Cs-VPO/SiO2 catalyst, preparation method therefor and use of Cs-VPO/SiO2 catalyst in preparation of acrylic acid through catalyzing condensation of acetic acid and trioxymethylene

A technology of paraformaldehyde and catalysts, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, and the preparation of organic compounds. It can solve the problems of low price, complicated process, and overcapacity, and achieve good catalytic activity and stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] Catalyst preparation:

[0022] Cs-VPO / SiO 2 The catalyst is prepared by an organic phase method: first weigh 1.5288g of vanadium pentoxide, add it to a three-necked flask, then add 60mL of isobutanol and 60mL of benzyl alcohol (V:V=1:1), stir and reflux at 140°C 6h, until the vanadium pentoxide is completely dissolved. According to the composition requirement of P / V=2.2 ratio in the catalyst, weigh 4.2555g of phosphoric acid with a mass fraction of 85%, slowly add it into the flask and then reflux for 6h; turn off the heating switch, according to the load P and V content accounted for 20% of the load % requirements, add 8g of SiO 2 , stirring; at the same time, according to the composition requirements of the catalyst, according to the molar ratio requirements of P / V / Cs=2.2 / 1 / 0.05, cesium carbonate is used as the cesium source, and the cesium carbonate aqueous solution with a concentration of 25 to 50 mg / mL is added to three ports In the flask, stir rapidly for 3 hou...

Embodiment 2

[0028] Same as Example 1, but the ratio of P / V / Cs in the catalyst was changed so that the P / V / Cs molar ratio was 2.2 / 1 / 0.1, and the obtained results are shown in Table 2.

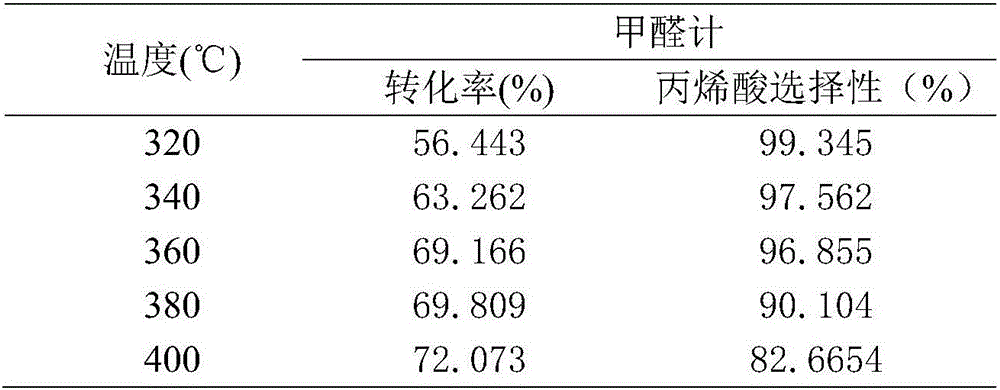

[0029] Table 2. Cs-VPO / SiO 2 (P / V / Cs=2.2 / 1 / 0.1) catalyzed formaldehyde acetate to prepare acrylic acid result table

[0030]

Embodiment 3

[0032] Same as Example 1, but changing the ratio of P / V / Cs in the catalyst so that the P / V / Cs molar ratio is 2.2 / 1 / 0.2, the results are shown in Table 3.

[0033] Table 3. Cs-VPO / SiO 2 (P / V / Cs=2.2 / 1 / 0.2) catalyzed formaldehyde acetate to prepare acrylic acid result table

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com