Mineral floatation foaming agent and preparation method thereof

A technology for mineral flotation and foaming agent, which is used in flotation, sulfonate preparation, solid separation, etc. It can solve the problems of harsh reaction conditions and unsatisfactory foaming performance, and achieve mild synthesis conditions, good air affinity and Hydrophilic performance, excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Get 10g of isopropanol and 30g of epichlorohydrin and put in a 150ml round bottom flask, stir and mix well, then add 0.10g of triethylbenzyl ammonium chloride and 12ml of sodium hydroxide solution with a mass concentration of 40%, and heat to 60 ~ 65 ° C, continue to stir for 3 hours, the reaction is completed and the reaction product is cooled to room temperature. Then place the reaction product in a rotary evaporator to distill off the unreacted epichlorohydrin under reduced pressure to obtain the product chlorinated fatty alcohol ether. Take 30 g of chlorinated fatty alcohol ether and put it in a 100 ml round bottom flask, stir and slowly add 5 g of 1.0 mol / L sodium hydroxide solution, stir and react at room temperature for 50 min to obtain fatty alcohol epoxy ether. Mix sodium sulfite and sodium bisulfite at a mass ratio of 5:1 to make a saturated solution. Take 10g of fatty alcohol epoxy ether, 20g of saturated sodium sulfite and sodium bisulfite solution and add ...

Embodiment 2

[0024] Take 12g of isobutanol and 30g of epichlorohydrin in a 150ml round-bottomed flask, stir and mix well, add 0.10g of tetrabutylammonium bromide and 15ml of sodium hydroxide solution with a mass concentration of 50% in turn, and heat to 70~ 75 ° C, continue to stir for 4 hours, the reaction is completed and the reaction product is cooled to room temperature. Then place the reaction product in a rotary evaporator to distill off the unreacted epichlorohydrin under reduced pressure to obtain the product chlorinated fatty alcohol ether. Take 30 g of chlorinated fatty alcohol ether and put it in a 100 ml round bottom flask, stir and slowly add 6 g of 0.8 mol / L sodium hydroxide solution, stir and react at room temperature for 60 min to obtain fatty alcohol epoxy ether. Mix sodium sulfite and sodium bisulfite at a mass ratio of 5:1 to make a saturated solution. Take 10g of fatty alcohol epoxy ether, 25g of saturated sodium sulfite and sodium bisulfite solution and add them to a ...

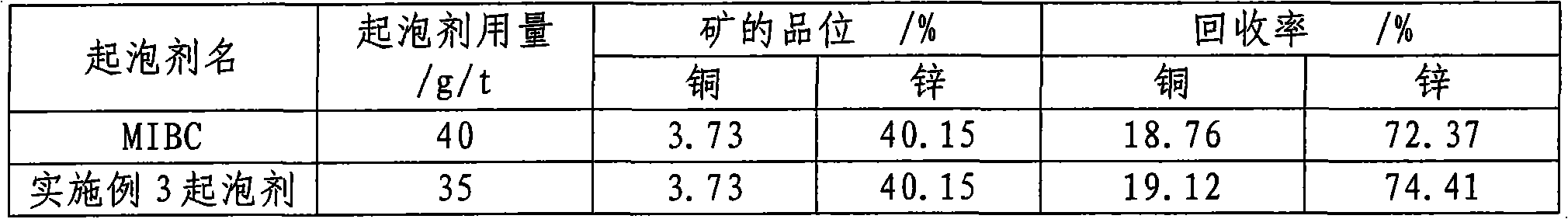

Embodiment 3

[0026] Take 10g of tert-butanol and 25g of epichlorohydrin in a 150ml round-bottomed flask, stir and mix well, add 0.15g of tetrabutylammonium bromide and 15ml of sodium hydroxide solution with a mass concentration of 60% in sequence, and heat to 80~ 85°C, continue to stir for 5 hours, after the reaction is completed, the reaction product is cooled to room temperature. Then put the reaction product in a rotary evaporator to distill the unreacted epichlorohydrin under reduced pressure to obtain the product chlorinated fatty alcohol ether. Take 25 g of chlorinated fatty alcohol ether and put it in a 100 ml round bottom flask, stir and slowly add 2.5 g of 0.5 mol / L sodium hydroxide solution, stir and react at room temperature for 30 min to obtain fatty alcohol epoxy ether. Mix sodium sulfite and sodium bisulfite at a mass ratio of 5:1 to make a saturated solution, take 12g of the above-mentioned fatty alcohol epoxy ether and 36g of the saturated solution and add them to a 150ml r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com