Preparation method for synergetic reinforcing and toughening polypropylene composite material

A composite material and polypropylene-based technology, which is applied in the preparation of synergistically reinforced and toughened polypropylene-based composite materials and the reinforcement and toughening process of extrusion-molded polypropylene-based composite materials, can solve the problems of decreased strength and rigidity, complex process, The problem of high cost is to achieve the effect of balancing excellent toughness and rigidity, simple preparation process and remarkable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Polypropylene (PP, 1300, Maoming Petrochemical) and polyolefin elastomer (POE, 8150, DuPont-Dow Chemical) were selected as experimental raw materials, and the melt indices of the two were 2.5g / 10min (215°C, 2.16 Kg) and 0.8g / 10min (230°C, 5Kg). The blend of polypropylene and polyolefin elastomer with a mass ratio of 80 / 20 is mixed and granulated by twin-screw extrusion, and vacuum-dried before use. The temperature of each stage of twin-screw extrusion granulation is set at 165-190- 200-195°C;

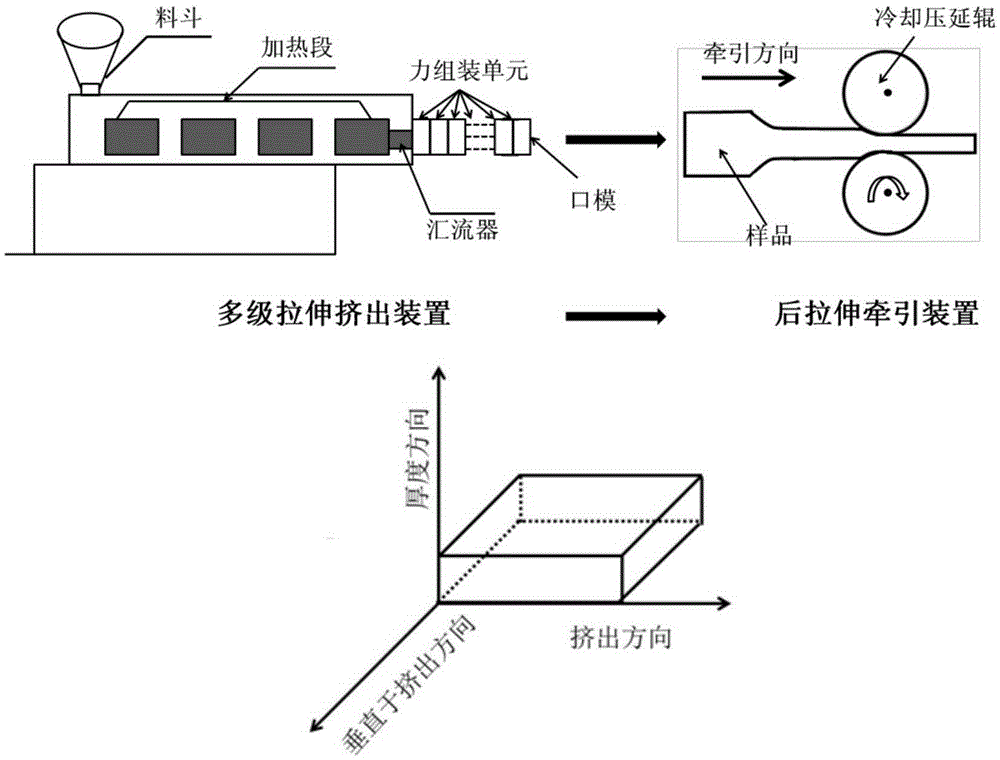

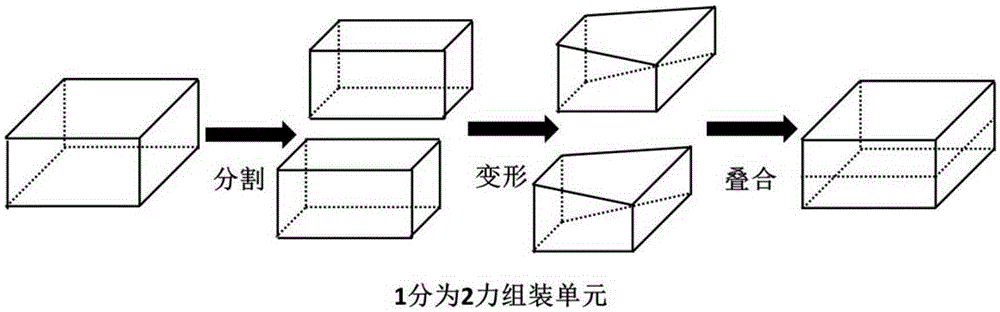

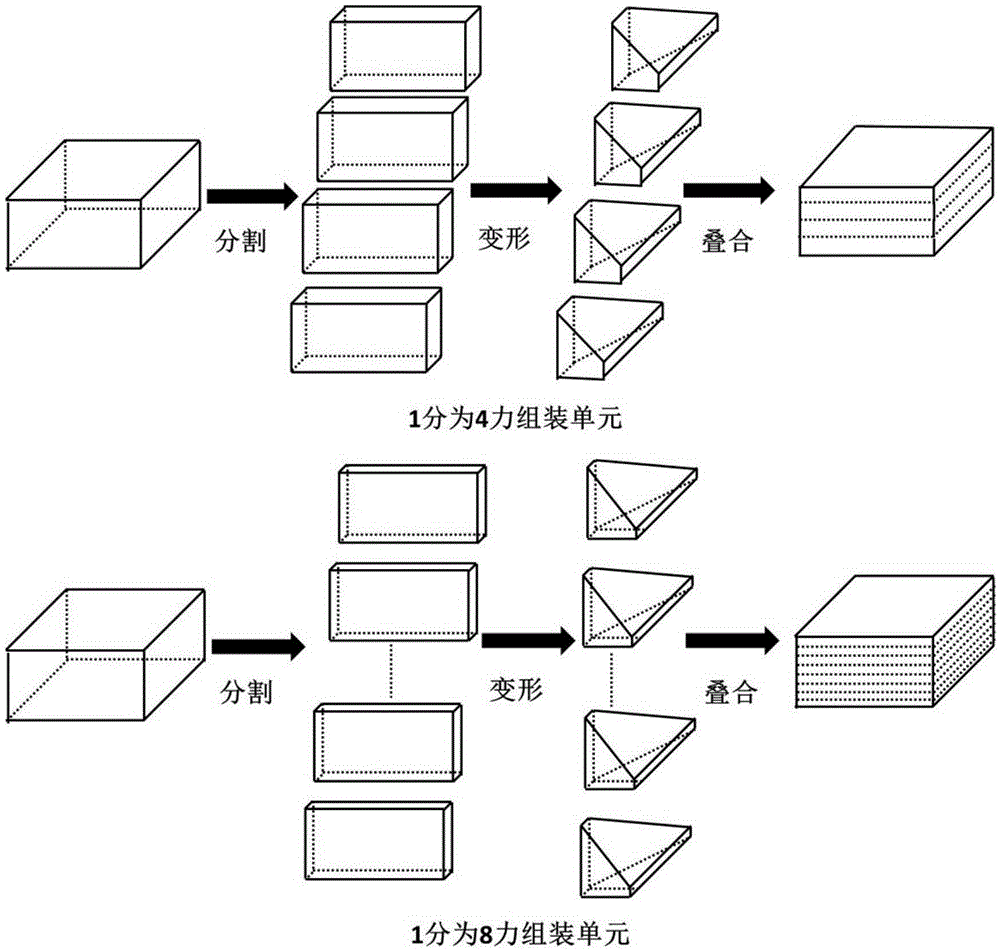

[0036] (2) Put the dried blend masterbatch into a multi-stage stretching device consisting of a single-screw extruder (1), a confluence (2), a force assembly unit (3), and a cooling roll (4) (see figure 1 ) in a single-screw extruder. Through the continuous splitting and shearing action of four one-two-force assembly units, it flows out from the discharge port, and after traction, calendering and cooling, a polypropylene-based sheet with a thickness of about 1.8mm is obtain...

Embodiment 2

[0040] (1) Polypropylene (PP, 1300, Maoming Petrochemical) and polyolefin elastomer (POE, 8150, DuPont-Dow Chemical) were selected as experimental raw materials, and the melt indices of the two were 2.5g / 10min (215°C, 2.16 Kg) and 0.8g / 10min (230°C, 5Kg). The blend of polypropylene and polyolefin elastomer with a mass ratio of 80 / 20 is mixed and granulated by twin-screw extrusion, and vacuum-dried before use. The temperature of each stage of twin-screw extrusion granulation is set at 165-190- 200-195°C;

[0041] (2) Put the dried blend masterbatch into a multi-stage stretching device consisting of a single-screw extruder (1), a confluence (2), a force assembly unit (3), and a cooling roll (4) (see figure 1 ) in a single-screw extruder. After 6 assembling units divided into two, it flows out from the discharge port, and after being drawn and calendered by a traction cooling roller, a polypropylene-based sheet with a thickness of about 1.8mm is obtained. The temperatures of t...

Embodiment 3

[0048] (1) Polypropylene (PP, K1001, Yanshan Petrochemical) and polyolefin elastomer (POE, 8200, Dow Chemical) were selected as experimental raw materials, and the melt indices of the two were 1.0g / 10min (215°C, 2.16Kg) and 5.0g / 10min (215°C, 2.16Kg). The blend of polypropylene and polyolefin elastomer with a mass ratio of 80 / 20 is subjected to twin-screw extrusion, mixing, granulation, and vacuum drying before use. The temperature of each stage of twin-screw extrusion granulation is set at 175-195- 210-205°C;

[0049] (2) Put the dried blend masterbatch into a multi-stage stretching device consisting of a single-screw extruder (1), a confluence (2), a force assembly unit (3), and a cooling roll (4) (see figure 1 ) in a single-screw extruder. After three assembling units divided into two, it flows out from the discharge port, and after traction, calendering and cooling, a PP / POE composite material with a thickness of about 0.6mm is obtained. The temperatures of the feeding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com