3D printing high-molecular polyformaldehyde powder and preparation method

A 3D printing, high molecular weight technology, applied in the field of preparation of polyoxymethylene powder, can solve the problems of harsh control conditions, complicated process, increase the complexity and cost of production methods, and achieve the effect of good comprehensive performance of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

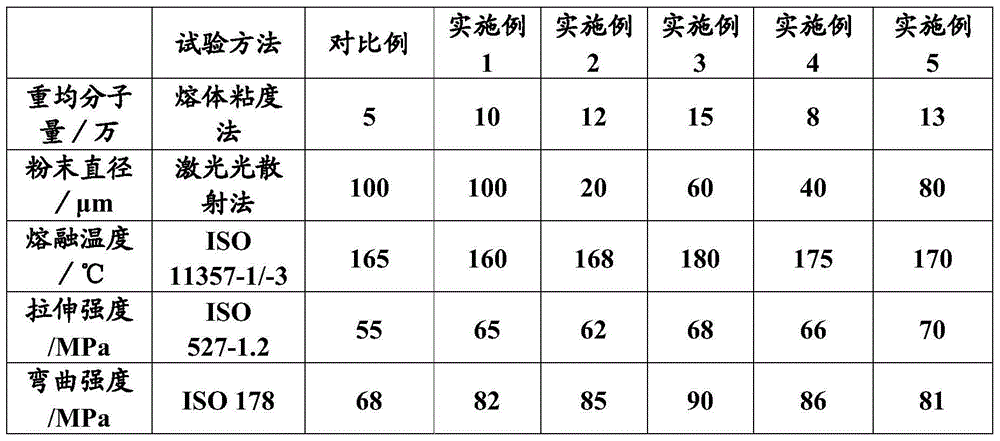

[0042] Using cyclohexane as a solvent, put 32g of refined paraformaldehyde and 0.64g of dioxolane in a reaction kettle, raise the temperature to 50°C, and add 0.0032g of boron trifluoride-diethyl ether complex under constant stirring. During the polymerization process, 25°C cooling water was introduced, and the temperature in the kettle was controlled at about 50°C for 2 hours. Put the reaction material into the termination kettle, add 0.032g of antioxidant 1098, 0.032g of melamine and 0.064g of sodium stearate in sequence, and stir for 1 hour to obtain a white polyoxymethylene powder with a weight average molecular weight of 100,000 and a particle size of 100 microns The mechanical properties of the 3D printed products are shown in Table 1.

Embodiment 2

[0044]Using petroleum ether as a solvent, put 64g of refined paraformaldehyde and 0.64g of dioxolane in a reaction kettle, raise the temperature to 60°C, and add a mixture of 0.0032g of paratungstic acid and 0.64g of dioxolane under constant stirring liquid. During the polymerization process, 30°C cooling water was introduced, and the temperature in the kettle was controlled at about 60°C for 1.5 hours. Put the reaction material into the termination tank, add 0.16g of antioxidant 1096, 0.064g of polyamide PA6 and 0.128g of calcium hydroxide in sequence, and stir for 0.5h to obtain a white polyamide with a weight average molecular weight of 120,000 and a particle size of 20 microns. The mechanical properties of formaldehyde powder and 3D printing products are shown in Table 1.

Embodiment 3

[0046] Using dichloroethane as a solvent, put 32g of refined paraformaldehyde and 0.64g of 1,4-butanediol formal in a reaction kettle, raise the temperature to 70°C, add 0.0032g of n-butyl phosphomolybdic acid under constant stirring base ether solution. During the polymerization process, 35°C cooling water was introduced, and the temperature in the kettle was controlled at about 70°C for 1 hour. Put the reaction material into the termination tank, add 0.16g of antioxidant 168, 0.064g of polyamide PA66 and 0.128g of magnesium hydroxide in sequence, and stir for 1 hour to obtain a white polyoxymethylene with a weight average molecular weight of 150,000 and a particle size of 60 microns. The mechanical properties of powder and 3D printing products are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com