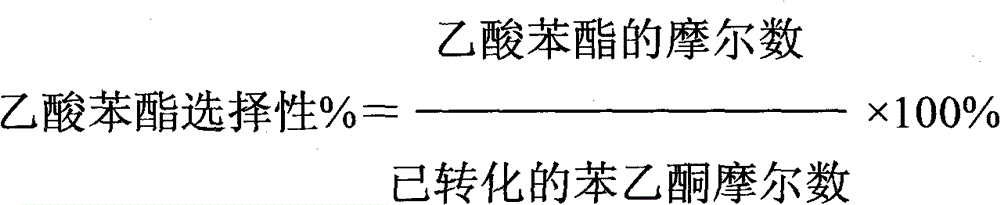

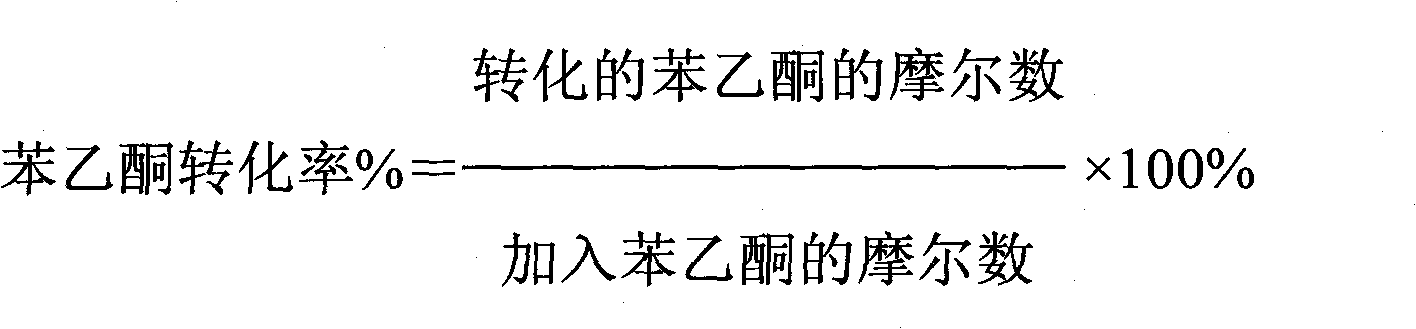

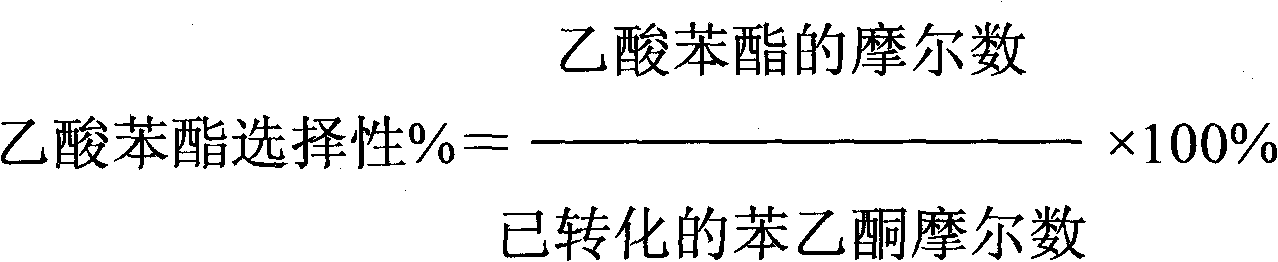

Method for catalytically oxidizing acetophenone

ActiveCN103012133AImprove conversion rateGood choiceMolecular sieve catalystsOrganic compound preparationMolecular sieveCatalytic oxidation

The invention discloses a method for catalytically oxidizing acetophenone. The method comprises the step of contacting acetophenone, hydrogen peroxide and a catalyst. The method is characterized in that the catalyst contains titanium silicalite molecular sieves and multi-metal oxyacid and / or multi-metal oxysalt. The method is environment-friendly, is simple in production process and is beneficial to industrial production and application.

Owner:CHINA PETROLEUM & CHEM CORP +1

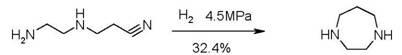

Preparation method of homopiperazine

InactiveCN101891692ASave raw materialsThe synthesis process is simpleOrganic chemistryEthylenediamineAlcohol

The invention discloses a preparation method of homopiperazine, comprising the following steps of firstly, obtaining N-(2-formylethyl) formamide by carrying out reflux reaction on ethylenediamine and formylation reagent, wherein the molar ratio of the ethylenediamine to the formylation reagent is 1:2-4; secondly, obtaining 1,4-dicarboxy homopiperazine by reacting the N-(2-formylethyl) formamide with 1,3-propane dihalide under the alkaline condition, wherein the molar ratio of the N-(2-formylethyl) formamide to the 1,3-propane dihalide is 1:1.0-1.2; and thirdly, obtaining the homopiperazine by removing formyl of the 1,4-dicarboxy homopiperazine in alcohol hydrochloride solution. The invention has the advantages of cheap raw materials, simple synthesis technology, mild protection conditions, mild technological conditions, simple equipment and easy recovery and reuse of used solvent in the whole process.

Owner:SHANGHAI RECORD PHARM CO LTD +1

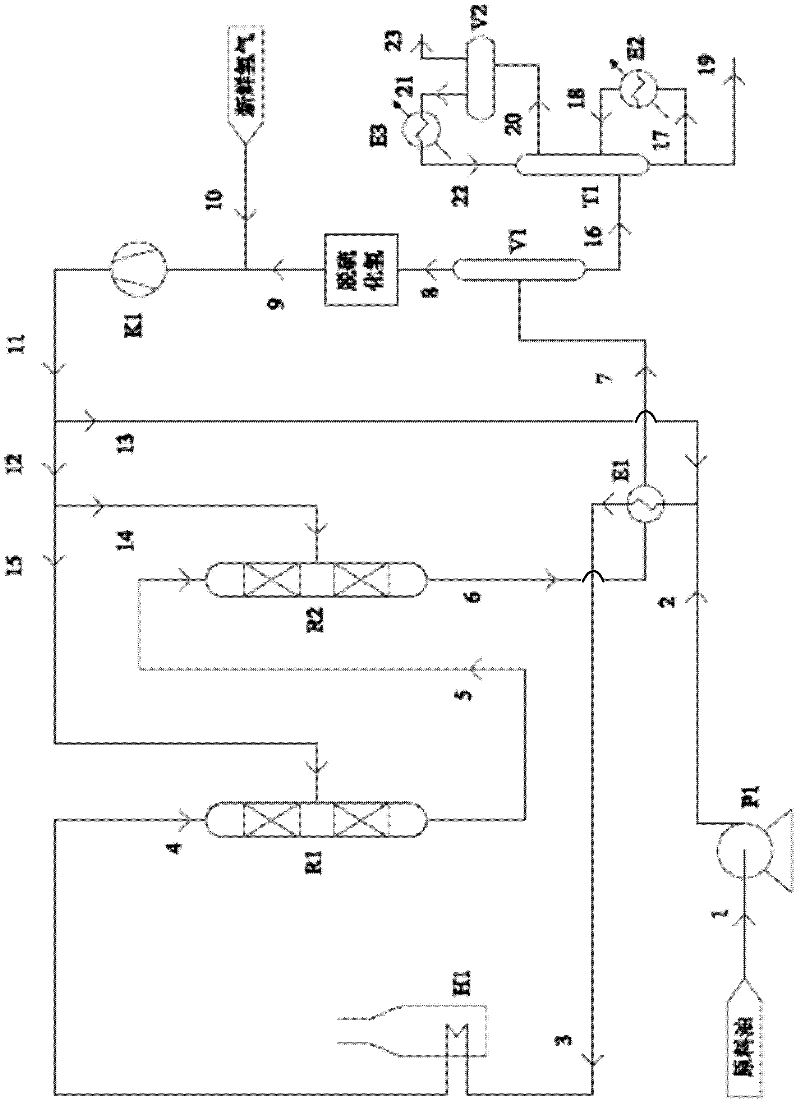

Method for reducing sulfur content in sulfur-containing light oil

InactiveCN102399588AReduce lossesControl reductionTreatment with hydrotreatment processesHydrodesulfurizationFixed bed

The invention relates to a method used for reducing the sulfur content in sulfur-containing light oil. The method comprises steps that: a light oil raw material is delivered into a primary hydrodesulfurization processing reactor, and is subject to contact reaction with a hydrodesulfurization catalyst C1; an effluent is delivered into a secondary hydrodesulfurization processing reactor, and is subject to contact reaction with a hydrodesulfurization catalyst C2; an effluent is processed through gas-liquid separation, such that a light oil product with low sulfur content is obtained. According to the invention, a fixed bed reactor structure is adopted in both the primary hydrodesulfurization processing reactor and the secondary hydrodesulfurization processing reactor. The two stages of hydrodesulfurization processing reactors are connected in series. The sulfur-containing light oil is processed through two times of continuous hydrodesulfurization reactions, such that sulfur content is reduced. Hydrodesulfurization is ensured, an alkene reducing phenomenon can be effectively controlled, loss of octane number can be controlled, and the reaction conditions are mild. The hydrogenation-modified light oil product provided by the invention is not required to be processed through alkali washing, the octane number loss of the product is low, and a yield of the product is higher than 99%.

Owner:DALIAN UNIV OF TECH

Production and processing method of organic fertilizer by using livestock and poultry manure

InactiveCN107641051ANo pollution in the processHigh granularityBio-organic fraction processingOrganic fertiliser preparationPoultry manureOrganic fertilizer

The invention discloses a production and processing method of an organic fertilizer by using livestock and poultry manure. The production and processing method has the advantages that the investment cost is low, the structure is simple, the operation is convenient, the production process is continuous and moderate, the production of pollution wastes is avoided, the utilization degree is high, andthe like; the suitability of raw materials is wide, the requirements are low, the matching degree between systems is high, and the link is nature. The prepared fertilizer has the advantages that the forming degree of particle is high, the daily output is high, the efficiency is high, and the clean and environment-friendly effects are realized; after the fertilizer is applied to agricultural products, the high-yield, high-quality and safety effects are realized, the soil can be optimized, the dependency on chemical fertilizer is decreased, and the higher social and economic value is realized.

Owner:安庆市华劲农化有限责任公司

Adhesive composition for coating of glass slide and single-surface coating technology

ActiveCN108641634AImprove mechanical propertiesHigh tensile strengthMacromolecular adhesive additivesCoatingsAdhesivePolyvinyl alcohol

The invention relates to an adhesive composition for coating of a glass slide and a single-surface coating technology. The adhesive composition is prepared from the following components according to amass / volume ratio: a component 1 and a component 2, wherein the component 1 is prepared from 0.05 to 0.3% of film forming agent (polyvinyl alcohol), 0.02 to 0.25% of adhesive (carboxymethylcellulose), and the balance of water; the component 2 is prepared from 0.2 to 1mg / 100ml of cationic swelling agent (polylysine), and the balance of water. The single-surface coating technology comprises the following steps of cleaning the glass slide by ultrasonic waves in an alkaline solution, drying, spraying and coating the component 1 to the front surface according to the amount of 20 to 50mu l per piece, drying at the temperature of 35 to 55 DEG C, cooling to room temperature, spraying and coating the component 2 to the same surface according to the amount of 10 to 30mu l per piece, drying at the temperature of 35 to 55 DEG C, and packaging under the vacuum condition. The adhesive composition has the advantages that the effects of high adhesivity, uniform distribution and high definition of cells or tissues on the glass slide are realized; the continuous, automatic, stable, uniform and batch type single-surface zonal spraying and coating technology is realized. The prepared pathology slidecan resist the repeated washing and soaking by various alcohols and reagents, be suitable for the wall attaching, single-layer distribution and no falling of the cells, the tissues and the like, and can reach the effects of clear background and no impurity.

Owner:HANGZHOU YIGUOREN BIOTECH CO LTD

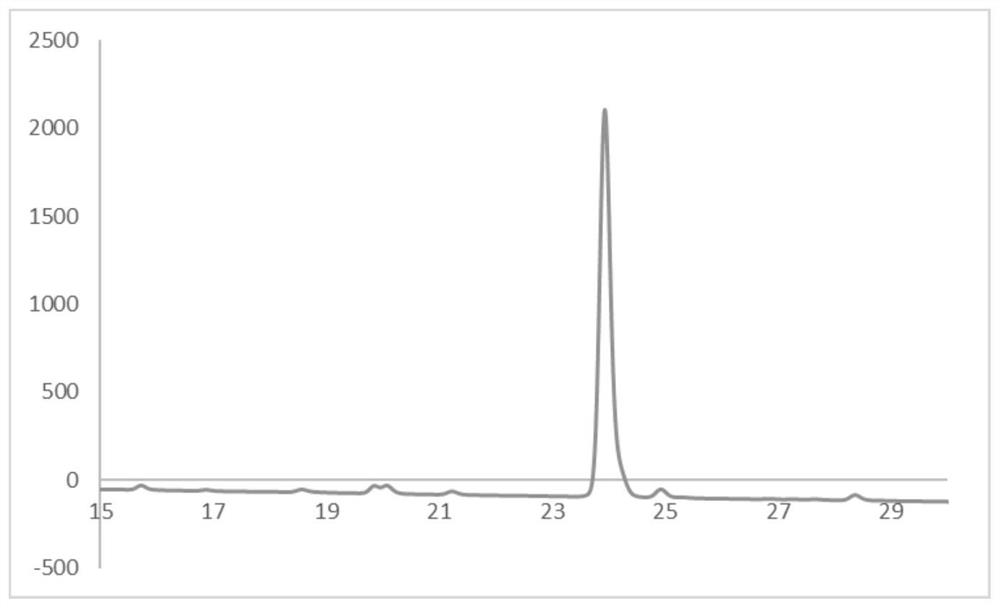

Preparation method for N-[2-(2-hydroxyethoxy)-4-nitrophenyl] ethanol amine

ActiveCN104744273AHigh yieldHigh purityOrganic compound preparationAmino-hyroxy compound preparationNitrophenolEthyl ester

The invention relates to a preparation method for N-[2-(2-hydroxyethoxy)-4-nitrophenyl] ethanol amine. The preparation method comprises the following steps: mixing 2-amino-5-nitrophenol used as a raw material with an alkali and a solvent, then adding a hydroxyethylation reagent, and reacting at certain pressure and temperature to generate 2-(3-nitro-6-aminophenoxy) ethanol; and then reacting 2-(3-nitro-6-aminophenoxy) ethanol with chloroethyl chloroformate under the action of a catalyst, and obtaining N-[2-(2-hydroxyethoxy)-4-nitrophenyl] ethanol amine through condensation and hydrolysis. The N-[2-(2-hydroxyethoxy)-4-nitrophenyl] ethanol amine disclosed by the invention has the advantages of being high in yield, high in purity, good in quality, moderate in production process, less in three-waste generation, and the like; the preparation method disclosed by the invention is economical and environmentally friendly, and suitable for industrialized production.

Owner:ZHEJIANG DINGLONG TECH

Profiled polylactic acid fiber and preparation method thereof

ActiveCN101608346BImprove hydrophilicityFluffy goodHollow filament manufactureFilament manufactureStretch ratioProcess conditions

The invention discloses a profiled polylactic acid fiber and a preparation method thereof. Cross section of the profiled polylactic acid fiber can be of C shape, hollow circular shape, trilobal shape, cross shape and triangular shape; and compared with common circular polylactic acid fiber, the profiled polylactic acid fiber has good hydrophilicity, bulkiness, flexibility, luster and excellent mechanical properties. The invention also discloses a preparation method of the profiled polylactic acid fiber. The profiled polylactic acid fiber with uniform structure and excellent mechanical properties is prepared by using profiled spinneret orifices in the melt spinning process at moderate spinning speed, lower heat stretching and heat treatment temperature, stretching ratio and mild melt spinning process conditions in a liquid phase thermostatic bath by improving spinning dynamics.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method of preparing granular sodium tert-butoxide

ActiveCN102001914BAvoid health hazardsAvoid harmPreparation of metal alcoholatesOrganic solventNitrogen gas

The invention discloses a method of preparing granular sodium tert-butoxide, which includes the following steps: using metal sodium, tert-butanol and an inert organic solvent as raw materials; adding the tert-butanol and the inert solvent into a reaction kettle and then adding the metal sodium into the reaction kettle; under the protection of a nitrogen gas, refluxing for 8-40 h; at a normal temperature, distilling the tert-butnaol; after totally distilling the tert-butanol, reducing the pressure to -0.08 to -0.098 MPa to distil the remained insert organic solvent; then adjusting the stirringrate of the reaction kettle to 10-80 r / min; reducing the pressure to distil the inert organic solvent; obtaining a residual granular sodium tert-butoxide product in the reaction kettle; cooling the product to less than 40 DEG C to obtain the required granular sodium tert-butoxide. The method can perform a production by using universal chemical equipment. An operation condition is moderate; a protection technique is simple; and the raw materials used are easily obtained. The quality of the product is stable and reliable. The shelf life of the product can be effectively prolonged.

Owner:GENCHEM & GENPHARM CHANGZHOU CO LTD

Method for preparing granular potassium tert-butoxide

ActiveCN101962315AAvoid health hazardsAvoid harmPreparation of metal alcoholatesPotassium tert-butoxideOrganic solvent

The invention discloses a method for preparing granular potassium tert-butoxide, which comprises the following steps of: with metal potassium, tertiary butanol and an inert organic solvent as raw materials, charging the tertiary butanol and the inert solvent into a reactor, charging the metal potassium into the reactor and carrying out reflux reaction under the protection of nitrogen for 8-40 hours; evaporating the tertiary butanol at normal pressure; after the tertiary butanol is completely evaporated, decompressing to minus 0.08-minus 0.098MPa; evaporating residual inert organic solvent; then adjusting the stirring speed of the reactor to 10-80RPM; decompressing and evaporating the inert organic solvent; retaining a granular potassium tert-butoxide rough product in the reactor; and cooling to below 40 DEG C to obtain needed granular potassium tert-butoxide. The invention has the advantages of production by utilizing universal chemical equipment, more mild operation condition, simpleproduction process, convenience and easy acquisition of raw material use, stable and reliable product quality and effective extension of quality guarantee period of products.

Owner:GENCHEM & GENPHARM CHANGZHOU CO LTD

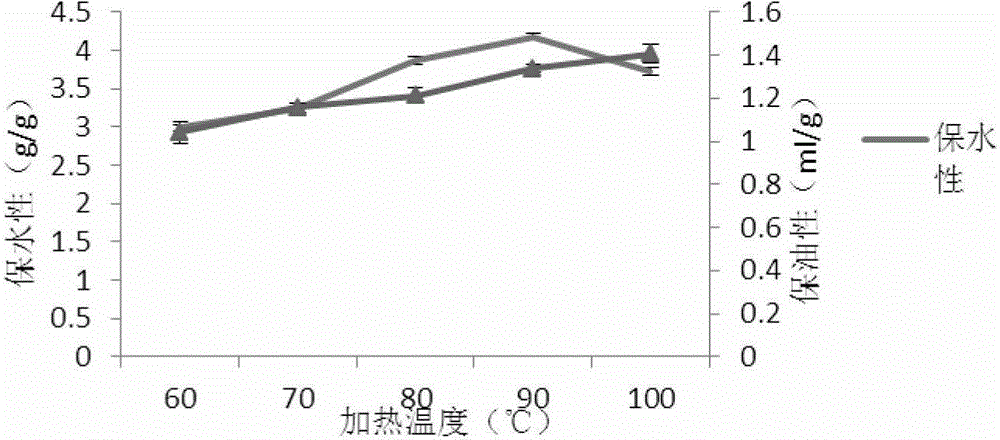

Preparation method of special soybean protein isolate for frozen meat product and application thereof

ActiveCN103211081BReduce cooking lossImprove eating effectProtein composition from vegetable seedsVegetable proteins working-upBiotechnologyNutritive values

The invention discloses a preparation method of a special soybean protein isolate for a frozen meat product and an application of the preparation method, and belongs to the field of food processing. The preparation method comprises the following steps of: taking low-temperature soybean meal as the raw material, subjecting the soybean meal to alkali extraction and acid precipitation treatment to obtain neutral liquid soybean protein, subjecting the liquid soybean protein to high pressure homogenization and water-bath heating treatment, and subjecting the resulting product to spray drying to obtain the product. When the preparation method disclosed by the invention is applied for preparing the soybean protein isolate, high pressure homogenization and heating are applied to treating the liquid soybean protein in combination to obtain the soybean protein product which is high in nutritional value, good in water and oil holding capacity in a frozen condition, and strong in specificity in the meat product. The method disclosed by the invention is wide in raw material resources, low in cost, simple in needed equipment, safe in operation, and free from toxic and side effects, not only improves the added values of the low-temperature soybean meal and the soybean protein isolate, but also provides a soybean protein additive which is strong in specificity and stabler in functions to a frozen meat product industry, simultaneously greatly reduces the production cost of an enterprise, and has wide application prospect.

Owner:SOYBEAN TECH DEV RES CENT HEILONGJIANG PROV

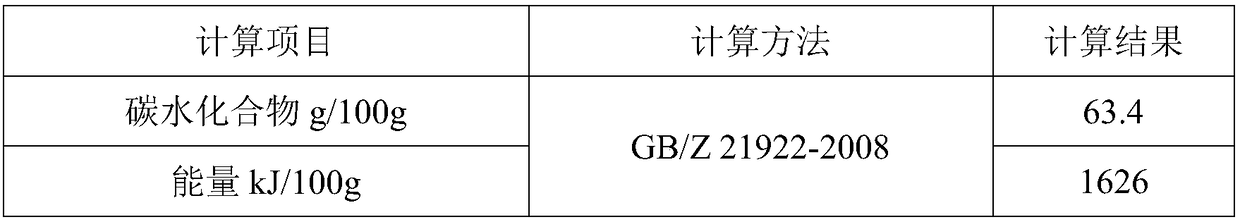

Fully-vegetarian composite nutritional product and production technology thereof

InactiveCN108936637ARich varietyComprehensive and rich in nutrientsFood ingredient functionsMeal replacementAdditive ingredient

The present invention provides a fully-vegetarian composite nutritional product and a production technology thereof, and belongs to the technical field of nutritional products. The fully-vegetarian composite nutritional product is characterized by being prepared from the following raw material types: five cereals and coarse cereals, fruits, vegetables, nuts, fungi, medicinally and edibly homologous materials, probiotics, vitamins, plant comprehensive enzymes, etc.; the nutrients are 50 kinds or more and all vegetarian ingredients; and the fully-vegetarian composite nutritional product is richin nutrients, high in food flavor acceptance and easy to eat, can meet needs of various types of people for meal replacement, can effectively improve human body constitution in a long-term consumption. The fully-vegetarian composite nutritional product can be made into tablets or powder as needed, and is flexible in production, low in cost and wide in market promotion space.

Owner:江苏汉典生物科技股份有限公司

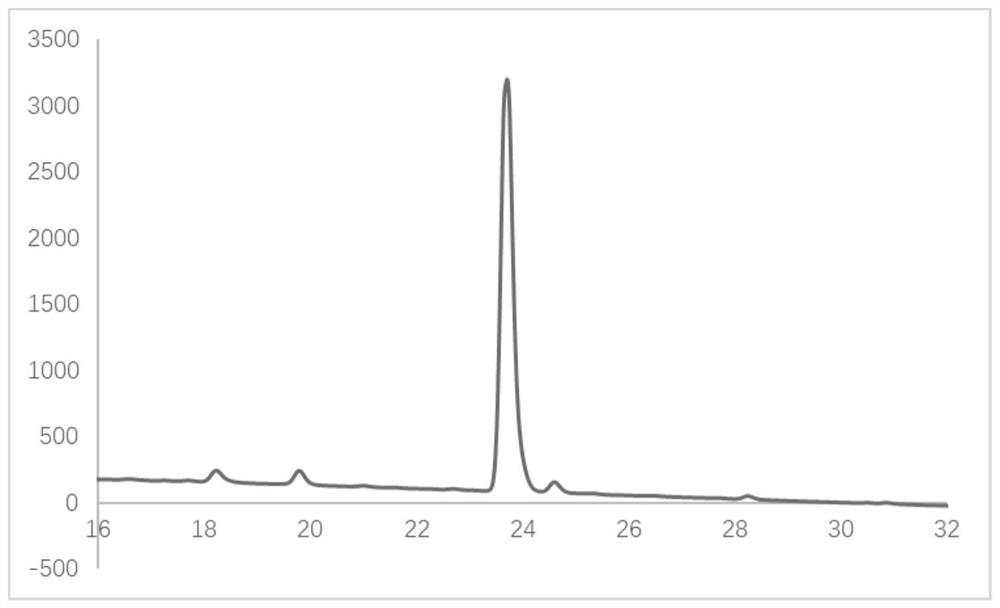

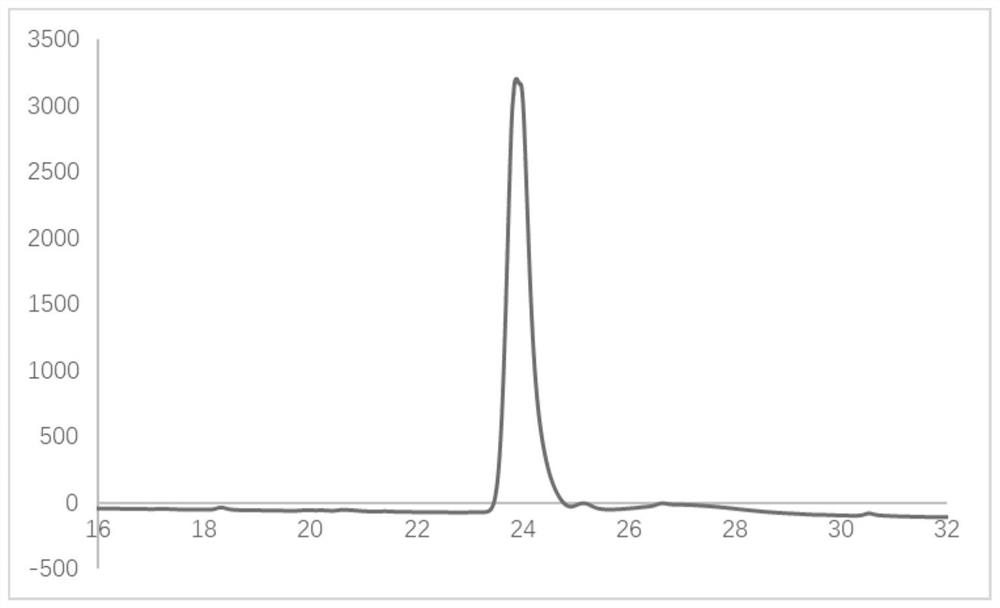

Preparation process of enoxaparin sodium

InactiveCN106832061APrevent embolismPrevent venous thromboembolismOrganic active ingredientsMetabolism disorderFreeze-dryingHeparin degradation

The invention discloses a preparation process of enoxaparin sodium, which comprises the steps of preparing heparin sodium solution, preparing heparin degradation solution, preparing reducing solution, preparing crude product, refining, freeze-drying and the like. The weight-average molecular weight of the obtained product is 5000-6000, the peak molecular weight is 3000-6000, the component with molecular weight less than 3000 is not more than 11%, the component with molecular weight greater than 8000 is not more than 13%, and the anti-Xa activity is ≥ 135IU / mg.

Owner:QINGDAO JIULONG BIO PHARMA

A kind of method that formaldehyde aqueous solution and acetic acid synthesize acrylic acid

ActiveCN103586067BProcess raw materials are cheapGentle production processMolecular sieve catalystsOrganic compound preparationAcetic acid earSesquioxide

The invention discloses a catalyst suitable for synthesizing acrylic acid by an aqueous formaldehyde solution and acetic acid and a preparation and application method of the catalyst. The catalyst is mainly characterized by adopting one or more of activated carbon, aluminum sesquioxide, silicon dioxide or molecular sieve as carriers, and loading phosphorus pentoxide and one or more alkaline-earth metal oxides, wherein phosphorus pentoxide accounts for 1%-20% of the total mass of the catalyst, and the alkaline-earth metal oxides account for 5%-30% of the total weight of the catalyst. The catalyst is prepared by the steps of impregnation, temperature programmed calcination and the like, and a vacuum-ultrasonic impregnation technique is introduced during the preparation process. According to the invention, a fixed bed reactor is adopted for produce acrylic acid continuously under the suitable reaction conditions, the conversion per pass of formaldehyde is up to 35%, and the selectivity of acrylic acid is up to 55%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

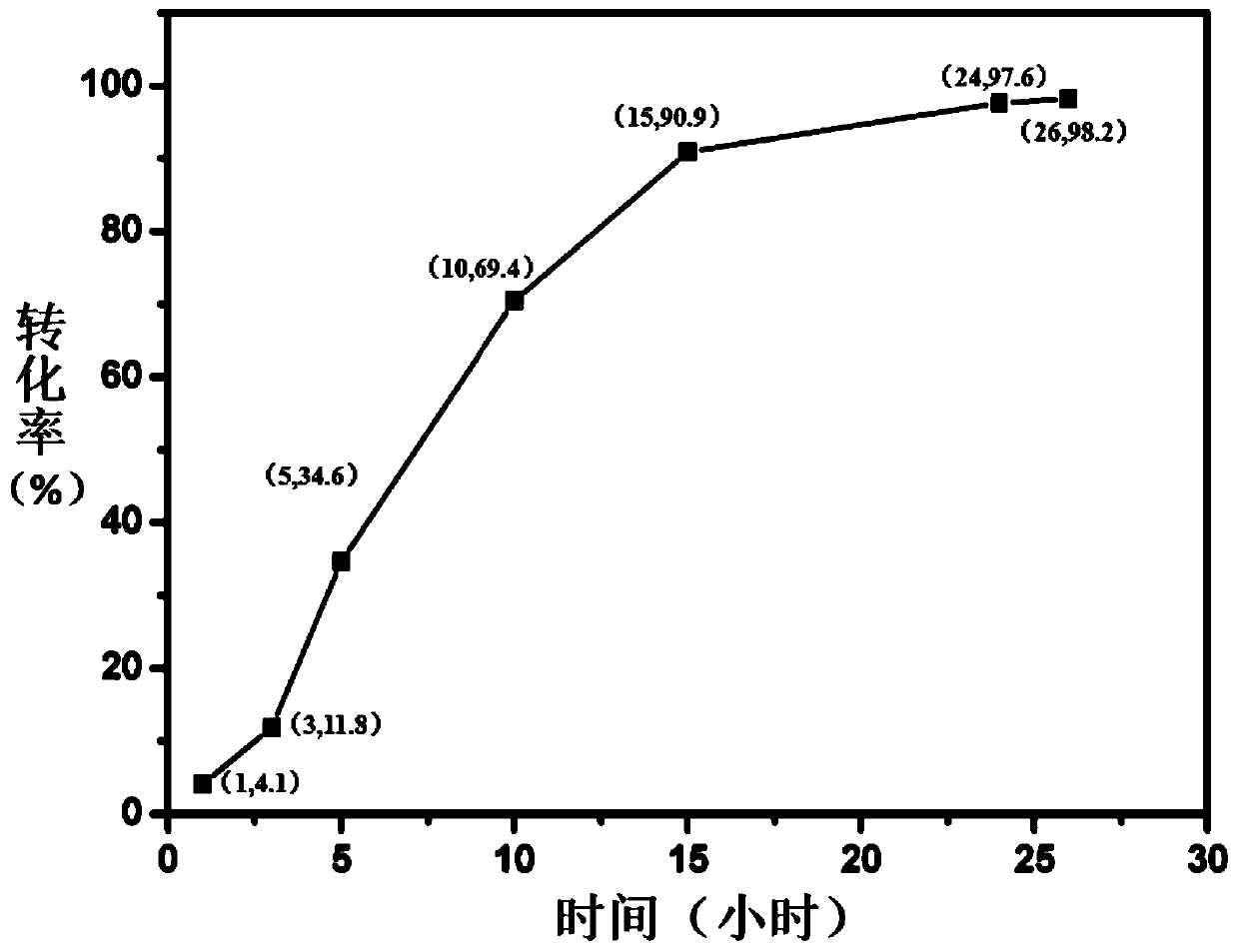

Method for preparing camellia-oil fatty acid esters

The invention provides a method for preparing camellia-oil fatty acid esters. The method comprises the following steps: adding a bio-enzyme catalyst in a mixed solution of camellia oil, alcohol and acosolvent, and carrying out an esterification reaction, thereby obtaining the camellia-oil fatty acid esters, wherein the cosolvent is selected from camellia-oil fatty acid esters such as camellia-oilfatty acid ethyl ester, camellia-oil fatty acid triglyceride, camellia-oil fatty acid octyl ester and camellia-oil fatty acid ethyl hexyl ester. According to the method, the cosolvent the same as thecamellia-oil fatty acid esters is added during an esterification reaction between the camellia oil and the alcohol, the cosolvent has good intersolubility with both the camellia oil and the alcohol,thus, reactants can be mixed uniformly, and the rate of reaction and conversion ratio of reaction can be remarkably increased.

Owner:GUANGDONG JUSHI CHEM CO LTD +1

A kind of preparation method of cephalosporin anti-infection medicine

ActiveCN105017286BSimple preparation processReduce generationOrganic chemistry7-ACACefazedone sodium

The invention relates to a preparation method for a cephalosporin anti-infective drug-cefazedone sodium, belonging to the field of pharmaceutical synthesis. According to the invention, the method uses GCLE as a raw material to substitute 7-ACA and overcomes the defects of low yield, high pollution and the like in prior art; the preparation method with mild reaction conditions, little side reaction and simple process is provided; meanwhile, the method has the advantages of cheap and easily-available raw materials, low cost, high product yield, high product purity and applicability to industrial production.

Owner:SHANDONG LUOXIN PHARMA GRP CO LTD

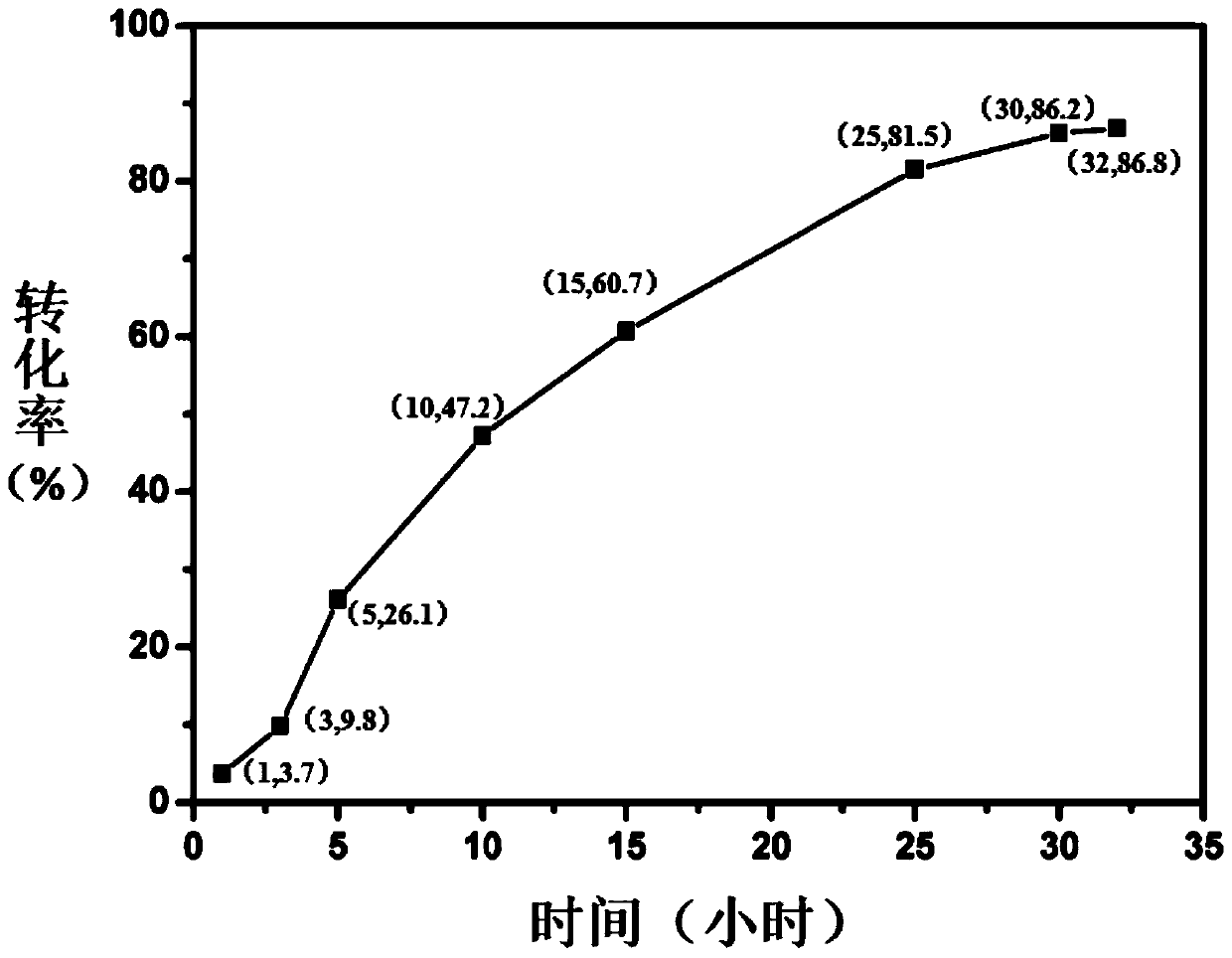

Method for synthesizing leuprorelin in full liquid phase

InactiveCN113861275AGreen production processGentle production processLuteinising hormone-releasing hormonePeptide preparation methodsBiotechnologyLeuprorelin

The invention provides a method for synthesizing leuprorelin in a full liquid phase, which comprises the following steps: carrying out condensation reaction on R4-Pyr-His(R3)-Trp(Boc)-Ser(tBu)-Tyr(tBu)-D-Leu-Leu-OH and H-Arg(pbf)-Pro-NHEt to obtain R4-Pyr-His(R3)-Trp(Boc)-Ser(tBu)-Tyr(tBu)-D-Leu-Leu-Arg(pbf)-Pro-NHEt, and then carrying out reaction on the R4-Pyr-His(R3)-Trp(Boc)-Ser(tBu)-Tyr(tBu)-D-Leu-Leu-Arg(pbf)-Pro-NHEt in the cutting fluid to obtain leuprorelin. Compared with the prior art, the method adopts a full liquid phase synthesis method, the production process is green and mild, any highly toxic and precursor reagent is not used, the purity of the product is high, the crude product can reach 90% or above, the cost is greatly reduced, and the preparation method is very suitable for large-scale production.

Owner:HUNAN SANTAI PHARM CO LTD

Method for full-liquid-phase synthesis of leuprorelin

PendingCN114149491AGreen production processGentle production processLuteinising hormone-releasing hormonePeptide preparation methodsLeuprorelinFluid phase

The invention provides a method for synthesizing leuprorelin in a full liquid phase, which comprises the following steps: carrying out condensation reaction on R4-Pyr-His (R3)-Trp (Boc)-Ser (tBu)-Tyr (tBu)-D-Leuu-Leg-Pro-NHEt and H-Arg (pbf)-Pro-NHEt to obtain R4-Pyr-His (R3)-Trp (Boc)-Ser (tBu)-Tyr (tBu)-D-Leuu-Leg-Arg (pbf)-Pro-NHEt, and then carrying out reaction on the R4-Pyr-His (R3)-Trp (Boc)-Ser (tBu)-Tyr (tBu Compared with the prior art, the preparation method adopts a full liquid phase synthesis method, the production process is green and mild, any highly toxic and precursor reagent is not used, the purity of the produced product is high, the crude product can reach 90% or above, the cost is greatly reduced, and the preparation method is very suitable for large-scale production.

Owner:HUNAN MICRO PEPTIDE BIOMEDICAL CO LTD

Manufacturing method of granular potassium tert-pentylate

ActiveCN101962316BAvoid health hazardsAvoid harmPreparation of metal alcoholatesOrganic solventNitrogen

The invention discloses a manufacturing method of granular potassium tert-pentylate, comprising the following steps: taking potassium metal, tert-amyl alcohol and inert organic solvent as raw materials; adding tert-amyl alcohol and inert organic solvent into a kettle; then, adding potassium metal into the kettle; after reflowing for 8-40 hours under the protection of nitrogen, evaporating tert-amyl alcohol at normal pressure; after tert-amyl alcohol is completely evaporated, decompressing to -0.08--0.098 MPa, and evaporating residual organic solvent; then, regulating the stirring rate of the kettle to 10-80 turns / min; decompressing to evaporate inert organic solvent, and leaving granular potassium tert-pentylate products in the kettle; and cooling to be below 40 DEG C to obtain the granular potassium tert-pentylate. The invention can carry out production by using general chemical equipment, has moderate operation condition, simple production technology, convenient and abundant raw material, and stable and reliable product quality and can effectively prolong the quality guarantee period of the product.

Owner:GENCHEM & GENPHARM CHANGZHOU CO LTD

Method for catalytically oxidizing acetophenone

ActiveCN103012133BImprove conversion rateGood choiceMolecular sieve catalystsOrganic compound preparationMolecular sieveCatalytic oxidation

The invention discloses a method for catalytically oxidizing acetophenone. The method comprises the step of contacting acetophenone, hydrogen peroxide and a catalyst. The method is characterized in that the catalyst contains titanium silicalite molecular sieves and multi-metal oxyacid and / or multi-metal oxysalt. The method is environment-friendly, is simple in production process and is beneficial to industrial production and application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for full-liquid-phase synthesis of deslorelin

InactiveCN113831393AGreen production processGentle production processLuteinising hormone-releasing hormonePeptide preparation methodsBiotechnologyFluid phase

The invention provides a method for full-liquid-phase synthesis of deslorelin. The method comprises the following steps: carrying out condensation reaction on R4-Pyr-His(R3)-Trp(Boc)-Ser(tBu)-Tyr(tBu)-D-Trp-Leu-OH and H-Arg(pbf)-Pro-NHEt to obtain R4-Pyr-His(R3)-Trp(Boc)-Ser(tBu)-Tyr(tBu)-D-Trp-Leu-Arg(pbf)-Pro-NHEt, and then carrying out reaction in a cutting fluid to obtain the deslorelin. Compared with the prior art, the method adopts a full liquid phase synthesis method, the production process is green and mild, any highly toxic and precursor reagent is not used, the purity of the product is high, the crude product can reach 90% or above, the cost is greatly reduced, and the method is very suitable for large-scale production.

Owner:HUNAN SANTAI PHARM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method for N-[2-(2-hydroxyethoxy)-4-nitrophenyl] ethanol amine Preparation method for N-[2-(2-hydroxyethoxy)-4-nitrophenyl] ethanol amine](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/591107ff-edeb-4b60-a0b3-0ba9323ae6e6/DEST_PATH_IMAGE002.PNG)