Polymeric acid solution thickener

A technology of polymer acid and thickener, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of unfavorable large-scale industrial production, high reaction temperature of preparation process, increase of product dissolution time, etc., and achieve production High efficiency, reduced production costs, and mild production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

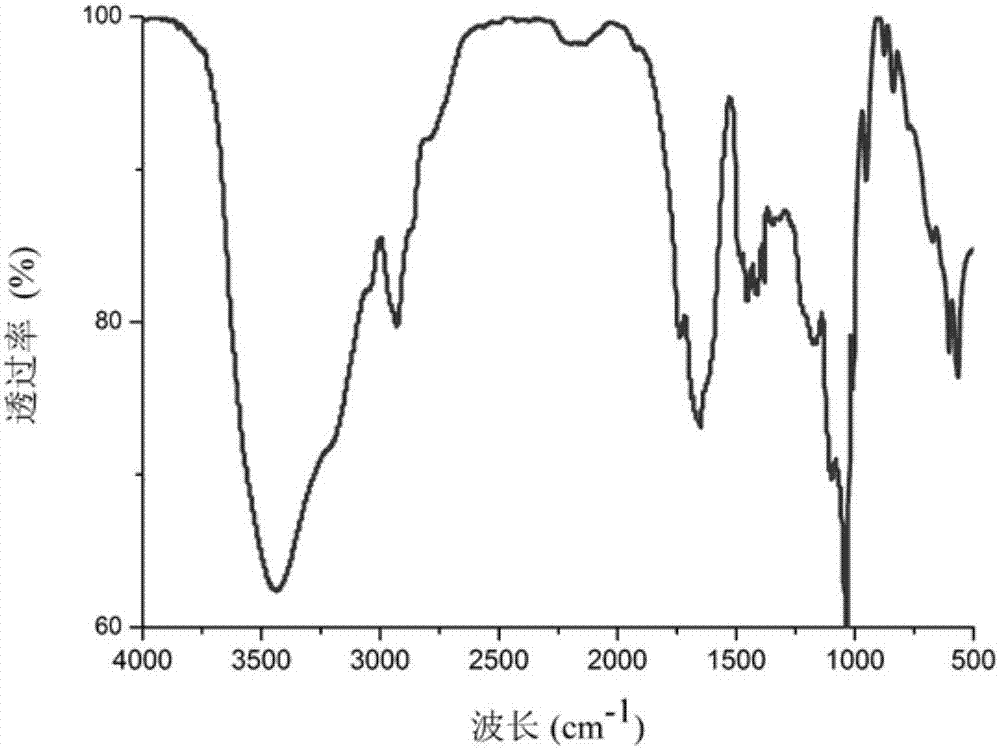

Method used

Image

Examples

Embodiment 1

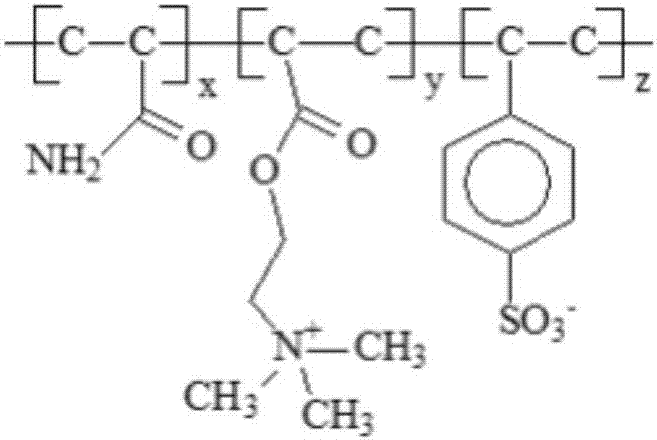

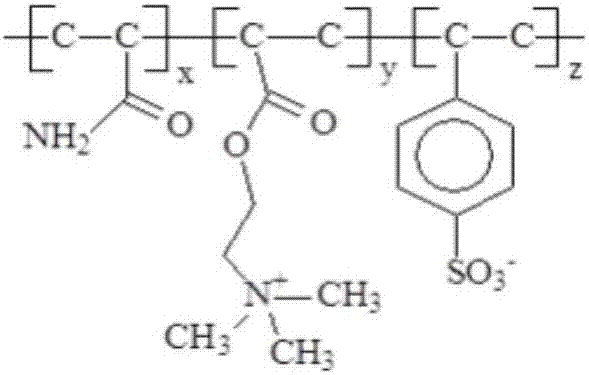

[0030] The preparation technology of polymer acid solution tackifier of the present invention comprises the following steps:

[0031] (a) Add 30g of monomer to 100g of distilled water and stir to dissolve, wherein acrylamide is 80% of the total molar weight of the monomer, sodium styrene sulfonate is 10% of the total molar weight of the monomer, and acryloyloxyethyl Trimethylammonium chloride is 10% of the total molar weight of monomers.

[0032] (b) The reaction solution is added to a three-necked round-bottomed flask, and nitrogen is vented to adjust the bubbles to be uniform and consistent;

[0033] (c) Use 10% NaOH solution to adjust the pH value to be neutral, heat to 45°C, and keep the temperature constant for 30min;

[0034] (d) adding initiator (NH 4 ) 2 S 2 o 8 -NaHSO 3 , the mass concentration of the initiator was 0.3% of the total mass of the monomers, nitrogen was continued, and the reaction was continued for 4 hours.

[0035] (e) after precipitation, filtra...

Embodiment 2

[0040] The preparation technology of polymer acid solution viscosifier comprises the following steps:

[0041] (a) Add 25g of monomer to 100g of distilled water and stir to dissolve, wherein acrylamide is 90% of the total molar weight of the monomer, sodium styrene sulfonate is 5% of the total molar weight of the monomer, and acryloyloxyethyl Trimethylammonium chloride is 5% of the total molar weight of monomers.

[0042] (b) The reaction solution is added to a three-necked round-bottomed flask, and nitrogen is vented to adjust the bubbles to be uniform and consistent;

[0043] (c) Use 10% NaOH solution to adjust the pH value to be neutral, heat to 50°C, and keep the temperature constant for 30min;

[0044] (d) adding initiator (NH 4 ) 2 S 2 o 8 -NaHSO 3 , the mass concentration of the initiator was 0.7% of the total mass of the monomers, nitrogen was continued, and the reaction was continued for 5 hours.

[0045] (e) after precipitation, filtration, and vacuum drying a...

Embodiment 3

[0050] The preparation technology of polymer acid solution viscosifier comprises the following steps:

[0051] (a) Add 30g of monomer to 100g of distilled water and stir to dissolve, wherein acrylamide is 75% of the total molar weight of the monomer, sodium styrene sulfonate is 15% of the total molar weight of the monomer, and acryloyloxyethyl Trimethylammonium chloride is 10% of the total molar weight of monomers.

[0052] (b) The reaction solution is added to a three-necked round-bottomed flask, and nitrogen is vented to adjust the bubbles to be uniform and consistent;

[0053] (c) Use 10% NaOH solution to adjust the pH value to be neutral, heat to 40°C, and keep the temperature constant for 30min;

[0054] (d) adding initiator (NH 4 ) 2 S 2 o 8 -NaHSO 3 , the mass concentration of the initiator was 0.7% of the total mass of the monomers, nitrogen was continued, and the reaction was continued for 8 hours.

[0055] (e) after precipitation, filtration, and vacuum drying a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com