Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

147 results about "Crystal habit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mineralogy, crystal habit is the characteristic external shape of an individual crystal or crystal group. A single crystal's habit is a description of its general shape and its crystallographic forms, plus how well developed each form is.

Oral osmotic controlled drug delivery system for a sparingly soluble drug

InactiveUS6534090B2Control swellingIncrease in sizePowder deliveryPill deliveryCelluloseHydrophilic polymers

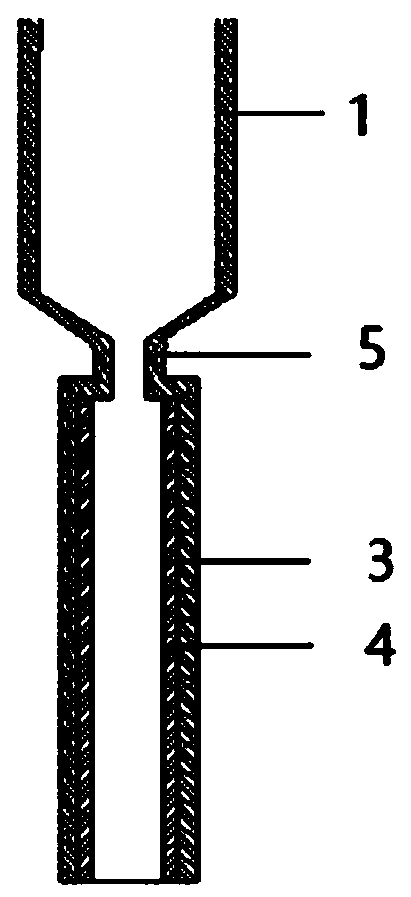

The present invention is for an oral osmotic controlled drug delivery system for a sparingly soluble drug comprising:a. a core comprising (i) finely particulate anhydrous carbamazepine (ii) a polymeric swelling agent consisting of one or more swellable hydrophilic polymers selected such that the polymeric swelling agent exhibits controlled swelling and the wall does not rupture or burst, (iii) a crystal habit modifier in whose presence, upon contact with an aqueous medium, the anhydrous carbamazepine being transformed into cuboidal or rod-shaped crystals of the dihydrate of carbamazepine, or mixtures thereof, and (iv) water-soluble compounds for inducing osmosis,b. a wall made of acylated cellulose which is impermeable to the components of the core, but permeable to water, andc. a passageway through the wall for releasing the components present in the core to the surrounding environment.

Owner:SUN PHARMA INDS

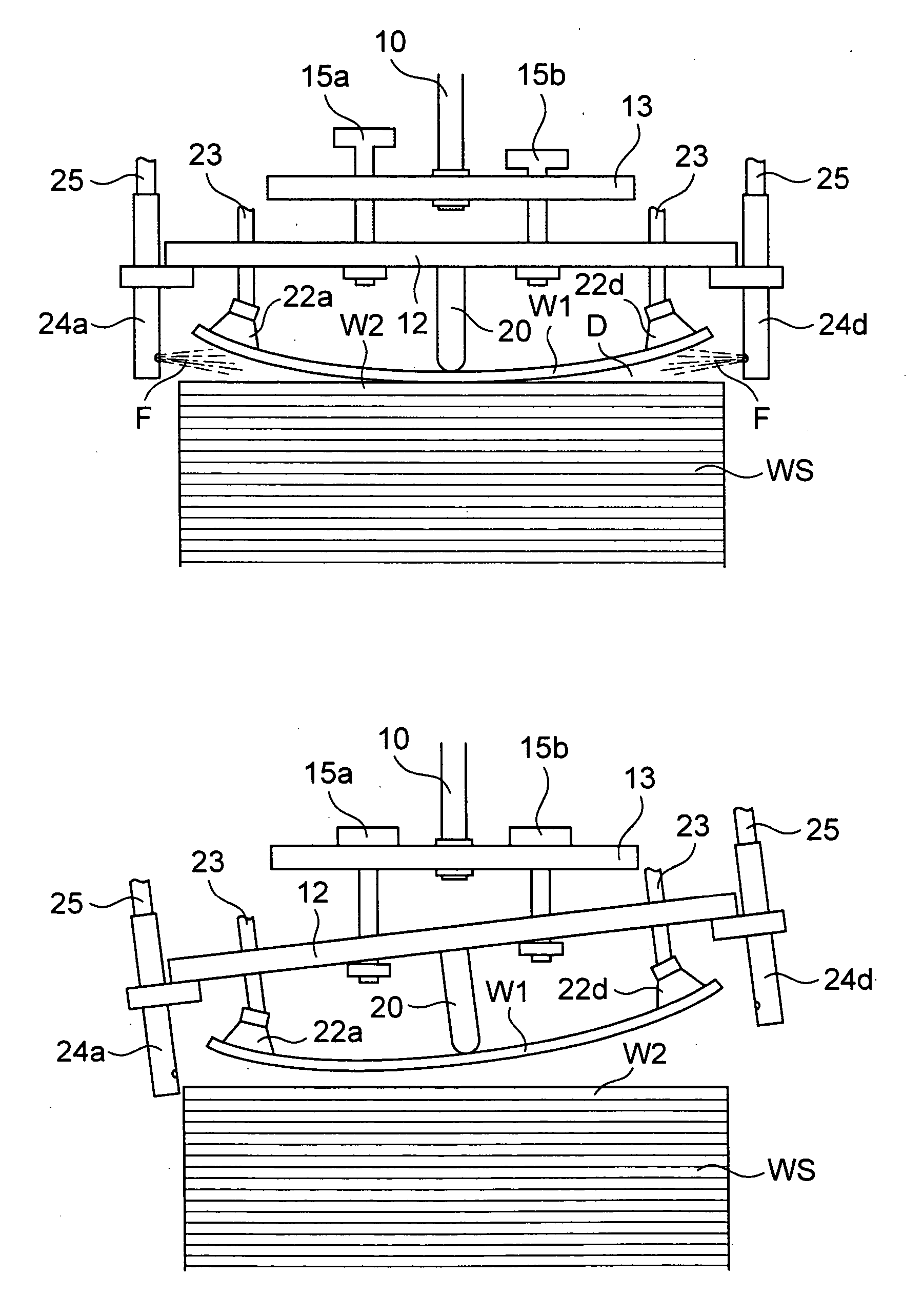

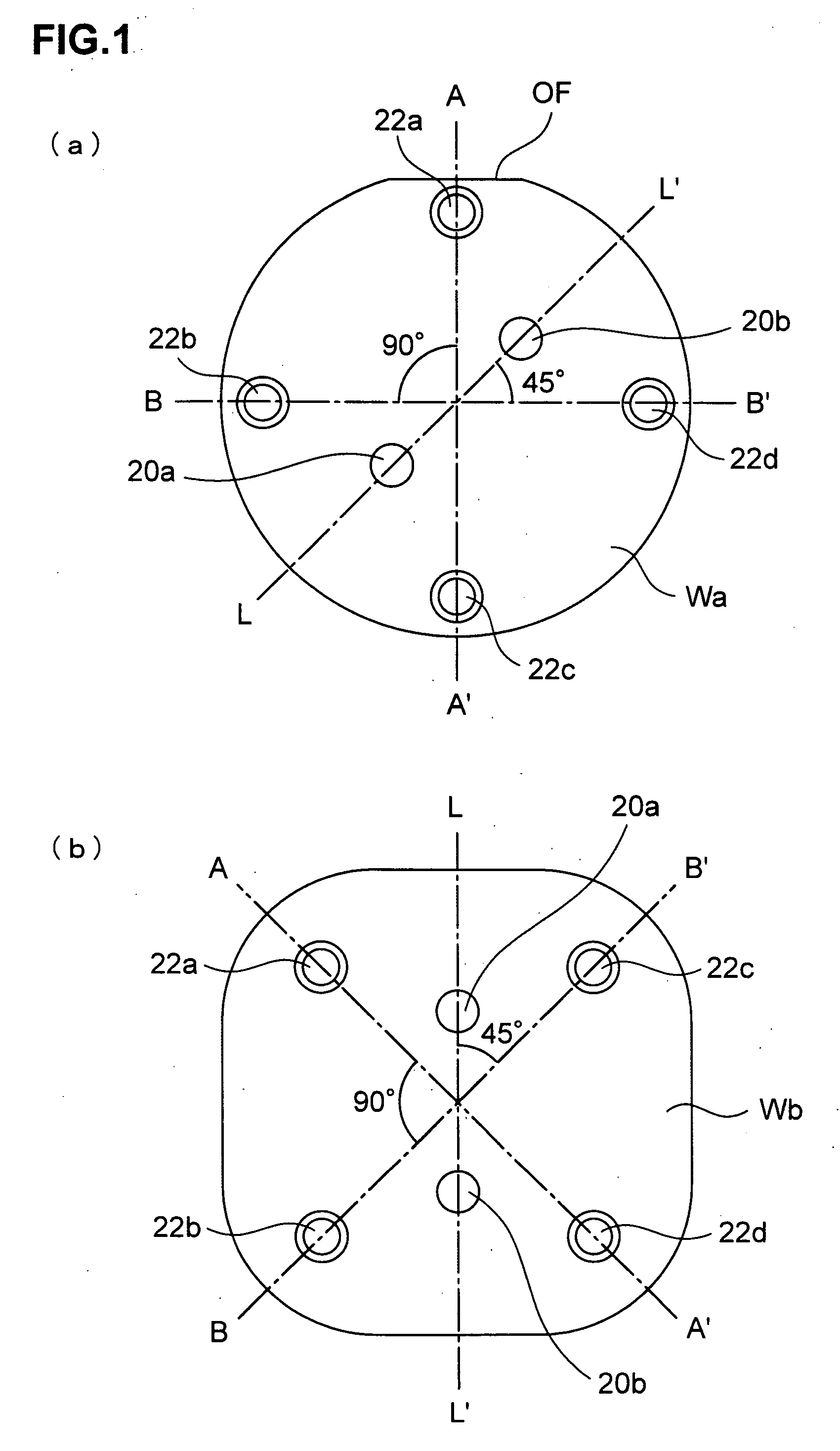

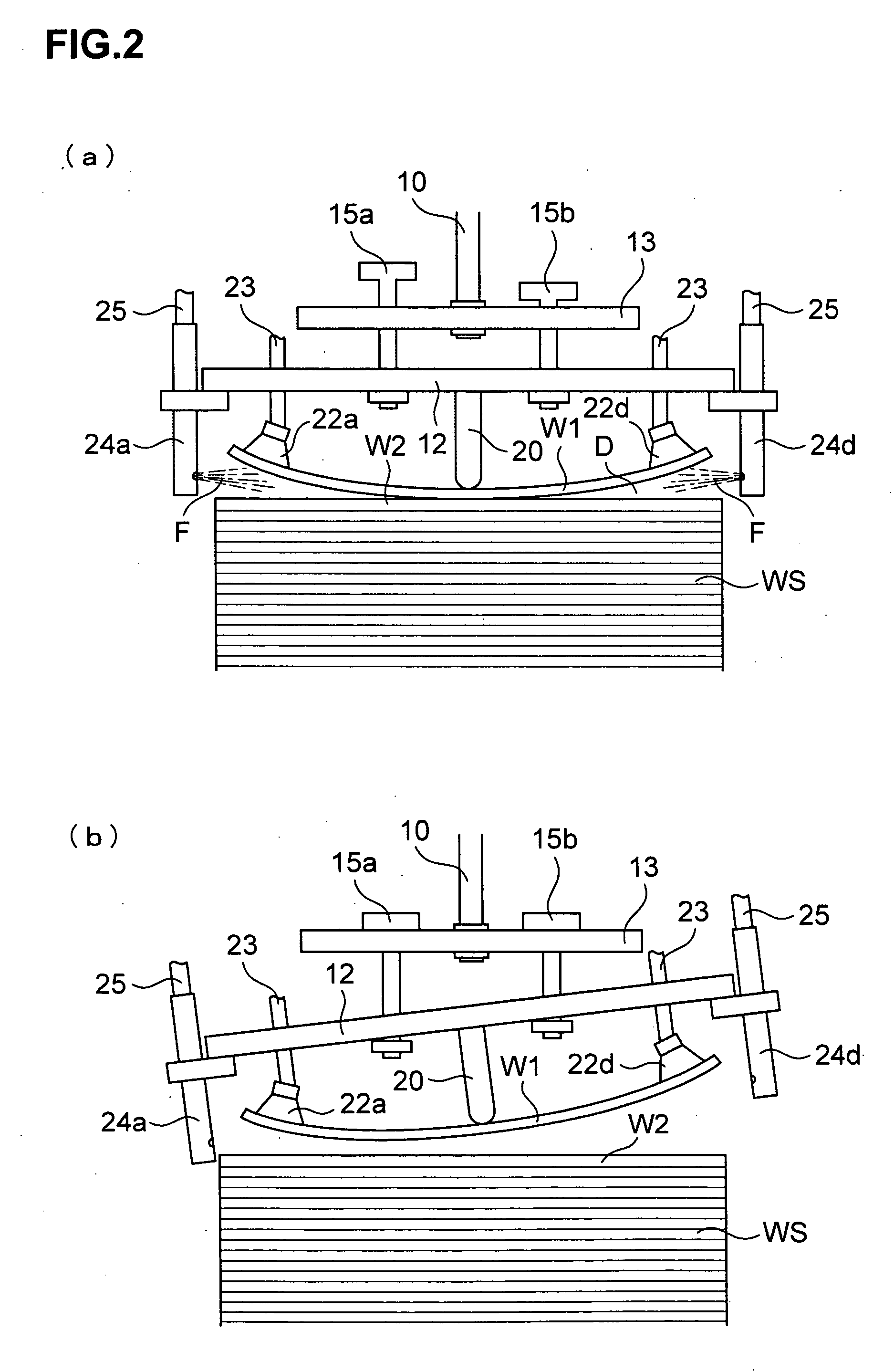

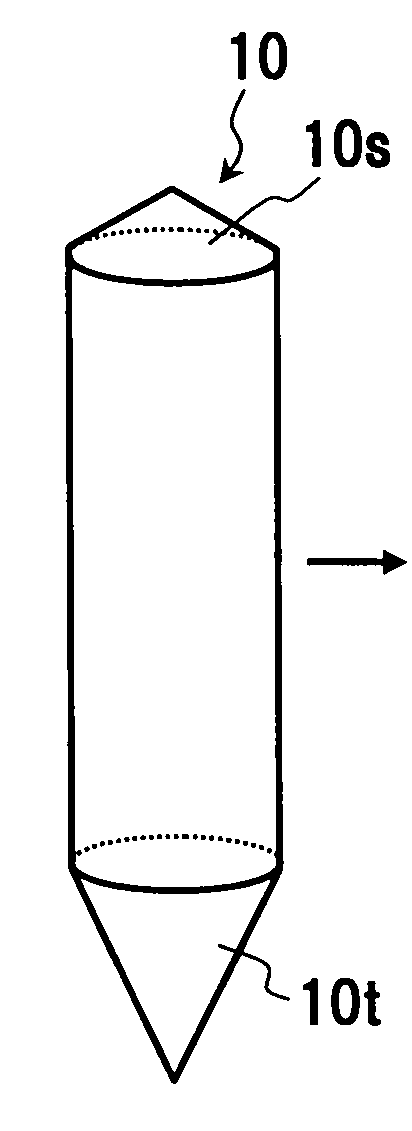

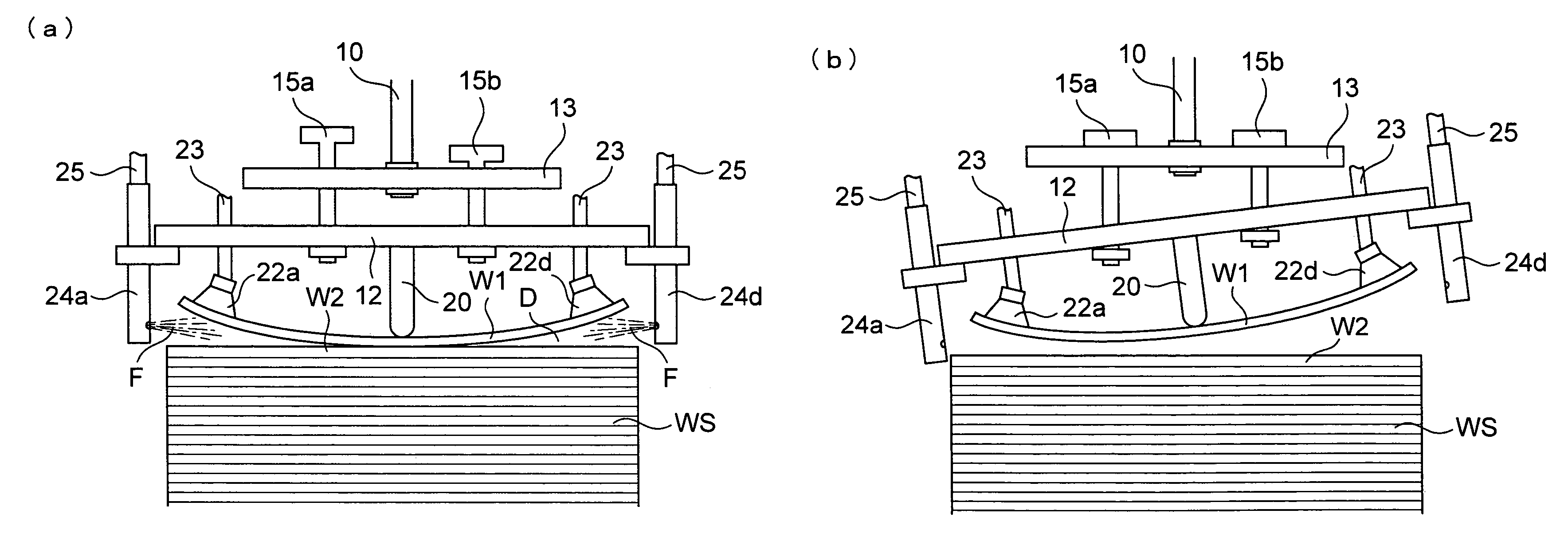

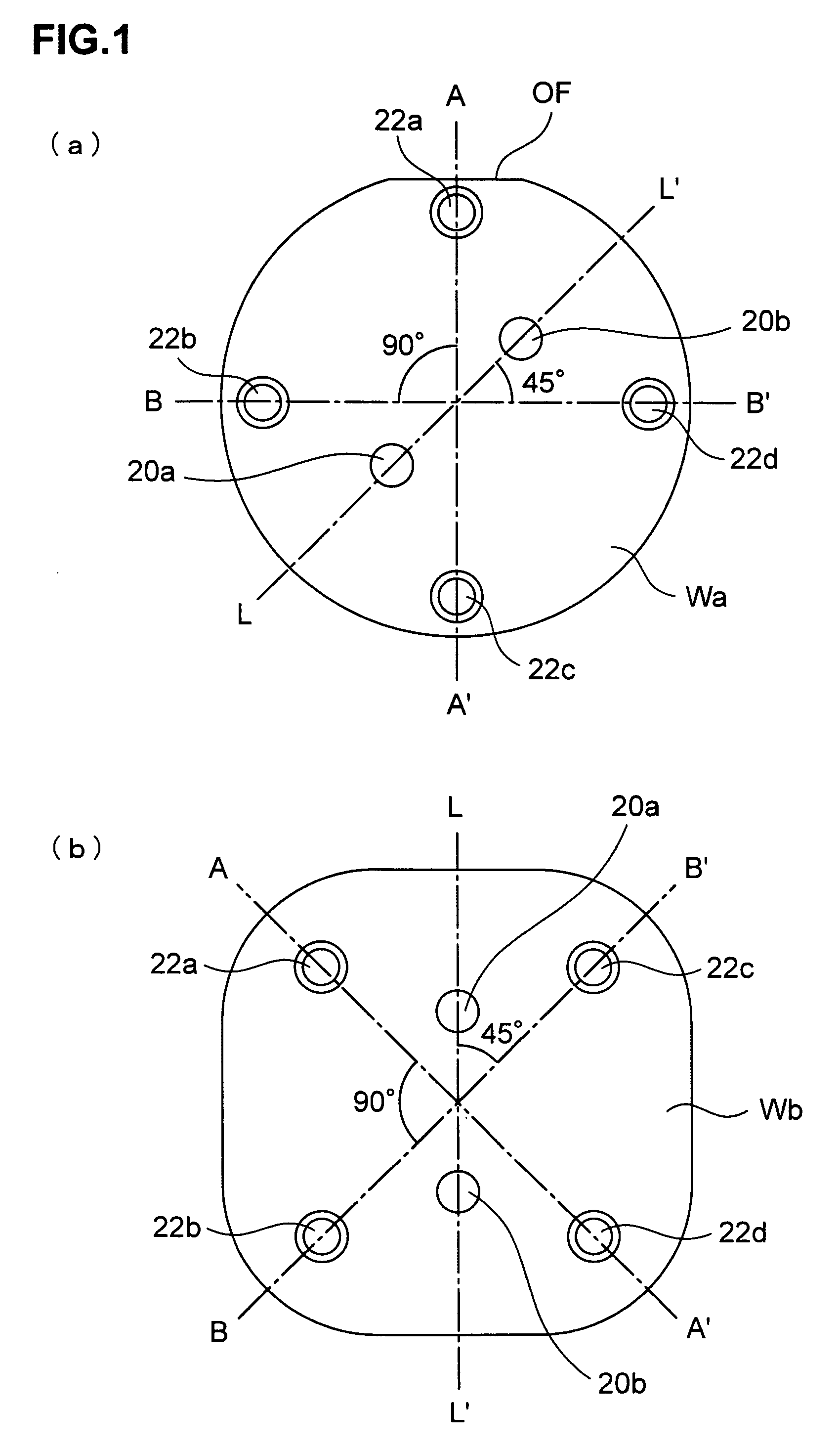

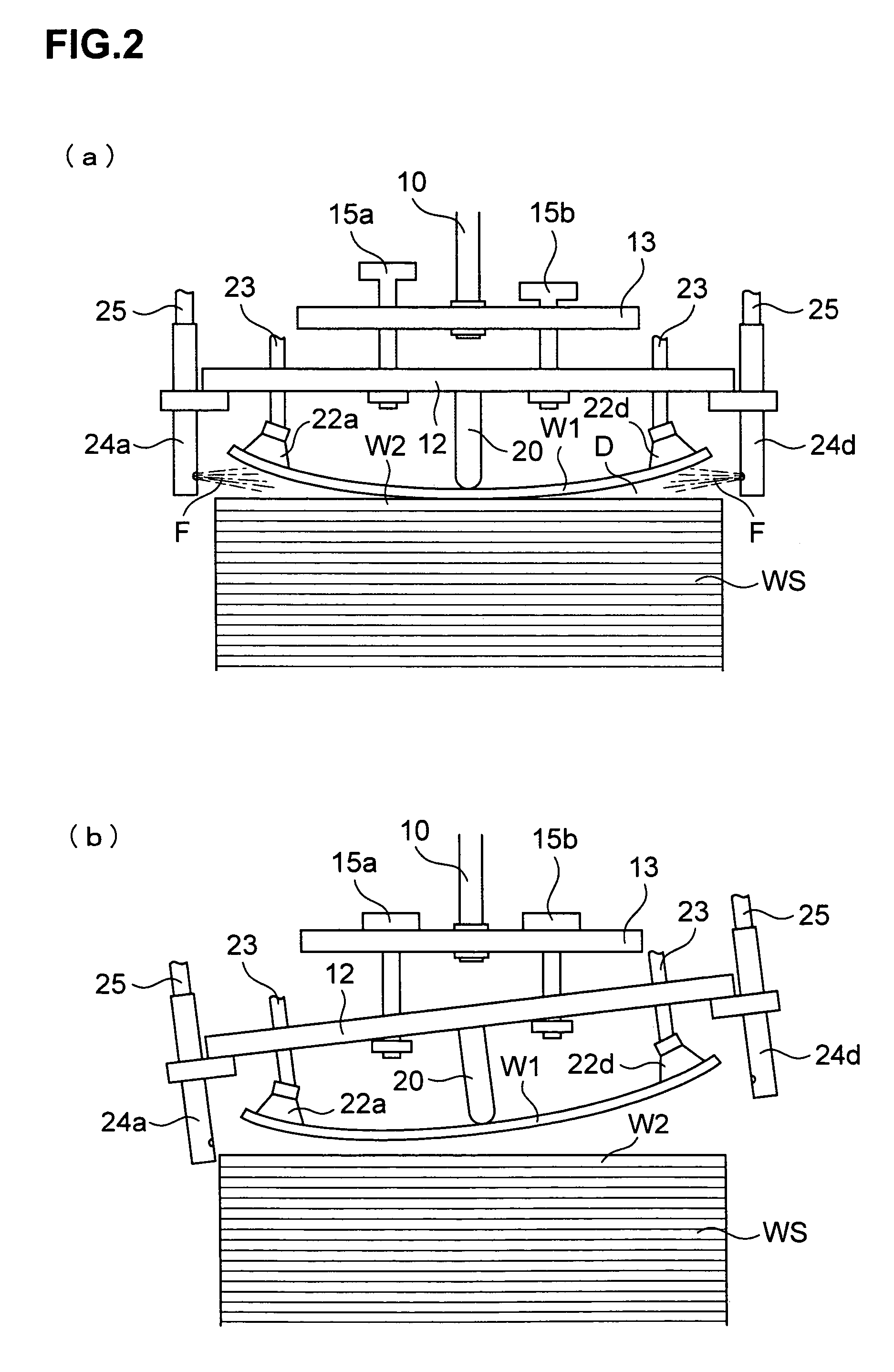

Wafer demounting method, wafer demounting device, and wafer demounting and transferring machine

ActiveUS20060286769A1Improve processing efficiencyHighly convenientSemiconductor/solid-state device manufacturingArticle separationEngineeringCrystal habit

It is an object of the present invention to provide a wafer release method capable of releasing a wafer safely, simply and certainly and improving a wafer releasing rate, a wafer release apparatus and a wafer release transfer machine using the wafer release apparatus. A wafer release method of the present invention comprises the steps of: pressing the uppermost wafer along an axis direction (L-L′) shifted by an angle in the range of from 15 to 75 degrees from a crystal habit line axis (A-A′) or (B-B′) of the uppermost wafer clockwise or counterclockwise; bending upwardly the peripheral portion of the uppermost wafer so as to cause a bending stress in the uppermost wafer in the axis direction (L-L′) shifted by the angle; blowing a fluid into a clearance between the lower surface of the uppermost wafer and the upper surface of the lower wafer adjacent thereto; and raising the uppermost wafer for releasing.

Owner:MIMASU SEMICON IND CO LTD

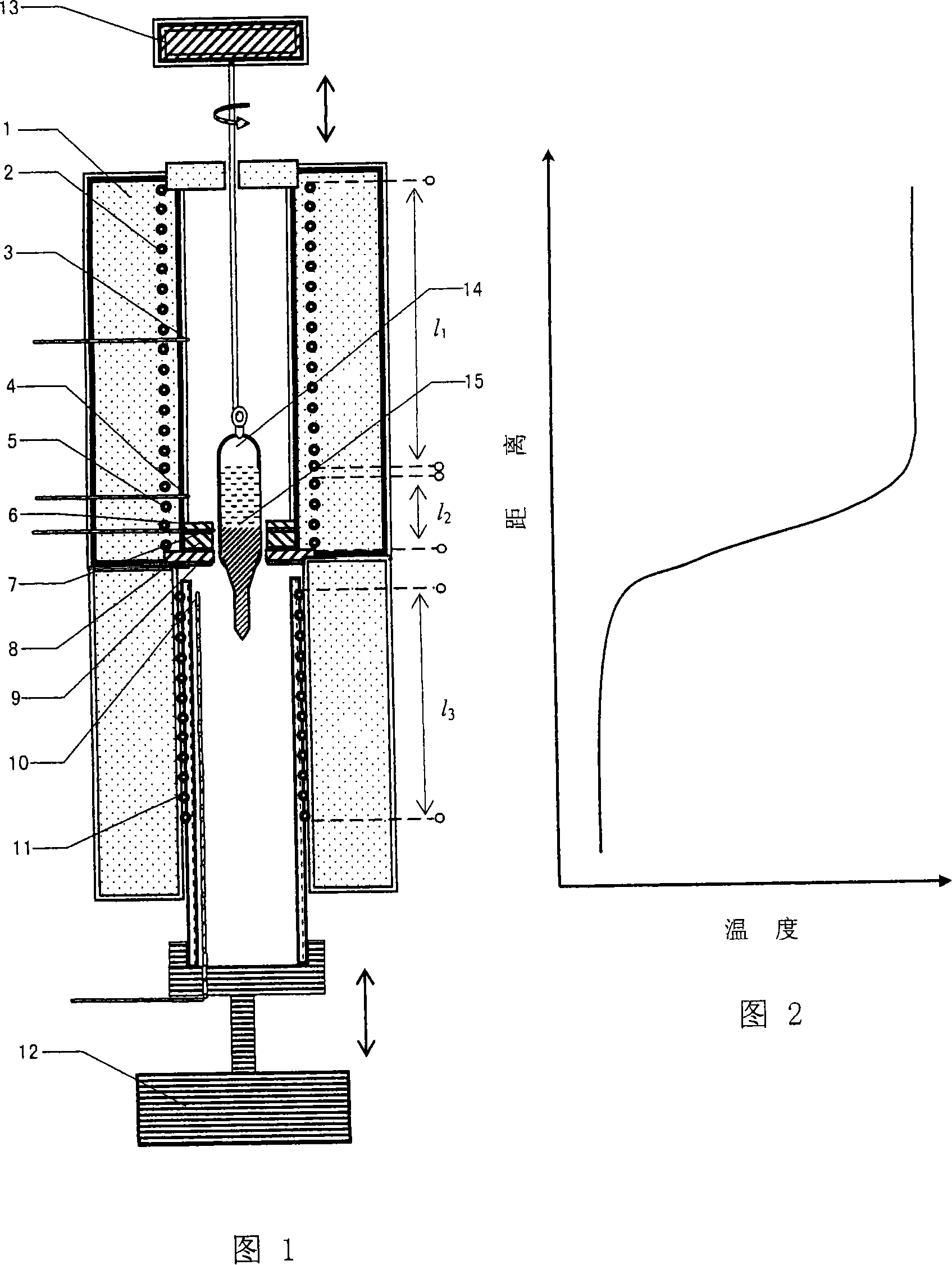

Preparation method for multi-element compounds semiconductor single-crystal and growth device thereof

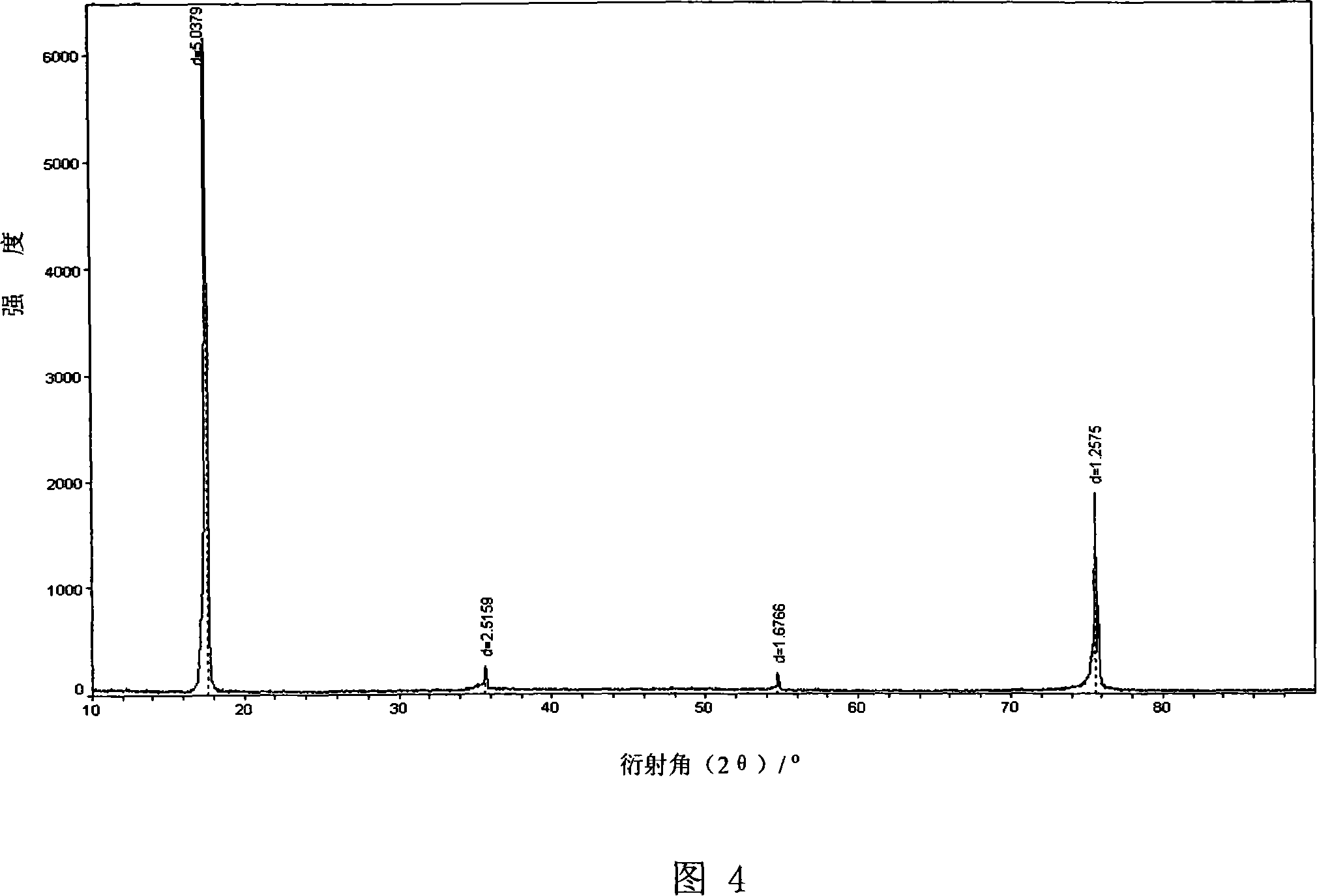

InactiveCN101122045ARealize temperature field adjustmentComplete appearanceFrom frozen solutionsCrucibleSingle crystal

A method for preparing a multi-component semiconductor single crystal, the process steps are: (1) cleaning a crucible, (2) charging and degassing and sealing, (3) crystal growth, and (4) annealing and cooling. The single crystal growth device matched with this method includes a movable lower furnace heater and a single crystal growth furnace with an auxiliary heater in the middle, which can flexibly adjust the temperature field in the crystallization temperature gradient area according to the crystallization habit of the multi-component compound, and obtain The narrow temperature zone and large temperature gradient crystallization temperature field distribution required for the growth of compound single crystals maintain the stability of the solid-liquid interface and realize the flat interface growth of single crystals. Using the growth device, various multi-element compound semiconductor single crystals with complete appearance and good crystallization performance can be successfully grown by adopting the crucible descending method.

Owner:SICHUAN UNIV

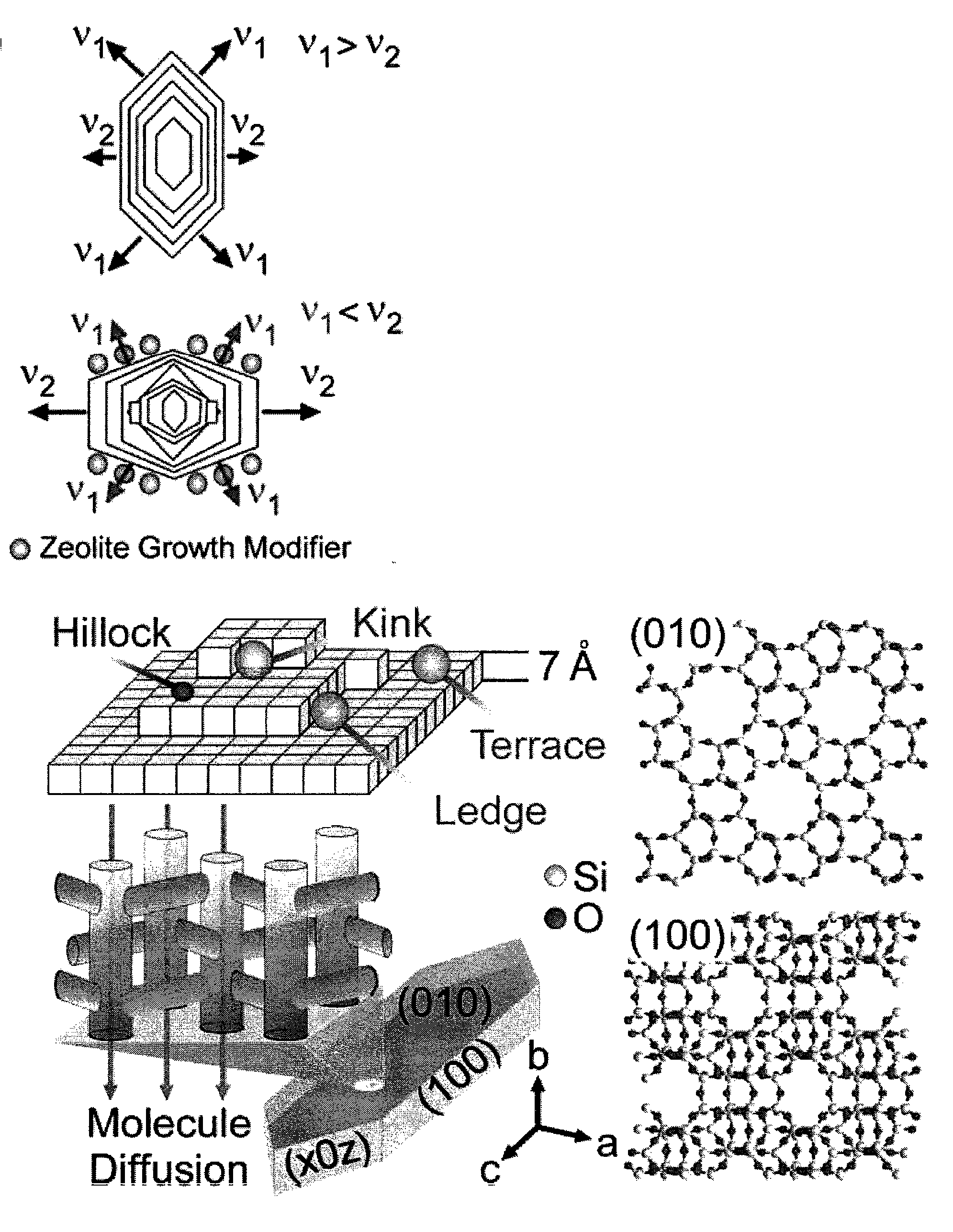

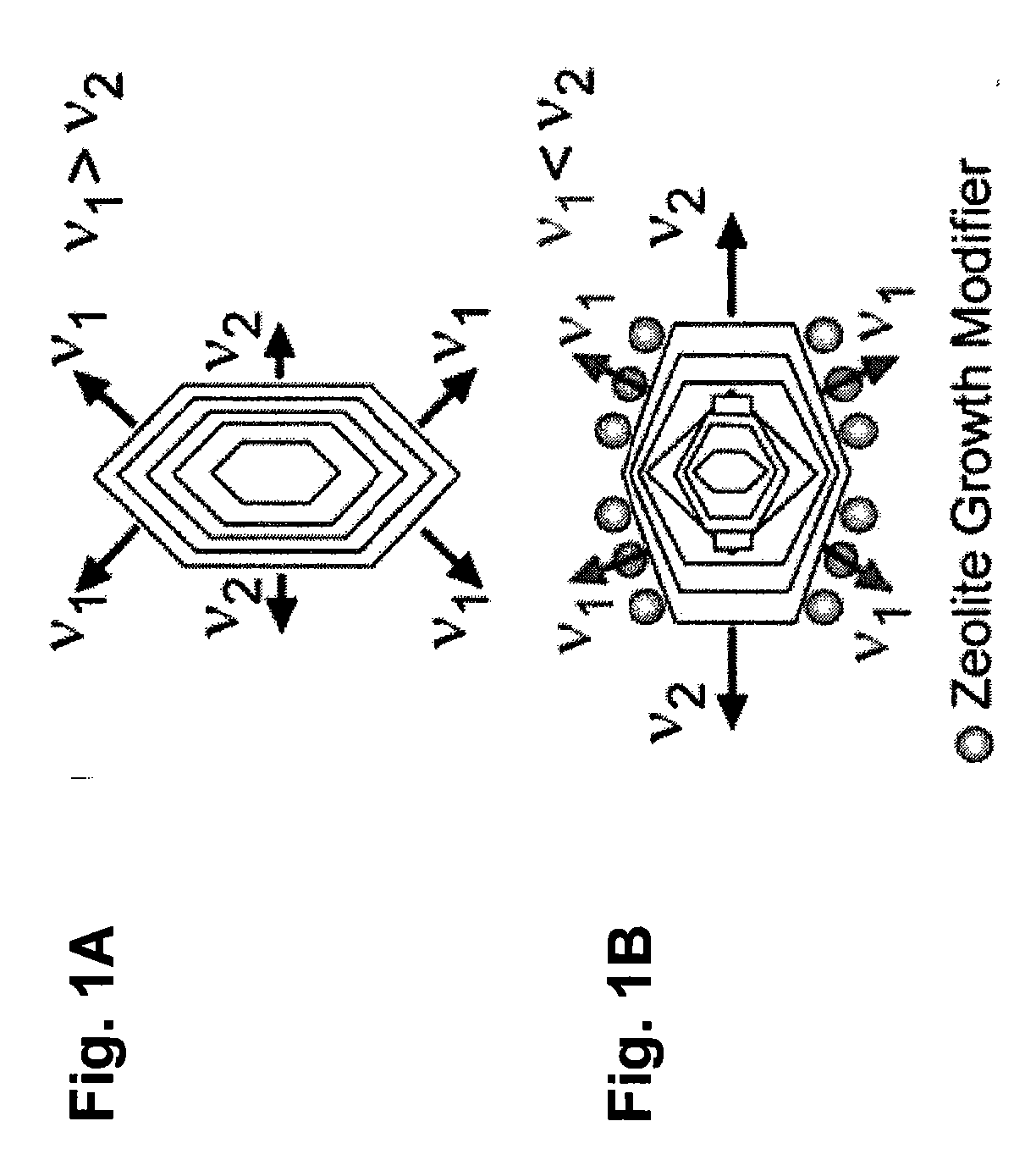

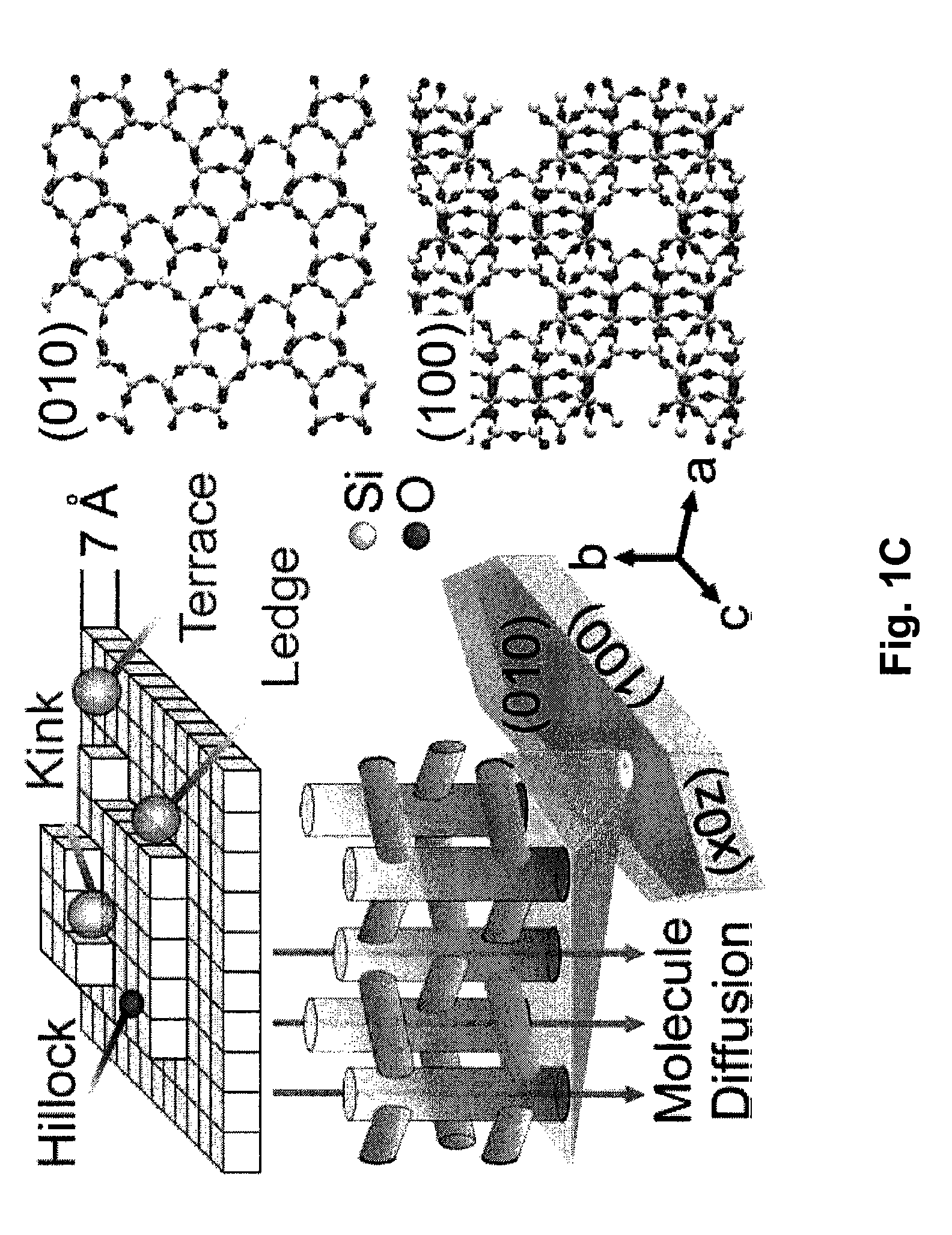

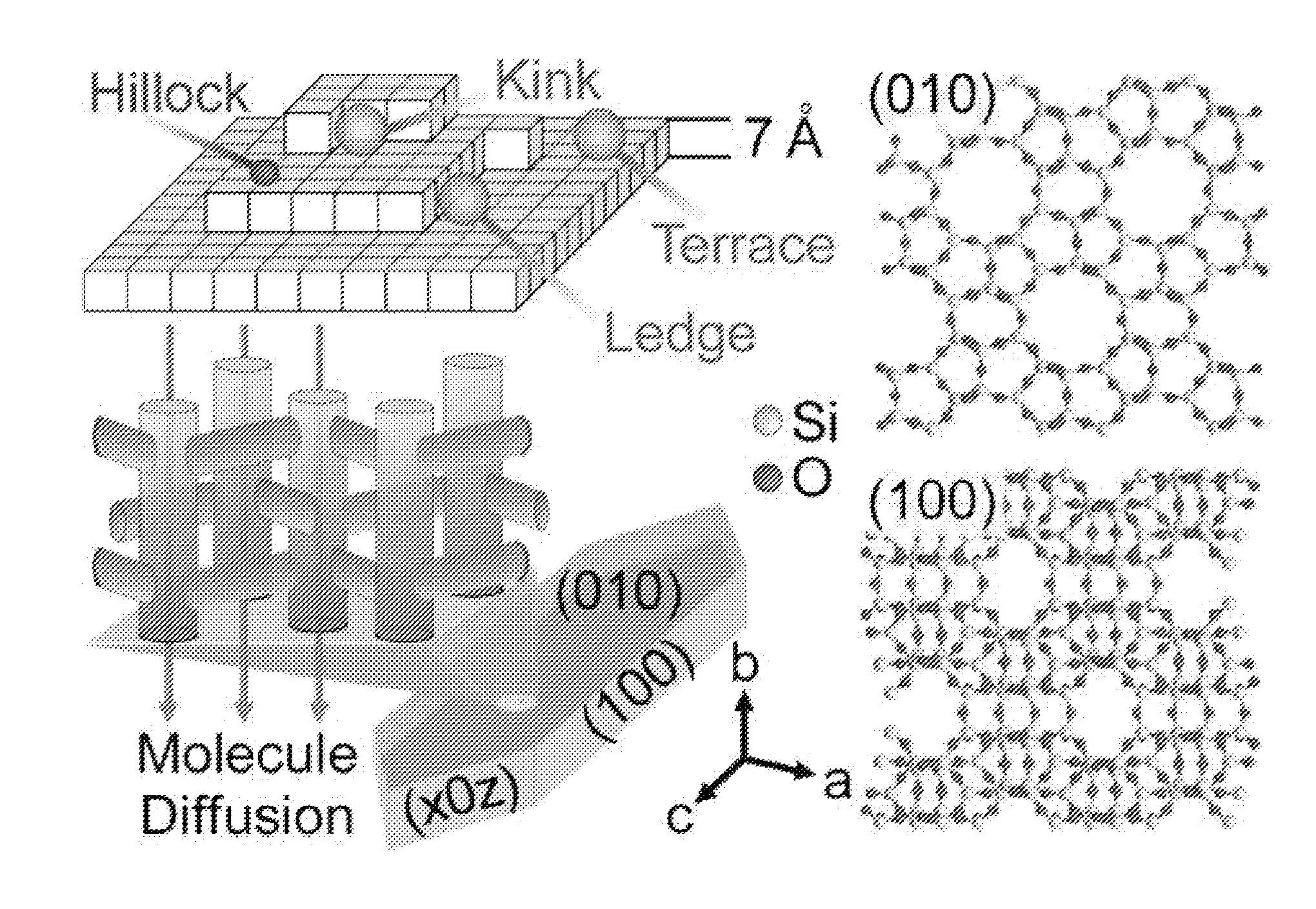

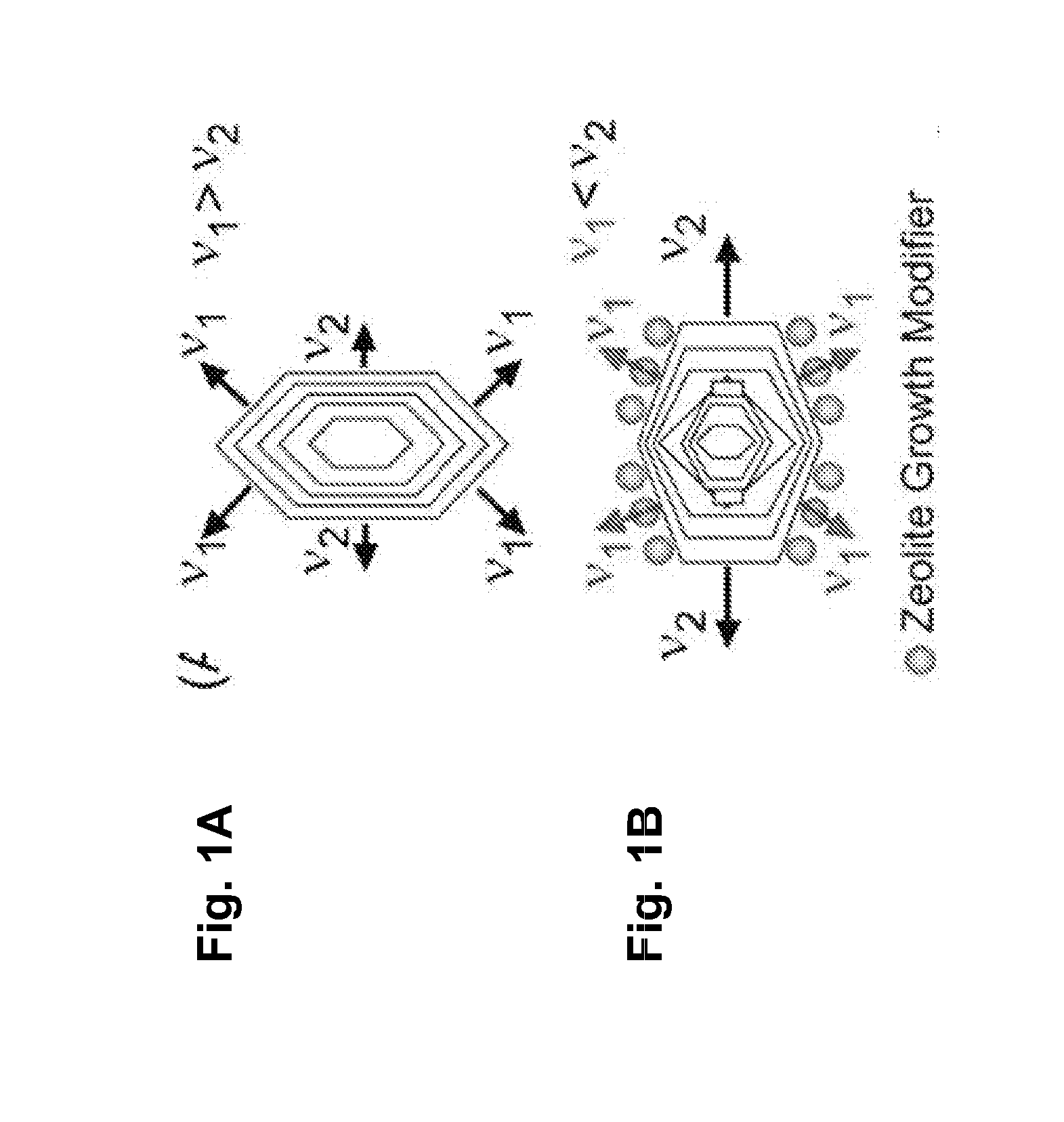

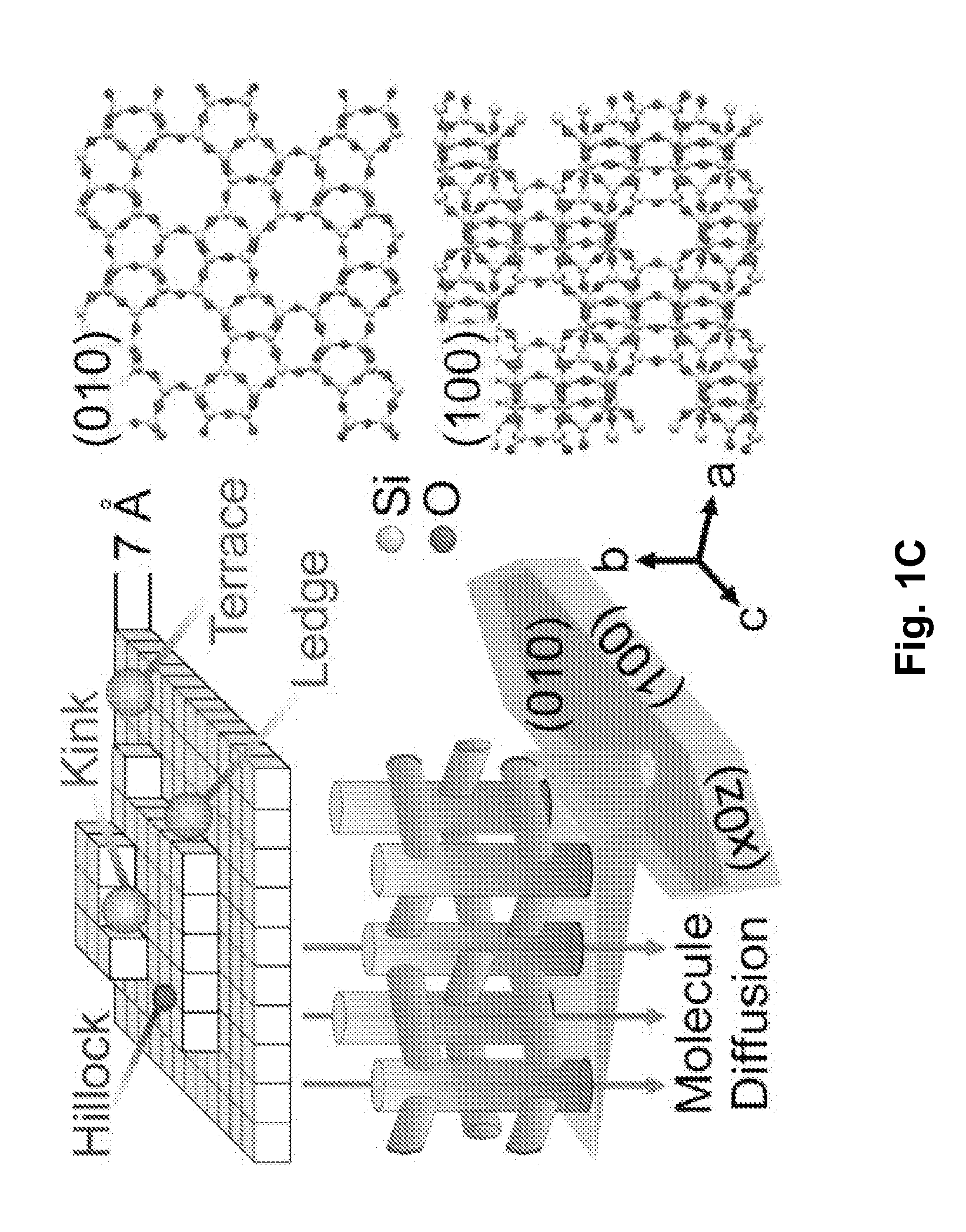

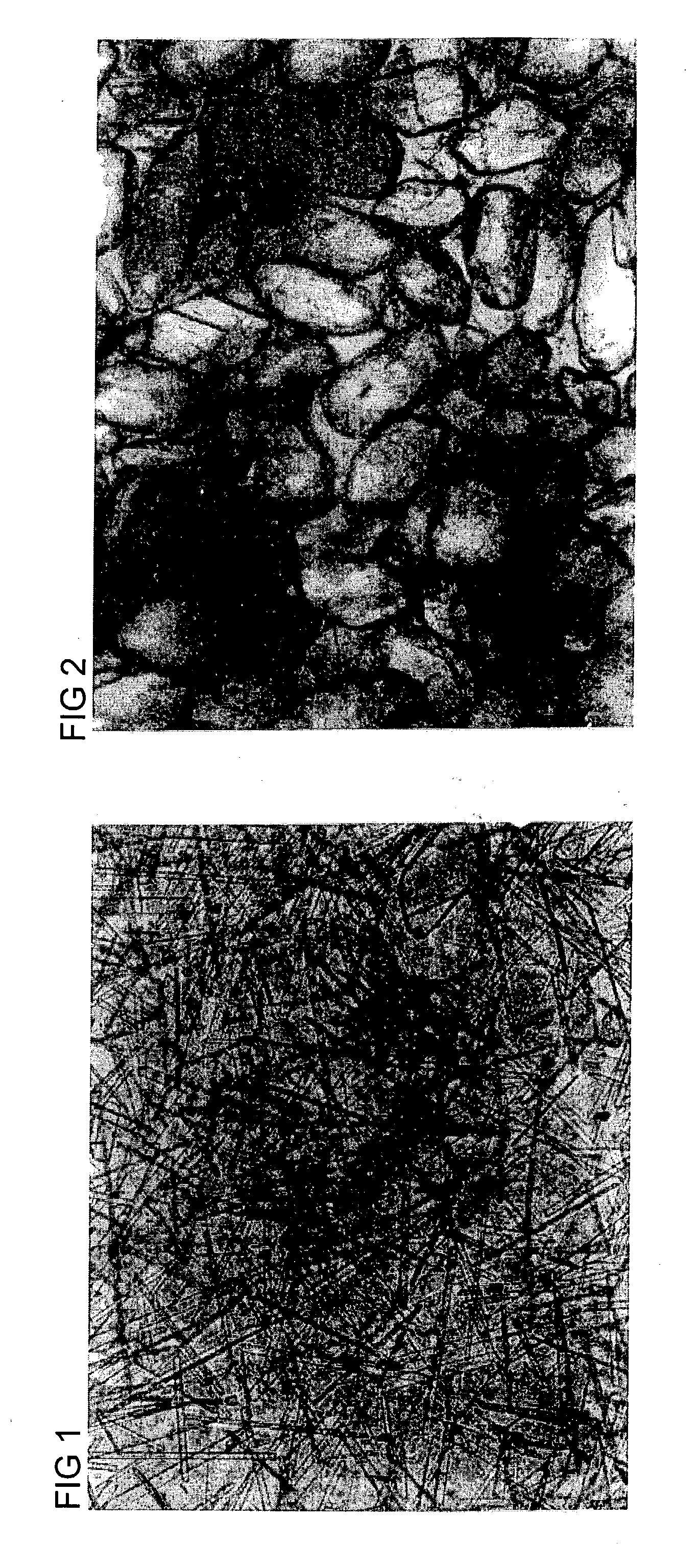

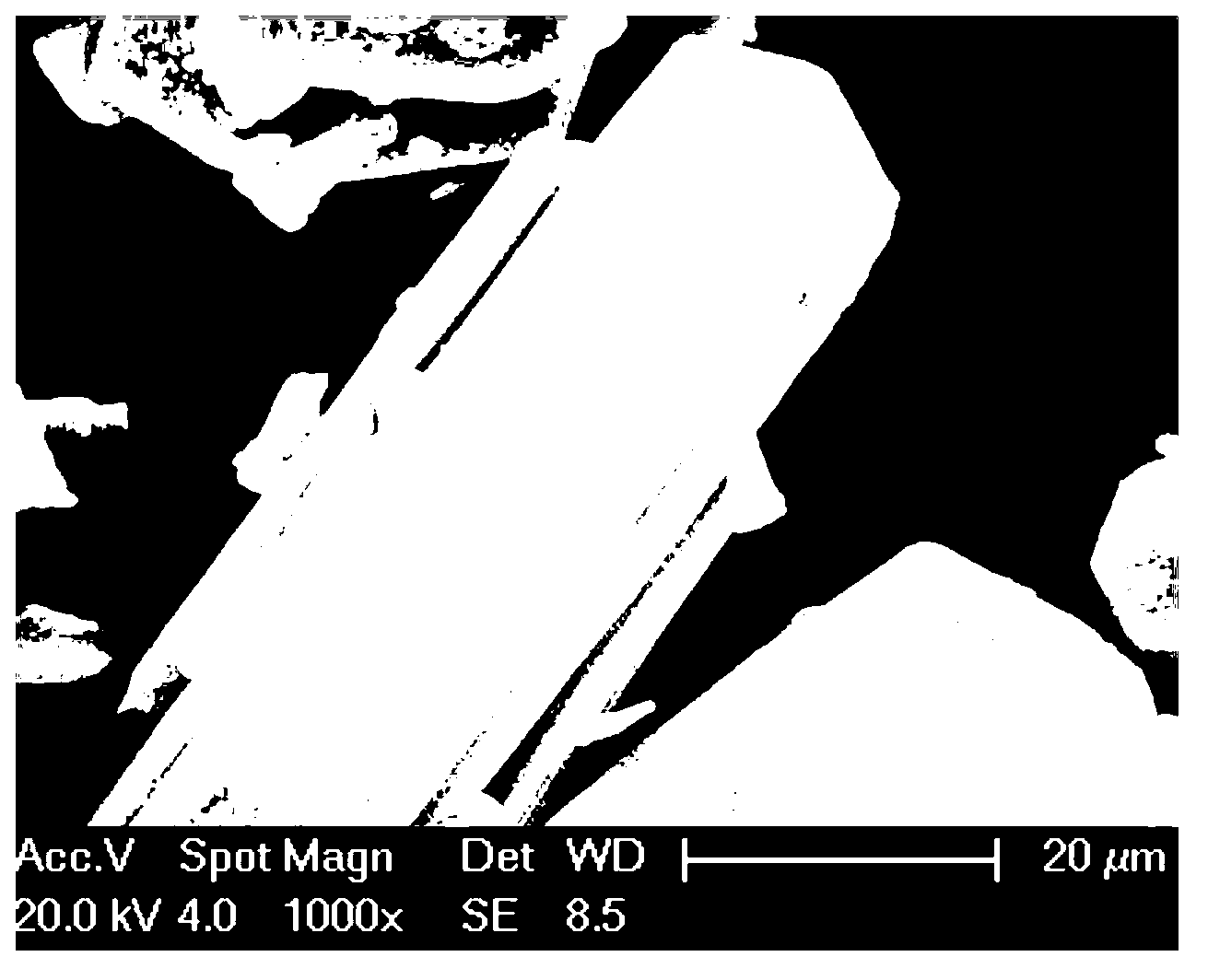

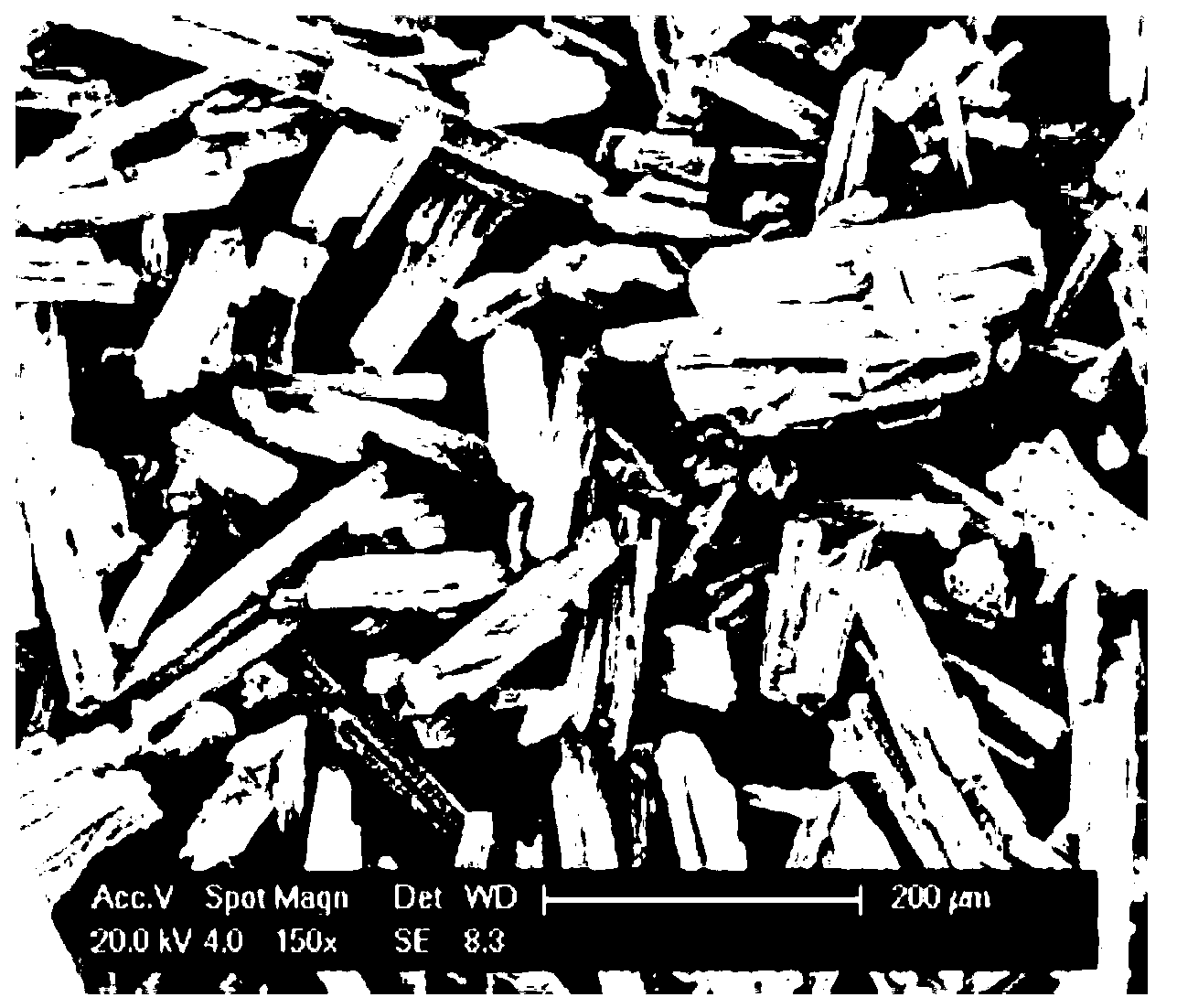

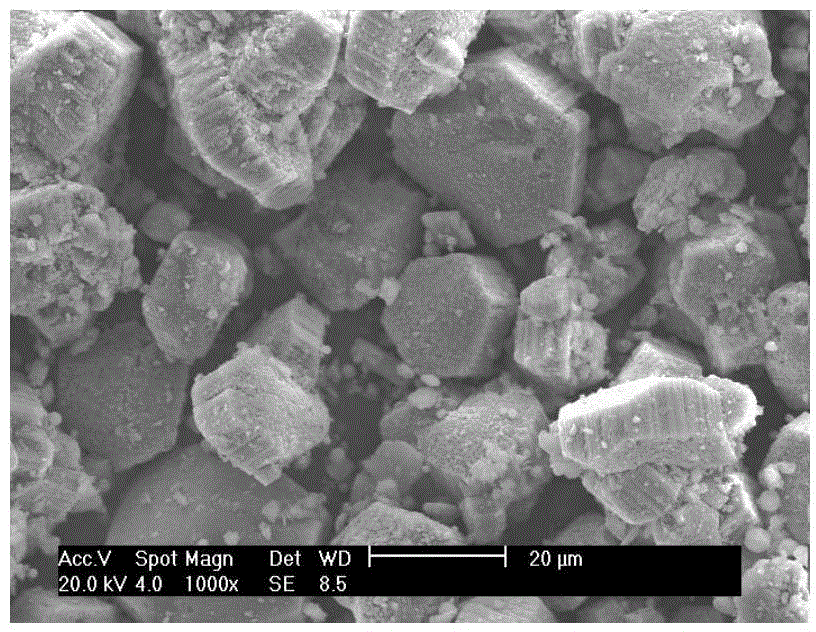

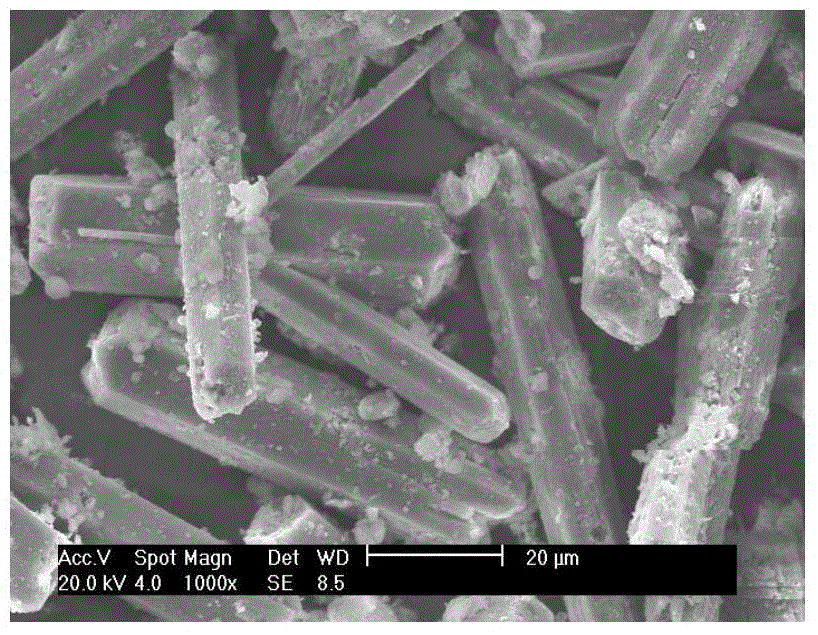

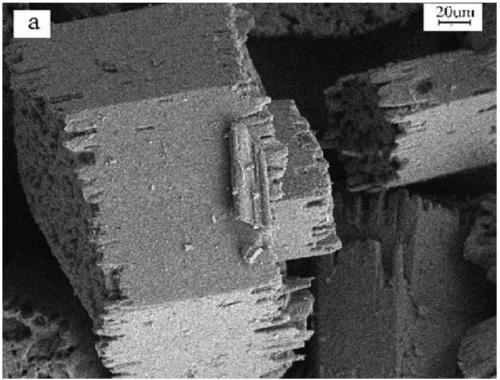

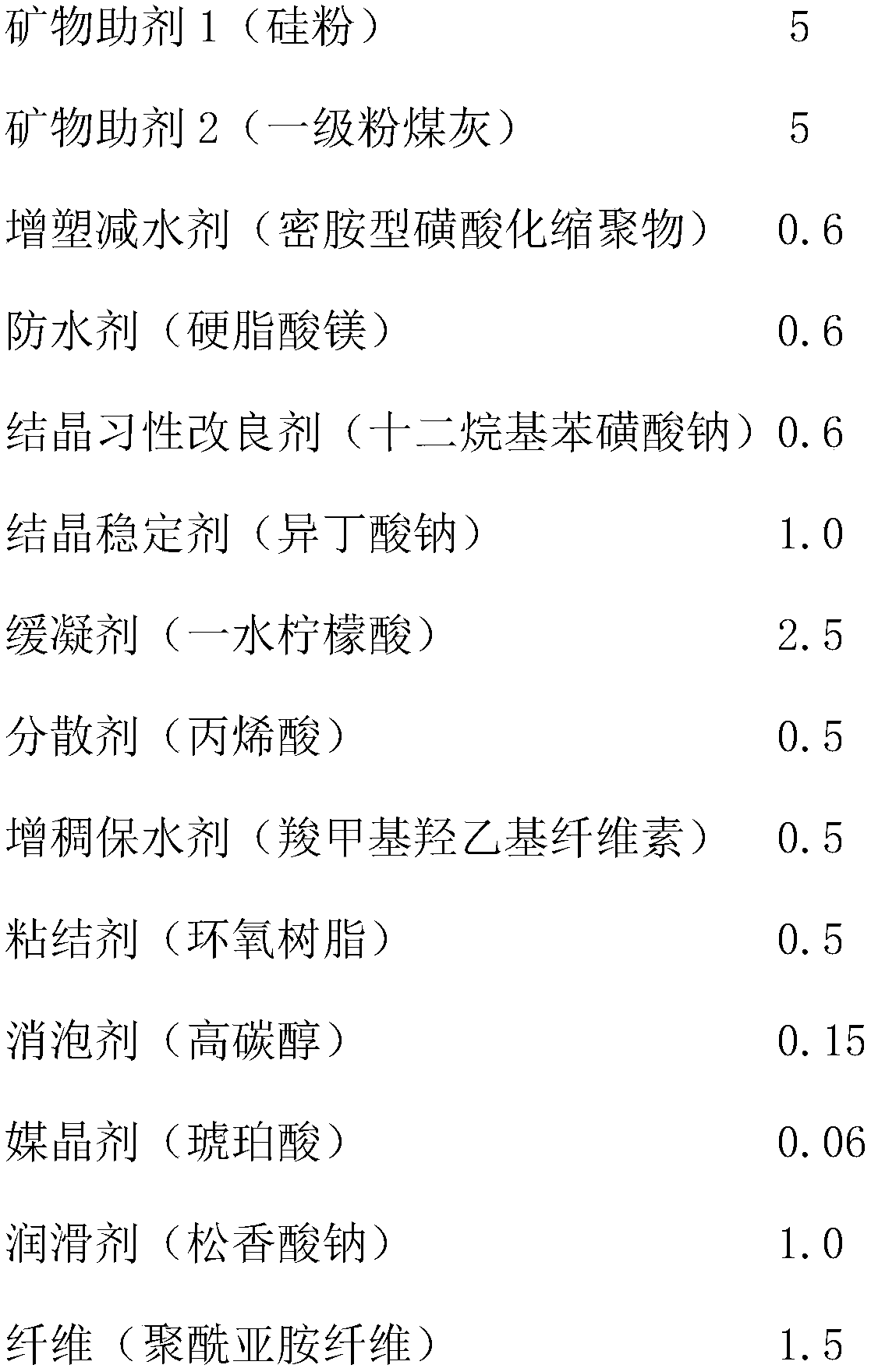

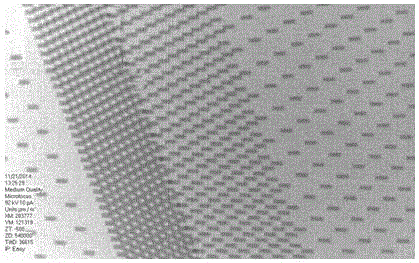

Zeolite compositions and methods for tailoring zeolite crystal habits with growth modifiers

InactiveUS20120202006A1Minimized crystal thicknessShortened internal diffusion pathlengthPolycrystalline material growthFrom normal temperature solutionsCrystal habitCrystal growth rate

Embodiments of the invention generally provide compositions of crystalline zeolite materials with tailored crystal habits and the methods for forming such crystalline zeolite materials. The methods for forming the crystalline zeolite materials include binding one or more zeolite growth modifiers (ZGMs) to the surface of a zeolite crystal, which results in the modification of crystal growth rates along different crystallographic directions, leading to the formation of zeolites having a tailored crystal habit. The improved properties enabled by the tailored crystal habit include a minimized crystal thickness, a shortened internal diffusion pathlength, and a greater step density as compared to a zeolite having the native crystal habit prepared by traditional processes. The tailored crystal habit provides the crystalline zeolite materials with an aspect ratio of about 4 or greater and crystal surfaces having a step density of about 25 steps / μm2 or greater.

Owner:UNIV HOUSTON SYST

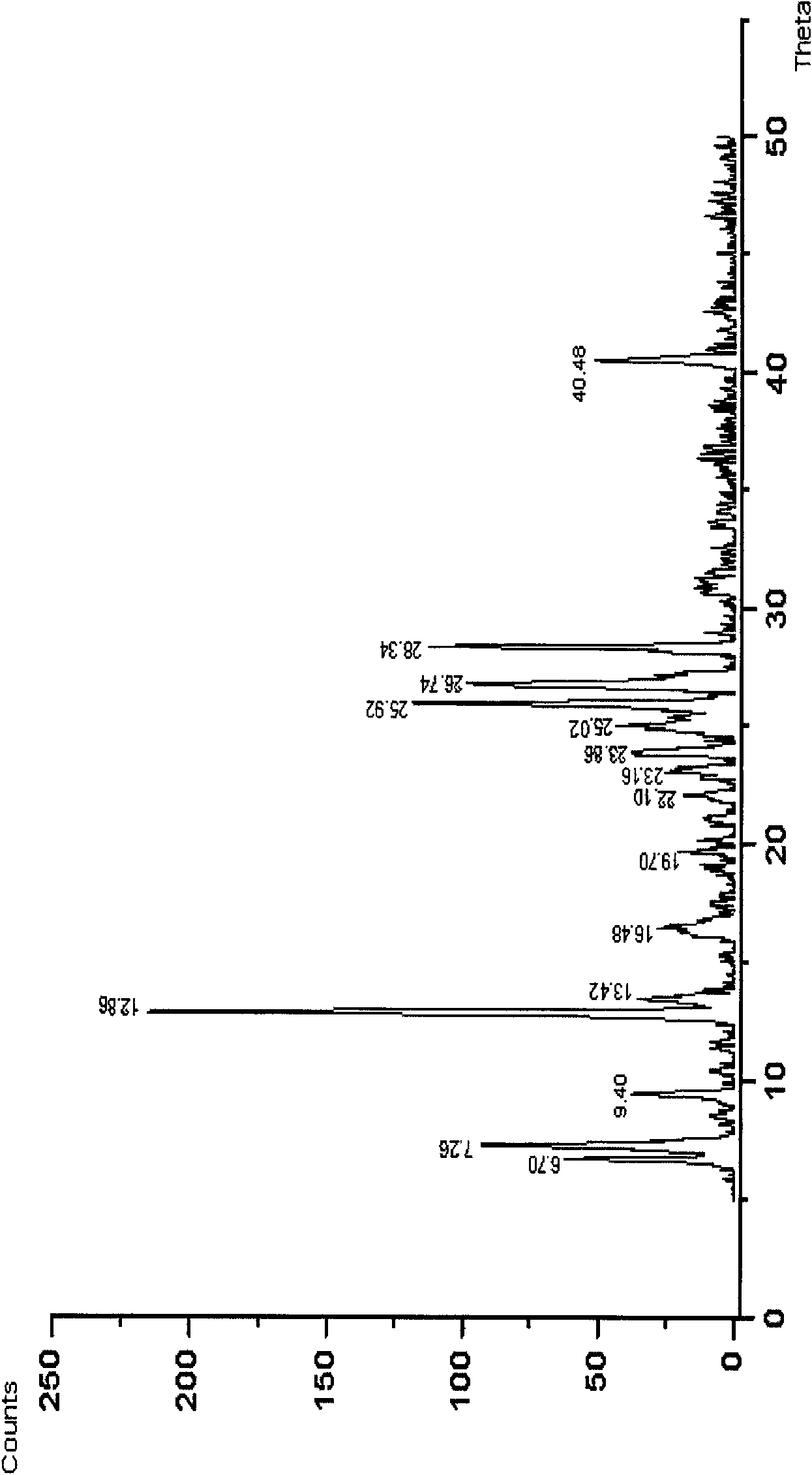

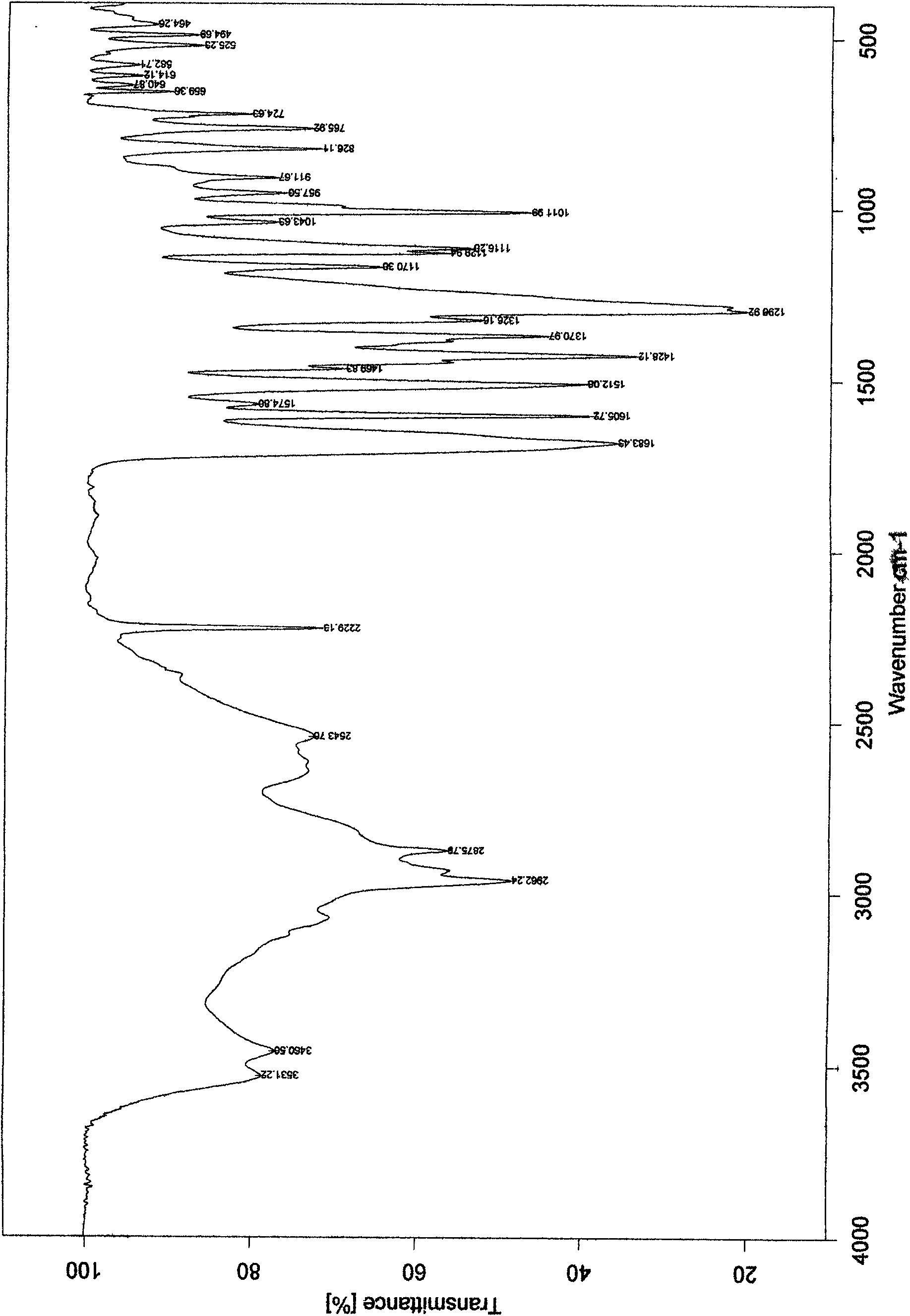

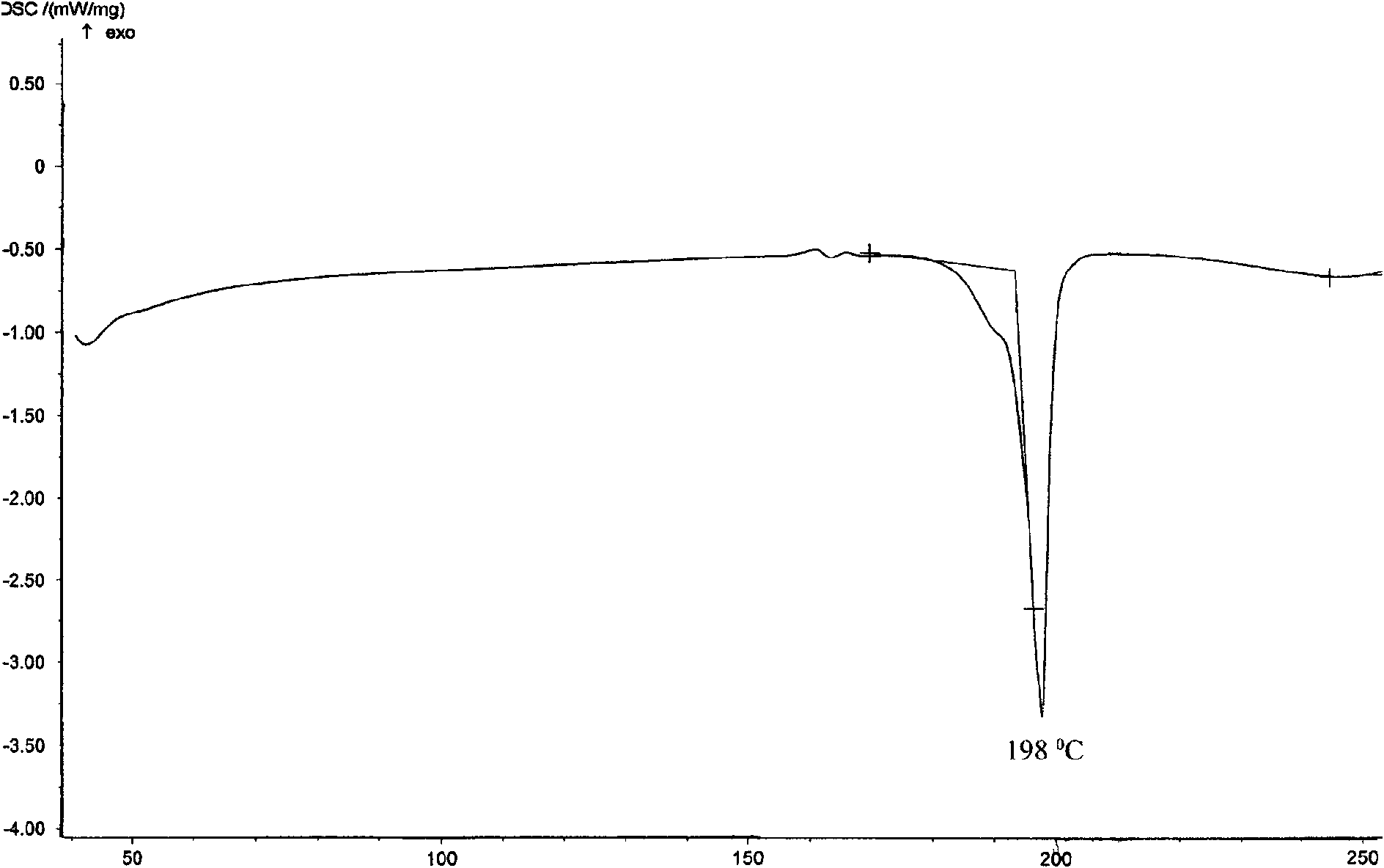

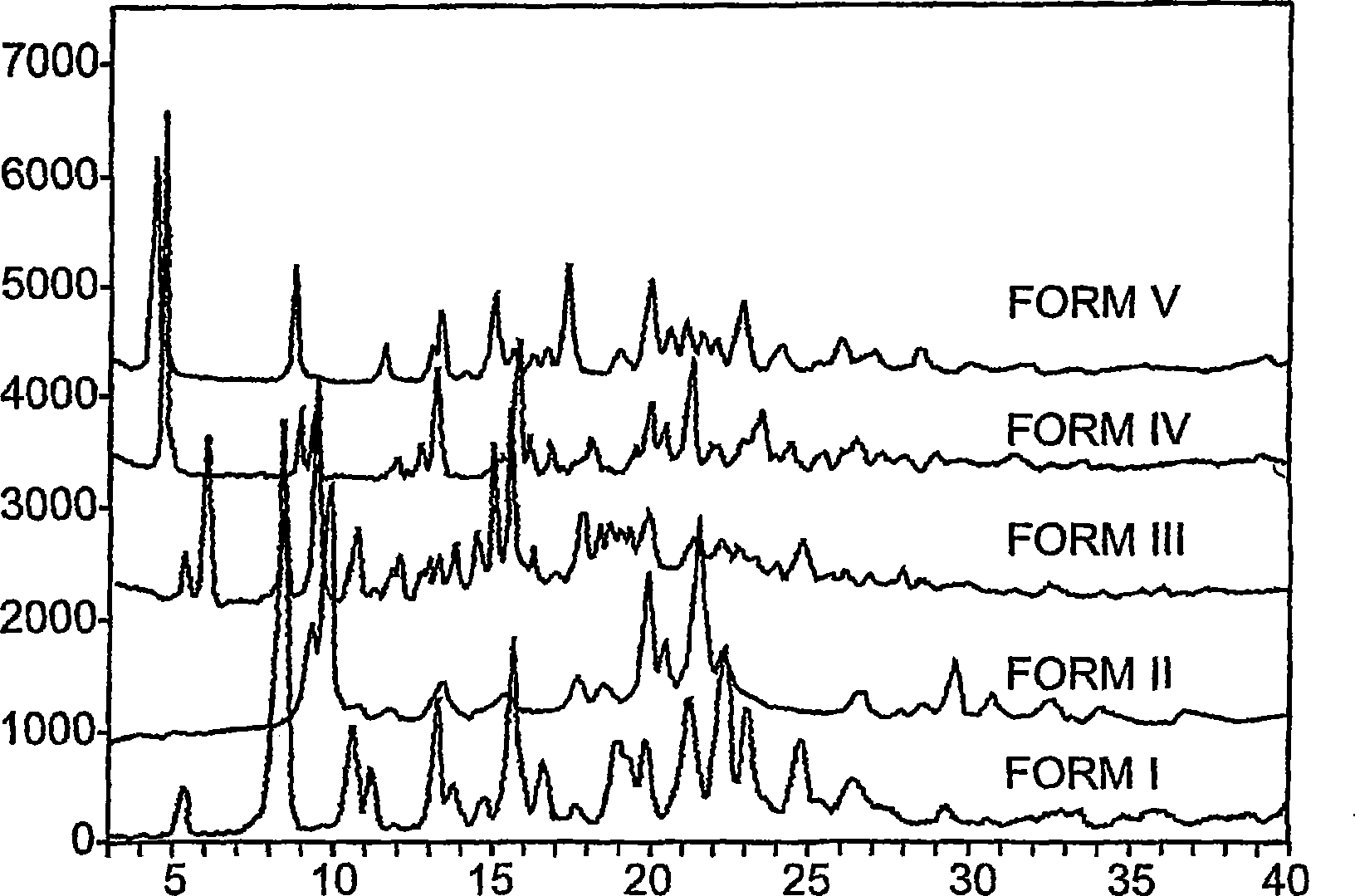

Uloric crystal and preparation method thereof

The invention relates to the field of medicinal chemistry, in particular to an Uloric crystal and a preparation method thereof. The Uloric crystal is characterized in that x-ray powder diffraction feature absorption peak (2theta) values have feature peaks at the parts of 6.70 degrees, 7.26 degrees, 9.40 degrees, 12.86 degrees, 13.42 degrees, 16.48 degrees, 19.70 degrees, 22.10 degrees, 23.16 degrees, 23.86 degrees, 25.02 degrees, 25.92 degrees, 26.74 degrees, 28.34 degrees and 40.48 degrees. An Uloric alpha crystal form of the invention has simple process operation and low cost. Only Uloric needs to be dissolved in a single solvent of ethylene glycol monomethyl ether so as to avoid solvation crystal habit, and the crystal form is stable and has good reproducibility. Moreover, the Uloric alpha crystal form has good solubility and better dissolution rate than A crystals in a solid preparation.

Owner:CHINA PHARM UNIV +1

Zeolite compositions and methods for tailoring zeolite crystal habits with growth modifiers

ActiveUS20150360964A1Minimized crystal thicknessShortened internal diffusion pathlengthIon-exchange process apparatusPolycrystalline material growthVolumetric Mass DensityCrystal habit

Embodiments of the invention generally provide compositions of crystalline zeolite materials with tailored crystal habits and the methods for forming such crystalline zeolite materials. The methods for forming the crystalline zeolite materials include binding one or more zeolite growth modifiers (ZGMs) to the surface of a zeolite crystal, which results in the modification of crystal growth rates along different crystallographic directions, leading to the formation of zeolites having a tailored crystal habit. The improved properties enabled by the tailored crystal habit include a minimized crystal thickness, a shortened internal diffusion pathlength, and a greater step density as compared to a zeolite having the native crystal habit prepared by traditional processes. The tailored crystal habit provides the crystalline zeolite materials with an aspect ratio of about 4 or greater and crystal surfaces having a step density of about 25 steps / μm2 or greater.

Owner:UNIV HOUSTON SYST

Method for preparing single-crystal high-temperature alloy from seed crystal subjected to solid-solution treatment

ActiveCN108624959AOvercome the need to set up a spiral crystal selector to suppress the formation of miscellaneous crystals below the remelting interface inside the seed crystalOvercoming the problem of stray crystal formation below the remelt interfacePolycrystalline material growthFrom frozen solutionsSolution treatmentSingle crystal superalloy

The invention discloses a method for preparing single-crystal high-temperature alloy from seed crystal subjected to solid-solution treatment. The method is characterized in that the original structurestate of seed crystal is converted into a uniform structure from a thick seed crystal structure through a solid-solution thermal treatment way, so that a structure on the upper part of a mushy zone under a melting-back interface forms a complex network shaped structure in a seed crystal single-crystal preparation process; un-melted solid phases are connected with each other to improve ability ofresisting deformation, so that flow speed when melt is poured to the upper end of the seed crystal does not need to limit, and therefore, the purpose of removing a spiral crystal selector structure ina mould shell is achieved. In a process of preparing the single-crystal high-temperature alloy, the seed crystal re-melting region is completely inhibited to form mixed crystal, so that the structureof the corresponding mould shell is simplified, mechanical degree and assembly precision of shell making are improved, and cost is reduced, and therefore, the defect of using a spiral crystal selecting section in the mould shell in a process of producing single-crystal high-temperature alloy by repeatedly using seed crystal is avoided.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Hydrous salt cold storage agent with phase-transition temperature of 5-8 DEG C and preparation method thereof

InactiveCN105038715AAdjustable temperatureLarge latent heat of phase changeHeat-exchange elementsCold chainPhase change

The invention relates to a hydrous salt cold storage agent with the phase-transition temperature of 5-8 DEG C and a preparation method thereof. The cold storage agent comprises the following components in percentage by weight: 68.5-86.9% of a main energy storage agent, 1-3% of a supercooling prevention agent, 1-3% of an acid and alkali neutralizer, 1-5% of a thickening agent, 10-20% of a cooling agent, 0.1-0.5% of a crystal habit modifier and free water having the same molar ratio as that of sodium sulfate decahydrate. The phase-transition temperature of the cold storage agent can be adjusted in the range of 5-8 DEG C, the latent heat of phase change ranges from 20.0 J / g to 140 J / g, and the cold storage agent is long in cold-keeping time, simple in preparation process, low in cost, non-toxic, odourless, pollution-free and gelatinous and can be widely used for cold-chain transportation of fruits and vegetables, biomedical products and the like.

Owner:JIANGNAN UNIV

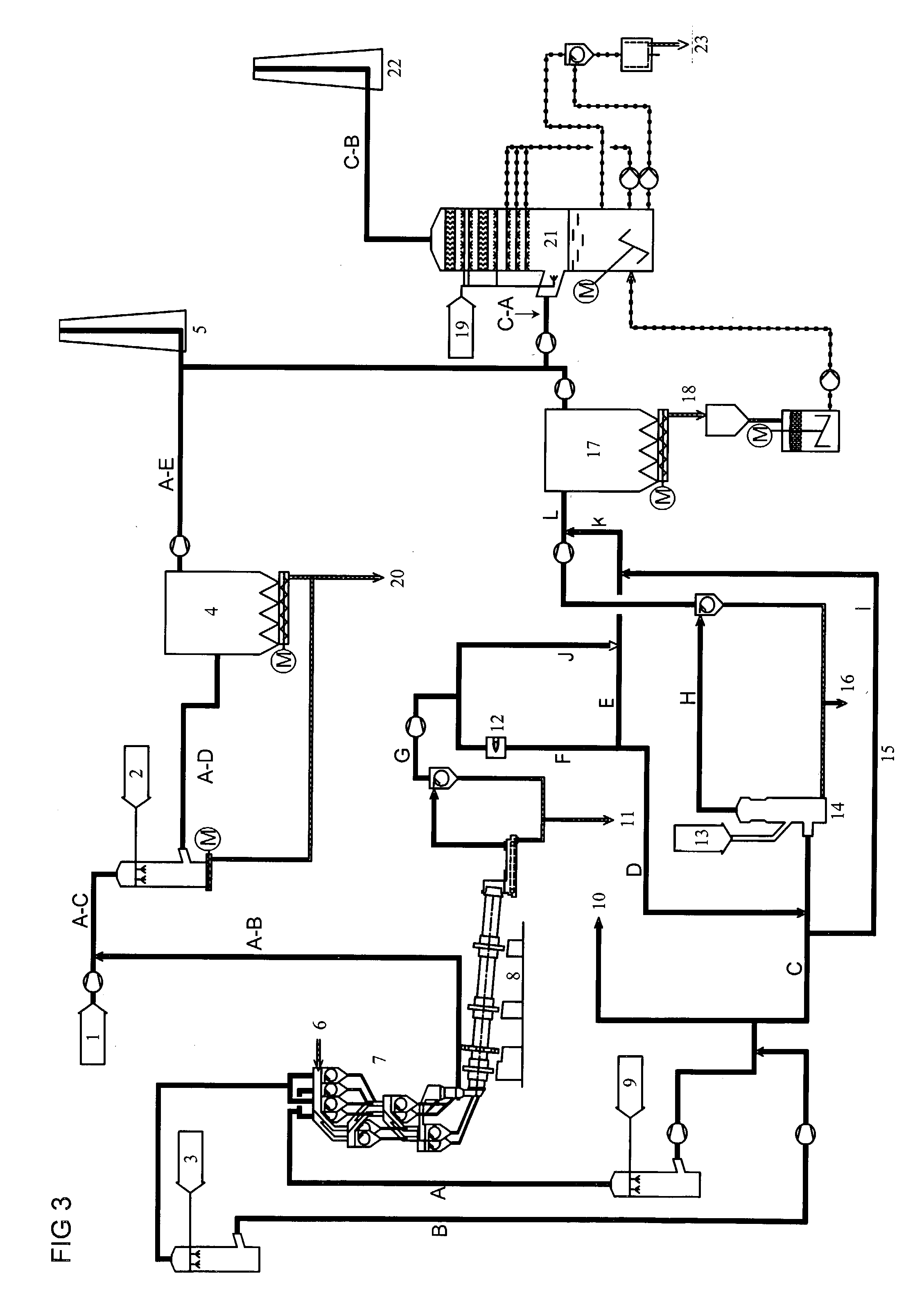

FGD gypsum dewatering improvement through crystal habit modification by carboxylic acids

InactiveUS20030175193A1Fast crystal growthHigh operating requirementsCalcium/strontium/barium sulfatesDispersed particle separationCarboxylic acidCrystal habit

Owner:F L SMIDTH AIRTECH

Personal care composition and method of making

This invention relates to an improved crystallization process of hydrogenated castor oil structurant which results in (i) a dispersion having a high concentration of the structurant, and (ii) a crystal habit / form that results in a higher yield stress in the final product, imparting high stability, for a given amount structurant. In addition, the resulting personal care product is consumer desired, as less structurant residue is observed on hair after the use of the personal care product.

Owner:THE PROCTER & GAMBLE COMPANY

Process for producing thiourea dioxide

The present invention belongs to the field of peroxide preparing technology in organic chemistry. Into reactor, water is added in advance, thiourea is thrown in batches and hydrogen peroxide solution containing stabilizer is dripped to produce thiourea dioxide. After finishing the reaction, thiourea dioxide is filtered and stoved to obtain crystallized thiourea dioxide powder. The added amountof the stabilizer is 0.1-5 wt% of thiourea and crystal habit modifier in 0..005-2 wt% of thiourea may be also added into water. The improved thiourea dioxide producing process has improved crystal state of thiourea dioxide and raised product purity and is suitable for industrial production in large scale.

Owner:陶华西

Process for preparing peroxide urea

InactiveCN1418871AGood storage stabilityOvercome temperatureOrganic chemistryInorganic ChemicalReaction temperature

The preparation method of urea peroxide uses hydrogen peroxide and urea as raw material, and is characterized by that adding urea in hydrogen peroxide whose mass percentage concentration is above 50%, at the same time adding stabilizing agent and crystal habit modification agent, after reaction, obtaining wet urea peroxide, drying to obtain white crystal granules, at the same time coating the surface of said urea peroxide white crystal granule with a layer of coating compound. Said invention is economic and practical, its simple batch yield rate can be up to above 85%, the ure peroxide content is up to above 92%.

Owner:陶华西

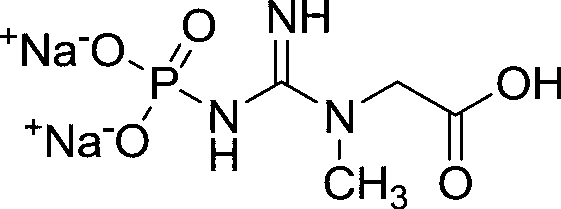

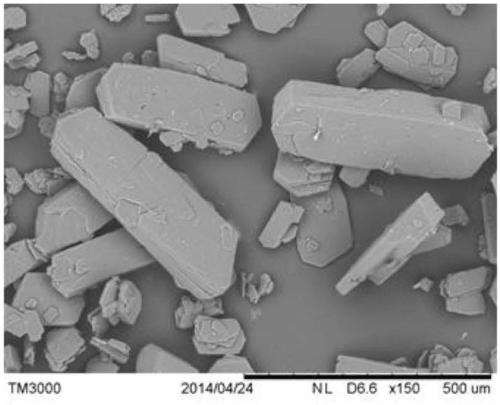

Crystal preparation method of creatine phosphate sodium

ActiveCN103012472AHigh crystallinityCrystal habit completeGroup 5/15 element organic compoundsPhosphateKetone

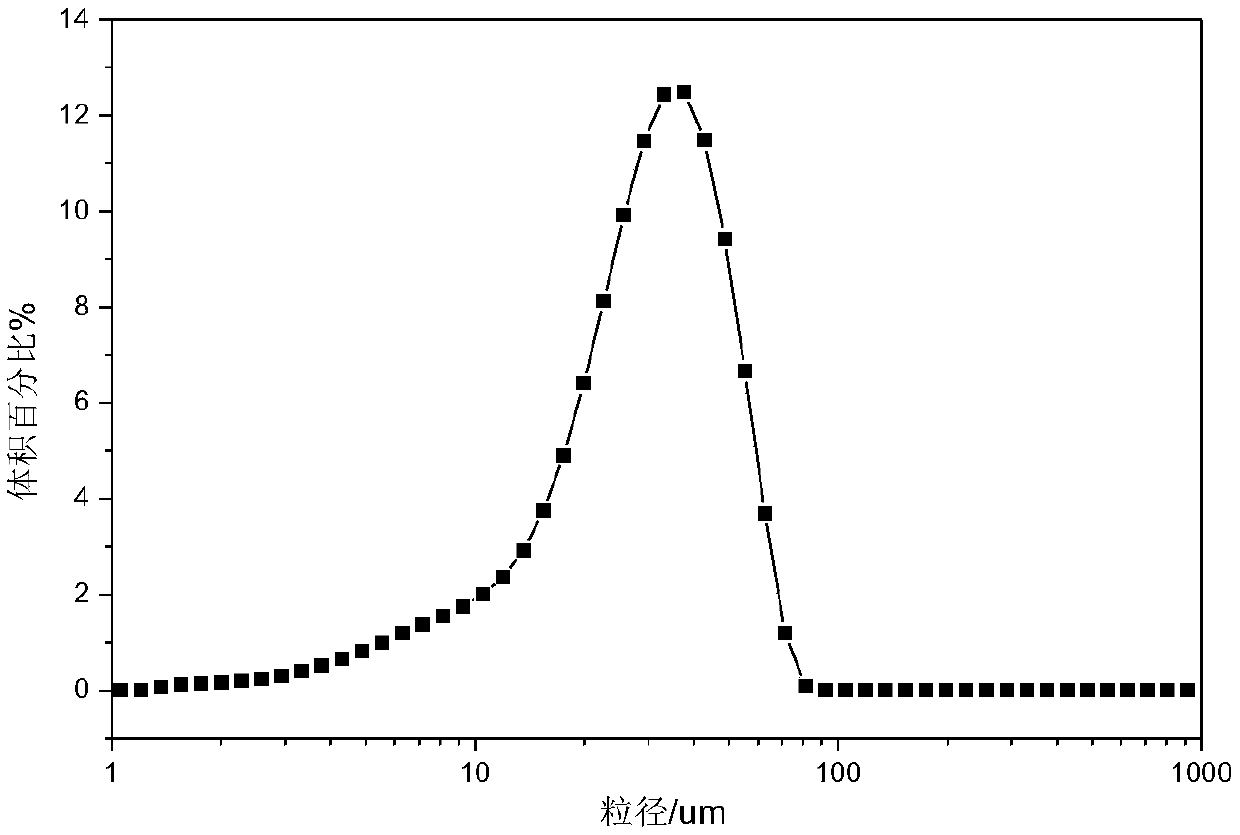

The invention discloses a crystallizing method for preparing high-purity creatine phosphate sodium. The crystallizing method comprises the following steps of: dissolving a creatine phosphate sodium crude product in water to prepare a 0.5-1.1 g / ml creatine phosphate sodium aqueous solution, continuously stirring for 30-60 minutes to decolor; after filtering, transferring a filtrate into a crystallizer, controlling a system temperature to be within 5-45 DEG C, and adding an alcohol or ketone organic solvent to perform solvent-out crystallization; after crystallizing, and separating through filtering, washing with a solvent and drying to obtain a creatine phosphate sodium product. The creatine phosphate sodium crystal provided by the invention is high in crystallinity degree, complete in product crystal habit, and uniform in particle size distribution; and a primary particle size is 67.1-70.2 mu m. The product purity reaches more than 99.5%, and a single molar yield during the crystallizing process is more than 98.0%; and the method is simple in process, low in cost and suitable for industrial production.

Owner:TIANJIN UNIV

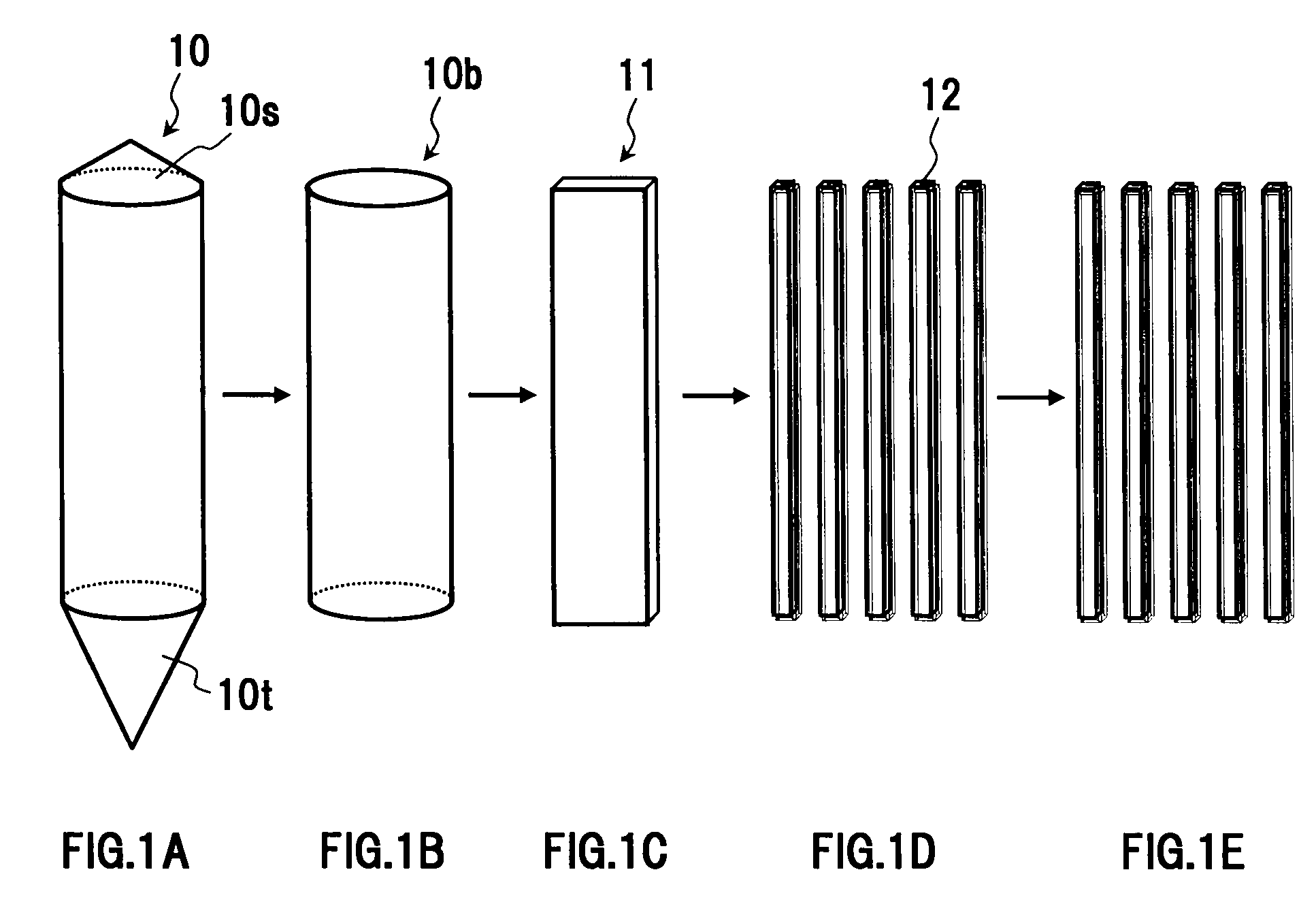

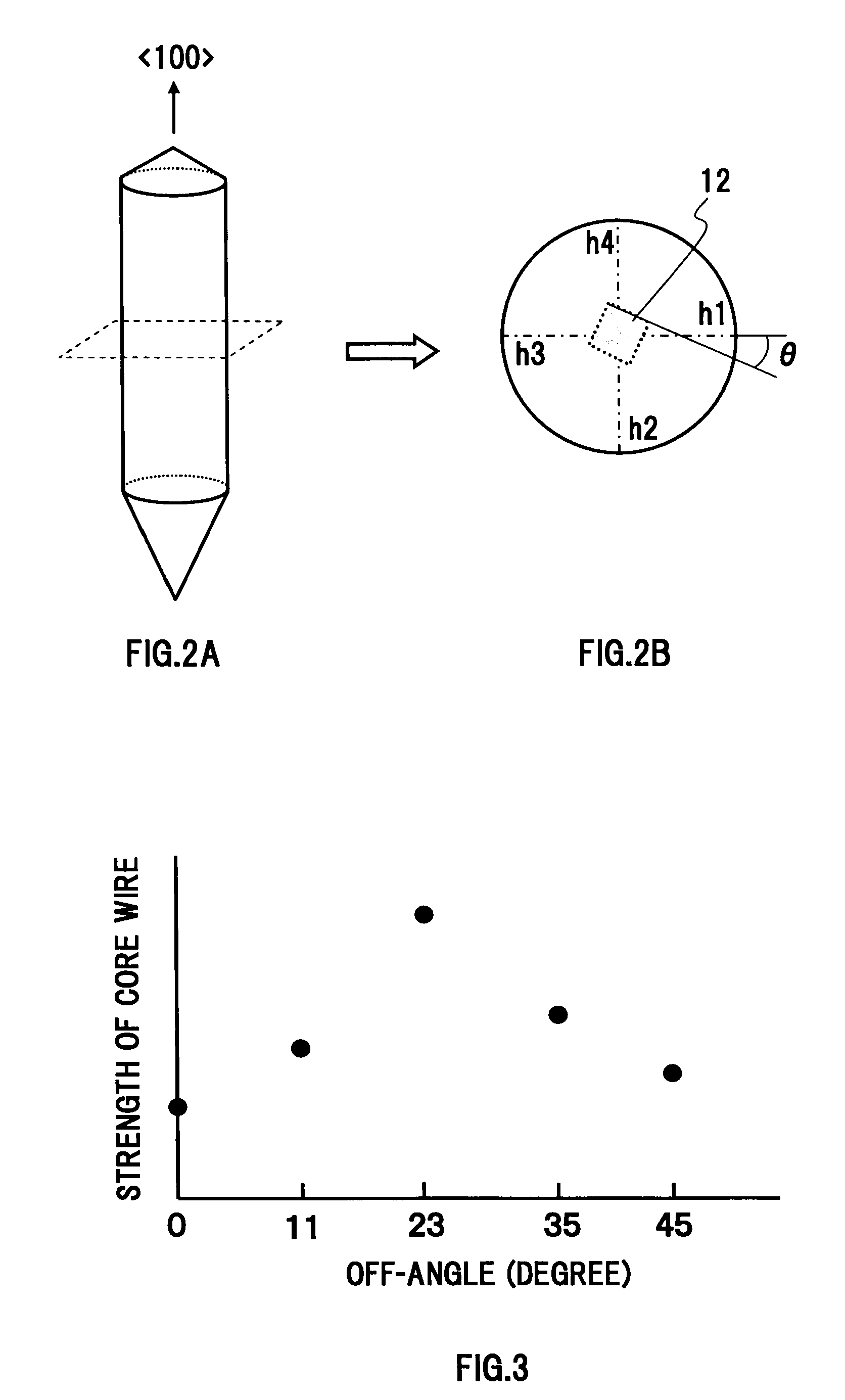

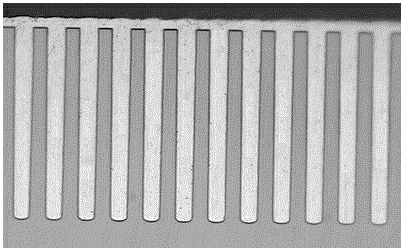

Method of manufacturing polycrystalline silicon rod

ActiveUS20090269493A1Reduce impurity pollutionHigh purityPolycrystalline material growthSiliconSingle crystalIngot

The present invention utilizes a silicon member (single-crystalline silicon rod), which is cut out from a single-crystalline silicon ingot which is grown by a CZ method or FZ method, as the core wire when manufacturing a silicon rod. Specifically, a planar silicon is cut out from a body portion which is obtained by cutting off a shoulder portion and a tail portion from a single-crystalline silicon ingot and is further cut into thin rectangles to obtain a silicon bar. In the case that the crystal growth axis orientation is <100>, there are four crystal habit lines, and the silicon bar is cut out such that the surface forms an off-angle θ in a predetermined range with the crystal habit line. The provided polycrystalline silicon rod has a low impurity contamination and high single-crystallization efficiency.

Owner:SHIN ETSU CHEM IND CO LTD

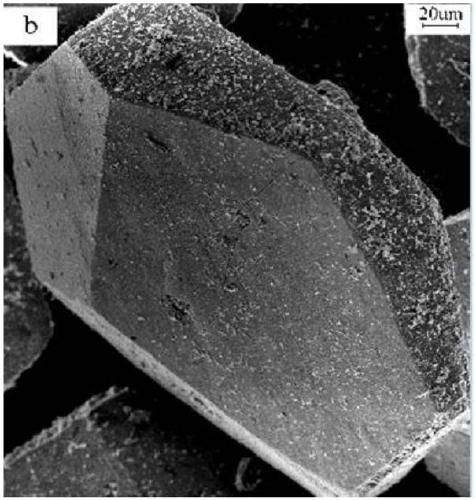

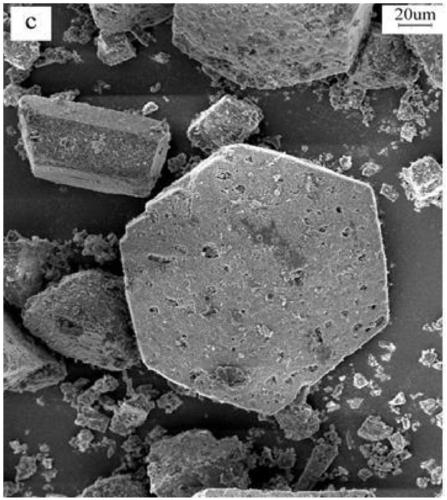

Method for preparing high-strength alpha-semi-hydrated gypsum from flue gas desulfurization gypsum

The invention belongs to the field of material science, and relates to a method for preparing high-strength alpha-semi-hydrated gypsum from flue gas desulfurization gypsum. The method comprises the following steps: 1) preparing desulfurization gypsum slurry: sufficiently mixing the flue gas desulfurization gypsum and water according to a solid-liquid mass ratio of 1: (4-10), and warming to 80-95 DEG.C; 2) adding a habit modifier to prepare mixed slurry: adding the habit modifier in the desulfurization gypsum slurry according to a condition that the mass ratio of the flue gas desulfurization gypsum to the habit modifier is 1: (0.5-1.5), wherein the habit modifier is a mixture of magnesium chloride hexahydrate and magnesium sulfate hexahydrate in a mass ratio of 1: (0.1-0.2), continuously warming to boil, and refluxing; 3) adding a crystal habit modifier: adding the crystal habit modifier in the mixed slurry obtained in the step 2) according to a condition that the mass ratio of the flue gas desulfurization gypsum to the crystal habit modifier is 1: (1%-5%); and 4) crystal transforming. The uniform short hexagonal prism alpha-semi-hydrated gypsum can be prepared by the method simple in process, the rupture strength reaches 14.4 MPa, and the compressive strength reaches 44.5 MPa.

Owner:TIANJIN UNIV

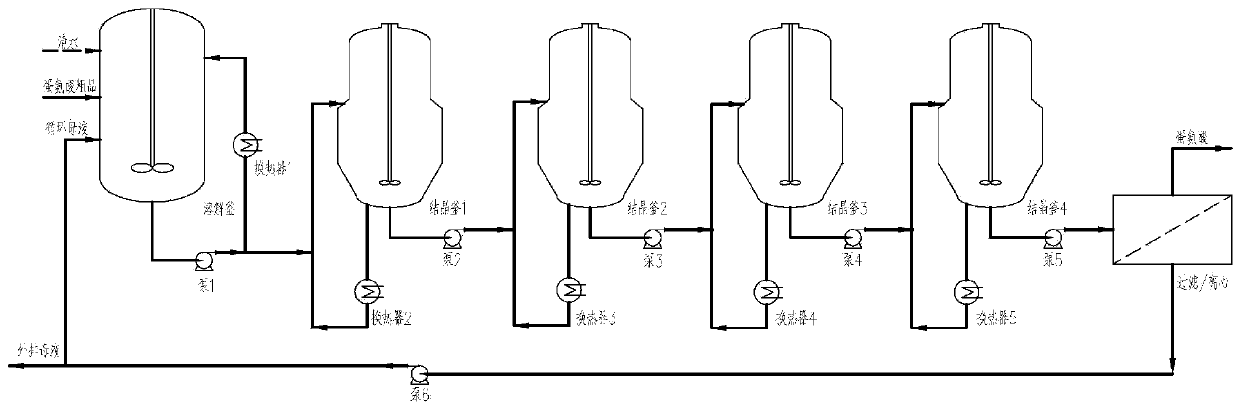

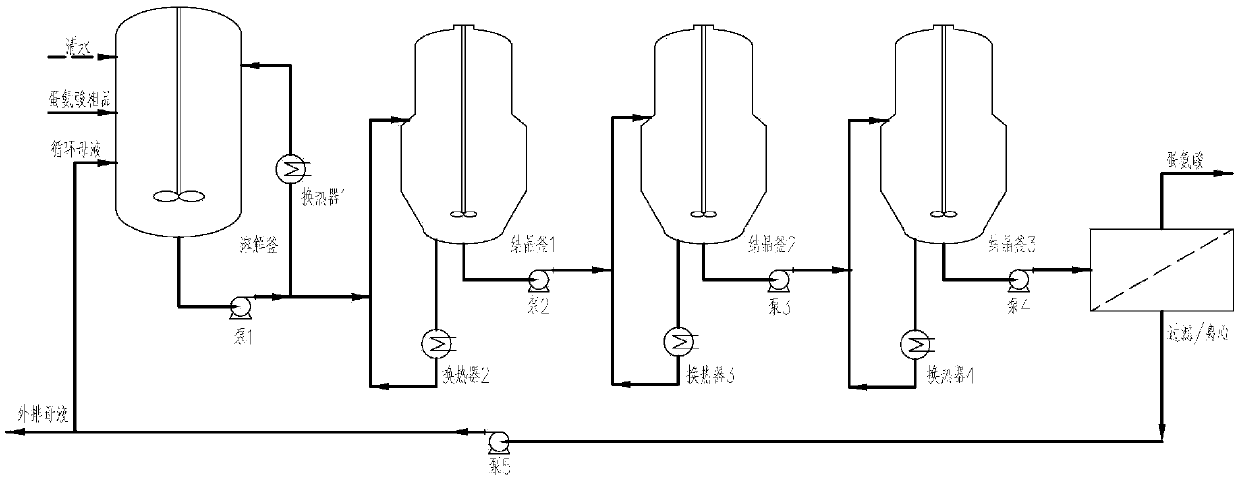

Multistage continuous crystallization method of short rod-like methionine crystals

ActiveCN109608372ASmall particle sizeControl granularityOrganic compound preparationOrganic chemistry methodsSlurryMethionine biosynthesis

The invention provides a multistage continuous crystallization method of short rod-like methionine crystals. The method includes: connecting a plurality of crystallizers in series; under the action ofa circulating device, dissolving a methionine raw material at 80-130DEG C; letting the dissolved feed solution enter a first stage crystallization kettle, and controlling the kettle temperature at 60-80DEG C; enabling the slurry to enter a second stage crystallization kettle, and controlling the kettle temperature at 40-60DEG C; enabling the slurry to enter a third stage crystallization kettle, and controlling the kettle temperature at 25-40DEG C; letting the slurry enter a fourth stage crystallization kettle, and controlling the kettle temperature at 15-25DEG C; letting the final slurry flowout of the crystallization kettle and enter a solid-liquid separation system, discharging the separated solid out of the system, and returning part of the mother liquor into a dissolution kettle forfurther circulation, with the circulation volume being 20-60% of the mother liquor volume. The stage number of the crystallization kettles is supposed to be optimized according to the actual situation, and the general ideal situation is 2-4 stages. The prepared methionine crystals have short rod-like crystal habit, the crystal size is uniform, the bulk density is high, the fluidity is good, the quality is stable, the operation is simple, and the production efficiency is high, therefore the method is suitable for large-scale industrial production.

Owner:TIANJIN UNIV +1

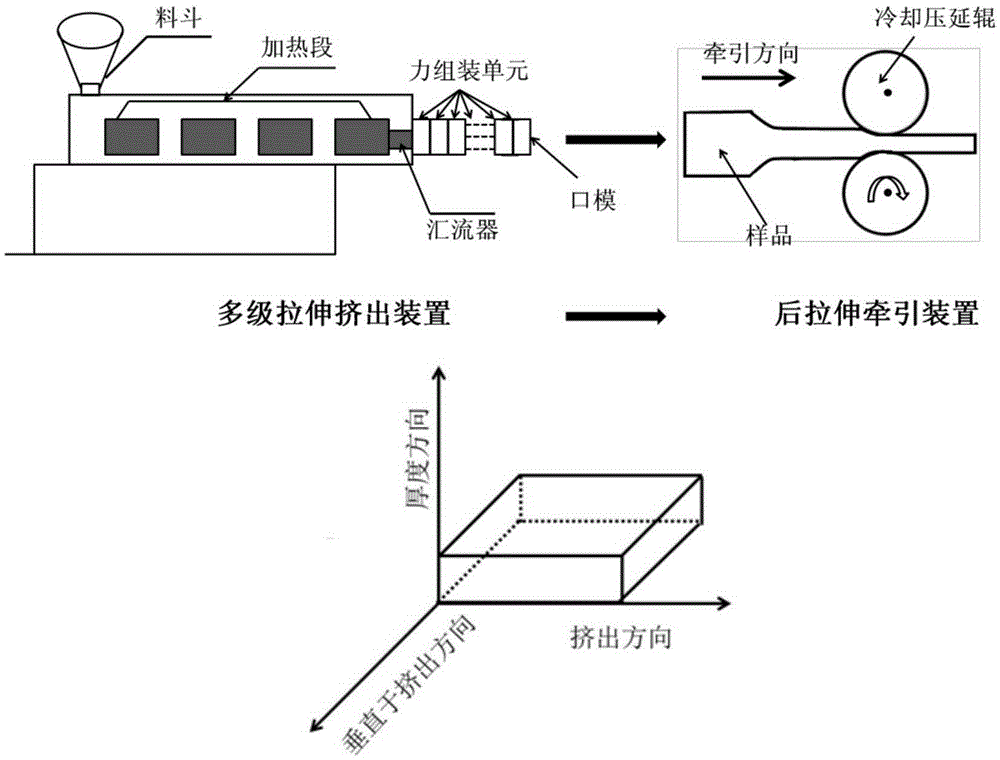

Preparation method for synergetic reinforcing and toughening polypropylene composite material

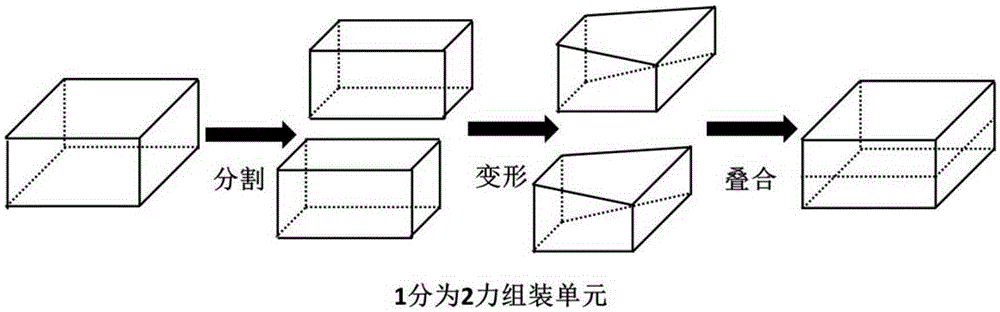

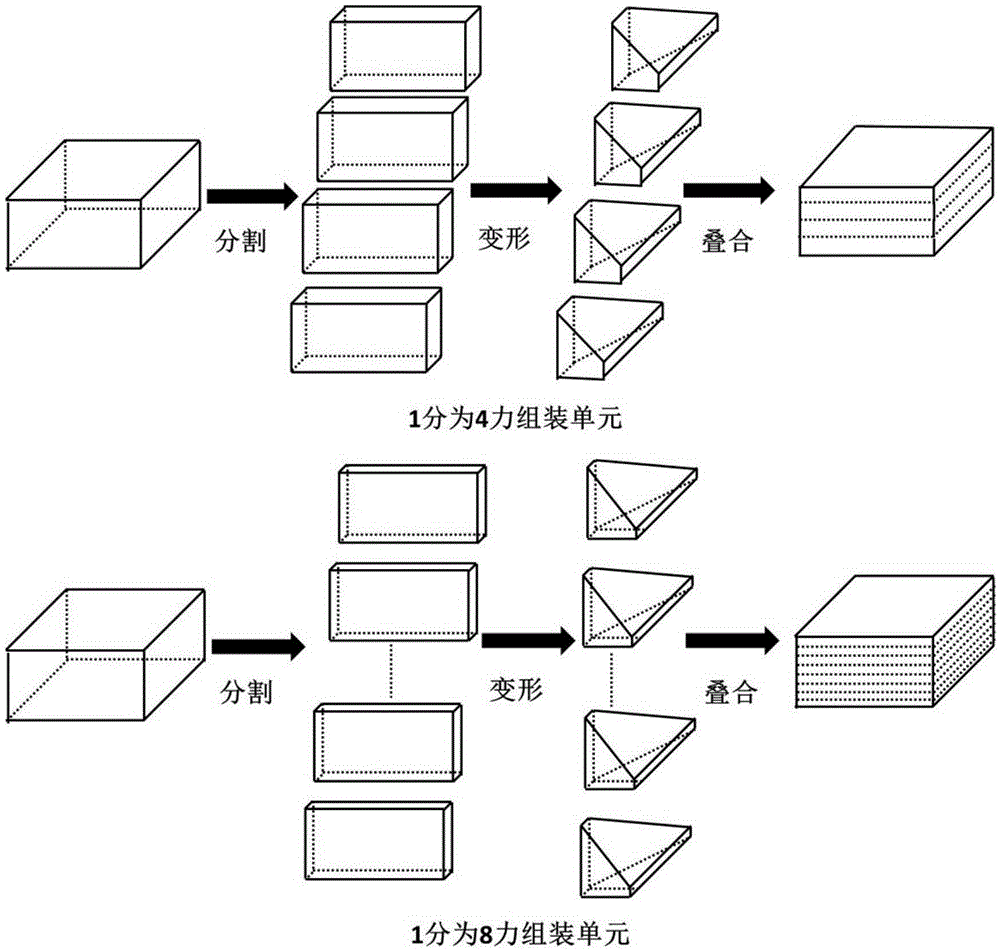

The invention discloses a preparation method for a synergetic reinforcing and toughening polypropylene composite material. The preparation method is characterized in that in the extrusion molding machining process, under the stimulation effect of an external stress field, the crystal habit of a polypropylene base is evolved into shish-kebab structures tightly arranged in a high orientation manner, and the intensity of the polypropylene material can be obviously improved through formation of the shish-kebab structures; and a flexibilizer dispersion phase form is evolved into the fiber shape and sheet shape from the sphere shape or ellipsoidal shape under the effects of a stretching force field and a rolling force field, and the toughness of the polypropylene material can be obviously improved through formation of the fiber or sheet-shaped dispersion phase form. By means of the preparation method, a force assembling unit is additionally arranged on a traditional extrusion device, operation is simple, continuous production can be achieved, control is convenient, the quality is stable, the production efficiency is high, the good industrialization and the good market prospect are achieved, and the preparation method can be widely applied to preparation of high strength and high toughness polypropylene base panels, sheets and film materials.

Owner:SICHUAN UNIV

Dehydrate desulfurated alpha high-strength gypsum based self-leveling mortar and production method thereof

The invention relates to dehydrate desulfurated alpha high-strength gypsum based self-leveling mortar and a production method of the mortar. The invention relates to reuse of dihydrate desulfurization gypsum as solid waste generated in a coal-fired power plant and belongs to the technical field of a recycled comprehensive utilization of industrial by-product gypsum. The dehydrate desulfurated alpha high-strength gypsum based self-leveling mortar comprises 50 to 60% of alpha high-strength gypsum, 35 to 50% of an aggregate material, 1 to 5% of an exciting agent, 0.01 to 0.1 of a water-retaining agent, 0.5 to 2% of a binder, 0.1 to 1% of a water reducer, 1 to 3% of a auxiliary agent and 0.1 to 0.5% of a antifoaming agent, wherein the alpha high-strength gypsum comprises 80 to 100% of dihydrate desulfurization gypsum, 10 to 20% of water, 0.02 to 0.06% of a crystal habit modifier 1, and 0.02 to 0.06% of a crystal habit modifier 2. The production method of the invention comprises mixing the dihydrate desulfurization gypsum and crystal habit modifiers to obtain slurry, then treating the slurry through a sequence of steps of isothermal stirring, temperature maintaining, pH value regulating, dehydrating, drying and grinding to obtain the dehydrate desulfurated alpha high-strength gypsum, and mixing the dehydrate desulfurated alpha high-strength gypsum and additives comprising the aggregate and the like according to the above ratios and stoichiometric proportion to obtain the dehydrate desulfurated alpha high-strength gypsum based self-leveling mortar. The dehydrate desulfurated alpha high-strength gypsum based self-leveling mortar has the advantages of high strength, favorable flowability and low cost. The dehydrate desulfurated alpha high-strength gypsum based self-leveling mortar is not utilized in our country at present.

Owner:SHANGHAI JINMA BUILDING MATERIALS

Production method of porous calcium carbonate

InactiveCN1515495ALow densityImprove adsorption capacityCalcium/strontium/barium carbonatesChemical reactionAmmonium Hydrogen Carbonate

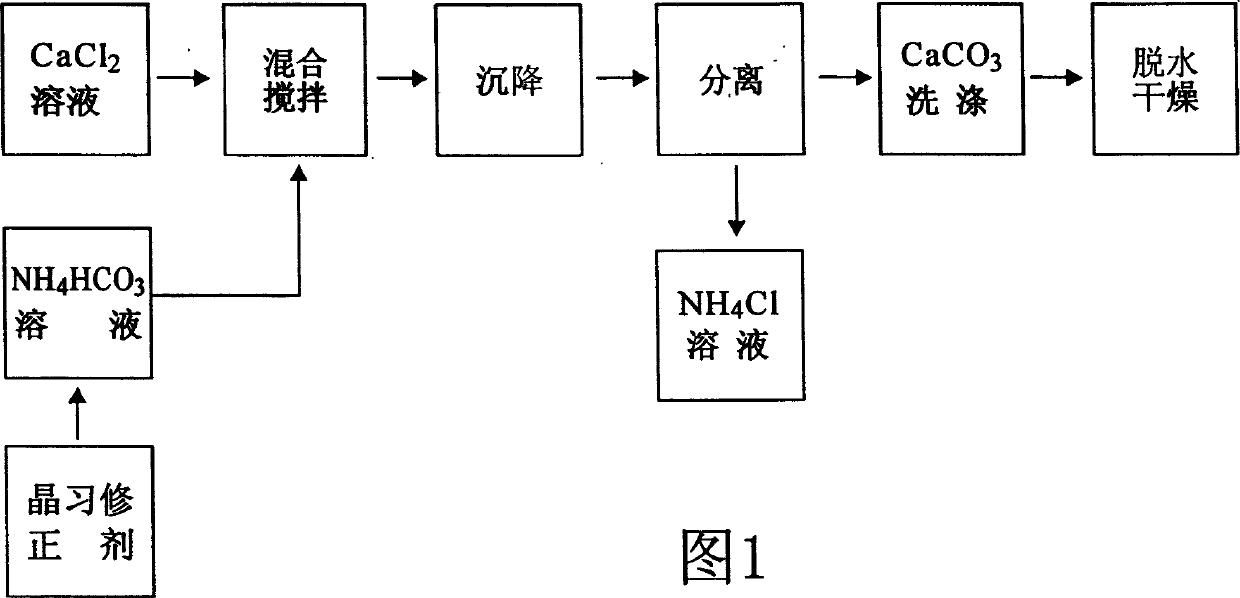

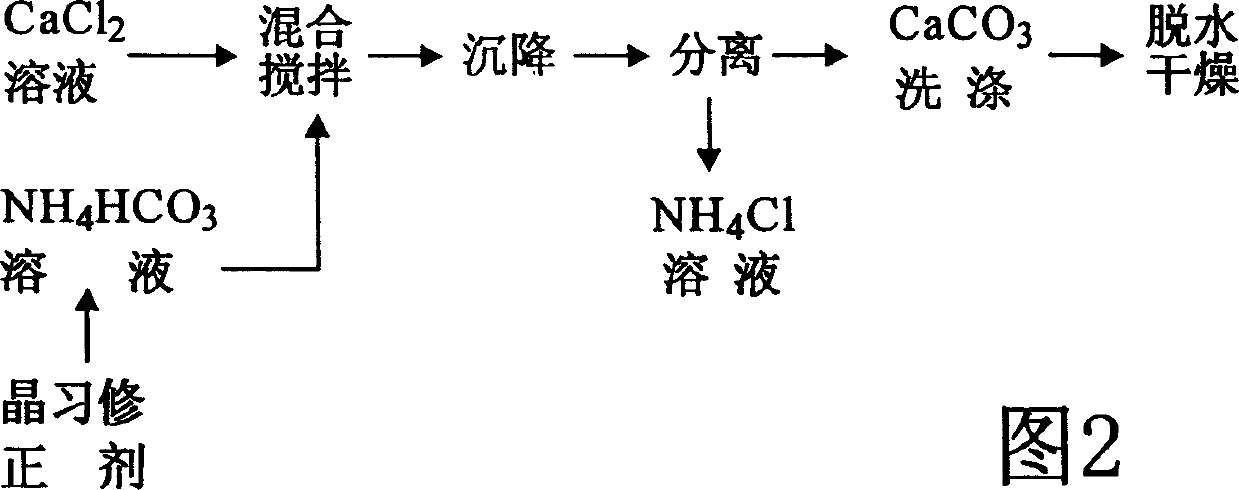

The preparation method of porous calcium carbonate includes the folloiwng steps: preparing calcium chloride aqueous solution and ammonium hydrogen carbonate aqueous solution, adding crystal habit correcting agent whose adding quantity is 0.01-0.05% of total mass of the above-mentioned two solutions; mixing them at 25-30 deg.C, fully stirring at normal pressure until the air is reacted, settling reaction product for 0.5-1 hr., separating sediment calcium carbonate from ammonium hydride solution, then washing said sediment calcium carbonate by using water, dewatering, drying so as to obtain the porous calcium carbonate product with strong adsorption force and penetrating quality. It can be extensively used in the industries of plastics paper-making, paint, printing ink and domestic chemicals, etc.

Owner:谢作文

Wafer demounting method, wafer demounting device, and wafer demounting and transferring machine

InactiveUS7364616B2Reduce surface tensionFast decaySemiconductor/solid-state device manufacturingArticle separationEngineeringCrystal habit

Owner:MIMASU SEMICON IND CO LTD

Composite crystal modifier for preparing alpha-type high-strength gypsum

ActiveCN109231863AHigh strengthPlay a role in crystal shape regulationCalcium/strontium/barium sulfatesCompressive strengthCrystal habit

The invention relates to a composite crystal modifier for preparing alpha-type high-strength gypsum, which belongs to the technical field of gypsum additives and gypsum deep processing. The crystal modifier is formed by compounding inorganic fluoride salt accounting for 0.02 to 6 percent of the mass of a dihydrate gypsum dry base, and multi-element organic acid or organic acid salt accounting for0.02 to 1 percent of the mass of the dihydrate gypsum dry base. By utilizing the composite crystal modifier disclosed by the invention, when the alpha-type high-strength gypsum is prepared from dihydrate gypsum under a hydrothermal condition, a crystal habit of the alpha-type semi-hydrate gypsum can be effectively regulated and controlled, the alpha-type semi-hydrate gypsum can form short cylindrical alpha-type semi-hydrate gypsum crystals, so that the high-strength gypsum with the pressure resisting strength greater than 25MPa and a product thereof can be prepared. The composite crystal modifier is particularly suitable for preparing the alpha-type high-strength gypsum by adopting phosphorus gypsum with high fluorine impurity content as a raw material.

Owner:东磐科技有限公司

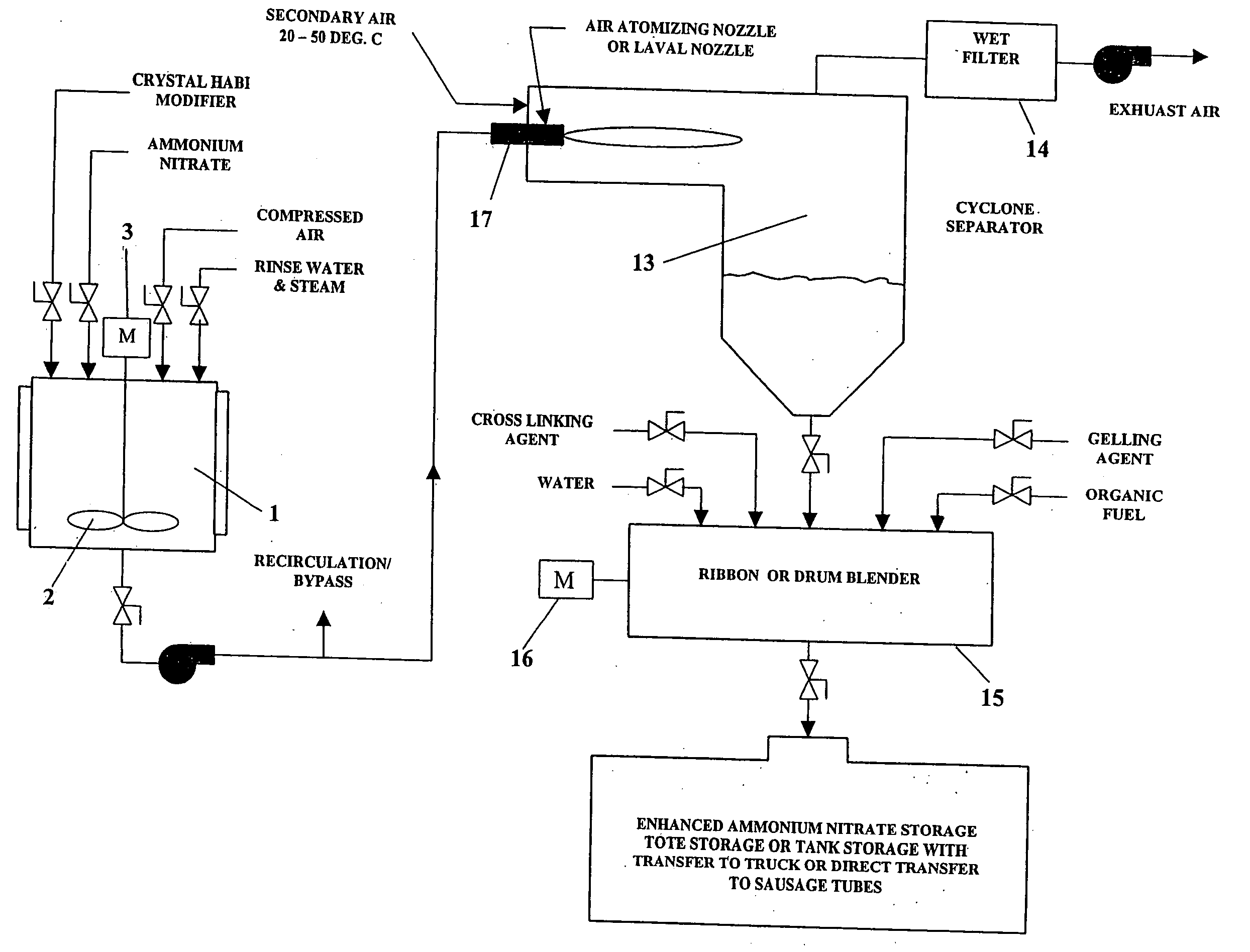

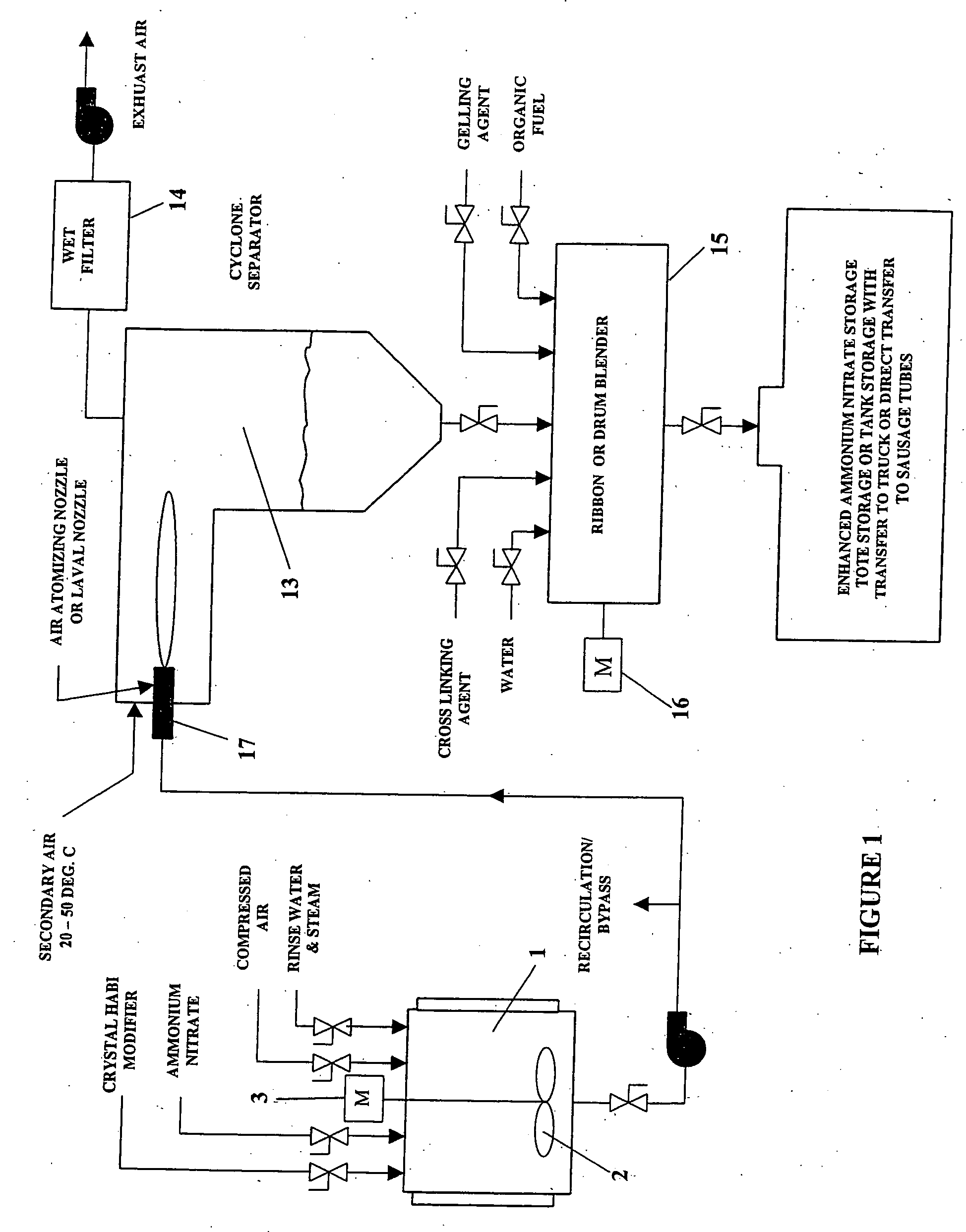

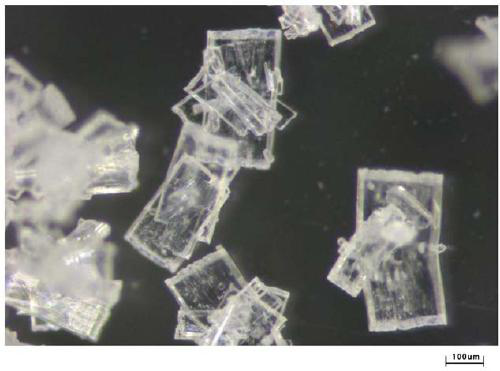

Ammonium nitrate bodies and a process for their production

InactiveUS6572833B1Reduce chanceLow usageAmmonium nitratesPerchloratesParticulatesAlkaline earth metal

A process for the production of ammonium nitrate bodies in particulate form wherein an ammonium nitrate / water liquid mixture containing at least 92% and preferably at most 97.5% by weight ammonium nitrate, optionally with a proportion of the ammonium nitrate substituted by alkali- and / or alkaline earth metal nitrate, and a small amount of poly-styrene sulphonate crystal-habit modifier is sprayed as droplets into an atmosphere in which cooling effects crystallization of the ammonium nitrate and which the crystallized particles are dried to remove moisture, wherein the liquid mixture also contains ammonium sulphate, the concentration of poly-styrene sulphonate in the liquid mixture being at least 0.01%, preferably in the range 0.02 to 0.06%, by weight, and the concentration of ammonium sulphate in the liquid mixture being greater than that of the poly-styrene suphonate and at least 0.04%, preferably in the range 0.06 to 0.15%, by weight. Ammonium nitrate bodies, preferably prills, produced by the process may contain less than 0.1% by weight water and be able to absorb not less than 6% of their weight of fuel oil while remaining a pourable particulate material.

Owner:ORICA EXPLOSIVES TECH PTY LTD

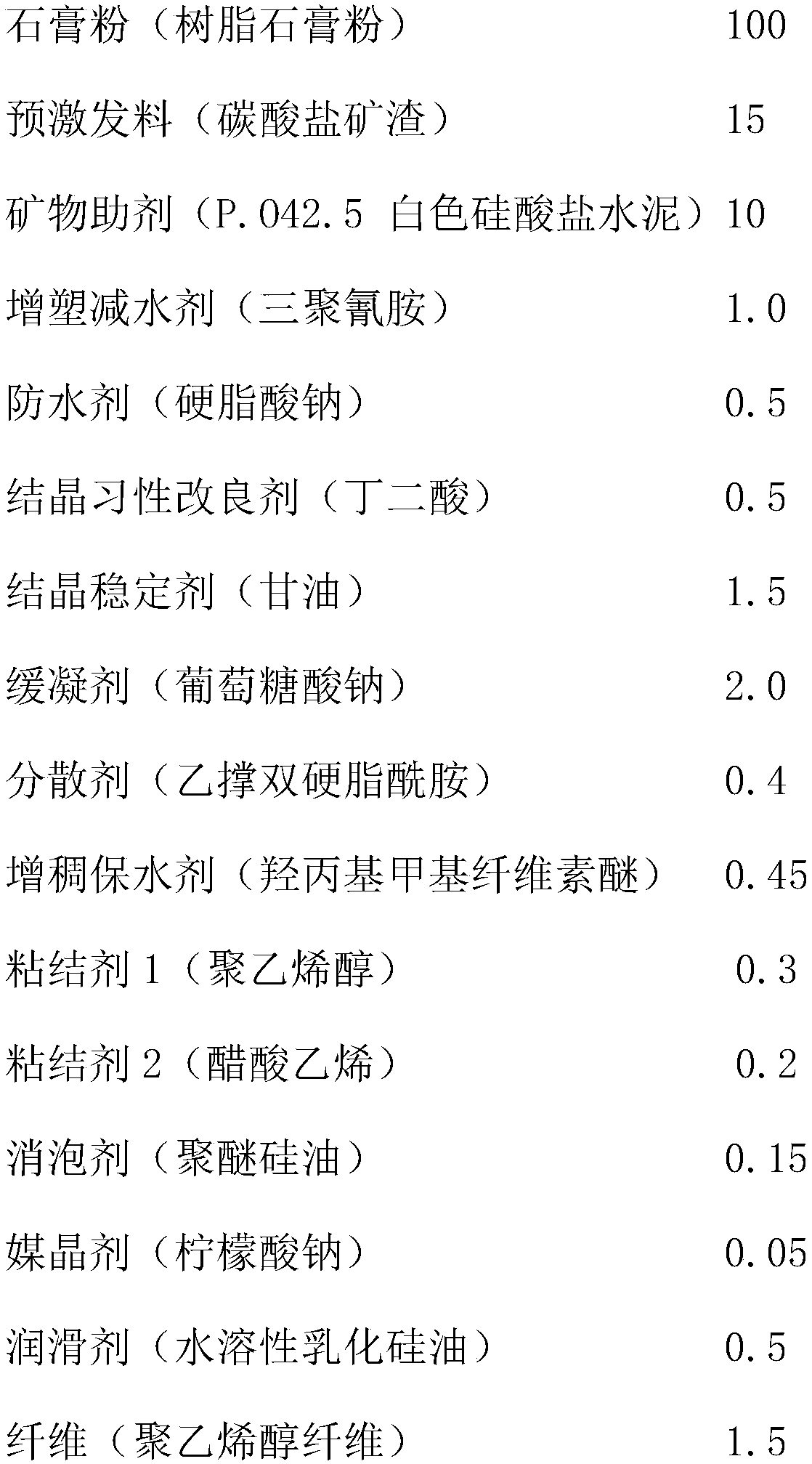

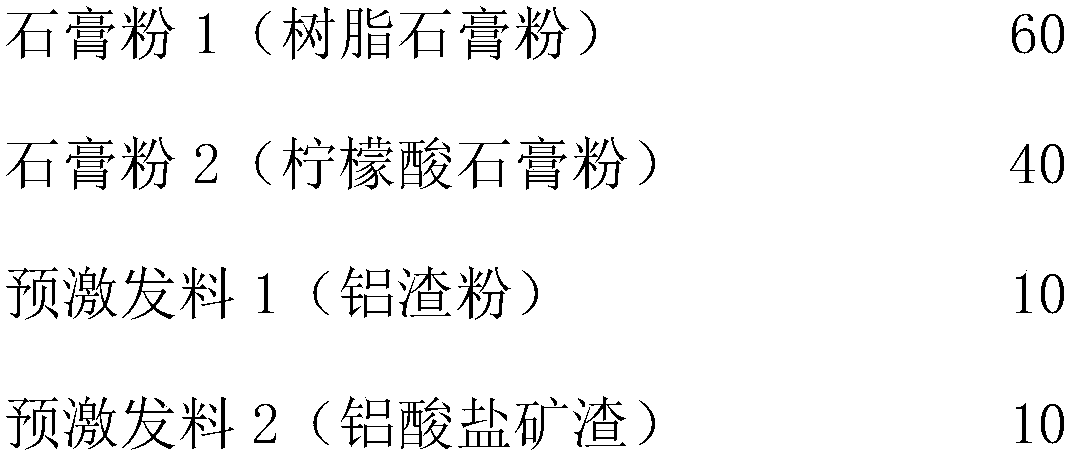

Gypsum-based composite binding material for extruded 3D printing and preparation method thereof

InactiveCN108383465AProlong clotting timeEasy to manufactureAdditive manufacturing apparatusCeramic shaping apparatusFiberCrack resistance

The invention discloses a gypsum-based composite binding material for extruded 3D printing and a preparation method thereof and relates to the field of civil engineering / 3D printing materials. Aimingat defects in the prior art, the invention provides the gypsum-based composite binding material for extruded 3D printing. The binding material is prepared from the following components: gypsum, pre-excited material, mineral additives, a plasticized water reducing agent, a waterproof agent, a crystal habit improver, a cystallizing stabilizer, a retarder, a dispersing agent, a water-retentive and thickening admixture, an adhesive, an antifoaming agent, a crystal modifier, a lubricating agent and fibers. The binding material disclosed by the invention has the beneficial effects that the preparedgypsum-based composite binding material for extruded 3D printing is wide in source, excellent in liquidity and environmentally friendly and has excellent extrusion continuity, constructability, mechanical property, water seepage resistance and cracking resistance.

Owner:深圳市明远建筑科技有限公司

Tigecycline without crystal habit and method of preparing the same

InactiveCN101367747AHigh antibacterial activityCarboxylic acid amide separation/purificationTigecyclineCrystal habit

The present invention provides a no-crystalline state tigecycline and a preparation method of the tigecycline. The present invention has obvious bacteriostasis activity.

Owner:SHANGHAI LAIYI BIOMEDICAL RES & DEV CENT +1

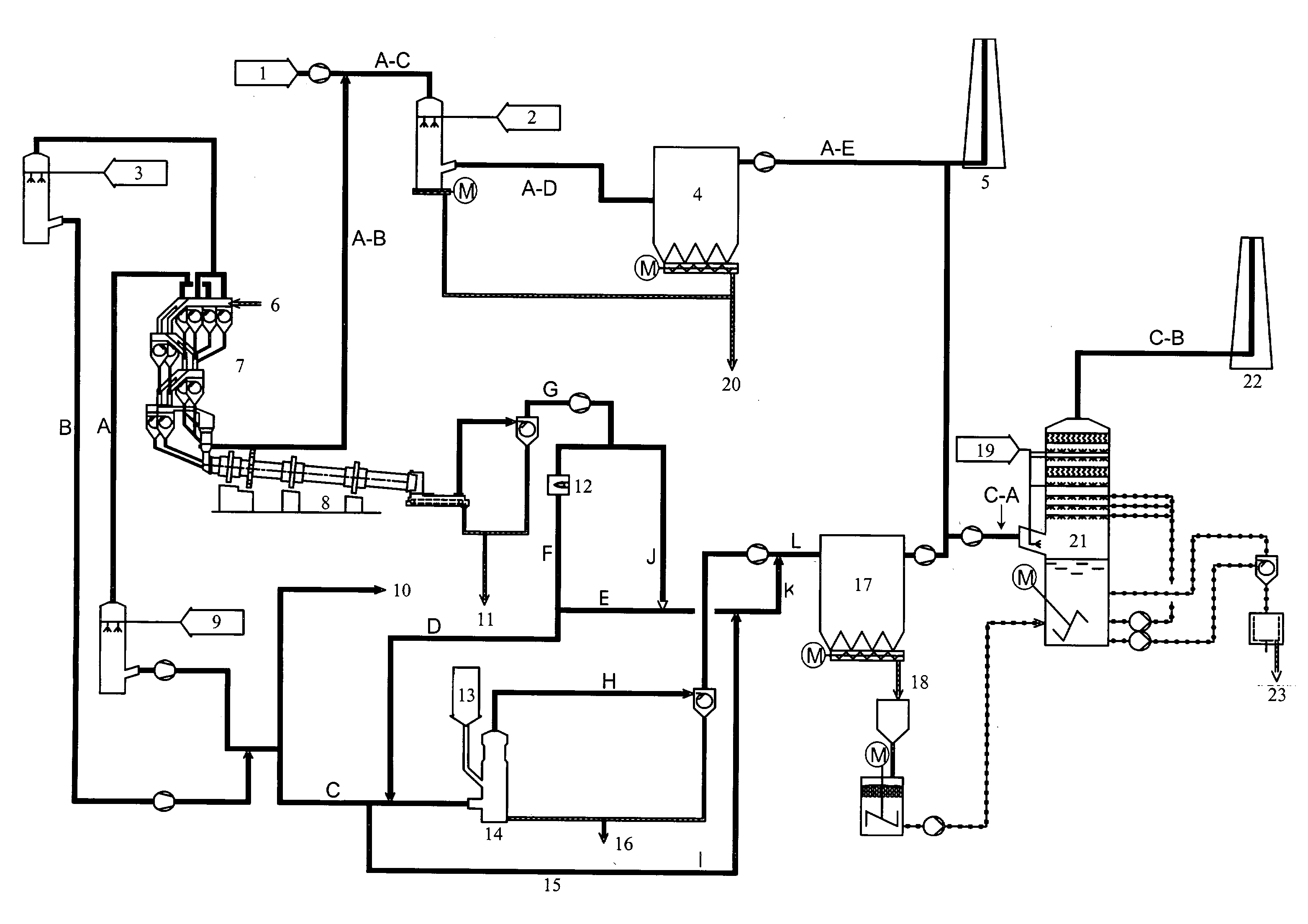

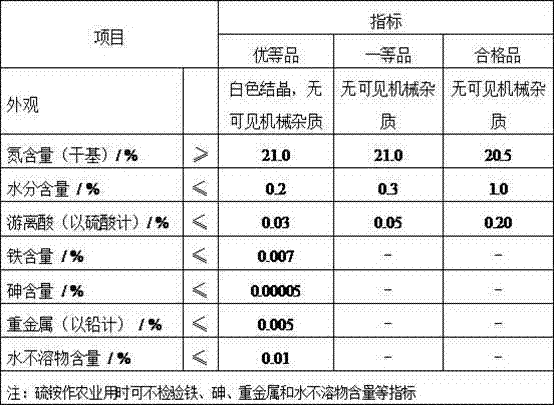

Method for producing industrial grade superior ammonium sulfate through coked coarse ammonium sulfate dilution crystallization

InactiveCN103496715AImprove color levelReduced growth rateAmmonium sulfatesActivated carbonCrystal habit

The invention particularly relates to a method for producing industrial grade superior ammonium sulfate through coked coarse ammonium sulfate dilution crystallization. According to the technical scheme, the method comprises the steps that the pH value of a coked coarse ammonium sulfate aqueous solution is adjusted through NaOH, activated carbon is further added, and the aqueous solution is filtered, so that a coked coarse ammonium sulfate crystallization mother solution is obtained; an acidity adjusting agent, a crystal habit modification agent and seed crystals are added to the mother solution, crystal is cultivated, and therefore suspended turbid crystal mush is prepared; finally, eluent is added to suspended turbid crystal mush flow, dilution crystallization is conducted, ammonium sulfate crystals are prepared through filtration and drying, the particle size distribution of a crystal product is concentrated, the surface is smooth, the purity is high, the liquidity is good, and the standard of an industrial grade superior product can be met. The particle size and the addition quantity of the seed crystals are changed so that the average particle size and the particle size distribution of the ammonium sulfate crystal product can be adjusted and controlled in the process of crystallization. The method for producing the industrial grade superior ammonium sulfate through coked coarse ammonium sulfate dilution crystallization has the advantages that the production cost is low, the production cycle is short, the average particle size is controllable, the particle size distribution is concentrated, one-way crystallization yield is high (no less than 95%), and the quality of the product is high.

Owner:WUHAN UNIV OF SCI & TECH

Oral osmotic controlled drug delivery system for a sparingly soluble drug

InactiveUS20030008006A1Increase in sizeControl swellingBiocidePowder deliveryCelluloseHydrophilic polymers

The present invention is for an oral osmotic controlled drug delivery system for a sparingly soluble drug comprising: a. a core comprising (i) finely particulate anhydrous carbamazepine (ii) a polymeric swelling agent consisting of one or more swellable hydrophilic polymers selected such that the polymeric swelling agent exhibits controlled swelling and the wall does not rupture or burst, (iii) a crystal habit modifier in whose presence, upon contact with an aqueous medium, the anhydrous carbamazepine being transformed into cuboidal or rod-shaped crystals of the dihydrate of carbamazepine, or mixtures thereof, and (iv) water-soluble compounds for inducing osmosis, b. a wall made of acylated cellulose which is impermeable to the components of the core, but permeable to water, and c. a passageway through the wall for releasing the components present in the core to the surrounding environment.

Owner:SUN PHARMA INDS

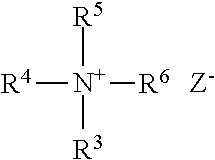

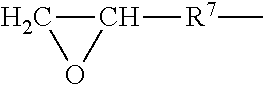

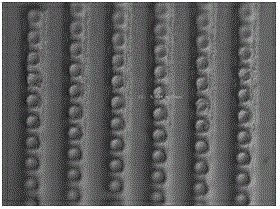

Additive B capable of controlling TSV deep hole copper plating crystallization and growth mode and application of additive B

The invention discloses an additive B capable of controlling the TSV deep hole copper plating crystallization and the growth mode and an application of the additive B. The additive B comprises, by weight, 1%-10% of one of polyethylene glycol and polyvinyl alcohol with the molecular weight being 200 to 20,000 or the mixture of polyethylene glycol and polyvinyl alcohol with different molecular weights, 0.01%-10% of an EO-PO-EO-quaternary ammonium compound, 0.1%-5% of a thioimidazole compound, 0.1%-10% of polyethylenimine and derivative thereof and the balance water. By means of the additive B, the TSV deep hole electroplating copper filling mode can be changed, the crystal habit of copper is changed, and thus defect-free micro protrusion filling along holes of TSV micro holes can be achieved; the copper crystallization shape and the hole opening growth mode are effectively controlled, the surface copper thickness is reduced, TSV deep hole opening micro protrusions are also reduced, hence, the subsequent CMP processing pressure is lightened, the subsequent processing cost is lowered, and the yield and the production efficiency are greatly improved.

Owner:SHANGHAI SINYANG SEMICON MATERIALS

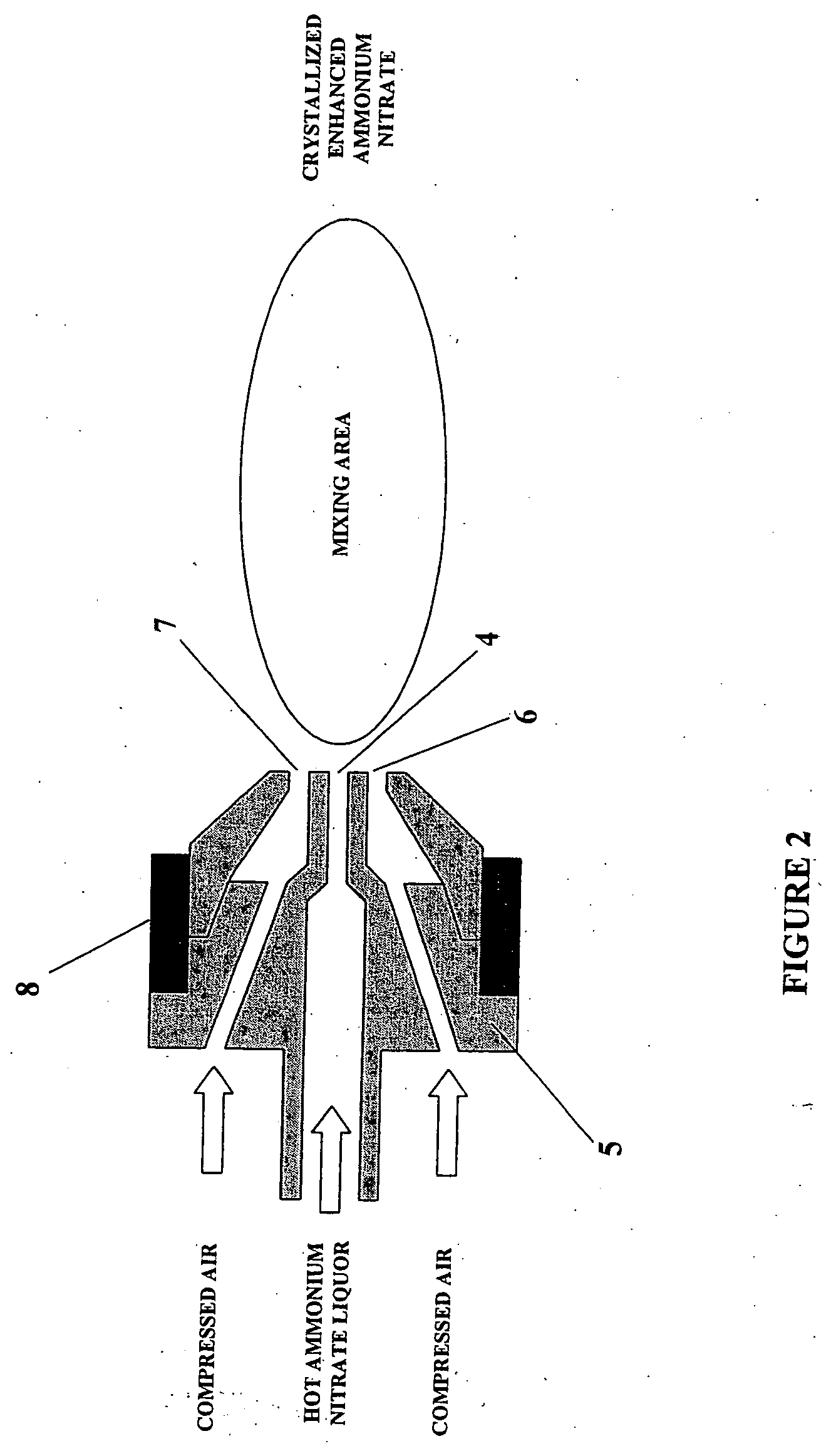

Ammonium nitrate blasting agent and method of production

InactiveUS20050269002A1Improve waterproof performanceProcess safetyAmmonium nitratesGranulation by liquid drop formationCrystal habitAmmonium nitrate

A method of producing an ammonium nitrate blasting agent and such an agent. The method comprises the steps of first combining together a crystal habit modifier with an aqueous solution of ammonium nitrate. Using the mixture of the crystal habit modifier and the ammonium nitrate solution, ammonium nitrate crystals are formed having a particle size of about 1 to about 500 microns. The ammonium nitrate crystals are then combined with an organic carbonaceous fuel at a ratio such that the organic carbonaceous fuel is from about 2 to about 10 percent by weight of the blasting agent.

Owner:NEXCO INC

Stable Aqueous Compositions

ActiveUS20160235071A1Effective controlSolve the stability is not highBiocideAnimal repellantsAlcoholChemical composition

The present invention relates to an herbicidal composition particularly stable at lower temperatures. The present invention provides a stable herbicidal composition comprising at least one pesticide in its salt form and a crystal habit modifying system comprising an alkoxylated alcohol and a polymer. Further the invention relates to a stable herbicidal composition comprising at least two pesticides in their salt form and a crystal habit modifying system comprising an alkoxylated alcohol and a polymer.

Owner:UNITED PHOSPHORUS LTD

Crystallization method for improving crystal habit of ethyl vanillin by adding polyvinylpyrrolidone

ActiveCN109534978AFine granularityIncreasing the thicknessCarbonyl compound separation/purificationMagmaFiltration

The invention relates to a crystallization method for improving the crystal habit of ethyl vanillin by adding polyvinylpyrrolidone. The method includes: adding an ethyl vanillin crude product and polyvinylpyrrolidone into a mixed solvent, performing stirring and heating to 35DEG C-50DEG C for dissolution, after the solid is completely dissolved, performing cooling to 15DEG C-25DEG C, adding ethylvanillin seed crystal, conducting grain growing for 10-40min, then performing cooling to 0DEG C-10DEG C, filtering the magma and conducting drying to obtain a ethyl vanillin crystal. The ethyl vanillin product prepared by the method provided by the invention has nonbreakable crystal, is thick flake shaped, has a height-to-width ratio of 0.11-0.25, large particle size, a main particle size of 275-508microm, a tap density up to 0.31-0.47g / mL, good fluidity and a repose angle of 37-47DEG C. The product obtained by the method is easy for filtration and drying, and is beneficial to storage and transportation, thus greatly improving the market competitiveness of the product.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com