Preparation process of stainless steel ultra-thin strip/carbon fiber pipe

A preparation process and technology for ultra-thin strips, applied in the field of preparation technology of stainless steel ultra-thin strips/carbon fiber pipes, can solve the problems of difficult bending and forming of metal sheets, limited weight reduction, difficult forming, etc. , the effect of good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

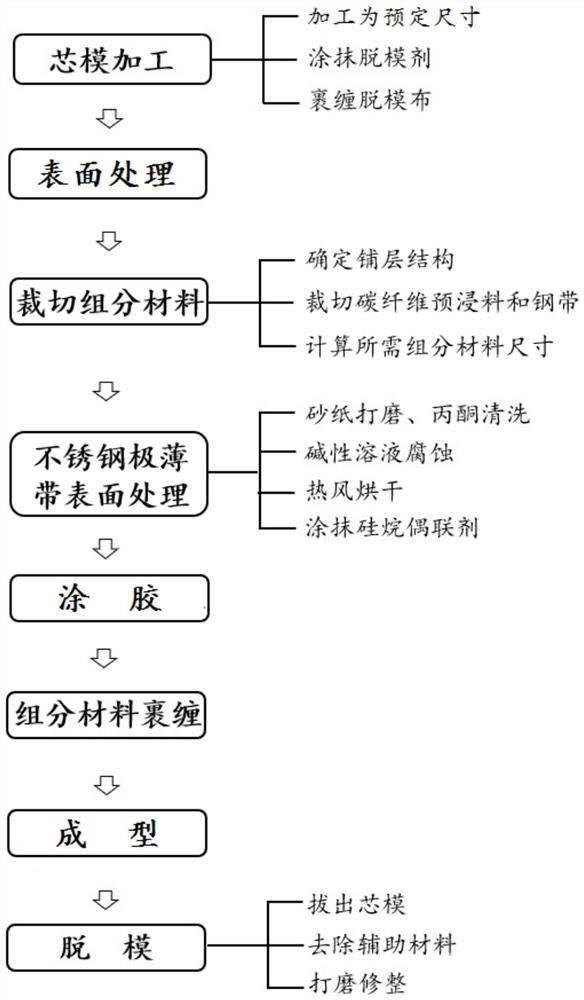

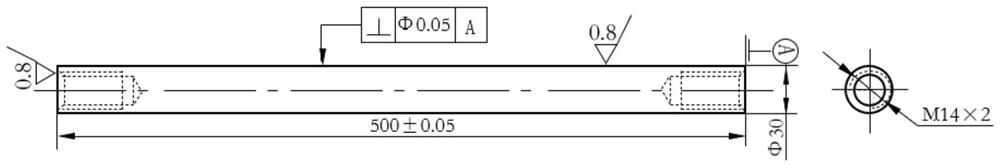

[0033] like figure 2 , Figure 4 Shown, a kind of preparation technology of stainless steel ultra-thin strip / carbon fiber pipe, it is characterized in that: comprise the steps:

[0034] Step 1. Mandrel processing: process the original mandrel into an invar steel round bar mandrel with a diameter of 30 mm and a length of 500 mm, with a surface finish of 0.8 and a verticality of 0.05 between the end face and the side of the bar mandrel; Threaded holes are processed at both ends to facilitate screwing in the handle for demoulding; the surface of the rod-shaped mandrel is finished to ensure that the surface roughness meets the requirements for applying the release agent;

[0035] Step 2. Surface treatment: Use acetone to clean the surface of the rod-shaped mandrel obtained in Step 1. After it is completely dry, apply a release agent and wrap it with a layer of release cloth;

[0036] Step 3. Cutting component materials: Determine the layer structure from inside to outside as 5 ...

Embodiment 2

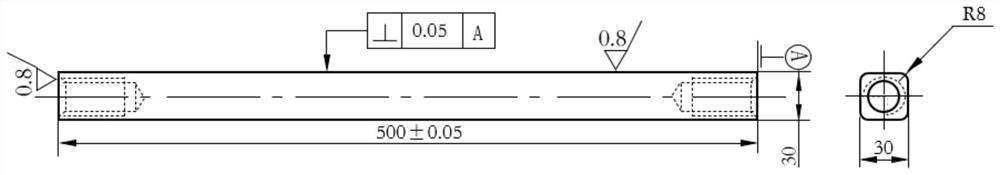

[0043] like image 3 , Figure 5 Shown, a kind of preparation technology of stainless steel ultra-thin strip / carbon fiber pipe, it is characterized in that: comprise the steps:

[0044] Step 1. Mandrel processing: process the original mandrel into an invar steel square bar mandrel with a side length of 30mm, a fillet radius of 5mm, and a length of 500mm. The surface finish is 0.8, and the perpendicularity between the end face and the side of the bar mandrel is 0.05; Process threaded holes at both ends of the rod-shaped mandrel to facilitate screwing in the handle for demoulding; finish the surface of the rod-shaped mandrel to ensure that the surface roughness meets the requirements for applying the release agent;

[0045] Step 2. Surface treatment: Use acetone to clean the surface of the rod-shaped mandrel obtained in Step 1. After it is completely dry, apply a release agent and wrap it with a layer of release cloth;

[0046]Step 3. Cutting the component materials: Determine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com