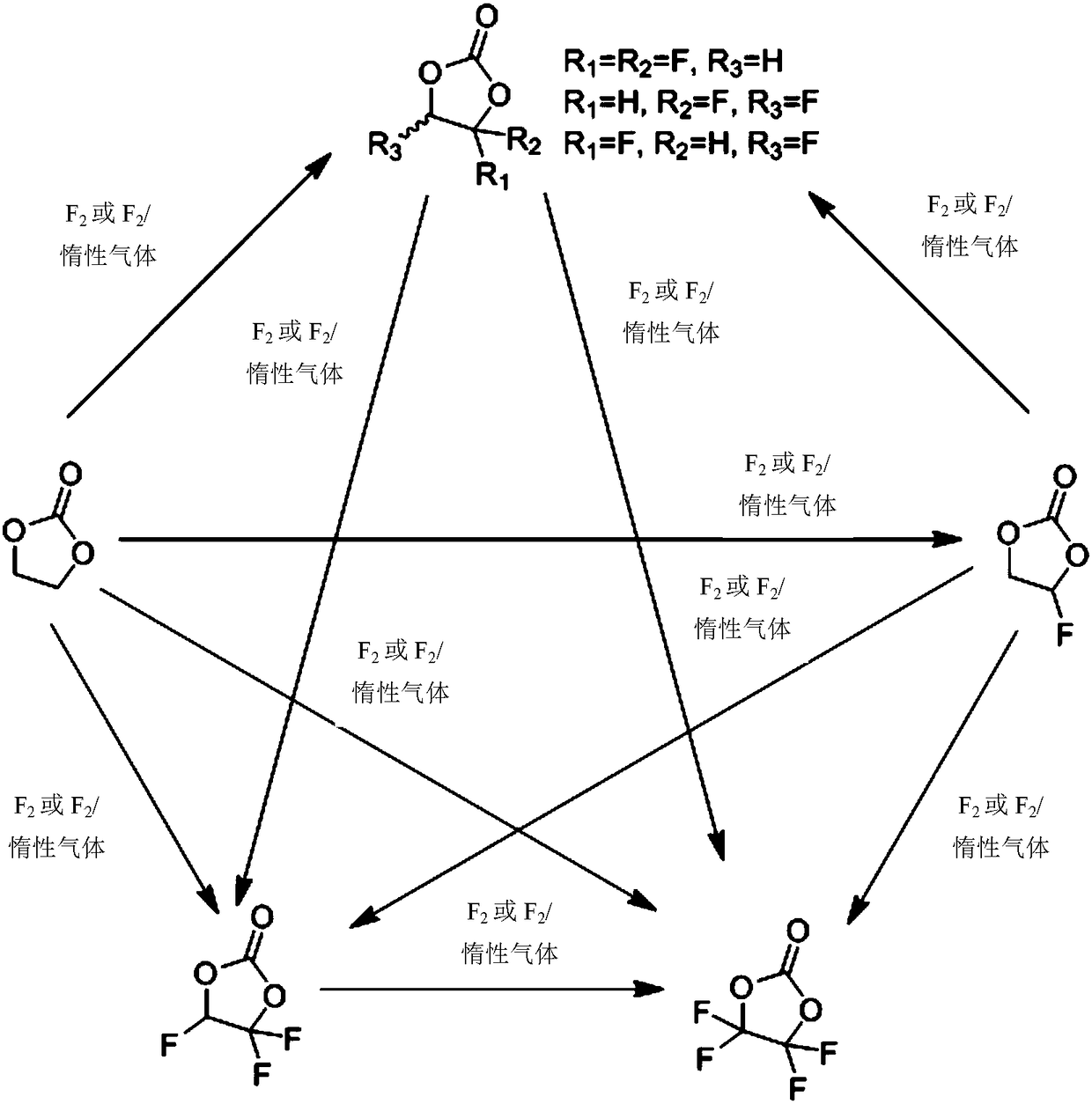

Rapid continuous flow synthesis process of fluoroethylene carbonate

A fluoroethylene carbonate and synthesis process technology, applied in the chemical field, can solve the problems of increasing the overall process control difficulty, the difficulty of the production site operation, the tedious and complicated process operation, and the low production efficiency, and is suitable for industrialized large-scale production. Overcome the amplification effect, overcome the effect of some

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

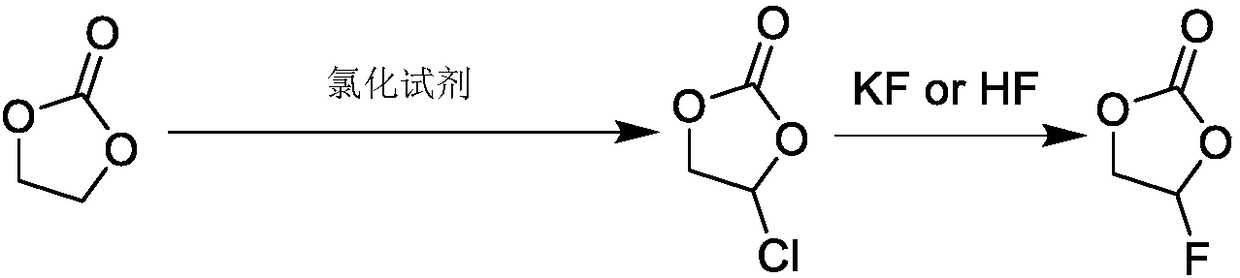

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0121] Fluoroethylene carbonate example:

[0122] In this embodiment, the concentrations of the raw materials to be fluorinated are all mass concentrations, and the concentrations of fluorine elemental substances in the fluorine gas are all volume concentrations, and the purity of the product is detected by gas chromatography (GC).

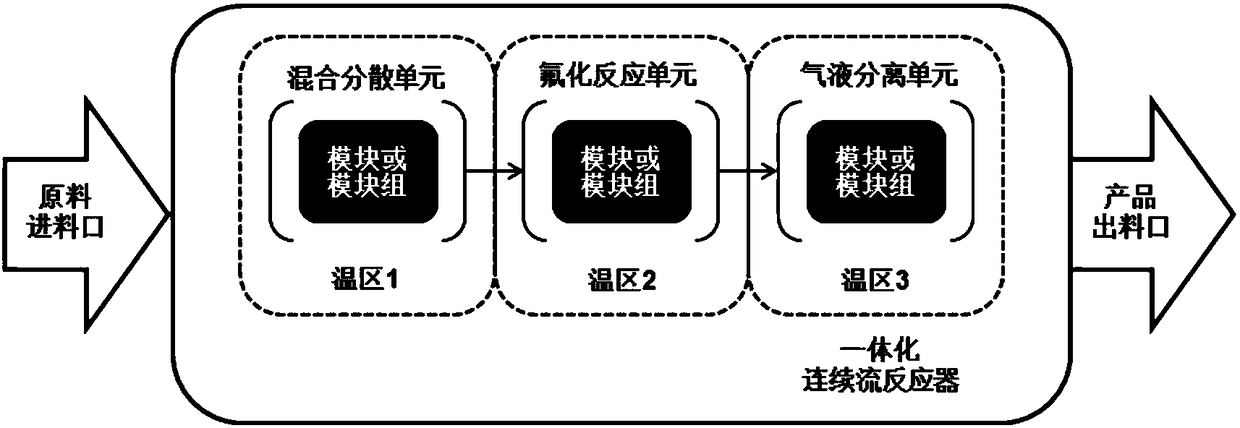

[0123] Among them, the temperature of temperature zone 1 is T1; the temperature of temperature zone 2 is T2; the temperature of temperature zone 3 is T3.

[0124] Raw material 1 (ethylene carbonate) is transported by constant flow pump, raw material 2 (20% F 2 and 80% N 2 Mixed gas) is introduced through the pipeline, and the two are in contact with the temperature zone 1, and flow through the temperature zone 1 to fully mix and initially react. The mixture flowing out of temperature zone 1 enters into temperature zone 2, and flows through temperature zone 2 where fluorinated ethylene carbonate corresponding to fluorinated reaction occurs until ...

Embodiment 2-6

[0129] Using the operating method of Example 1, the preparation of monofluoroethylene carbonate under different reaction parameters was investigated, and each parameter condition and results are shown in the table below.

[0130]

[0131]

[0132] *average value

Embodiment 7-11

[0134] Using the operating method of Example 1, the preparation of difluoroethylene carbonate under different reaction parameters was investigated, and the conditions and results of each parameter are shown in the table below.

[0135]

[0136]

[0137] *average value

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com