Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

392 results about "Fluoridation reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluoride ions sometimes react as a base. Then it can combine with H+ by giving electrons to hydrogen atoms. Reaction between water and fluoride ions produces hydrogen fluoride (HF). This is a reversible reaction. As fluoride ions are good for teeth, water plants add some amount of fluoride ions to the water.

Process for producing 1,1,1,3,3-pentafluoro-propane and/or 1-chloro-3,3,3-trifluoropropene

InactiveUS6403847B1Point becomes highManufactured continuously and efficientlyPreparation by dehalogenationPreparation by hydrogen halide split-offBoiling pointPropane

One or more materials selected from 1,1,1,3,3-pentachloropropane, 1,1,3,3-tetrachloropropene and 1,3,3,3-tetrachloropropene are used as the specific materials described above. Before submitting the materials and HF to a fluorination reaction, almost all water is removed from them.To continuously manufacture useful intended products efficiently as well as to prevent deactivation of the catalyst and the accumulation of organic substances with high boiling points when manufacturing said useful 1,1,1,3,3-pentafluoropropane and / or 1-chloro-3,3,3-trifluoropropene, by fluorinating the specific materials with HF in the presence of a catalyst.

Owner:DAIKIN IND LTD

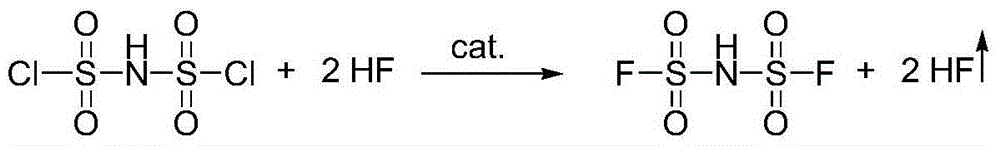

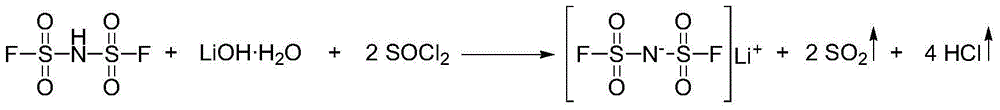

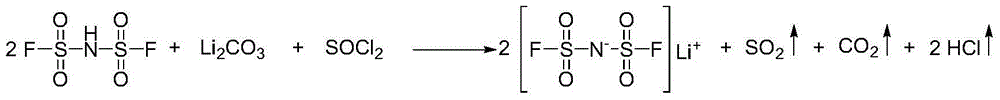

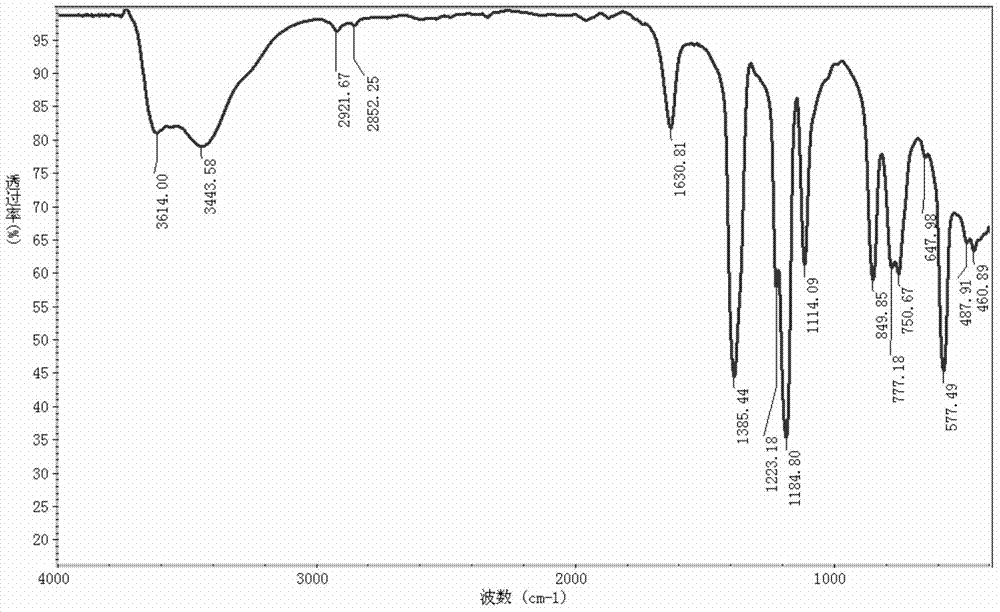

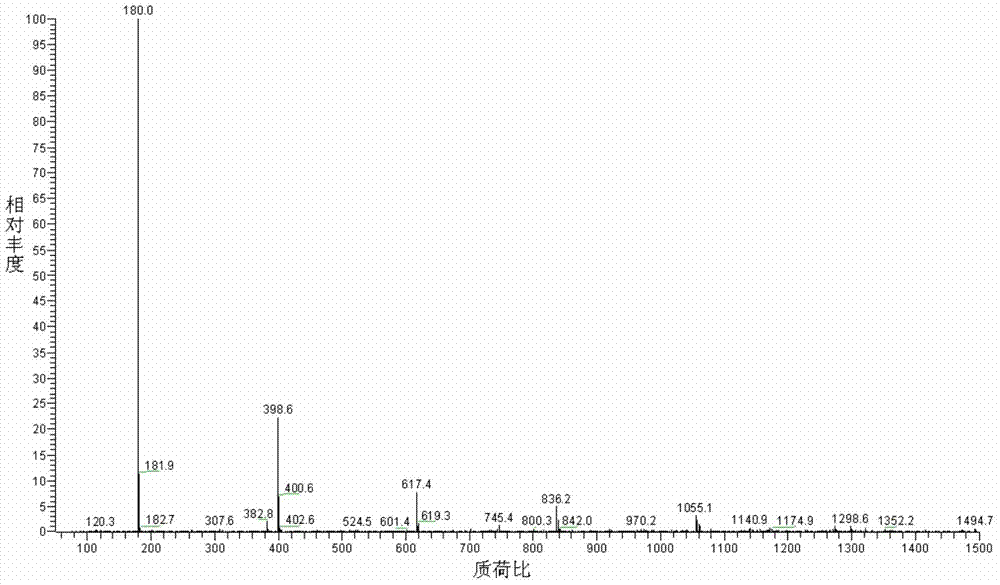

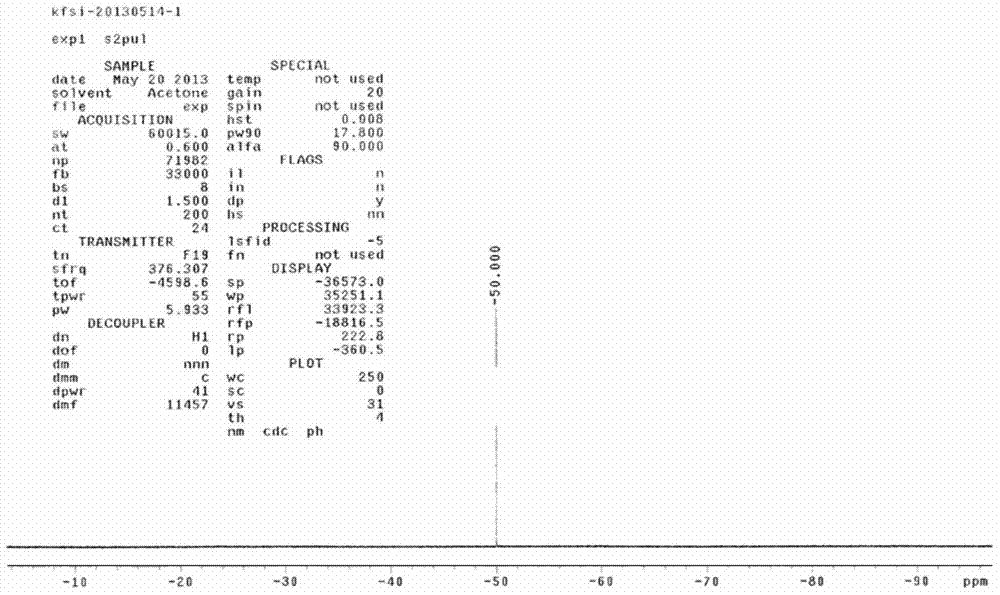

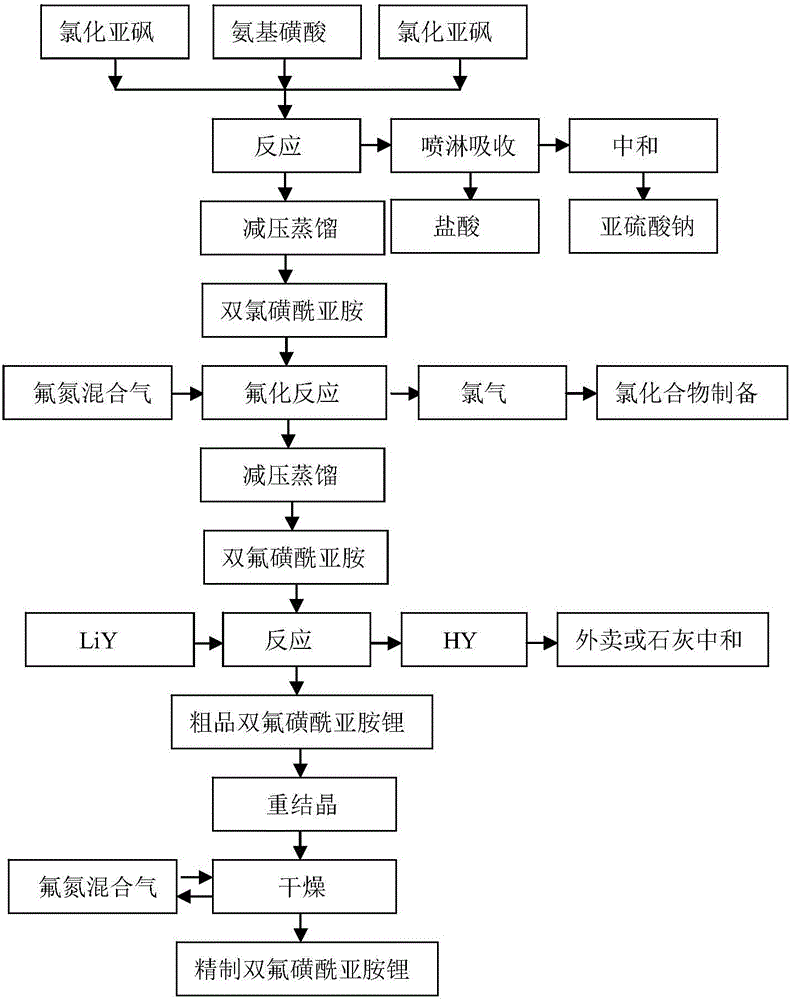

Preparation method for difluorosulfimide lithium salt

ActiveCN104925765AGuaranteed purityGuaranteed qualityNitrosyl chlorideAmidosulfonic acidHydrogen fluorideLithium-ion battery

The invention relates to the field of lithium batteries and lithium capacitors, in particular to a preparation method for difluorosulfimide lithium salt and application of the difluorosulfimide lithium salt. The preparation method for the difluorosulfimide lithium salt, provided by the invention, comprises the following steps: (1) performing fluorination reaction: synthetizing midbody difluorosulfimide from dichlorosulfimide and hydrogen fluoride under the action of a catalyst; (2) performing reaction between the difluorosulfimide obtained in the step 1 and alkaline lithium, and performing solid-liquid separation after the reaction to obtain an LiFSI product. The preparation method for the difluorosulfimide lithium salt, provided by the invention, is low in cost, few in by-product and simple in post-treatment, and the quality and the purity of the product are ensured, therefore the preparation method which is capable of obtaining the high-quality and high-purity product and is economic and practical is provided; the preparation method is suitable for industrial production.

Owner:SHANGHAI CHEMSPEC CORP +1

Preparation method of lithium bis(fluorosulfonyl)amide

The present invention provides a preparation method of lithium bis(fluorosulfonyl)amide. The method comprises the following steps: A) reacting chlorosulfuric acid with ammonia in the presence of an organic base to obtain organic alkali salt of bis(fluorosulfonyl)amide; B) mixing the bis(fluorosulfonyl)amide obtained in the step A) with HF for a fluorinated reaction to obtain an organic alkali salt of bis(fluorosulfonyl)amide; C) mixing the organic alkali salt of bis(fluorosulfonyl)amide obtained in the step B) with an alkaline substance for a neutralization reaction to obtain a bis(fluorosulfonyl)amid metal salt crude product; D) purifying the bis(fluorosulfonyl)amid metal salt crude product obtained in the step C) to obtain bis(fluorosulfonyl)amid metal salt; and E) mixing the bis(fluorosulfonyl)amid metal salt obtained in the step D) with a lithium reagent for a replacement reaction, so as to obtain lithium bis(fluorosulfonyl)amide. The preparation method provided by the invention has the characteristics of low raw material cost, low impurity content in the product and high yield of lithium bis(fluorosulfonyl)amide.

Owner:湖南福邦新材料有限公司

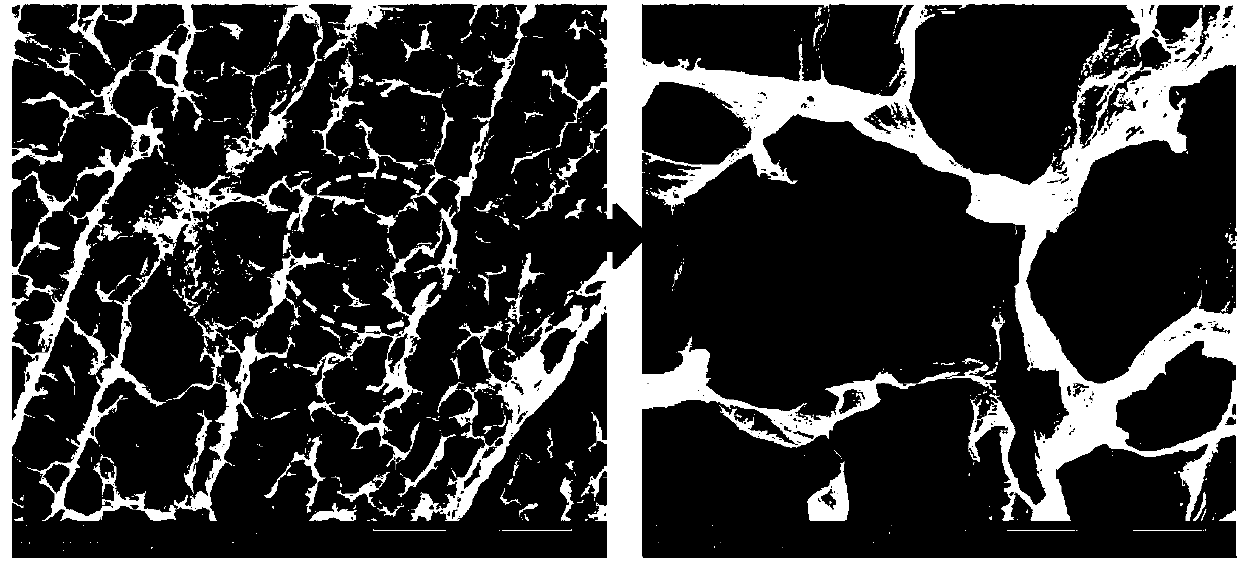

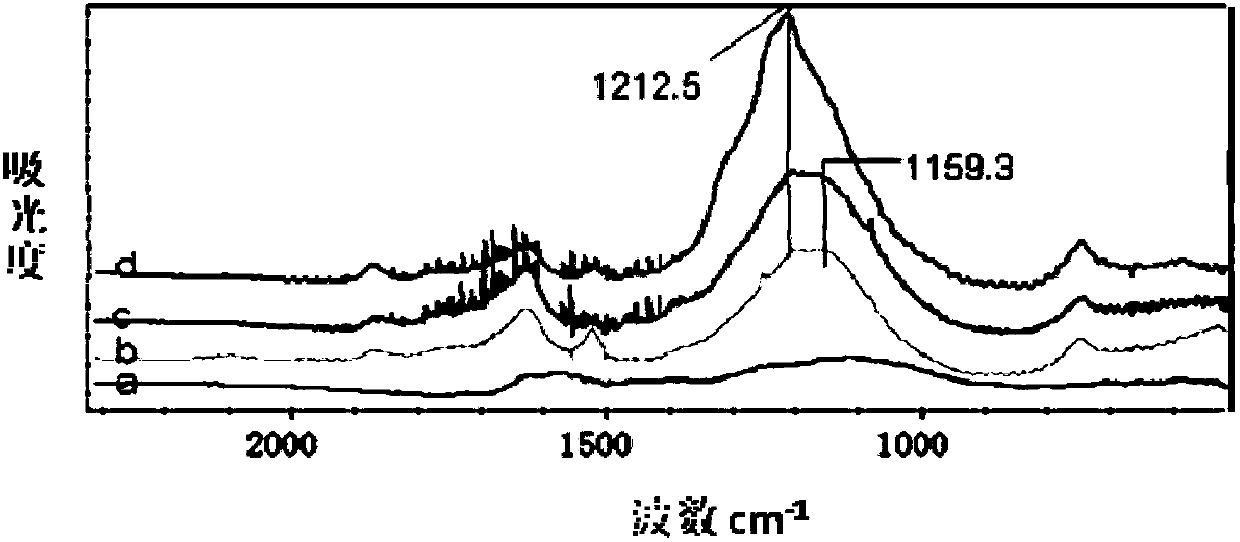

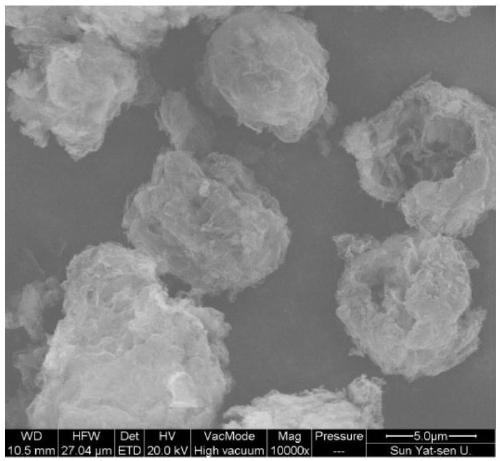

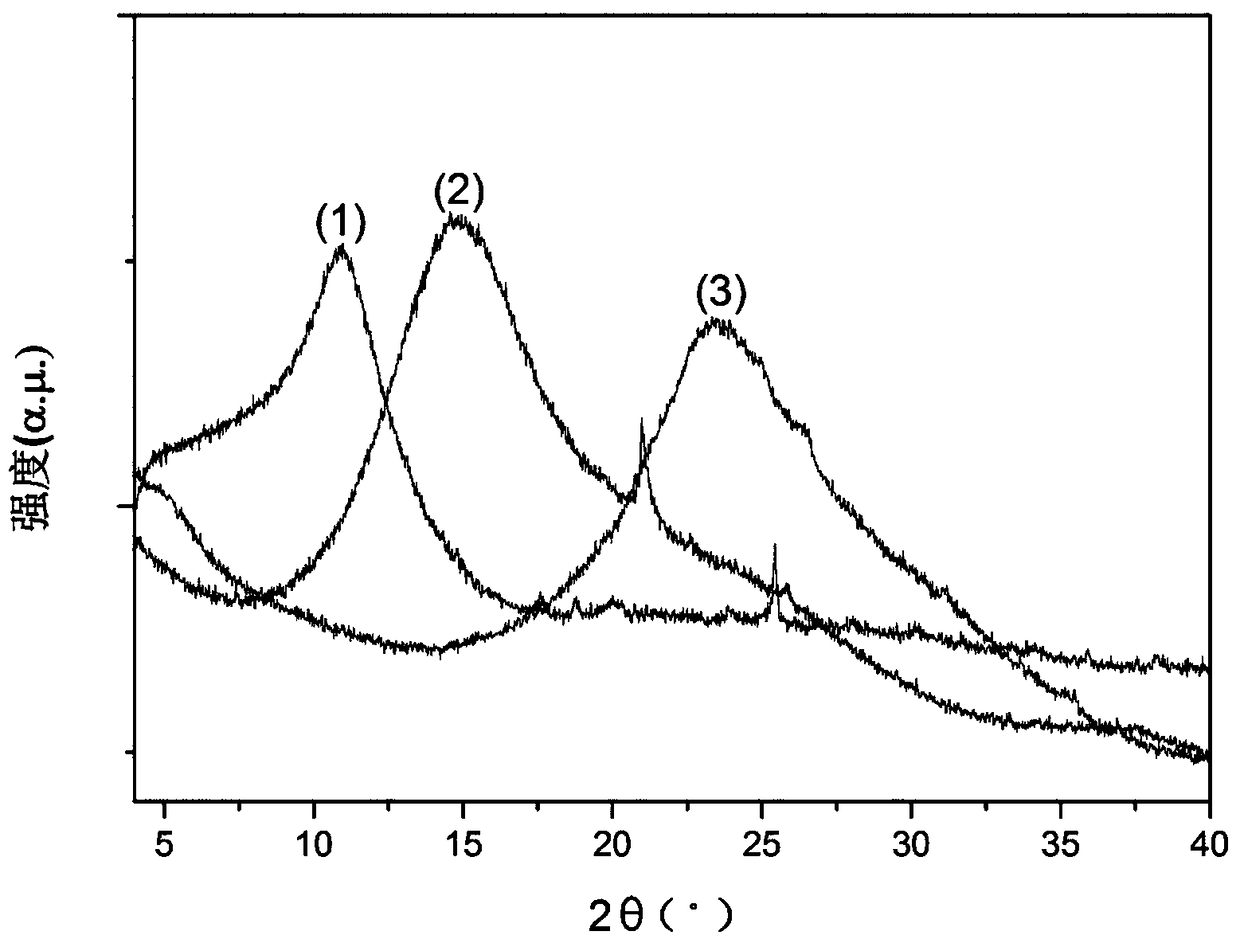

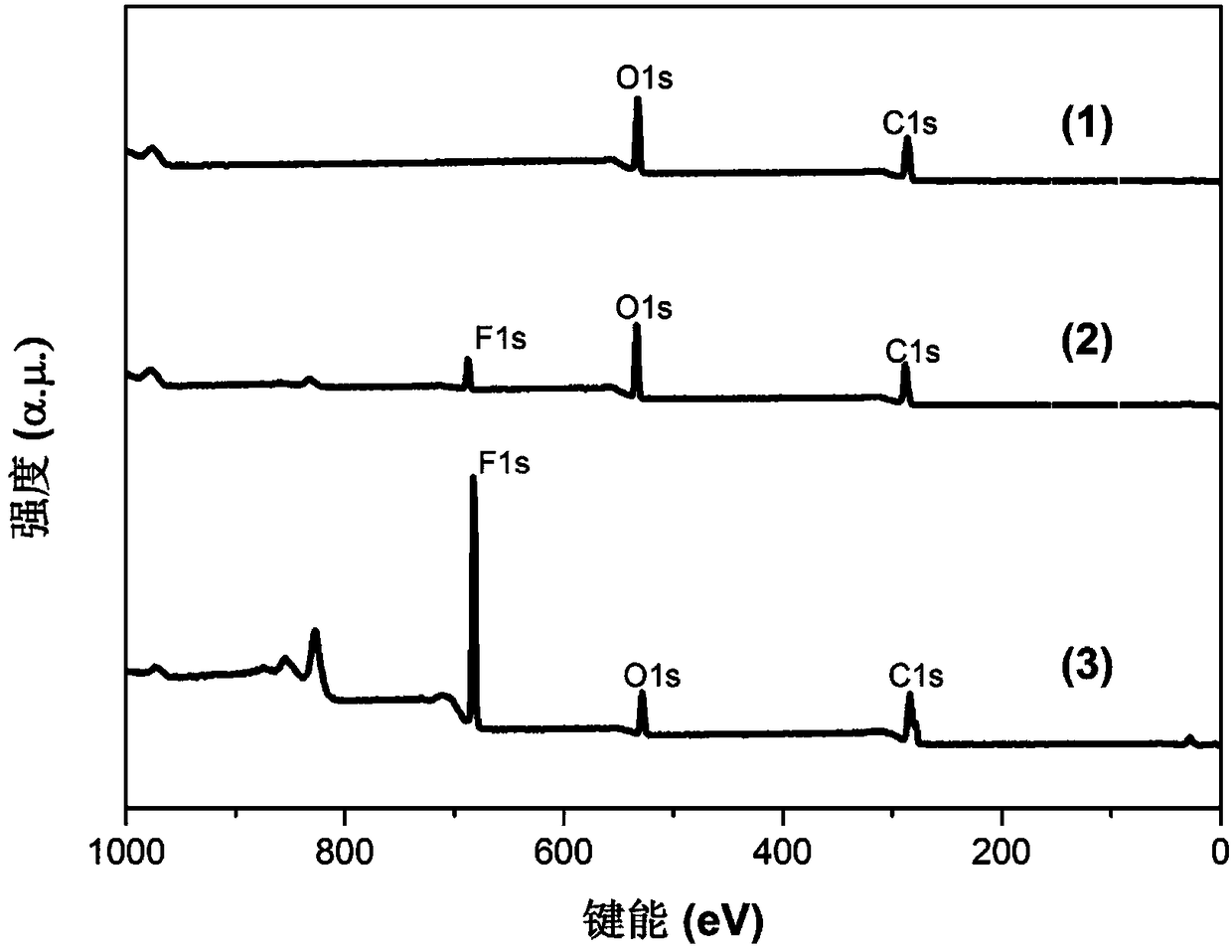

High-fluoride-content graphite fluoride and preparation method thereof

ActiveCN103420352AEasy to spreadFully contactedGrapheneCarbon fluoridesHigh fluorideReaction temperature

The invention discloses high-fluoride-content graphite fluoride and a preparation method thereof. The method comprises the following steps: preparing aqueous dispersion liquid of graphite oxide with a conventional improved Hummers method, then freezing the aqueous dispersion liquid of graphite oxide in liquid nitrogen to be completely frozen into solid, and freezing and drying to obtain cellular graphite oxide; under a mixed atmosphere of inert gas and fluoride, warming the cellular graphite oxide for fluoridation, and cooling to room temperature. The fluoride content of the prepared high-fluoride-content graphite fluoride is 55-70 percent, fluorine atoms are bonded with carbon atoms in a covalent bond mode, weightlessness peak temperature is larger than 470 DEG C, the heat stability is good, and the resistance is larger than 1012 omega. The prepared graphite fluoride has the advantages of high fluoride content, good heat resistance of fluorine-containing groups, low cost, simple process, lower reaction temperature, high safety and energy saving, is suitable for mass production, and has a better application prospect.

Owner:SICHUAN UNIV

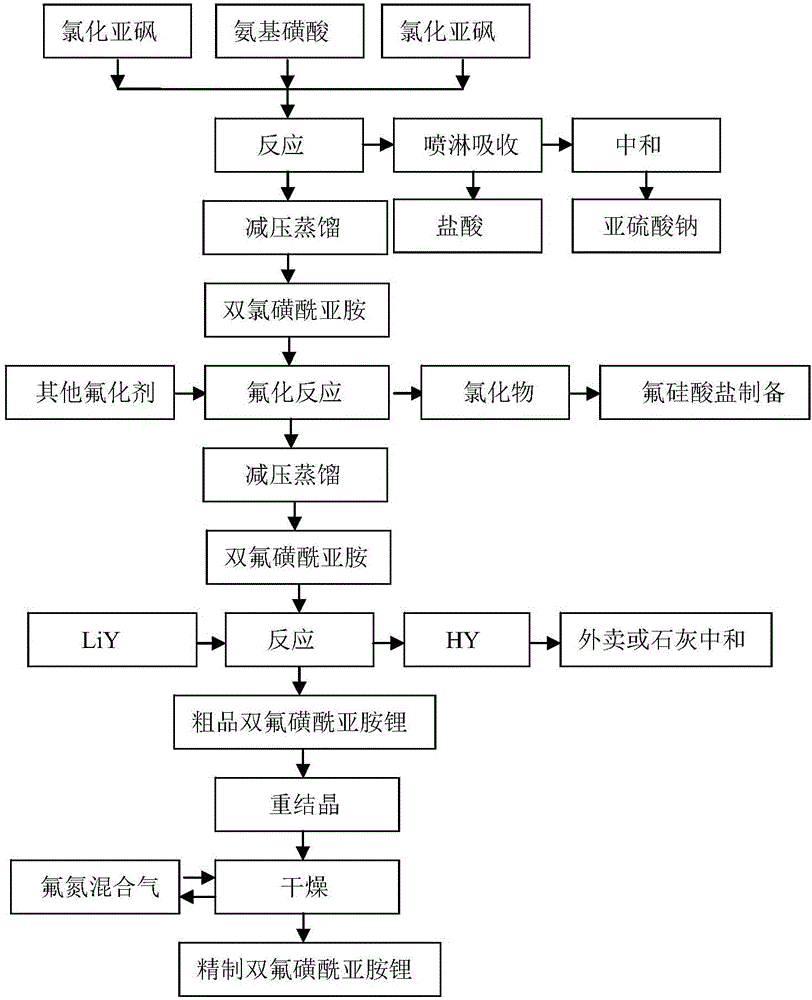

Preparation method of difluoro-sulfonyl imide lithium

The invention discloses a preparation method of difluoro-sulfonyl imide lithium. The preparation method comprises the following steps: 1) under a protective atmosphere, adding a fluorizating agent into difluoro-sulfonyl imide to perform a fluorination reaction so as to obtain a mixture, wherein the fluorizating agent is one of or a combination of fluorine, a fluorine-containing mixed gas, anhydrous hydrogen fluoride, potassium fluoride, antimonic fluoride and rubidium fluoride; 2) performing reduced pressure distillation on the obtained mixture to obtain a di(fluoro-sulfonyl) imide intermediate; and 3) under a protective atmosphere, performing synthetic reaction on the obtained di(fluoro-sulfonyl) imide intermediate and a lithium source, and performing solid-liquid separation to obtain difluoro-sulfonyl imide lithium. According to the preparation method disclosed by the invention, the fluorination reaction does not need a solvent or other auxiliary agent, is less in types of adopted reagents, does not introduce a new impurity, is simple in operation, and is easy to control; the method is less in side reaction, good in fluorination effect and low in fluorination cost; and the purity and the yield of the product namely difluoro-sulfonyl imide lithium obtained by a subsequent synthetic reaction are improved on the whole, and the method has good economic and environmental benefits.

Owner:DO FLUORIDE CHEM CO LTD

Preparation method of difluorosulfimide salt

The invention discloses a preparation method of difluorosulfimide salt. The preparation method comprises the following steps: (1) adding dichlorosulfimide and a nitrogen-containing hydrogen fluoride complex which are used as reaction raw materials into an organic solvent for reaction at 0-100 DEG C, and after reaction, distilling to remove the organic solvent to obtain a difluorosulfimide and nitrogen-containing ion compound; (2) adding the ion compound obtained in the step (1) into a water solution of metal alkali or salt, neutralizing until the solution is neutral, distilling, drying, re-crystallizing by using the organic solvent, and purifying to obtain difluorosulfimide salt. According to the preparation method, the nitrogen-containing hydrogen fluoride complex is adopted as a fluorating agent, so that the whole reaction is carried out in a homogeneous system, the fluorating reaction is relatively safe, the efficiency is relatively high, and the product yield is more than 98%; a process route is simple, the yield is high, and the production cost is relatively low.

Owner:ZHANGJIAGANG HICOMER CHEM CO LTD

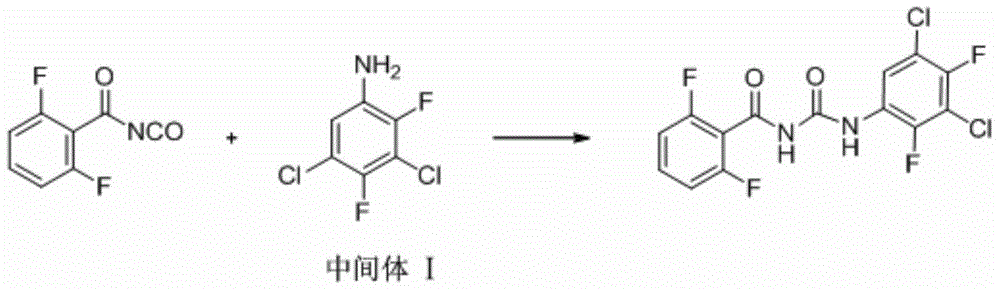

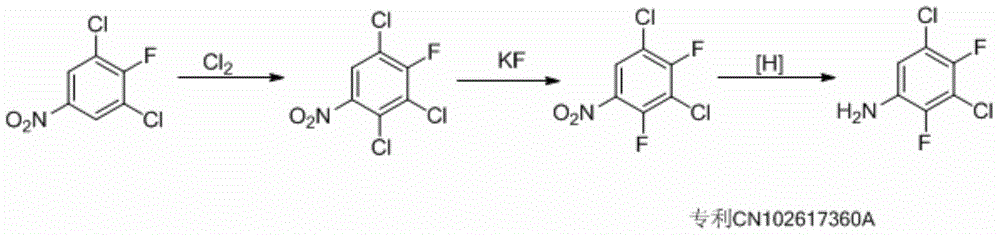

Preparation method for 3,5,-dichloro-2,4,-difluoroaniline

ActiveCN105801429AHigh yieldQuality improvementOrganic compound preparationAmino compound preparationOrganic synthesisReactive site

The invention relates to the field of organic synthesis, specifically to a preparation method for 3,5,-dichloro-2,4,-difluoroaniline and application thereof. The preparation method for 3,5,-dichloro-2,4,-difluoroaniline provided by the invention comprises the following steps: 1) nitration reaction; 2) reduction reaction; 3) diazotization reaction; 4) nitration reaction; 5) fluorination reaction; and 6) reduction reaction. The preparation method for 3,5,-dichloro-2,4,-difluoroaniline provided by the invention has the following beneficial effects: 1) the method has mild reaction conditions, is stable and controllable, has less active sites, is insusceptible to side reaction, and has good yield and quality in the whole line; and 2) raw materials are cheap and easily available, so cost can be effectively reduced, and energy is saved; meanwhile, the use of chlorine gas is avoided, so the method is environment-friendly.

Owner:安徽新北卡化学有限公司

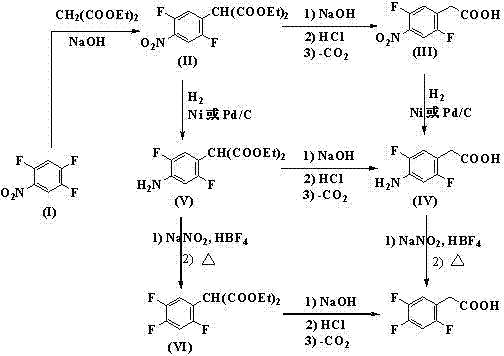

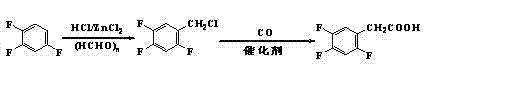

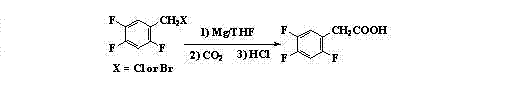

Preparation method 2,4,5-trifluorophenylacetic acid

ActiveCN103012111AFew synthetic stepsMild reaction conditionsOrganic compound preparationCarboxylic preparation by ozone oxidationPhenylacetic acidNitrobenzene

The invention discloses a preparation method 2,4,5-trifluorophenylacetic acid. The method is characterized by consisting of four reaction steps of: A, reaction of 2,4,5-trifluoronitrobenzene (I) and diethyl malonate which are condensed to prepare 2,5-difloro-4-nitrobenzophenone diethyl malonate; B, hydrolysis, acidification and decarboxylic reaction of dibasic ester; C, reduction reaction of nitryl; and D, diazotization fluoridation of amino. The four reaction steps can be sequentially carried out according to A, B, C and D, or A, C, B and D, or A, C, D and B. According to the preparation method provided by the invention, condensation of 2,4,5-trifluoronitrobenzene (I) and diethyl malonate is easy to realize by means of high substituting activity of nitryl p-fluorine, and the raw material 2,4,5-trifluoronitrobenzene (I) is low in cost and easy to obtain and can be easily prepared by nitration and fluorination of 2,4-dichlor fluorbenzene. Compared with the prior art, the preparation method provided by the invention has the characteristics of low-cost and easily obtained raw materials, mild reaction condition, high total yield, low production cost and the like, and is comparatively suitable for industrialized production.

Owner:江苏中丽新材料有限公司

Catalyst for fluorination

InactiveCN1680029AHigh activityHigh fluorination activityPhysical/chemical process catalystsOrganic chemistry methodsHydrogen fluorideMagnesium fluoride

To produce a catalyst having an enhanced fluorination activity in the catalyst used for a fluorination reaction using hydrogen fluoride as a fluorinating agent, and to provide a fluorination method using the catalyst. This catalyst for the fluorination reaction is characterized in that a porous support comprising calcium fluoride or magnesium fluoride is carried with an antimony halogenated substance represented by formula (1): SbFnCl(5-n) (wherein (n) represents a number of 0-5).

Owner:NAT INST OF ADVANCED IND SCI & TECH

Preparation method of imidodisulfuryl fluoride lithium salt

ActiveCN107215853AEasy to operateMild conditionsNitrosyl chlorideLi-accumulatorsHydrogen fluorideFluoride

The invention relates to a preparation method of imidodisulfuryl fluoride lithium salt. The preparation method comprises the following steps: (1) performing a fluorination reaction of imidodisulfuryl chloride by taking a hydrogen fluoride complex salt as a fluorinating agent in the presence of a solvent, the fluorinating agent and an initiator, performing filter pressing separation at the end of the reaction, distilling filtrate under a reduced pressure to remove the solvent, and rectifying under a reduced pressure to obtain imidodisulfuryl fluoride; (2) reacting the imidodisulfuryl fluoride with a lithium compound at the temperature of 80 to 110 DEG C to obtain a crude imidodisulfuryl fluoride lithium salt. The preparation method provided by the invention has the advantages of easiness in operation of a fluorinating process route, mild conditions, high operability and easiness in implementation of industrial production; the prepared imidodisulfuryl fluoride lithium salt is 99 percent or more in purity, and is suitable for lithium batteries.

Owner:SUZHOU HUAYI NEW ENERGY TECH CO LTD

Fluorinated graphene, and preparation method and application thereof

InactiveCN109179395AHigh activityImprove reaction efficiencyCarbon compoundsCell electrodesProduct gasVolume concentration

The invention provides a fluorinated graphene, and a preparation method and an application thereof. The preparation method of the fluorinated graphene is characterized in that reduced graphene oxide and a fluorinating agent undergo a fluorination reaction at 280-550 DEG C; and the fluorinating agent is a mixed gas of F2 and an inert gas, and the volume concentration of fluorine in the mixed gas is1-10%, preferably 3-10%, more preferably 3-8% and best preferably 3-5%. The reduced graphene oxide is fluorinated and modified with the mixed gas of F2 and the inert gas, so the safety, the stabilityand the controllability of the process are improved, the corrosion of high-purity F2 to a fluorination device is effectively reduced, and the problems of high cost and low fluorination quality in theprior art are solved.

Owner:HUBEI ENG UNIV

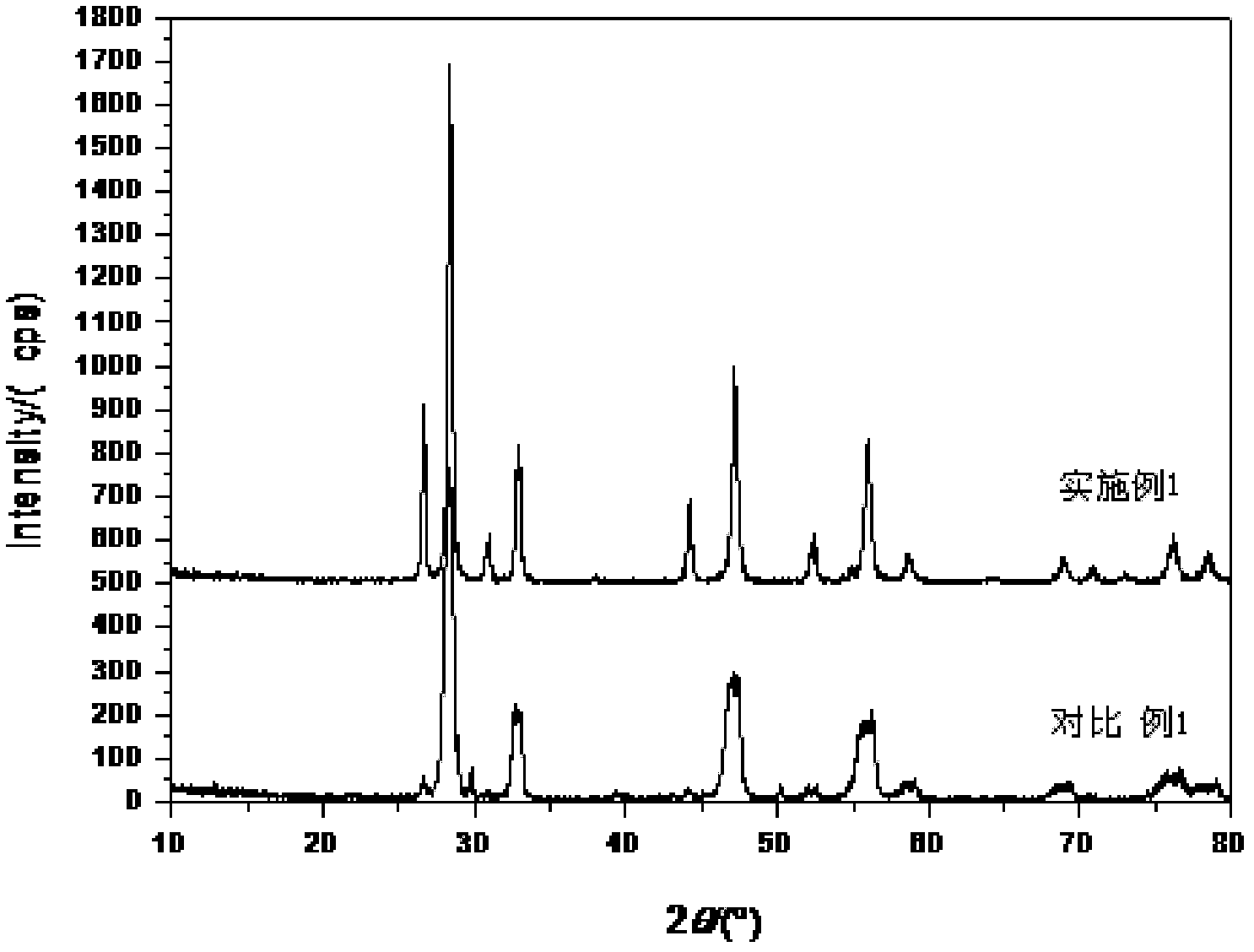

Cerium-based mixed rare earth polishing powder and preparation method thereof

ActiveCN103131385AEnsure Response UniformityGuaranteed uniformityOther chemical processesPolishing compositions with abrasivesRare earthCerium

The invention discloses cerium-based mixed rare earth polishing powder and a preparation method thereof. The cerium-based mixed rare earth polishing powder is a uniform solid solution composed of a rare earth oxyfluoride and a cubic-phase rare earth oxide. Compared with the prior art, the preparation method has the advantages that partly fluorinated rare earth carbonate is mixed with rare earth carbonate so that fluoridation reaction uniformity is guaranteed and the problems of poor dehydration effects and a low yield of rare earth carbonate one-step fluorination are solved; through control of fluorine content, fluorination uniformity is guaranteed, the problem of free fluorions and fluorides which are produced because of non-uniformity of fluorination and influence a polishing precision and a polishing rate is solved, and a particle having an abnormally large part is not produced in calcination; product wear resistance is good, a polishing rate is fast, and a polishing precision can be controlled easily; product uniformity is good, production efficiency is high, a cost is low, and pollution is avoided; and the cerium-based mixed rare earth polishing powder is suitable for surface polishing processes on precision devices such as an integrated circuit, a flat-panel displayer and optical glass in an electronic information industry.

Owner:上海华明高纳稀土新材料有限公司

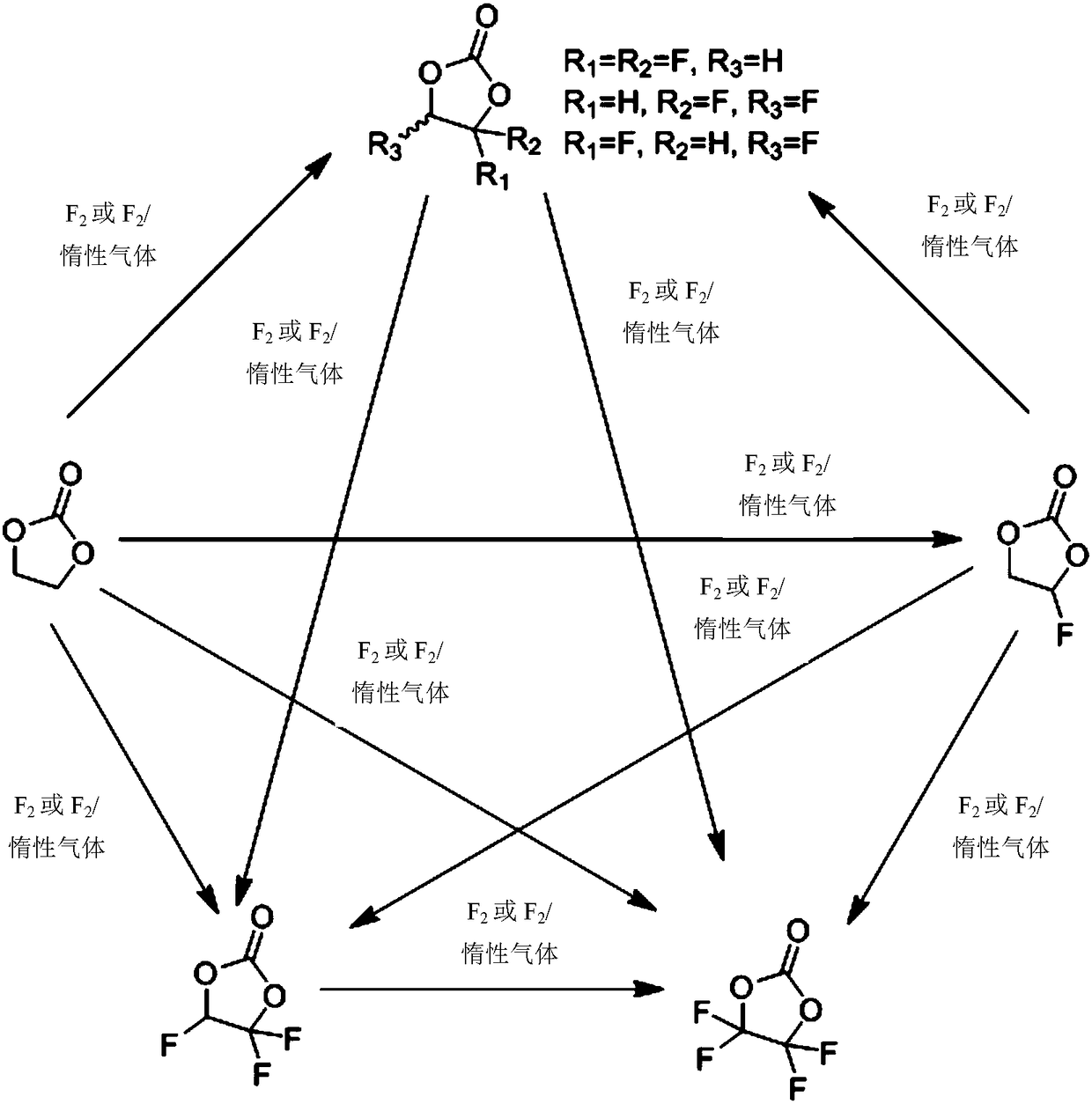

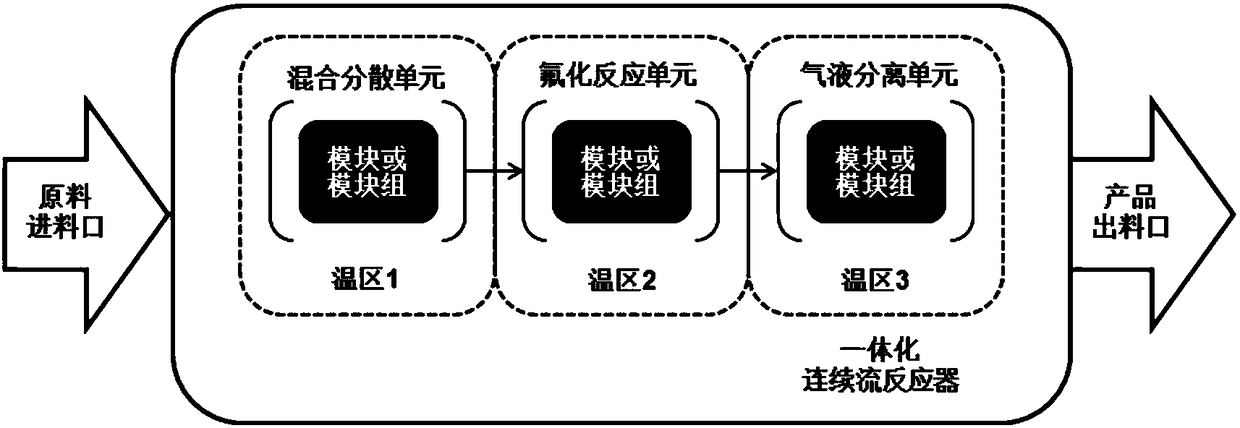

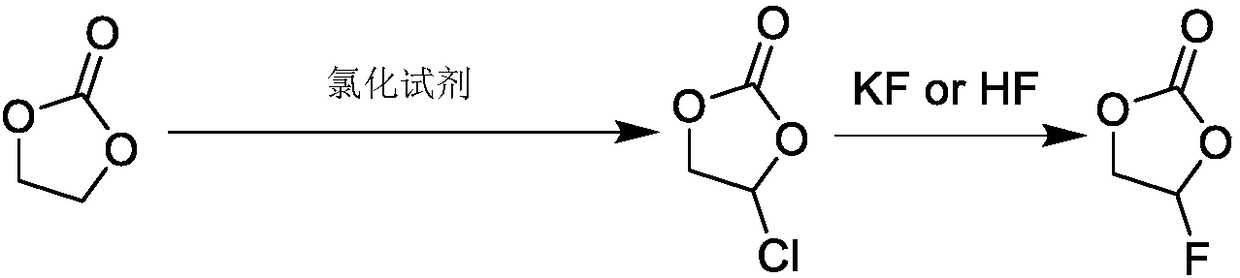

Rapid continuous flow synthesis process of fluoroethylene carbonate

InactiveCN108250176AOvercoming the defect of amplification effectNo effect on yieldOrganic chemistryContinuous flowCarbonate

The invention relates to a rapid continuous flow synthesis process of fluoroethylene carbonate and an integrated continuous flow reactor for realizing the process. The continuous flow synthesis process is characterized in that a raw material to be fluorinated and fluorine gas are used as reactants, and are continuously and successively subjected to steps of mixed dispersion, fluorination reaction,gas-liquid separation, so as to obtain the fluoroethylene carbonate; and the synthesis process is carried out in the integrated continuous flow reactor, the raw material to be fluorinated and the fluorine gas are continuously added to a feed inlet of the integrated continuous flow reactor, and the fluoroethylene carbonate is continuously obtained from a discharge port of the integrated continuousflow reactor with the reaction time equal to or less than 600 s. The process is a rapid, safe, efficient, highly versatile and easy for mass production continuous synthesis process of the fluoroethylene carbonate.

Owner:SHANGHAI HYBRID CHEM TECH

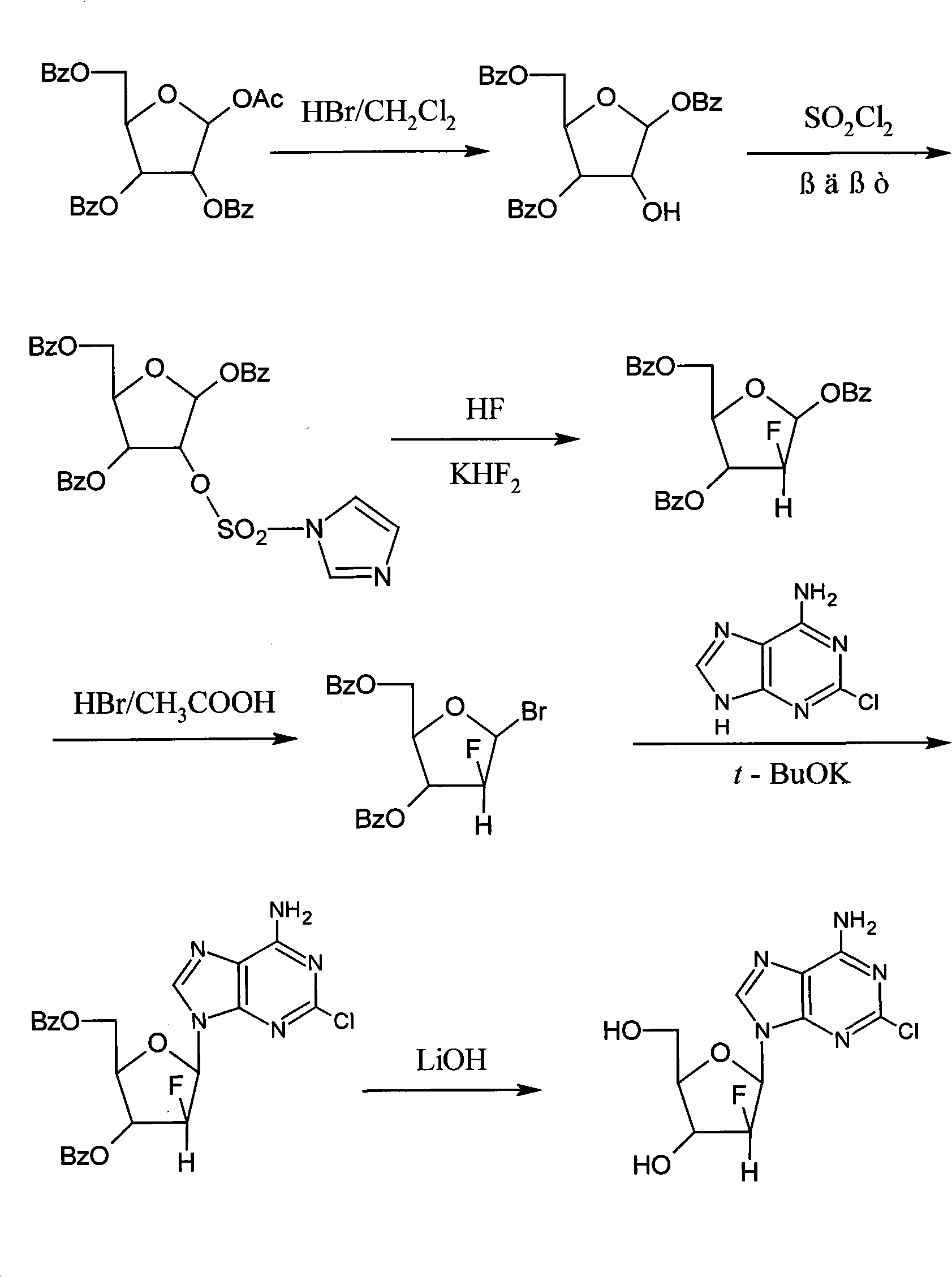

Method for synthesizing clofarabine

InactiveCN101265284AHigh selectivityHigh yieldSugar derivativesAntineoplastic agentsHydrobromidePhenacyl

The invention provides a preparation method of clofarabine, which includes allowing 1-acetyl-2,3,5-tri-o-benzoyl-Beta-D-ribofuranose as the initial raw material and dichloromethane solution of hydrobromide to perform the rearrangement reaction, reacting with sulfuryl chloride and imidazole, performing the fluoridation reaction in the presence of hydrogen fluoride aqueous solution and potassium hydrogen fluoride, and performing bromination reaction in acetic acid solution of hydrogen bromide, condensing with 2-chloro adenosine in alkaline condition, and removing benzoyl in the presence of lithium hydroxide to obtain clofarabine. Compared with prior art, the method has the advantages of high yield of each step, higher total yield, and easily realized industrialized production.

Owner:深圳万乐药业有限公司

Method for preparing potassium borofluoride through fluorine-containing wastewater

ActiveCN103332700ARich sourcesReduce pollutionBoron halogen compoundsHydrogen fluorideAfter treatment

The invention relates to a method for preparing potassium borofluoride through fluorine-containing wastewater. The method is characterized by comprising the following steps: (1) utilizing water to regulate the hydrogen fluoride content of the fluorine-containing wastewater until the mass content of hydrogen fluoride is 12%-17%; (2) completely mixing the wastewater after treatment in the step (1) with potassium chloride saturated solution according to a mass ratio of (3-5):1 so as to fluorate; (3) mixing borax with the wastewater after treatment in the step (1) according to a mass ratio of 1: (3-5), and stirring so as to completely dissolve the borax; mixing solution in the step 2 with solution in the step 3 according to a mass ratio of (0.8-1.2):1, stirring to react, and continuously separating potassium fluoborate out in a reaction process so as to prepare potassium fluoborate suspension; and (5) solid-liquid separating, washing and drying the potassium fluoborate suspension in the step (4) so as to obtain a potassium fluoborate product. The potassium fluoborate product prepared by the method can satisfy the requirements of potassium fluoborate use factories.

Owner:MORITA NEW ENERGY MATERIALS ZHANGJIAGANG CO LTD

Synthesis method for bis(fluorosulfonyl)imide salt

The invention discloses a synthesis method for a bis(fluorosulfonyl)imide salt, wherein the method comprises the following steps: (one) under the protection of nitrogen, dissolving a bis(chlorosulfonyl)imide salt in a nonprotic organic solvent to obtain a bis(chlorosulfonyl)imide salt organic solution; (two) under a stirring condition, adding an excess compound fluridizer into the organic solution, then heating to a temperature being 8 DEG C-20 DEG C higher than an organic solvent boiling point temperature, and making the bis(chlorosulfonyl)imide salt to undergo an effective fluorination reaction in the organic solvent, wherein the compound fluridizer is selected from at least two substances of antimony trifluoride, potassium fluoride, zinc fluoride and aluminum fluoride; (three) after the reaction is finished, filtering the reaction liquid, and concentrating the filtrate to obtain a concentrated solution; and (four) crystallizing the concentrated solution, filtering, drying, and thus obtaining the high-purity bis(fluorosulfonyl)imide salt. The synthesis method has the advantages of simple operation, high product productive rate, no toxic reagent to pollute the environment, and high purity of the product, and is suitable for large-scale production in industry.

Owner:JIANGSU GUOTAI SUPER POWER NEW MATERIALS

Method for synthetizing 2-chlorine-5-flumethiazine

Synthesis of 2-chlorine-5-trifluopyridine is carried out by taking 2-chlorine-5-chloromethyl pyridine as raw material, chlorination reacting at 60<=t<80íÒC with azodiisobutyronitrile, phosphorus trichloride and light radiation of iodo-tungsten light as evocator, carbon tetrachloride as organic solvent and below distilling purification 160íÒC and fluoridation reacting. It can be used for pesticide and medicine. Its advantages include simple raw material, low cost, high conversion efficiency, better reaction selectivity and more output.

Owner:KANGPENG AGRO CHEM JIANGYAN

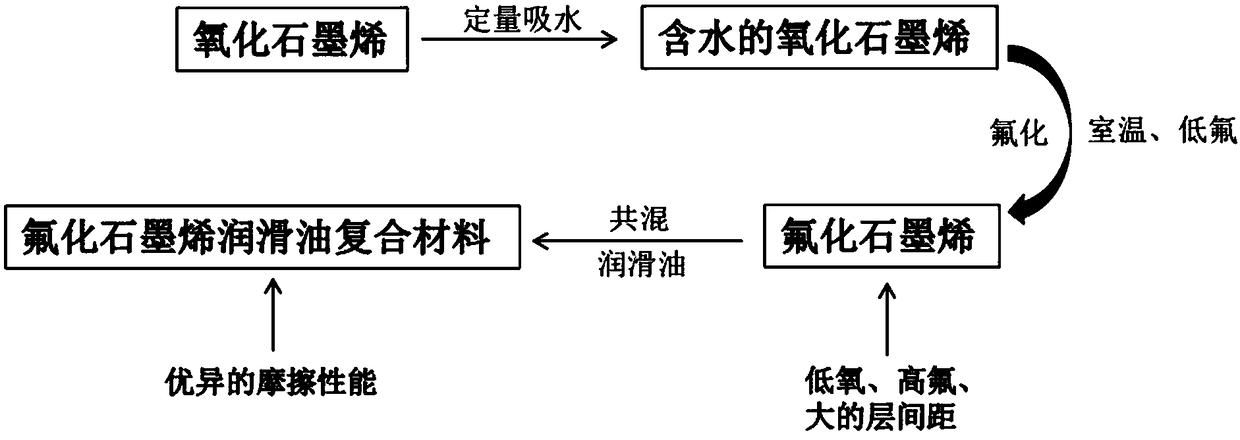

Fluorinated graphene lubricant additive and preparing method thereof and fluorinated graphene lubricant composite material

The invention discloses a fluorinated graphene lubricant additive and a preparing method thereof and a fluorinated graphene lubricant composite material, and relates to the technical field of lubricating materials. The preparing method of the lubricant additive comprises the step of conducting a fluorination reaction after absorbing moisture from graphene oxide. Through the fluorination process ofin-situ catalysis of graphene oxide by the moisture medium in graphene oxide, it is achieved that under the room temperature and the low fluorine gas concentration, fluorinated graphene with low oxygen content, high fluorine content and large interlayer spacing is prepared. The fluorinated graphene lubricant additive is simply mixed with lubricating oil, and does not easily get agglomerated in the lubricating oil, and the fluorinated graphene lubricant composite material with high dispersing stability is prepared. Compared with an original compound material, the friction coefficient is lowered by 52.3%, and the wearing ratio is lowered by 92.5%.

Owner:SICHUAN UNIV

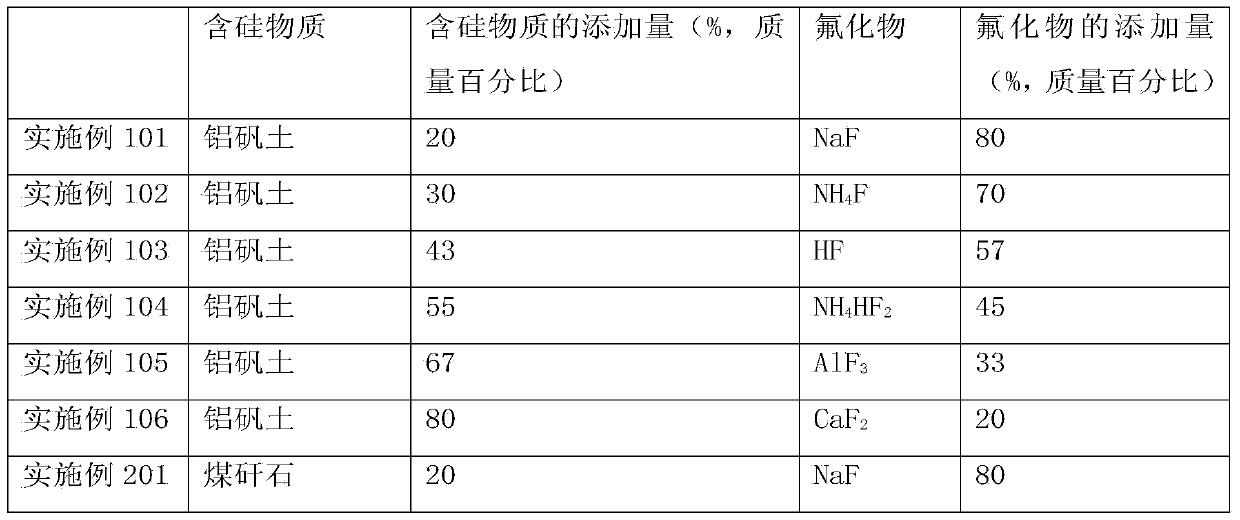

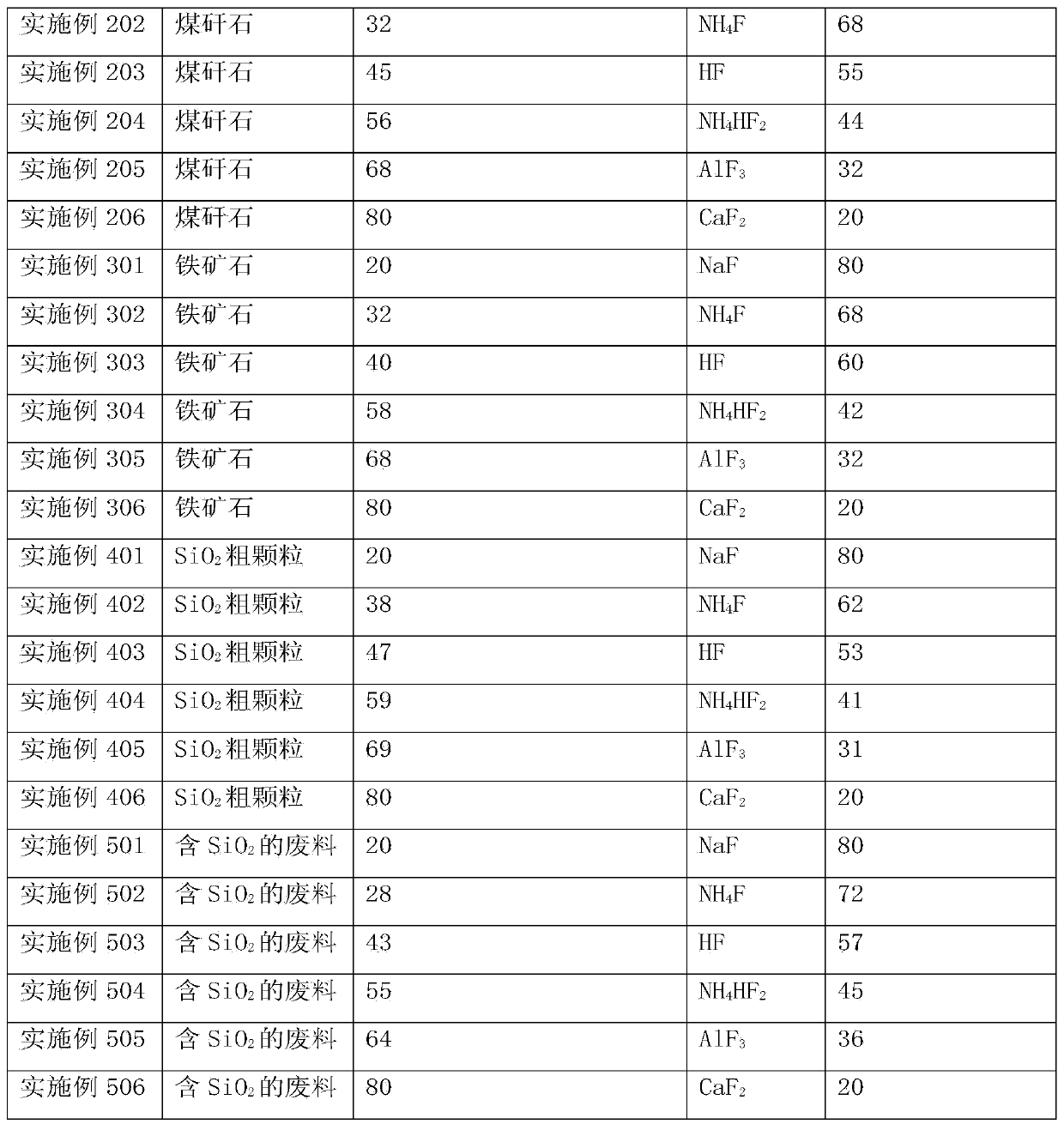

Method for recycling fluorides in preparation process of silicon-containing compound

The invention relates to the field of chemical industry, and particularly relates to a method for recycling fluorides in a preparation process of a silicon-containing compound. The method comprises the steps of: mixing a silicon-containing substance with fluoride to generate fluoridation to obtain silicon tetrafluoride gas and oxides of cations in the fluoride; carrying out pyrohydrolysis on the silicon tetrafluoride gas to obtain nanoscale silicon dioxide and hydrogen fluoride gas; reacting the hydrogen fluoride gas with the oxides of cations in the fluoride to obtain fluorides again. In the method for recycling the fluorides, during the whole reaction, fluorine element basically does not have any loss; as reactants, the fluorides are obtained again in the final reaction; and in the preparation of the silicon-containing compound, the fluorides are recycled.

Owner:贵州天合国润高新材料科技有限公司

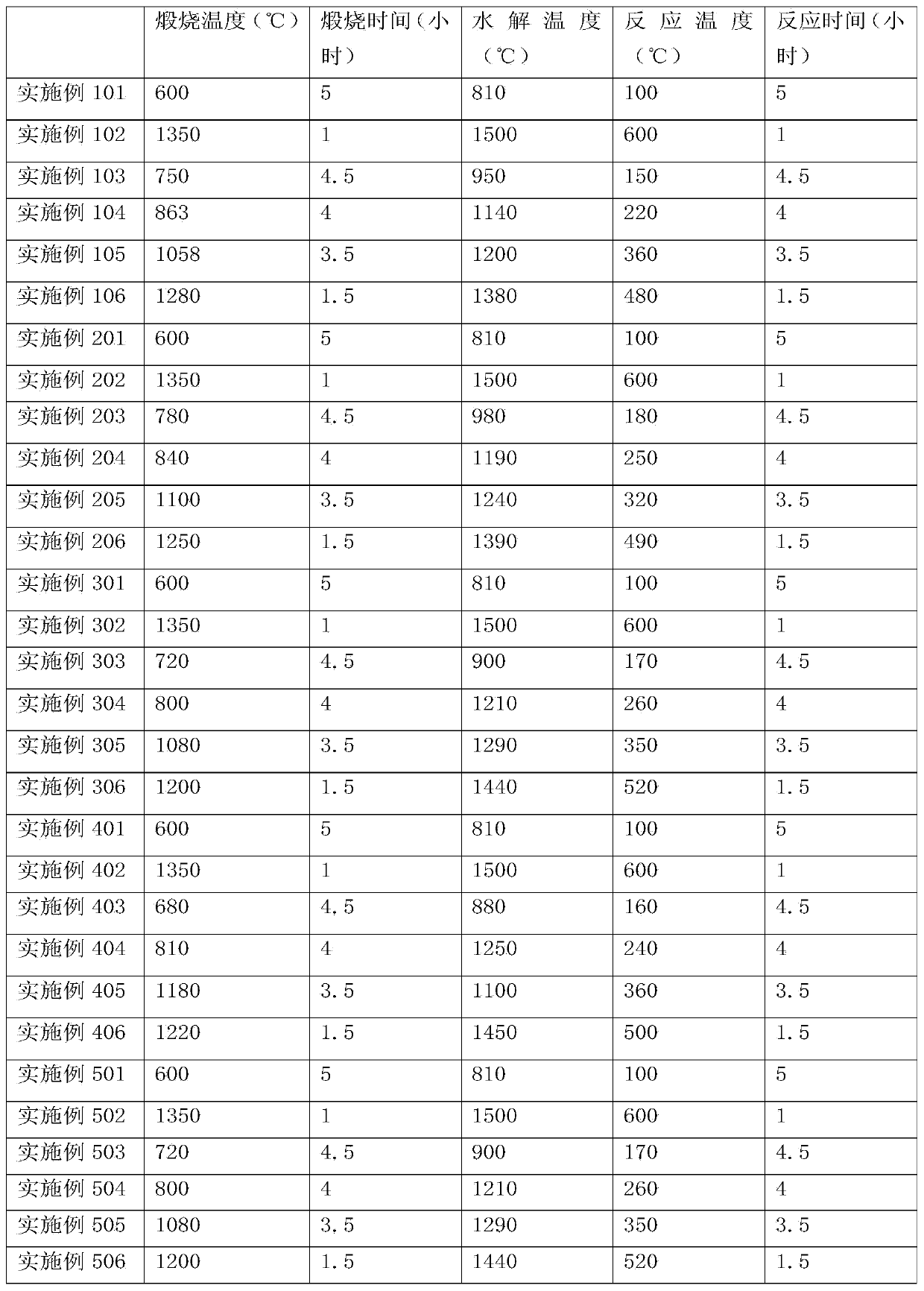

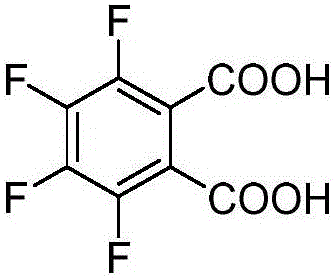

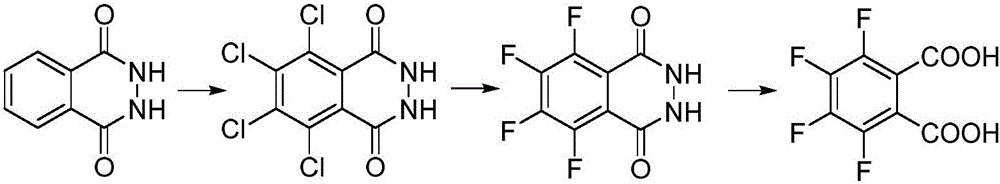

Synthesis method of 3, 4, 5, 6-tetrafluorophthalic acid

InactiveCN105693507AHigh yieldHigh selectivityOrganic compound preparationCarboxylic compound preparationDistillationPotassium fluoride

The invention discloses a synthesis method of 3, 4, 5, 6-tetrafluorophthalic acid, comprising the following steps: (1) adding phthalylhydrazine into mixed liquid of fuming sulfuric acid and diluted hydrochloric acid, then adding a catalyst I into the mixed liquid and stirring the mixture, controlling the filling of chlorine, and carrying out a thermal reaction; (2) adding potassium fluoride into a reaction device containing methyl alcohol, methylbenzene and a solvent I, heating up and then stirring the mixture, and carrying out atmospheric distillation on reaction liquid to recover the methyl alcohol and the methylbenzene; after that, under the protection of nitrogen, adding the tetrachloro phthalylhydrazine prepared in the step (1) and a catalyst II into the product, heating up to 120-200 DEG C and carrying out a fluoridation reaction; (3) adding the tetrachloro phthalylhydrazine and sodium peroxide which are prepared in the step (2) into water, carrying out a hydrolysis reaction for 2-8 hours at the temperature of 10-50 DEG C, then adjusting the acidity of the obtained reaction liquid until the pH value of the reaction liquid is equal to 1-4, carrying out suction filtration and drying to obtain the tetrafluorophthalic acid.

Owner:ZHEJIANG UNIV

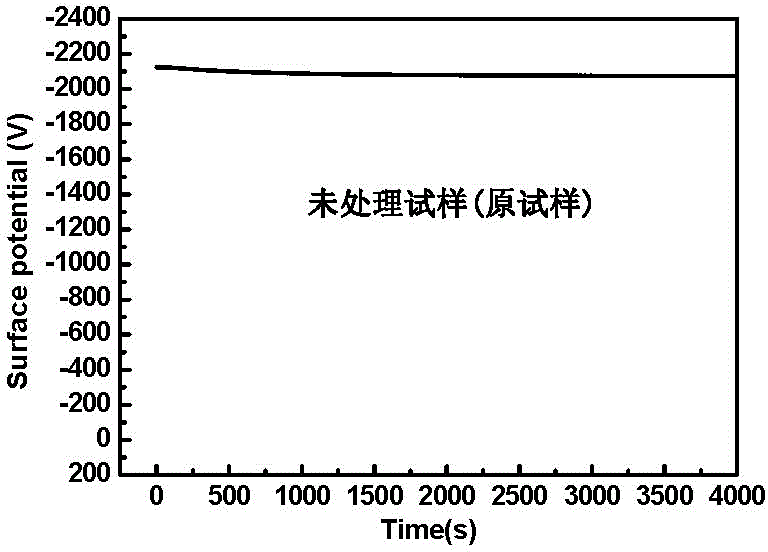

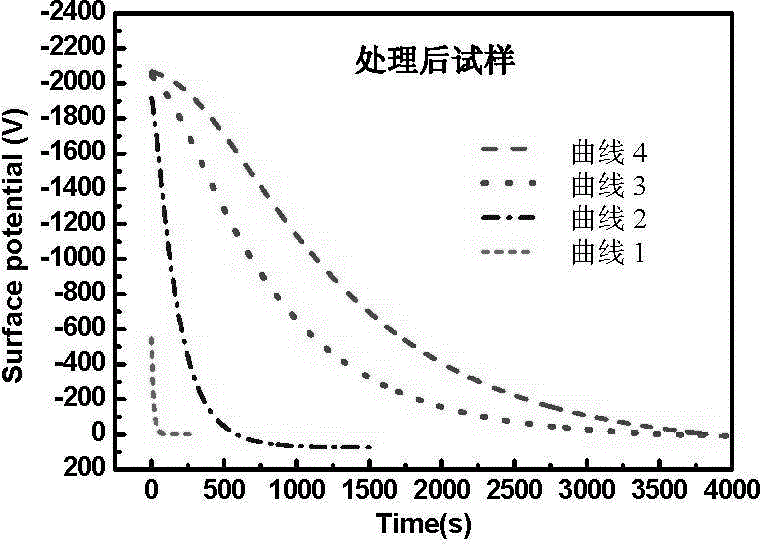

Method for inhibiting charge accumulation on polyimide insulation film

The invention relates to a method for inhibiting charge accumulation on a polyimide insulation film, and aims to effectively prevent charge accumulation on the polyimide insulation film and prolong the service life of electric apparatus. The method comprises the following steps: placing the polyimide insulation film in a reaction chamber for vacuumizing at first; then, introducing a mixed gas composed of fluorine, oxygen and nitrogen into the reaction chamber, and under the action of the mixed gas, conducting a 2-20 minutes' gas-phase oxygen-fluorine fluoridation reaction on the polyimide insulation film at 18-200 DEG C, wherein the mixed gas comprises 1-20% of fluorine, 1-20% of oxygen and the balance of nitrogen according to a volume ratio. The method is easy, simple to operate, low in cost and good in effect, and can be effectively utilized for inhibiting charge accumulation on the polyimide insulation film, thereby improving the corona resistance of the polyimide insulation film as well as the stability and service life of the polyimide insulation film in the technical filed of small-sized motor and electric apparatus frequency conversion.

Owner:SHANGQIU NORMAL UNIVERSITY

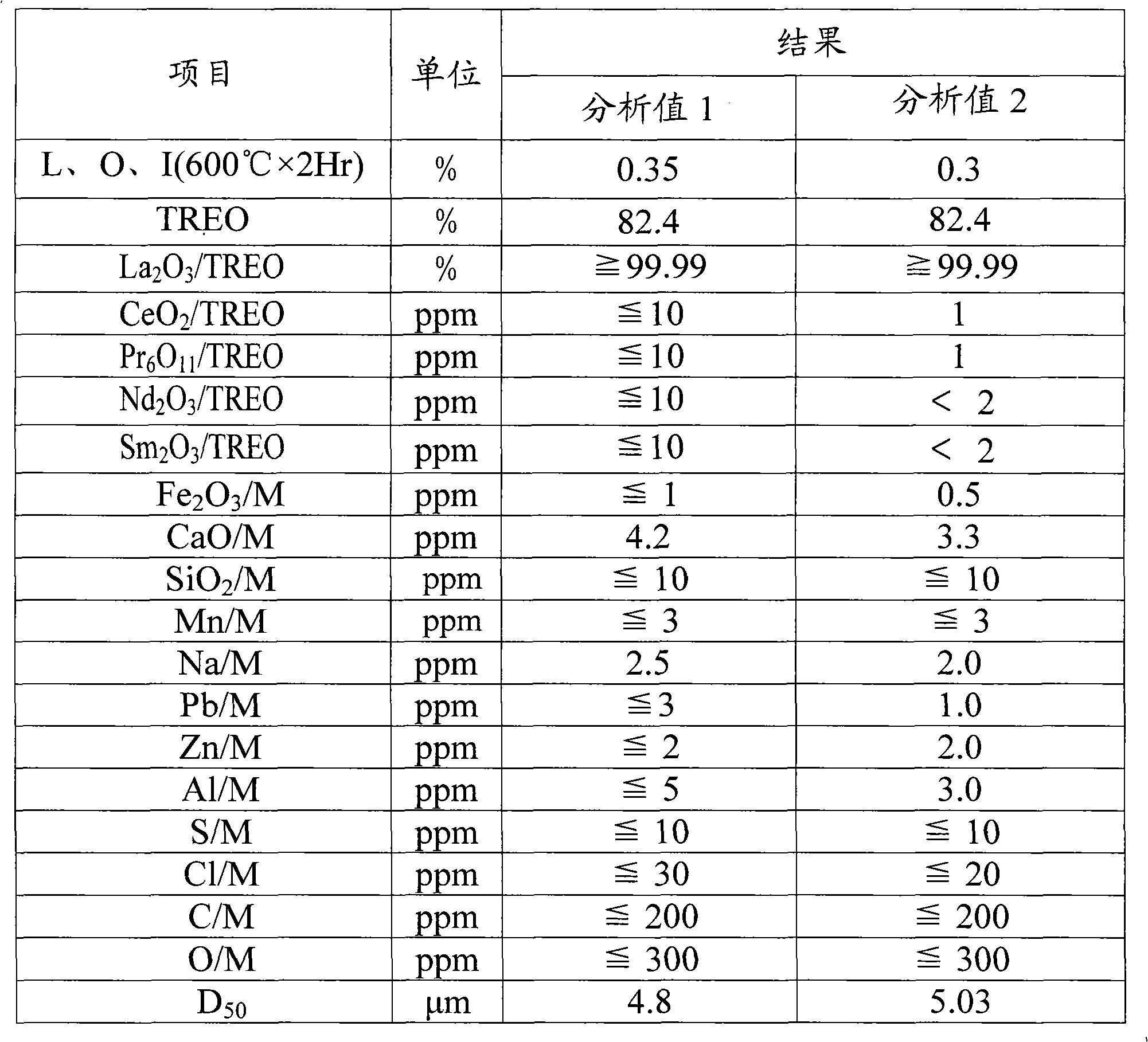

Anhydrous high-purity rare earth fluoride and preparation method thereof

The invention discloses an anhydrous high-purity rare earth fluoride and a preparation method thereof. The anhydrous high-purity rare earth fluoride mainly comprises minim non-rare earth impurity iron (Fe2O3<=1ppm), calcium (CaO<=10ppm), silicon (SiO2<=10ppm), carbon (C<=200ppm), oxygen (O<=200ppm), chloride (Cl<=30ppm), sulfur (S<=10ppm) and the like and has ignition loss not more than 0.5%. The product is mainly applied in the field of electronic and luminescent materials. The preparation method is characterized by pre-removing the non-rare earth impurity by enhancement on the basis of the traditional process and then carrying out conversion in the form of compound fluorinating agents; strictly controlling the feed liquor concentration and acidity, fluorinating agent addition, fluorination temperature and time, etc and obtaining the rare-earth fluoride which is coarse in fluorinated particles, fast in sedimentation and easy to wash and filter; and finally obtaining the anhydrous high-purity rare earth fluoride product through subsequent drying and particle integration.

Owner:QIANDONG RARE EARTH GRP

Preparation method of nano-scale silicon dioxide

ActiveCN103626191AWide variety of sourcesEasy to get materialsMaterial nanotechnologySilicaParticulatesChemical industry

Owner:贵州天合国润高新材料科技有限公司

Phase transfer catalyst for haloarene replacing fluorination

InactiveCN1457924AEasy to useLow reaction temperatureOrganic-compounds/hydrides/coordination-complexes catalystsOrganic halogenationSulfolaneCalixarene

The present invention belongs to fluorination catalyst technology. The catalyst is applied in the haloarene replacing fluorination between the haloarene and fluorinating agent inside sulfolane solution. The present invention features the catalyst being calixarene or its derivative, consumption of 0.01-1 mol and using temperature 80-230 deg.c. Using the catalyst in haloarene replacing fluorination can simplify the technological process, lower the product cost, raise the product yield and purity and simplify post-treatment. The present invention is suitable for industrial production.

Owner:TIANJIN UNIV

Method for preparing carbon fluoride/fluorinated metal composite material

ActiveCN110112394ARich inner poresLarge specific surface areaNegative electrodesCarbon compositesManganese

A method for preparing a carbon fluoride / fluorinated metal composite material comprises the steps of: carbonizing at least one of the group consisting of copper-based, iron-based, cobalt-based, nickel-based, and manganese-based metal organic framework materials at a high temperature in an inert gas atmosphere, then cooling the organic framework material to room temperature to obtain a composite material precursor; drying the composite material precursor in a reaction vessel, then introducing a mixed gas composed of a fluorine gas and a nitrogen gas, performing a fluorination under a heating condition, and performing vacuum drying to obtain the carbon fluoride / fluorinated metal composite material as a final product. The method is low in raw material cost, easy to operate and liable to industrial production. The fluorinated metal and carbon fluoride composite materials are prepared by an in-situ method. The two materials have high recombination degree, and the composite material has richinner pores and high specific surface area. The fluorinated metal and carbon fluoride composite materials have good chemical stability, high discharge specific capacity and high discharge voltage platform, and can be applied to lithium ion batteries and the like, and have very good application prospects.

Owner:CIVIL AVIATION UNIV OF CHINA

Preparation method of trans-1, 2-dichloro-3, 3, 3-trifluoropropene

ActiveCN105753637AImprove conversion rateHigh selectivityHalogenated hydrocarbon preparationHydrogen fluorideGas phase

The invention discloses a preparation method of trans-1, 2-dichloro-3, 3, 3-trifluoropropene. The method comprises the following steps: a, 1,1,1,2,2,3-hexachloropropane and / or 1,1,1,2,3,3-hexachloropropane are reacted with the existence of diluent gas and a catalyst, a gas-phase reaction is carried out for removing hydrogen chloride, and 1,1,2,3,3-pentachloropropene is produced; b. a liquid phase fluoridation reaction is carried out between 1,1,2,3,3-pentachloropropene and hydrogen fluoride with the existence of a liquid phase fluorination catalyst, or a gas phase fluorination reaction is carried out between 1,1,2,3,3-pentachloropropene and hydrogen fluoride with the existence of a gas phase fluorination catalyst; c. washing, alkali washing and drying are carried out for reaction products in the step b, and trans-1, 2-dichloro-3, 3, 3-trifluoropropene is obtained by rectification in a condition with normal pressure. The method has the characteristics of high reaction selectivity, high conversion rate and high stereoselectivity, and is mainly used for preparing trans-1, 2-dichloro-3, 3, 3-trifluoropropene.

Owner:XIAN MODERN CHEM RES INST

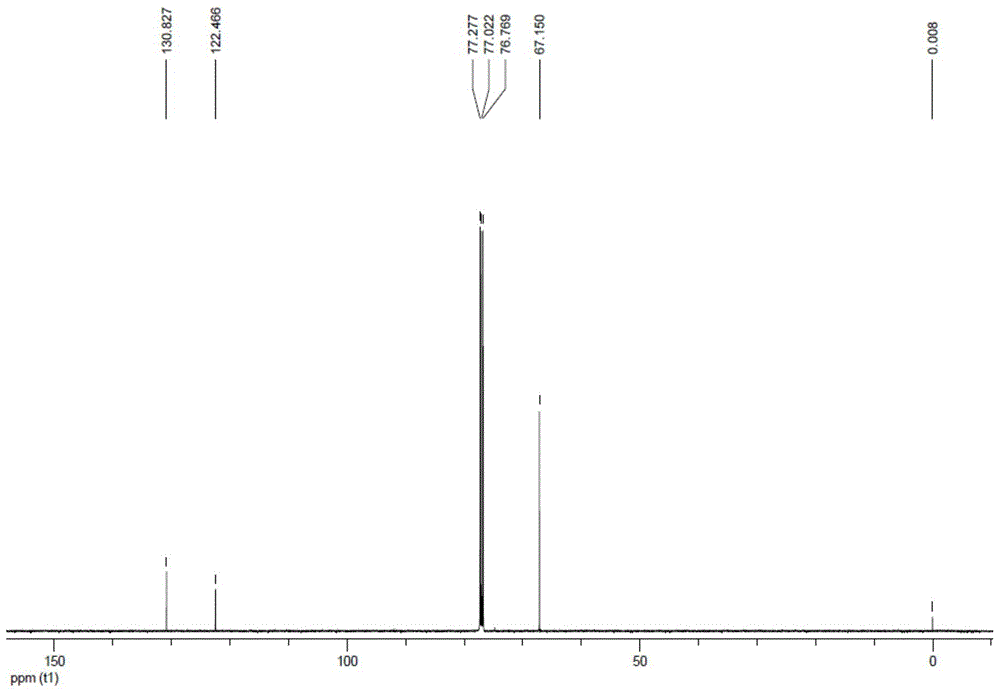

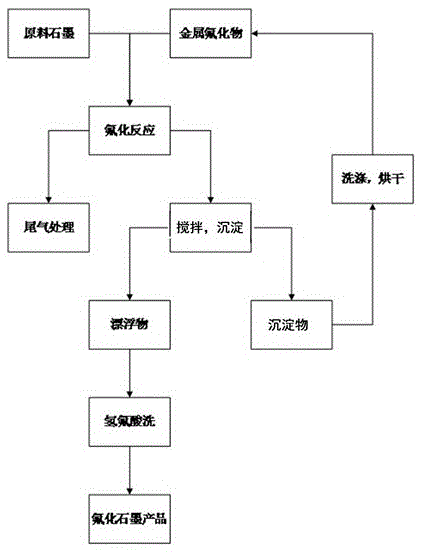

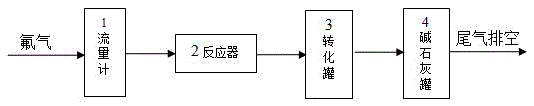

Method for preparing high-purity graphite fluoride according to catalytic method

ActiveCN105621398ARealize large-scale industrial productionAchieve recyclingCatalytic methodActivation energy

The invention discloses a method for preparing high-purity graphite fluoride according a catalytic method. The method comprises the following steps: pretreatment, fluoridation, off-gas treatment, product collection, graphite fluoride purification and catalyst recovery. Through the addition of metal fluoride as a catalyst, the activation energy of graphite and fluoride reaction is reduced, so that the reaction temperature is greatly reduced. The method disclosed by the invention has the advantages that the reaction temperature is low, the production cost is low, the process is simple, the safety is high, and the fluorine content of the prepared high-purity graphite fluoride can be flexibly changed through adjustment of reaction temperature, pressure and time, so that large-scale industrialized production of graphite fluoride is realized. The metal fluoride catalyst is insoluble in water, and can be separated from graphite fluoride according to a water-deposition method, so that the catalyst is recycled, and the production cost is greatly reduced.

Owner:SHANDONG ZHONGSHAN PHOTOELECTRIC MATERIAL CO LTD

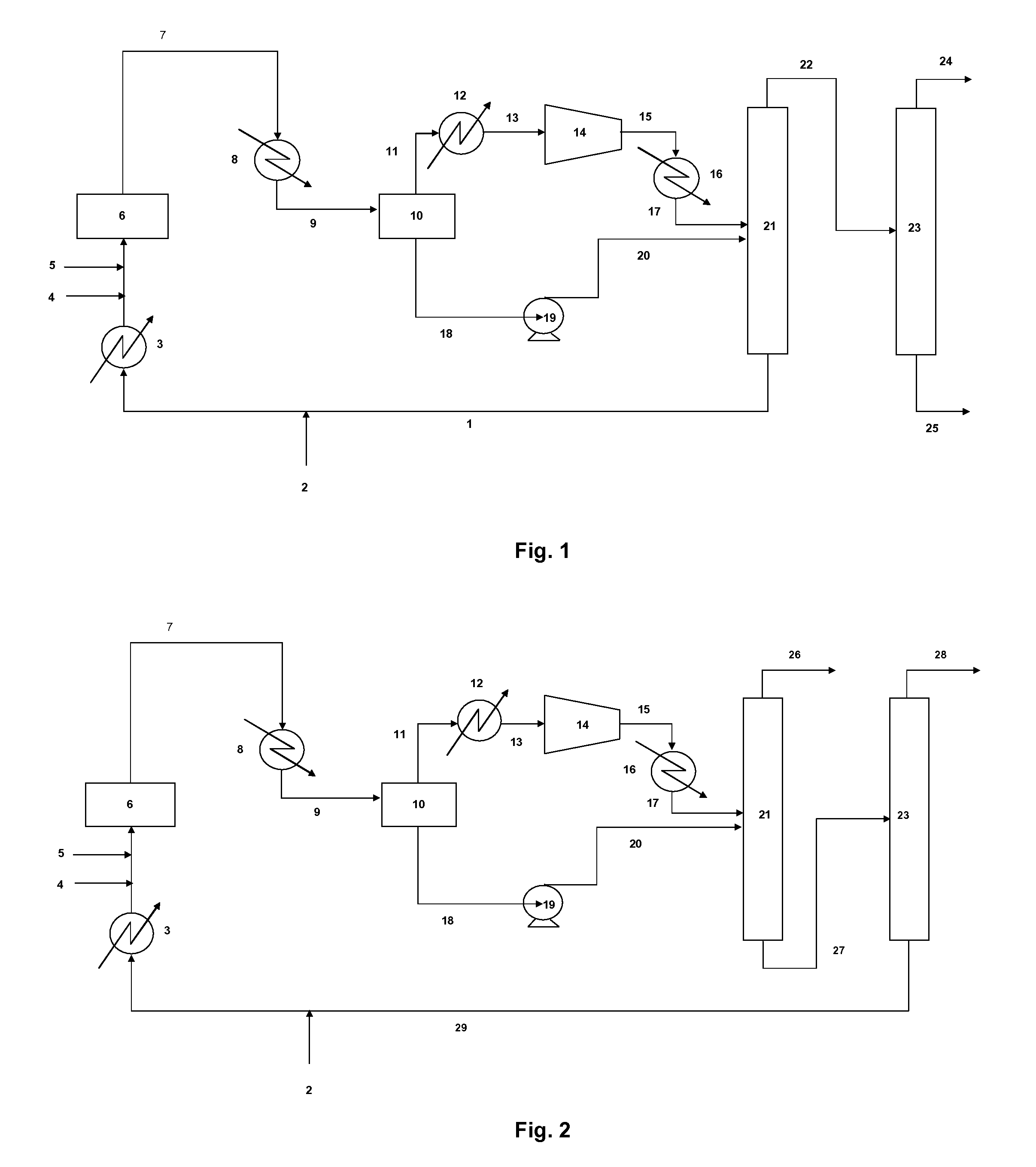

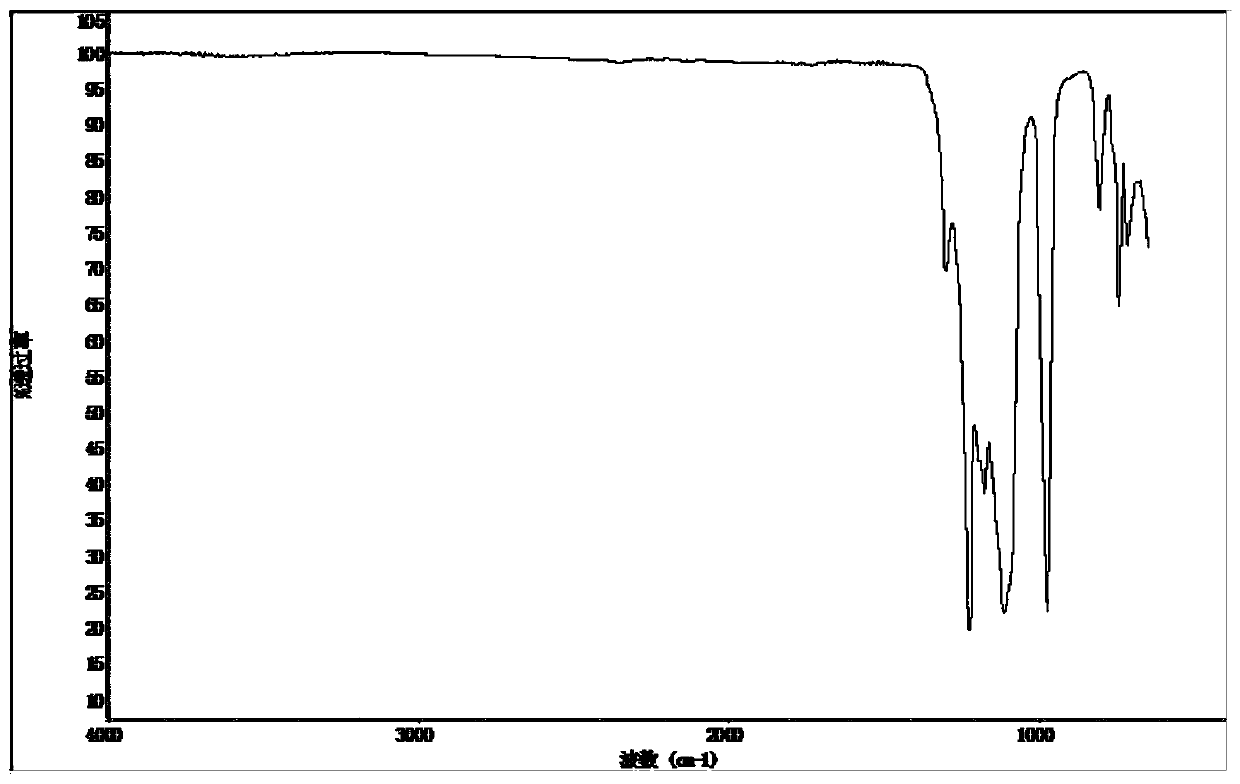

Method for Producing 2,3,3,3-Tetrafluoropropene

ActiveUS20150080619A1Simple designOvercomes drawbackSolidificationLiquefactionHydrogen fluorideDistillation

The invention concerns a method for producing 2,3,3,3-tetrafluoropropene comprising: a fluoridation reaction of a halopropane and / or halopropene into 2,3,3,3-tetrafluoropropene by means of hydrogen fluoride; the recovery of a gas stream resulting from the reaction; the cooling and partial condensation of the gas stream resulting from the reaction into a partially condensed stream; the separation of the partially condensed stream into a gas fraction and a liquid fraction; the compression of the gas fraction into a compressed gas fraction; the compression of the liquid fraction into a compressed liquid fraction; the distillation of the compressed gas fraction and compressed liquid fraction in order to provide a stream of 2,3,3,3-tetrafluoropropene, a stream of hydrochloric acid, and a stream of unreacted hydrogen fluoride. The invention also concerns an installation suitable for implementing said method.

Owner:ARKEMA FRANCE SA

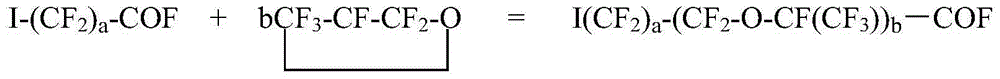

Technology for fluorinating unstable end group of perfluoropolyether

The invention relates to the technical field of fluorine chemical, and concretely relates to a technology for fluorinating the unstable end group of perfluoropolyether. The technology comprises the following steps: 1, vacuumizing a bubble tower fluorination reactor, adding an HFPO oligomer acid fluoride and / or perfluoropolyether carboxylic acid into the reactor from the upper end of the bubble tower fluorination reactor, and heating the bubble tower fluorination reactor to 130-170 DEG C; 2, adjusting the pressure in the bubble tower fluorination reactor; 3, introducing a fluorinating agent gas, carrying out a reaction for 45-90 min, and heating the reactor to a preset reaction temperature; and 4, carrying out a reaction for 4-48 h, stopping the introduction of the raw material when the reaction is finished, carrying out nitrogen purging, cooling the obtained material to 40 DEG C or below, and discharging the cooled material. The end group of the HFPO oligomer acid fluoride and / or perfluoropolyether carboxylic acid is treated with fluorine gas by using the bubble tower fluorination reactor, so the utilization efficiency of the fluorine gas is greatly improved, and an ideal effect isachieved.

Owner:SHANGHAI OULEIFEN BIOLOGICAL TECH

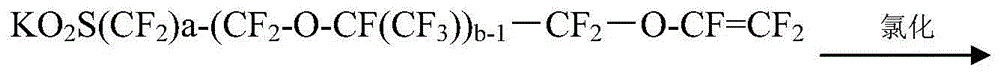

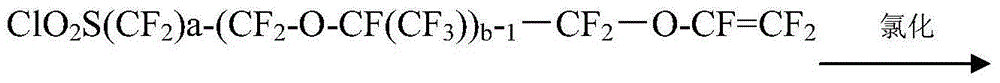

Method for preparing perfluoro alkene ether sulfonyl fluoride compound

The invention relates to a method for preparing a perfluoro alkene ether sulfonyl fluoride compound. The method comprises the following steps: carrying out an addition reaction on perfluoroiodoacetyl fluoride and hexafluoropropylene oxide in a solvent, cracking the obtained material in a solvent to prepare a perfluoroiodo alkene ether monomer, carrying out a mild reaction on the monomer to prepare perfluoro alkene ether sulfite, chlorinating the perfluoro alkene ether sulfite by using a chlorination reagent to obtain perfluoro alkene ether sulfonyl chloride, and carrying out a mild phase transfer catalytic fluorination reaction on the perfluoro alkene ether sulfonyl chloride to prepare a required perfluoro alkene ether sulfonyl chloride monomer with a high yield. A general catalyst and mild reaction conditions are adopted in the whole reaction enforcement process, reaction raw materials involved in the reactions can be prepared by using present technologies or can be purchased in the market, yields of all the reactions under above conditions are high, and a mixture obtained in the invention can be separated by using present technologies, so the target product with the purity of 99% or above, used for polymerizing preparation of perfluorinated ion resin can be obtained.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com