Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78results about How to "Will not bring in" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cultivation method for interplanting osmanthus trees in tea garden

The invention discloses a cultivation method for interplanting osmanthus trees in a tea garden. The tea garden is in hilly terrain, and the row / line space between tea trees is 25cm*1.5m. The cultivation method for interplanting the osmanthus trees in the tea garden comprises the following steps: 1) applying a base fertilizer to the entire land; 2) planting the osmanthus trees, wherein the distance between an osmanthus tree seedling and the tea tree is greater than 50 cm; and 3) performing subsequent management: pruning the osmanthus trees. By adopting the cultivation method disclosed by the invention, the gap between the tea trees can be sufficiently used, the workload of intertillage weeding is reduced, the water and soil are conserved, the tea garden fill is reduced, and higher economical benefits are achieved based on the limited land resources. The tea leaves picked by utilizing the cultivation method can be directly used for making osmanthus tea without bringing harmful substances into the osmanthus, the quality of the tea leaves is improved, the tea making processes are reduced, and the tea making cost is saved.

Owner:福州弥高仙茶业有限公司

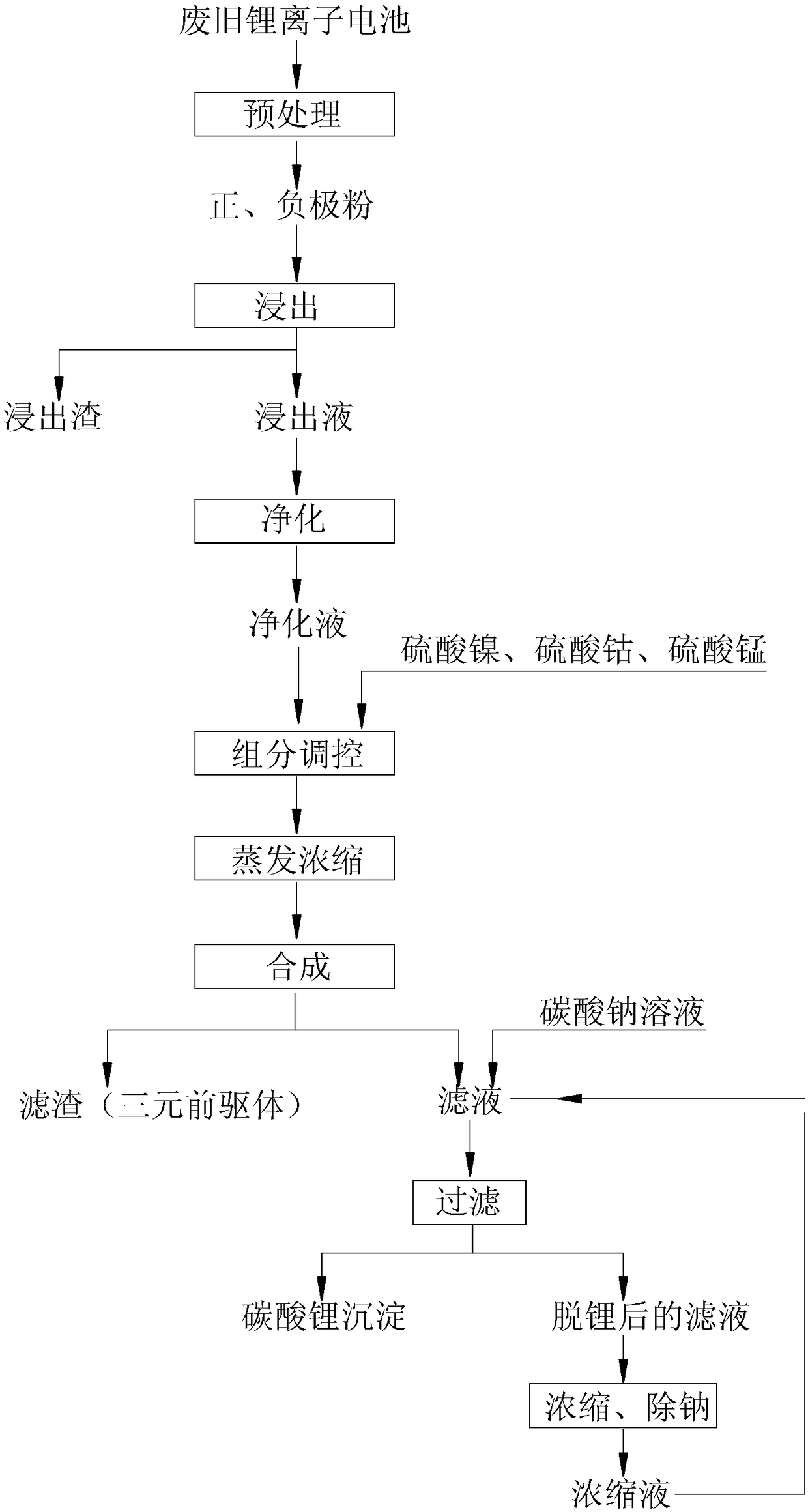

A method for recovering valuable metals from waste lithium ion batteries

ActiveCN108963371AReduce consumptionShort processWaste accumulators reclaimingProcess efficiency improvementPregnant leach solutionManganese

The invention discloses a method for recovering valuable metals from waste lithium ion battery, which comprises the following steps: (1) pretreatment: separating positive and negative electrode powderfrom waste lithium ion battery; 2, leaching, and taking leach solution; 3) purification: adding alkali to that leach solution to adjust the pH value, and removing iron, aluminum and copper to obtainpurified solution; (4) Component control and evaporation concentration: adjusting the proportion of nickel, cobalt and manganese in the purified solution; then evaporating and concentrating, enrichingnickel, cobalt and manganese to set concentration to form precursor preparation liquid; 5) synthesis: passing the precursor preparation liquid, NaOH solution and ammonia water into a reaction kettle,controlling the pH value of the solution in the reaction kettle, carrying out reaction, and filtering after the reaction, wherein the filtered residue is the a ternary precursor. The leaching solution of the invention is purified, nickel cobalt manganese salt is supplemented, evaporated and concentrated, and the precipitant is added to directly synthesize the ternary precursor. The utility modelhas the advantages of short process flow, low consumption of raw materials, high recovery rate and high added value of products.

Owner:赣州寒锐新能源科技有限公司

Preparation method of rare earth ferroalloy

ActiveCN111411372AThe composition is uniform and stableReduce segregationInduction furnaceLithium fluoride

The invention discloses a preparation method of a rare earth ferroalloy. The preparation method of the rare earth ferroalloy comprises the steps that a rare earth iron immediate alloy is prepared by non-self-consuming cathode electrolysis; an electrolyte is loaded in an electrolytic cell, a graphite carbon plate is used as an anode, a tungsten or molybdenum material is used as an cathode, and a crucible under the tungsten and molybdenum cathode is used as a receiver; in an electrolyte system of rare earth fluoride and lithium fluoride molten salt, rare earth oxide and iron are used as raw materials, then a direct current is passed for electrolysis, and the rare earth iron immediate alloy is obtained in the receiver; and the rare earth iron immediate alloy and iron are put into the crucibleas the raw materials, and the rare earth iron immediate alloy is further smelted by a melting and mixing method in a medium frequency induction furnace to obtain the rare earth ferroalloy. The rare earth ferroalloy obtained by the preparation method has uniform and stable composition, low impurity element content and close density and melting point to the density and melting point of steel, and the rare earth ferroalloy is easy to be added to the steel; and the rare earth ferroalloy can fundamentally solve the problem of effective addition of rare earth in the steel and can accurately controlthe content of the rare earth in the steel.

Owner:BAOTOU RES INST OF RARE EARTHS +1

Silicon wafer cleaning agent and use method thereof

InactiveCN101880609AEasy to operateWill not bring inSemiconductor/solid-state device manufacturingOrganic non-surface-active detergent compositionsOrganic baseStandard electrode potential

The invention discloses a silicon wafer cleaning agent and a use method thereof. The silicon wafer cleaning agent consists of oxidant, organic base, penetrant and water, and the volume ratio of the components is as follows: oxidant : organic base : penetrant : water equal to 0.02-0.1:1-4:0.5-1:30-50; the standard electrode potential of the oxidant is not less than 1.7V, and the oxidant is ozone or hydrogen peroxide; the organic base is selected from one or more of the following components: triethanolamine, sodium alkoxide, sodium alkyl, lithium alkyl, lithium amide and quaternary ammonium base; and the penetrant is fatty alcohol-polyoxyethylene ether or sodium diethylhexyl sulfosuccinate. The cleaning agent can be simply operated, silicon wafer cleaning does not become complex, the cost is low, no pollution is generated, and the cleaning agent cannot bring impurities to stain silicon wafers, and is environment-friendly.

Owner:GD SOLAR

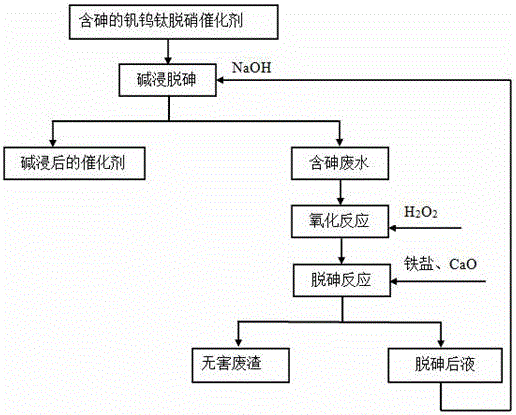

Method for dearsenization of arsenic containing waste water generated in regeneration process of vanadium, tungsten and titanium denitration catalyst

InactiveCN105668897AHigh removal rateSimple methodTreatment involving filtrationMultistage water/sewage treatmentPollutionSodium hydroxide

The invention relates to a method for removing arsenic from arsenic-containing wastewater produced in the regeneration process of a vanadium-tungsten-titanium denitrification catalyst, and belongs to the technical field of chemical engineering. The method is to carry out arsenic-containing catalyst and sodium hydroxide solution for alkali leaching dearsenic reaction. After the reaction, the catalyst and arsenic-containing wastewater after alkali leaching are obtained, and the arsenic-containing wastewater needs to be further treated for arsenic removal; Oxidation reaction is carried out by adding oxidizing agent hydrogen peroxide, then adding iron salt to adjust the pH of the solution>9, then adding CaO at 50-100° C., and continuing the reaction for 0.5-3 hours. After the reaction is finished, liquid-solid separation is carried out. The liquid phase is the liquid after de-arsenic, which can be prepared by adding sodium hydroxide to a solution containing sodium hydroxide, and then returns to participate in the alkali leaching de-arsenic reaction, which is recycled in the entire catalyst regeneration system; the solid phase It is harmless waste and can be piled up directly. The content of As in the waste water after arsenic removal treatment is less than or equal to 0.5 mg / l. This method not only reduces the cost, but also does not cause any pollution to the environment.

Owner:KUNMING METALLURGY INST

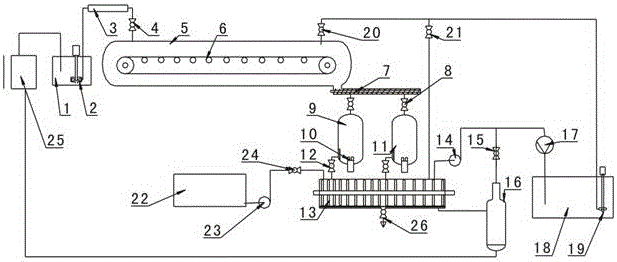

Production method and production apparatus for insoluble sulfur

ActiveCN106082139ANo pollution in the processEasy accessSulfur preparation/purificationDistillationVacuum pump

The invention discloses a production method for insoluble sulfur. The method comprises the steps of: sulfur melting and heating; quenching; conveying and solidification; coarse crushing; curing and fine crushing; and sieving, washing, drying, and oil charging. The invention also discloses a production apparatus of insoluble sulfur. The production apparatus consists of: a sulfur melting groove, a liquid sulfur pump, an electric heater, a reaction pot, a conveyer belt, a screw conveyer, aging pots, colloid mills, screen meshes, a rake dryer, a vacuum pump, a distillation tower, a condenser, a naphthenic oil storage tank, a submerged pump, a carbon disulfide storage tank, a metering pump and a sulfur purifier. Through the components, the process of sulfur melting, heating, quenching, conveying, solidification, coarse crushing, curing, fine crushing, sieving, washing, drying, and oil charging can be finished. The method and apparatus for production of insoluble sulfur provided by the invention can realize whole process closed production, completely eradicate dust, and achieve the purpose of environment-friendly and clean production.

Owner:黄煜

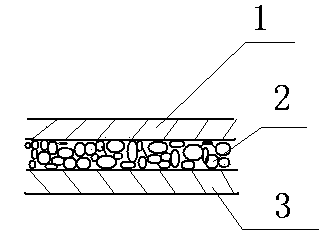

Geofabric used for ecological restoration

InactiveCN103568409AReduce absorptionDoes not affect respirationContaminated soil reclamationProtective foundationFiberEnvironmental resistance

The invention discloses a geofabric used for ecological restoration, and belongs to the field of textile geosynthetics used for industry. The geofabric is formed by a three-layer structure in a composite mode; the three-layer structure comprises an acupuncturing chopped fiber non-woven geofabric layer of 200 grams, a modified montmorillonite mineral powder layer, and a continuous fiber acupuncturing non-woven geofabric layer from top to bottom; and the three layers are connected together by acupuncturing technology in the composite mode. The geofabric is capable of absorbing heavy metals effectively, and have strong absorbability on heavy metals and low-molecule organic compounds. The content of formed complexes is extremely low in water solution. The geofabric is capable of effectively removing heavy metals and other toxic matters in surface water sources or air floating objects, further reducing soil and water pollution caused by heavy metals, and realizing water-saving and energy-saving, sustained release and environmental protection, prevention of water and soil loss via reinforcement, and the like. The geofabric can be used in projects such as farm field soil heavy metal treatment, garbage landfills and sewage processing plants. The geofabric is characterized in convenient construction, low cost, and the like, and is capable of solving problems of existing heavy metal processing that technical requirement is strict, and cost is high.

Owner:DEZHOU ORIENT GEOSYNTHETICS

Coating equipment

ActiveCN107983578AAvoid wrinklesEfficient removalLiquid surface applicatorsSpraying apparatusEngineeringSteel ball

The invention belongs to the technology for coating surfaces of objects through liquid or other fluid, and particularly relates to coating equipment. The coating equipment comprises a rack, a smoothening part, a bonding part, a cleaning part and a transmission mechanism, the rack is sequentially provided with a feeding unit, a bonding unit, a drying unit and a discharging unit, the smoothening part comprises a steel ball, a compressed spring and a cam for intermittently hitting the steel ball, the bonding part comprises an upper roller used for grinding base cloth and a lower roller used for supporting transfer paper, the cleaning part comprises a rotary barrel rotationally connected with the rack, the rotary barrel is rotationally provided with a cleaning piece used for cleaning the surface of the upper roller in a connected manner, and the transmission mechanism comprises a motor, a upper roller gear, a lower roller gear, a rotary barrel gear, a driving bevel gear and a driven bevelgear. According to the scheme, folding of the base cloth in the coating process can be effectively prevented.

Owner:NINGBO HIGH TECH ZONE SHENGWENTU TEXTILE CO LTD

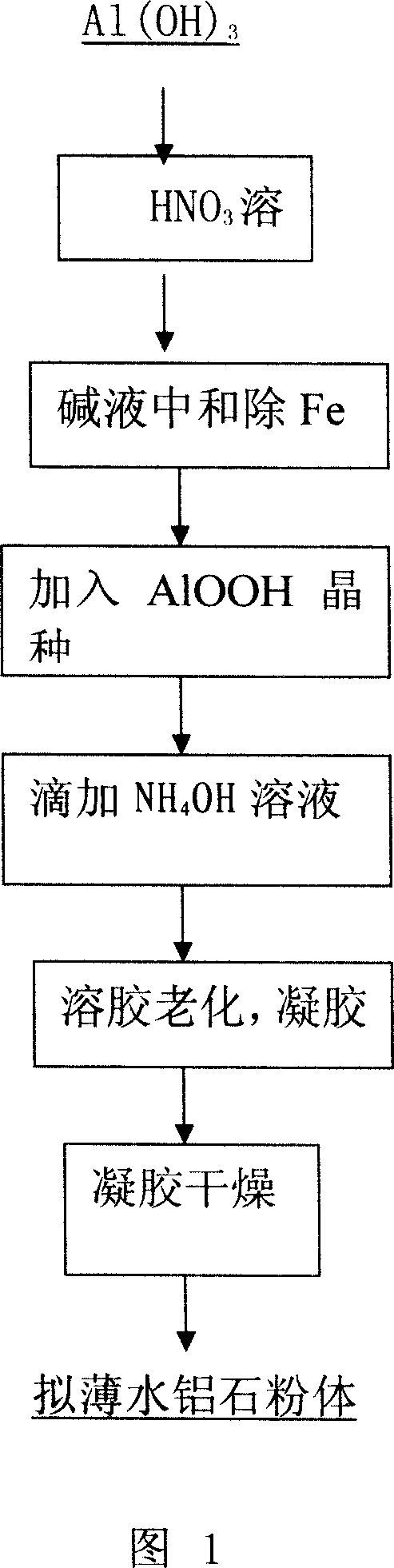

Prepn process of pseudoboehmite for luminescent material

InactiveCN1974389AWill not bring inHigh crystallinityAluminium compoundsLuminescent compositionsPseudoboehmiteCrystallinity

The present invention provides preparation process of pseudoboehmite for luminescent material, and belongs to the field of chemical material preparing technology. The preparation process includes dissolving Al(OH)3 as material in HNO3, neutralizing the solution and eliminating Fe with alkali solution, adding nanometer AlOOH crystal seed, adding NH4OH solution to form sol, ageing and stoving to obtain pseudoboehmite powder. The preparation process can raise the crystallinity of pseudoboehmite and has no impurity introduced, and the product may be used as aluminum-containing luminescent material.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

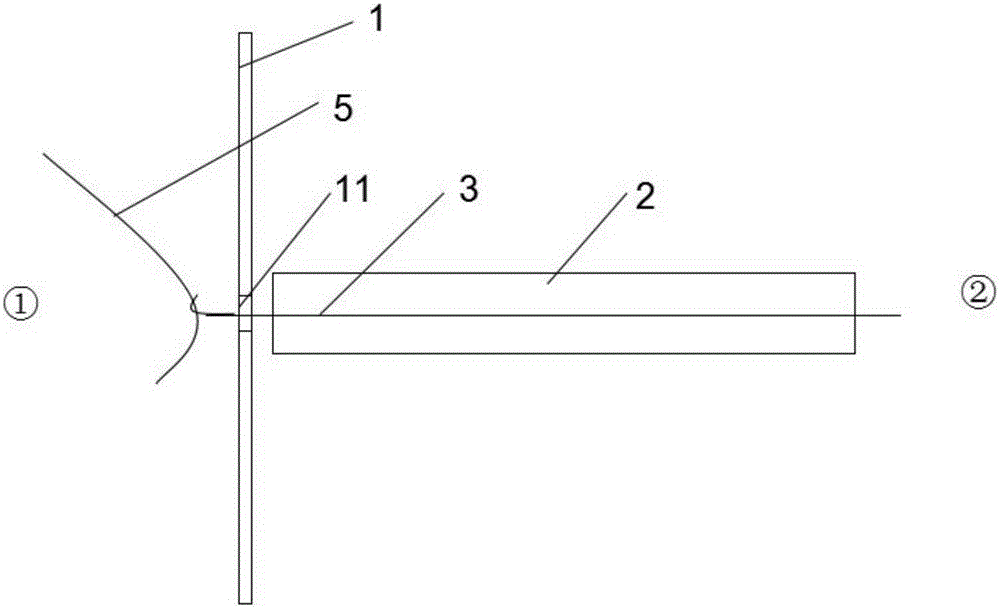

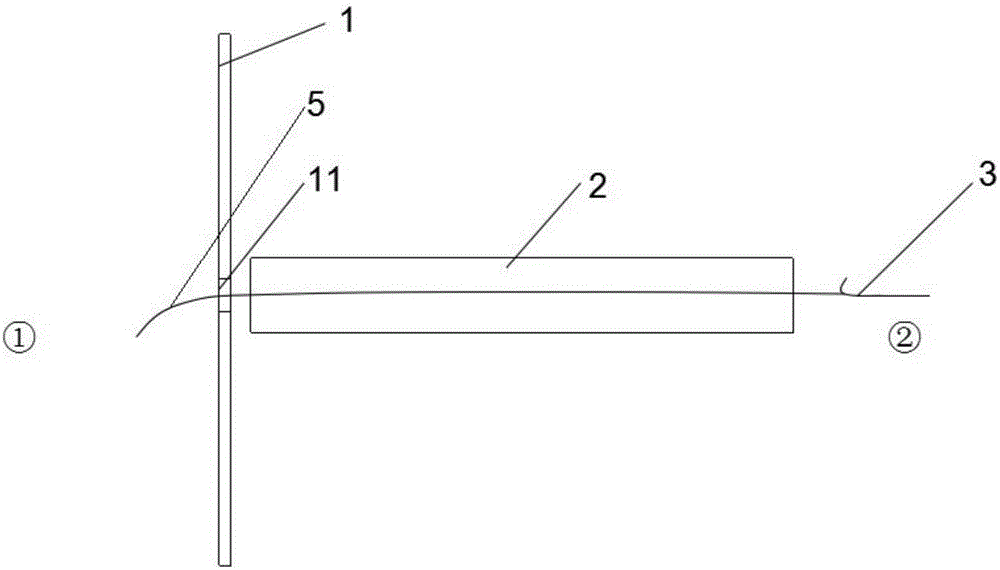

Automatic drafting machine and drafting method thereof

The invention discloses an automatic drafting machine and a drafting method thereof. The machine comprises a heddle, a rail, a crochet hook and a wallboard. The rail is half-enclosed, is composed of an upper concave block and a lower concave block which are oppositely arranged, and one side of the rail is fixed to the wallboard. The heddle is arranged on one side of the rail. A heddle eye is arranged at the position, corresponding to the position of the rail, of the heddle. After the crochet hook hooks a warp yarn, the crochet hook passes through the heddle eye and the rail, and then the drafting is completed. Nozzles are uniformly distributed in the length direction of the rail. The beneficial effects of the machine are that the nozzles are uniformly mounted in the rail through which the crochet hook passes; the nozzles are connected to an external air compression device, and the nozzles inject air in the rail; and when the crochet hook normally hooks the yarn and passes through the rail, the yarn which is attached on the surface of the rail as static electricity is generated due to friction can be blown out of the rail, so that mistakes can be reduced.

Owner:TORAY SAKAI WEAVING & DYEING NANTONG CO LTD

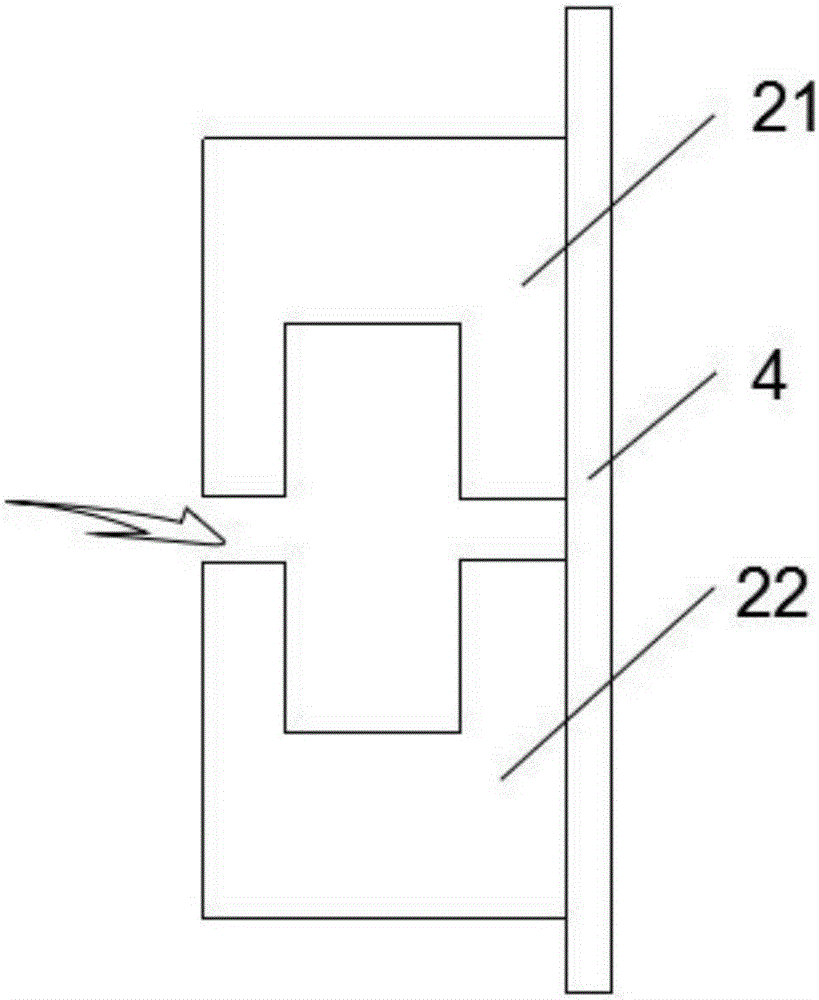

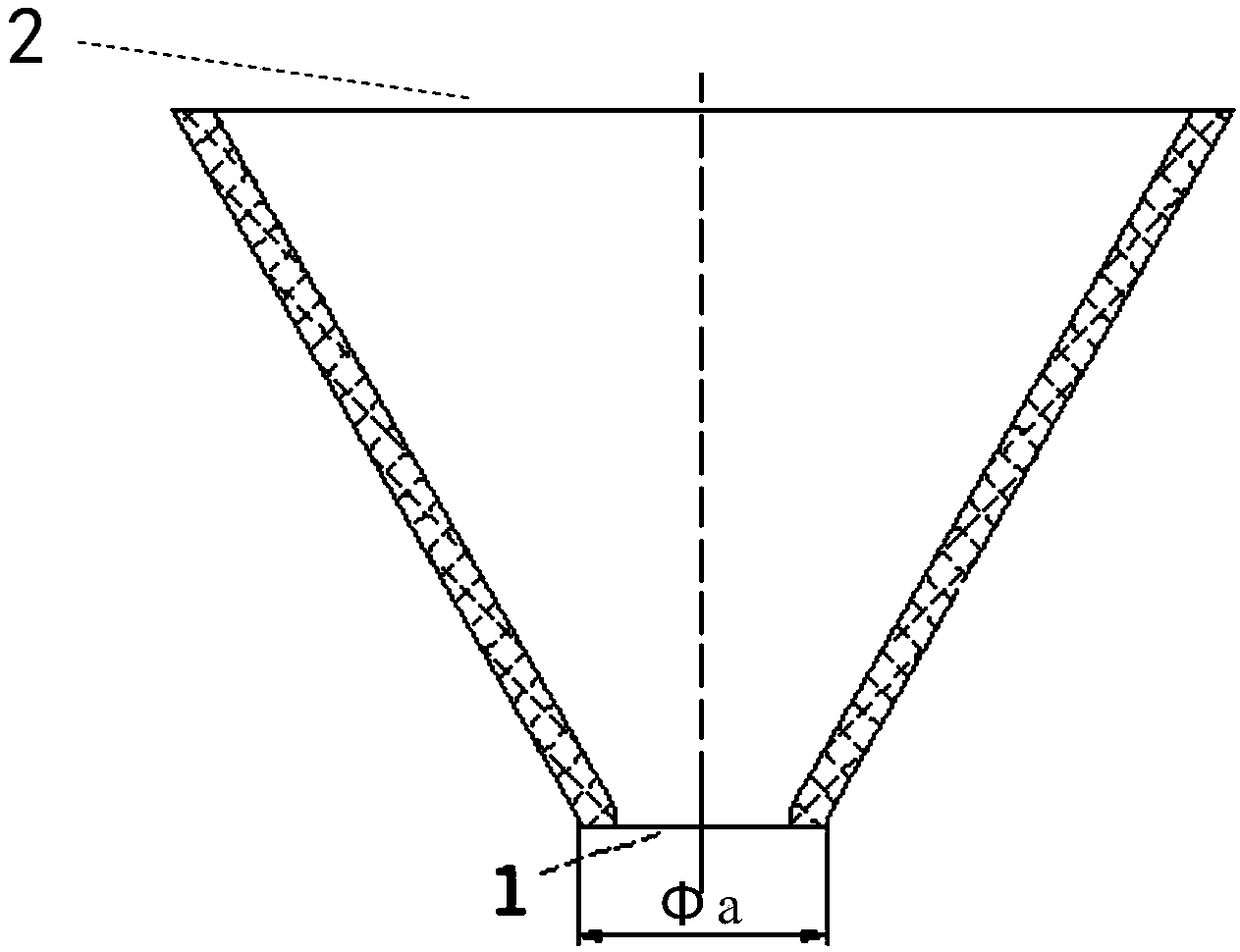

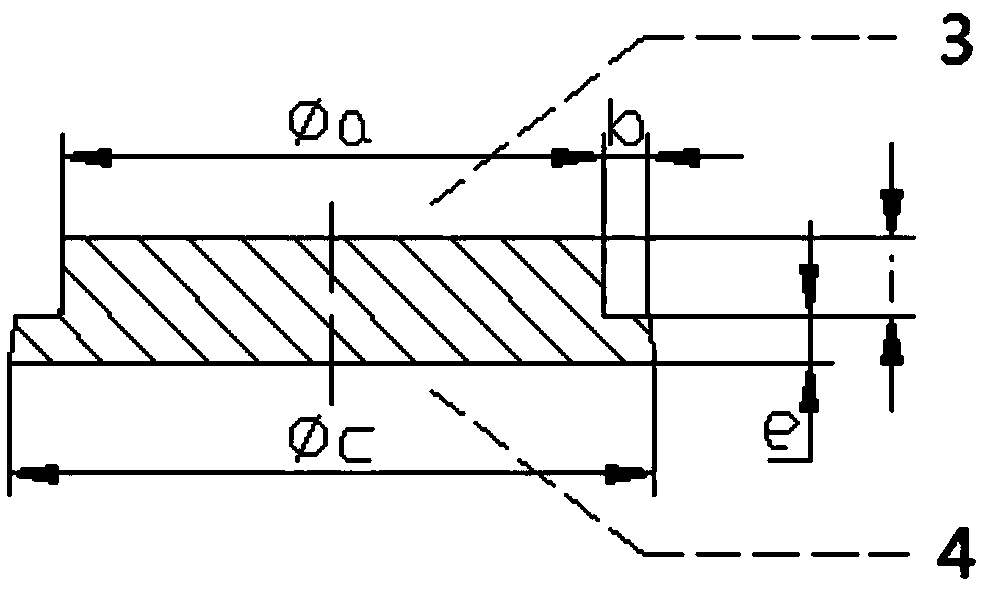

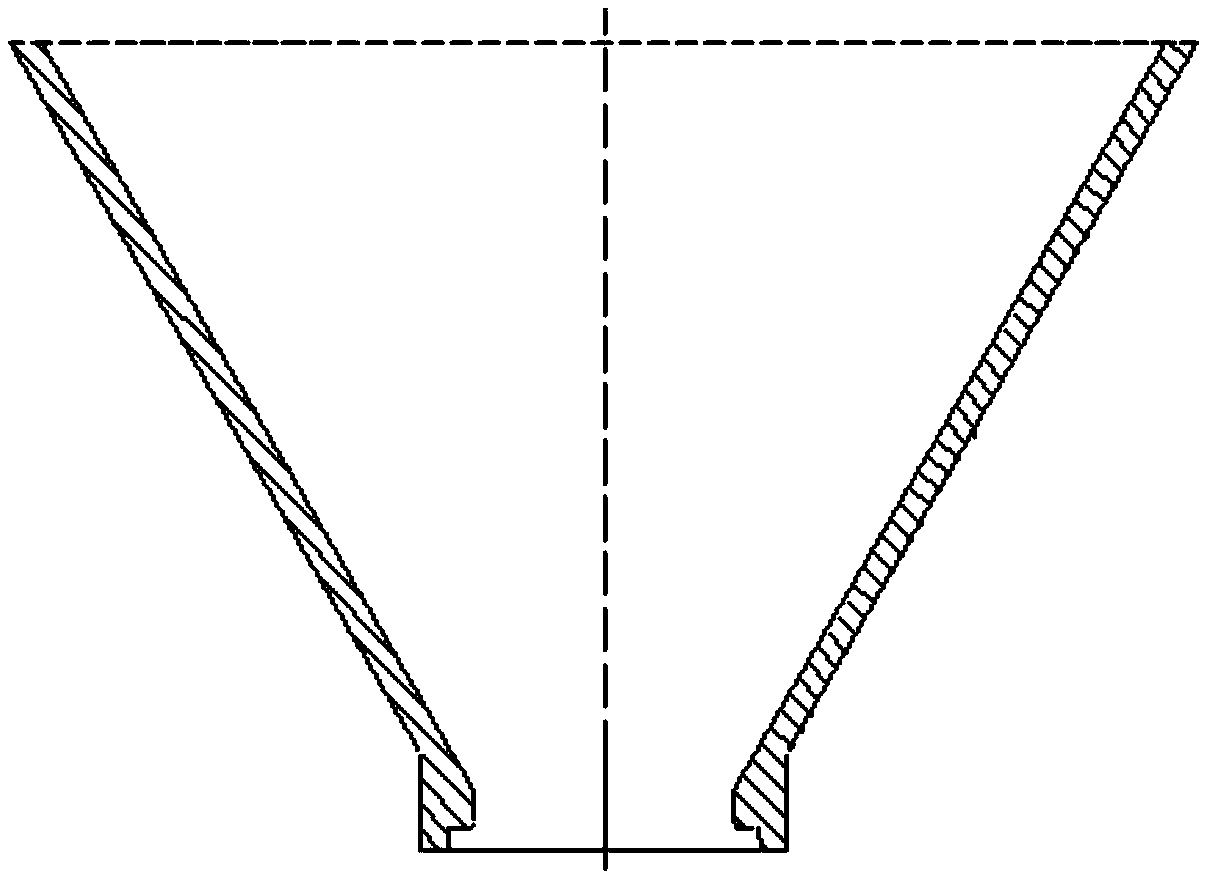

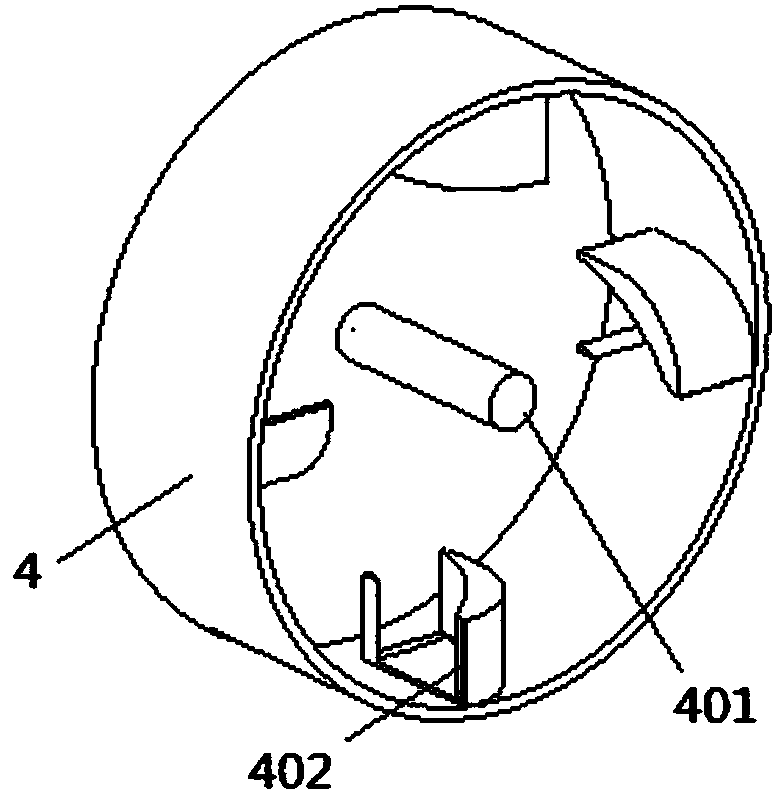

Connection method of anti-inclusion pouring cup for large casting

ActiveCN109332594AQuality improvementImprove metallurgical qualityFoundry mouldsFoundry coresWaxMaterials science

The invention discloses a connection method of an anti-inclusion pouring cup for a large casting. The process of the connection method of the anti-inclusion pouring cup for the large casting comprisesthe following steps that the wax patterns of the pouring cup and a pouring cup step segment are manufactured (please see attached drawings 1 and 2); the height e of the pouring cup step segment ranges from 10 mm to 20 mm, the pouring cup and the pouring cup step segment are connected, a shell is manufactured, and when coating of 4-5 layers of the shell is completed, a steel wire is wound (pleasesee the attached drawing 3); a pouring cup cooperation segment is manufactured according to the attached drawing 4, the size phi A is the same as the size phi a in the attached drawing 2, the size B is slightly smaller than b, and the size E is the same as e; a wax part of the pouring cup cooperation segment and a wax part of the casting are connected, and a shell is manufacture; and before pouring, the pouring cup and the casting shell are connected through refractory mortar. According to the connection method of the anti-inclusion pouring cup for the large casting, increase of inclusions inthe casting in the pouring cup connection process and the high-temperature pouring process can be completely avoided, the mounting and operation difficulty can be reduced, metal materials can be separated well, and the metallurgical quality of the casting can be improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

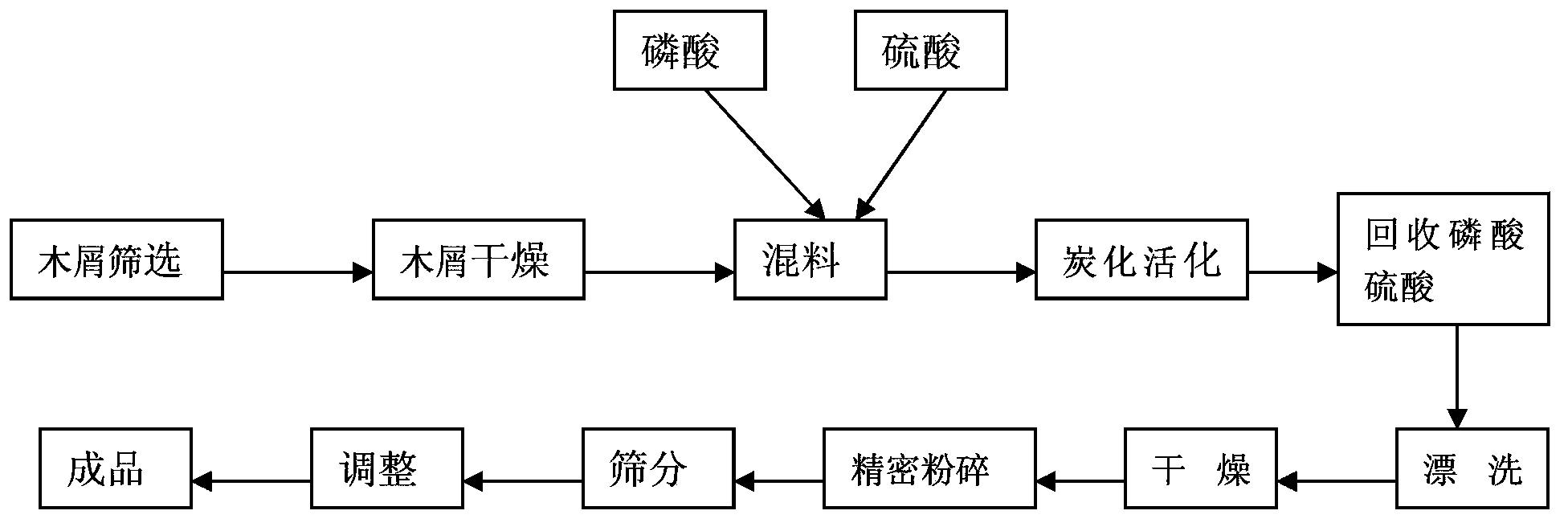

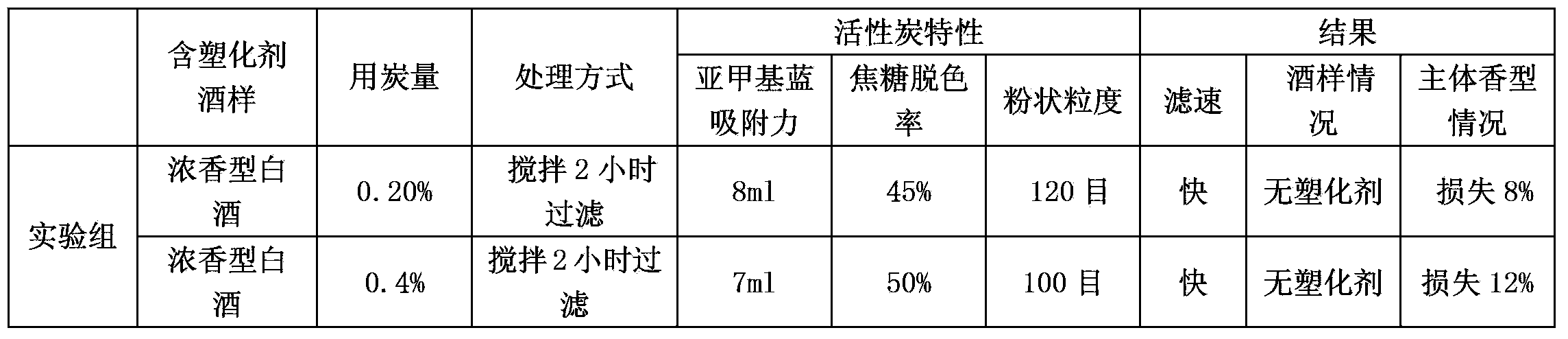

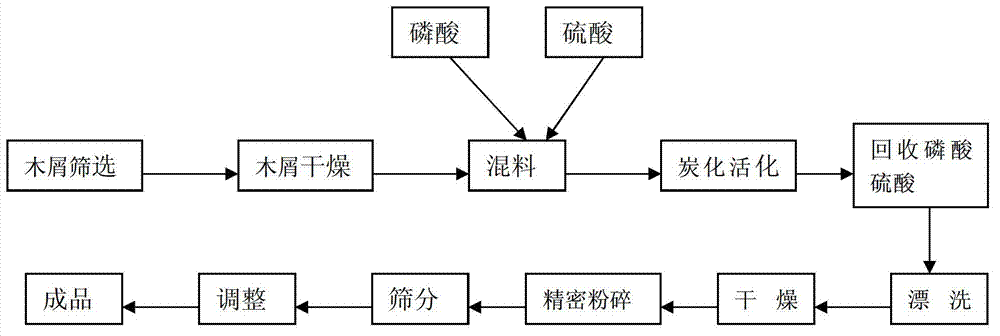

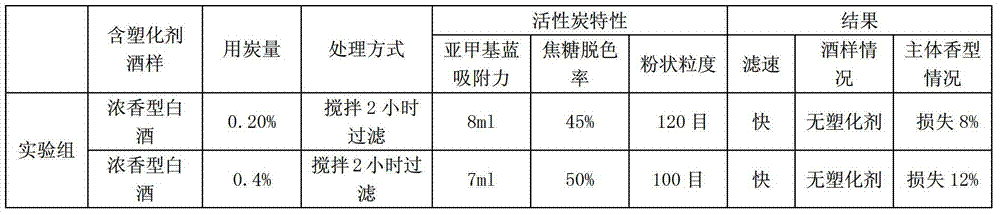

Special-purpose active carbon for removal of plasticizers in liquor and production method thereof

ActiveCN103394323AKeep the main flavorEfficient removalCarbon compoundsOther chemical processesActivated carbonPlasticizer

The invention provides special-purpose active carbon active carbon for removal of plasticizers in liquor, and the special-purpose active carbon active carbon is characterized in that: the methylene blue adsorption capacity of the activated carbon is 6-9 ml, and caramel decoloration rate is 30-60%. The invention also provides a production method and a use method of the active carbon. The special-purpose active carbon can effectively remove the plasticizers dissolved in the liquor, at the same time, main aroma types of various kinds of liquor can be maximumly retained, and the special-purpose active carbon is easy to remove without introduction of impurities.

Owner:CHONGQING BEYOND OCEAN CARBON MFR

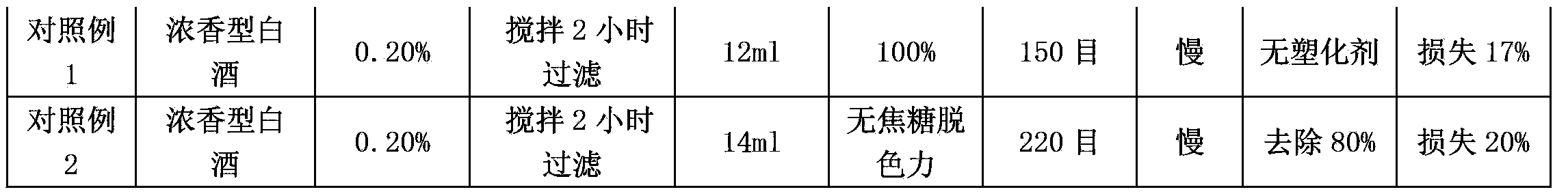

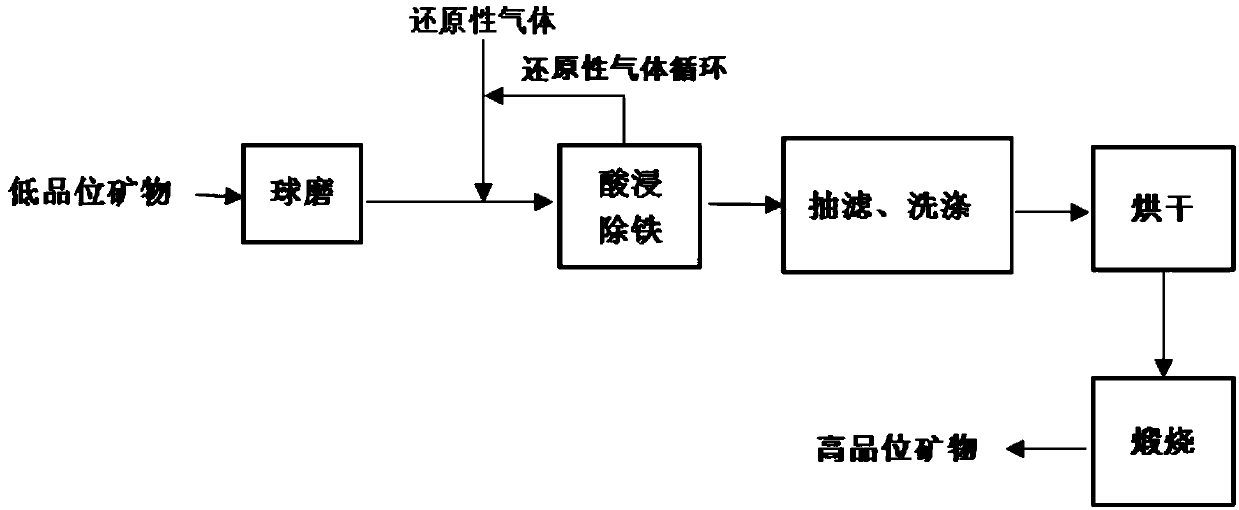

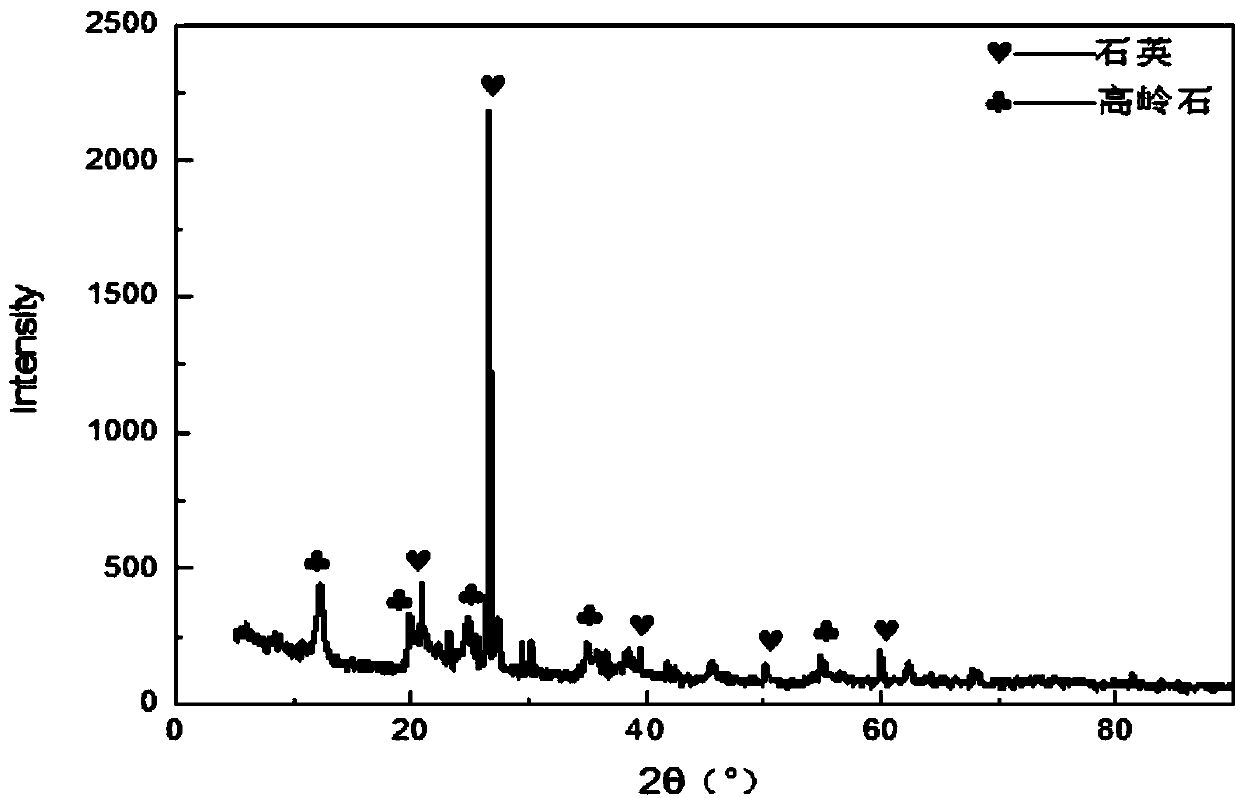

Rapid efficient iron-removing whitening method for low-grade raw material

InactiveCN109553382AAchieve iron removalTo achieve the purpose of whiteningClaywaresOrganic acidIron removal

The invention discloses a rapid efficient iron-removing whitening method for a low-grade raw material, comprising the following steps: pulverizing the low-grade raw material into mineral slurry, adding an organic acid, introducing a reducing gas, conducting a reaction at 25-95 DEG C, and after completion of the reaction, conducting solid-liquid separation, washing and drying to obtain a raw material having a reduced iron content. According to the invention, the reducing gas is directly introduced to perform iron removal and whitening when acid soaking is conducted, no new impurity is introduced, the operation is fast and efficient, and the introduced reducing gas can be recycled, so the method saves energy and is friendly to environment and low in processing cost. The raw material processed by the method is directly used for ceramic production, and the product whiteness and performance indicators fully meet the requirements of industry.

Owner:清远市简一陶瓷有限公司 +1

Method for extracting flavonoid glycoside substance

ActiveCN101670010AReduce extractionGood physical and chemical stabilityAntibacterial agentsMetabolism disorderAdditive ingredientDistillation

The invention provides a method for extracting flavonoid glycoside substance, comprising the following steps of: taking orange pericarp removed with impurities and dry powder of persimmon leaf as rawmaterials, and extracting with 20-80% alcohol; setting aside, precipitating, taking supernatant, adding diatomite that is 1-5% of supernatant in terms of mass, fully stirring, pressing and filtering by a plate filter, membrane-filtering the filtrate B with PES membrane material, and taking the micro-molecular solution passing through the membrane; putting the obtained micro-molecular solution intoa film evaporator to remove impurities by molecular distillation, collecting the required distillate, performing spray drying, and making into powder to obtain the flavonoid glycoside substance. Themethod for extracting flavonoid glycoside substance has quite simple and convenient operation and low cost, and can save a large amount of solvent, reduce the requirements on the device, also reduce pollution on the environment and well guarantee the natural quality of the flavonoid glycoside substance; the content of flavonoid glycoside component in the produced flavonoid extract is high with a total content of more than 70%, and the transfer rate of general flavone can reach more than 95% with less residual pigment.

Owner:HANGZHOU FUCHUN FOOD ADDITIVE +1

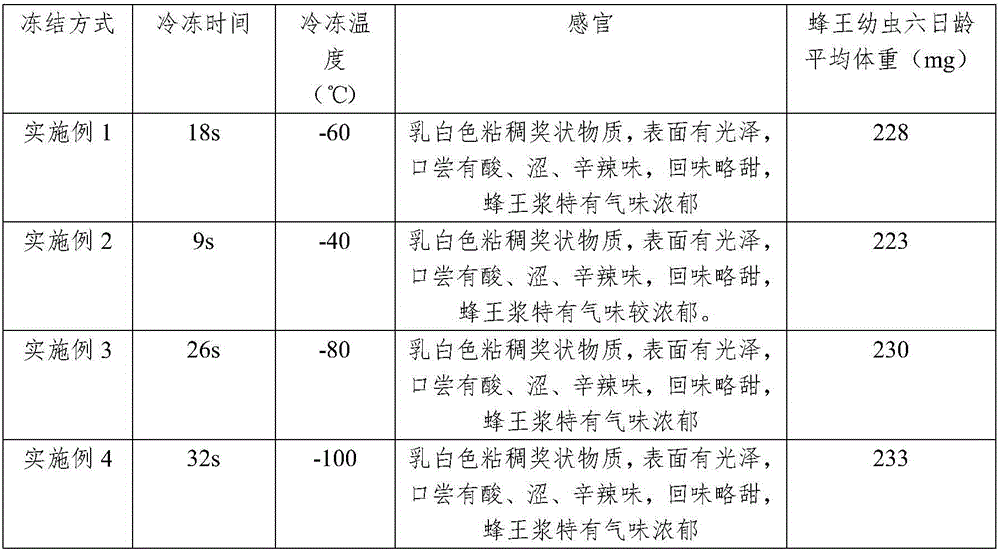

Refrigeration method and whole-process cold chain process for very fresh royal jelly

InactiveCN106666330AProtective textureProtect colorFood freezingFood processingCold chainQuick Freeze

The invention relates to a refrigeration method and a whole-process cold chain process for very fresh royal jelly. The refrigeration method comprises the following steps: taking out royal jelly from a queen cell, and performing quick-freeze treatment, namely, cooling the royal jelly to 196 DEG C below zero to 40 DEG C below zero within 9-68 seconds, and preserving at 30 DEG C below zero to 15 DEG C below zero. By adopting the refrigeration method, the quality, the color and the taste of the royal jelly can be maintained to the maximum extent, and freshness of a royal jelly raw material can be ensured from sources. In the practical operation process, collected royal jelly can be directly put into a liquid nitrogen heat-preservation bucket for quick-freeze, thus being convenient for bee farmers to use and safe and environmental-friendly. After the royal jelly is frozen, the temperature of procedures of transportation, processing, preservation, delivery and sale is strictly controlled, so that the royal jelly is treated at appropriate low temperature in the whole process, a whole-process cold chain can be formed, the quality of the royal jelly is ensured to the maximum extent, and the purposes of energy conservation and environmental-friendliness can be achieved.

Owner:北京中蜜科技发展有限公司

Method for producing bivalent manganous salt

InactiveCN107324395AReduce energy consumptionReduce pollutionOrganic compound preparationCarboxylic acid salt preparationManganeseChemical products

The present invention proposes a method for producing divalent manganese salt, which includes the following operations: mixing raw materials containing manganese dioxide, acidic aqueous solution and hydrogen peroxide, controlling the pH value of the reaction mixture to be no greater than 6.4, and generating divalent manganese salt after stirring ; Wherein, the acidic aqueous solution is an aqueous solution containing one or more of sulfuric acid, hydrochloric acid, nitric acid, acetic acid or citric acid. The invention provides a method with low energy consumption and low pollution, which converts manganese dioxide into divalent manganese salt, or removes manganese dioxide as impurities from raw materials. In the present invention, hydrogen peroxide, as a common chemical product, is cheap, produces water and oxygen after the reaction is completed, has no pollution, and does not bring impurities into the solution. According to specific needs, one or more aqueous solutions of sulfuric acid, hydrochloric acid, nitric acid, acetic acid or citric acid can be used to generate different manganese salts, so the product has good adaptability and high purity.

Owner:彭权刚 +2

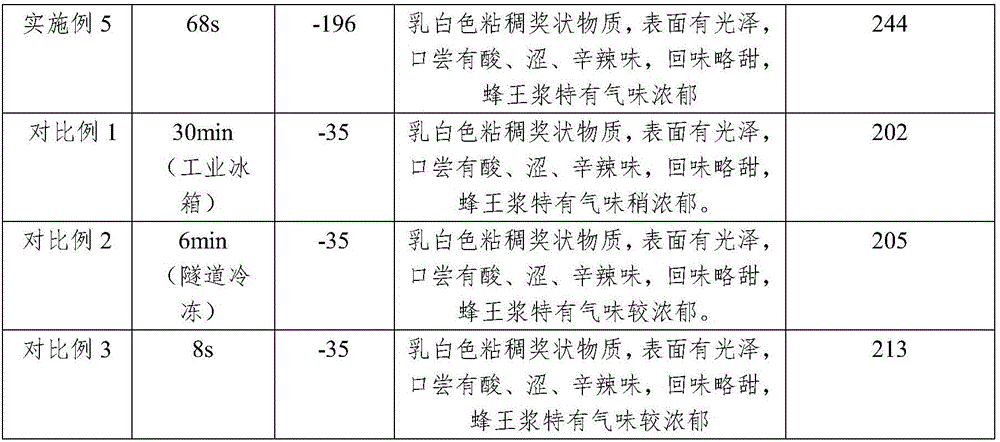

Method for removing impurities from zinc oxide leachate by using zinc hydrometallurgy purification residues

InactiveCN106756025AHigh total replacement rateQuality assuranceProcess efficiency improvementDisplacement reactionsReaction temperature

A method for removing impurities from zinc oxide leachate by using zinc hydrometallurgy purification residues uses an intermediate purification residues as a raw material, and comprises the following steps: 1, slurrying the purification residues; 2, displacing and removing impurities: removing impurities, and carrying out a displacement reaction on simple substance zinc in the purification residues and impurities in zinc oxide leachate at 70-75 DEG C under a pH value of 4.5-5.0 for 1-2 h; and 3, carrying out solid-liquid separation to obtain a displacement liquid and displacement residues. The method has the advantages of realization of open circuit removal of the impurities from the zinc oxide leachate, guaranteeing of the quality of a wet system zinc sulfate solution and increase of the economic benefits of zinc hydrometallurgy under extremely small investment cost and extremely low running cost by using the intermediate produced in the zinc hydrometallurgy system.

Owner:HUNAN SHUI KOU SHAN NONFERROUS METALS GRP

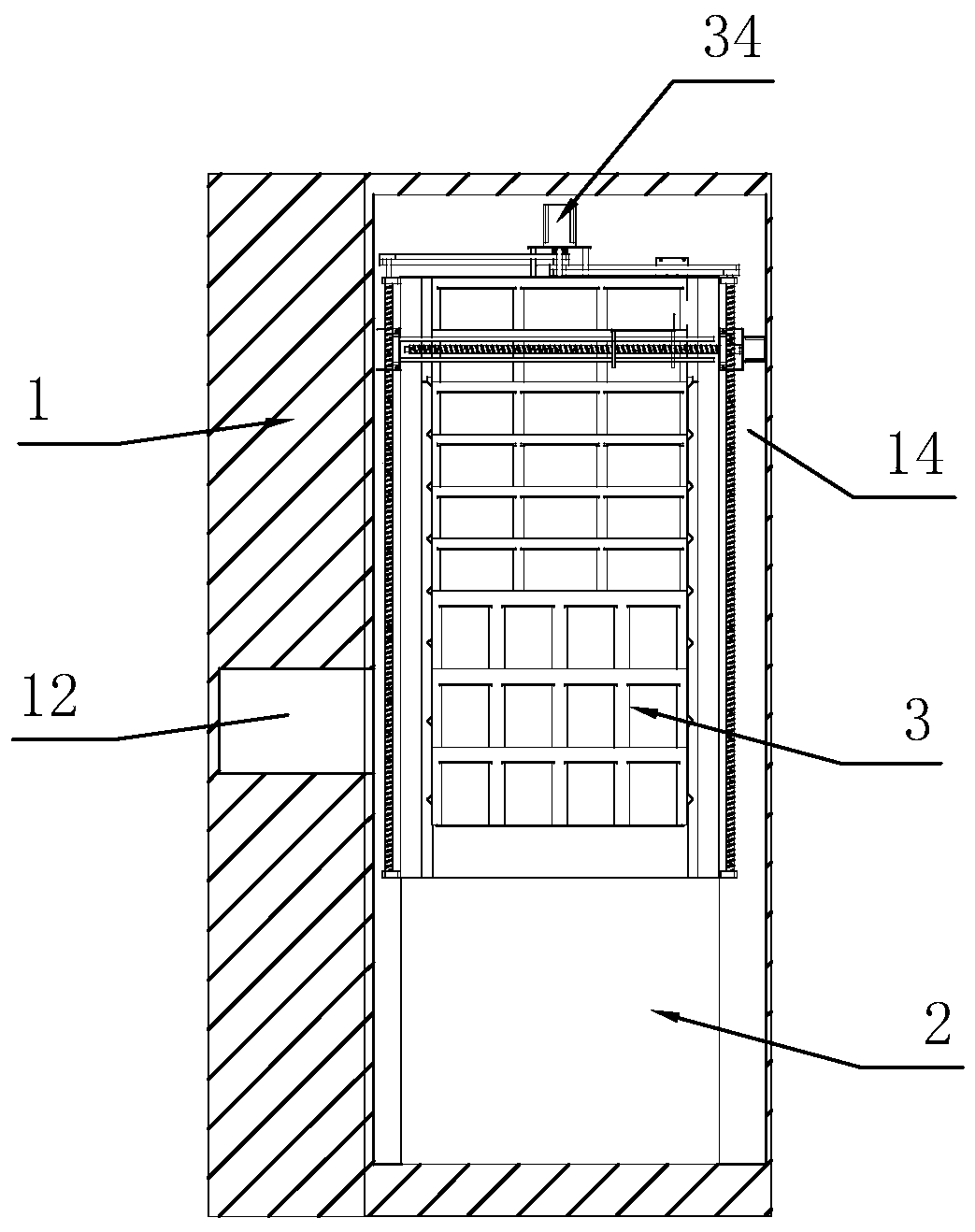

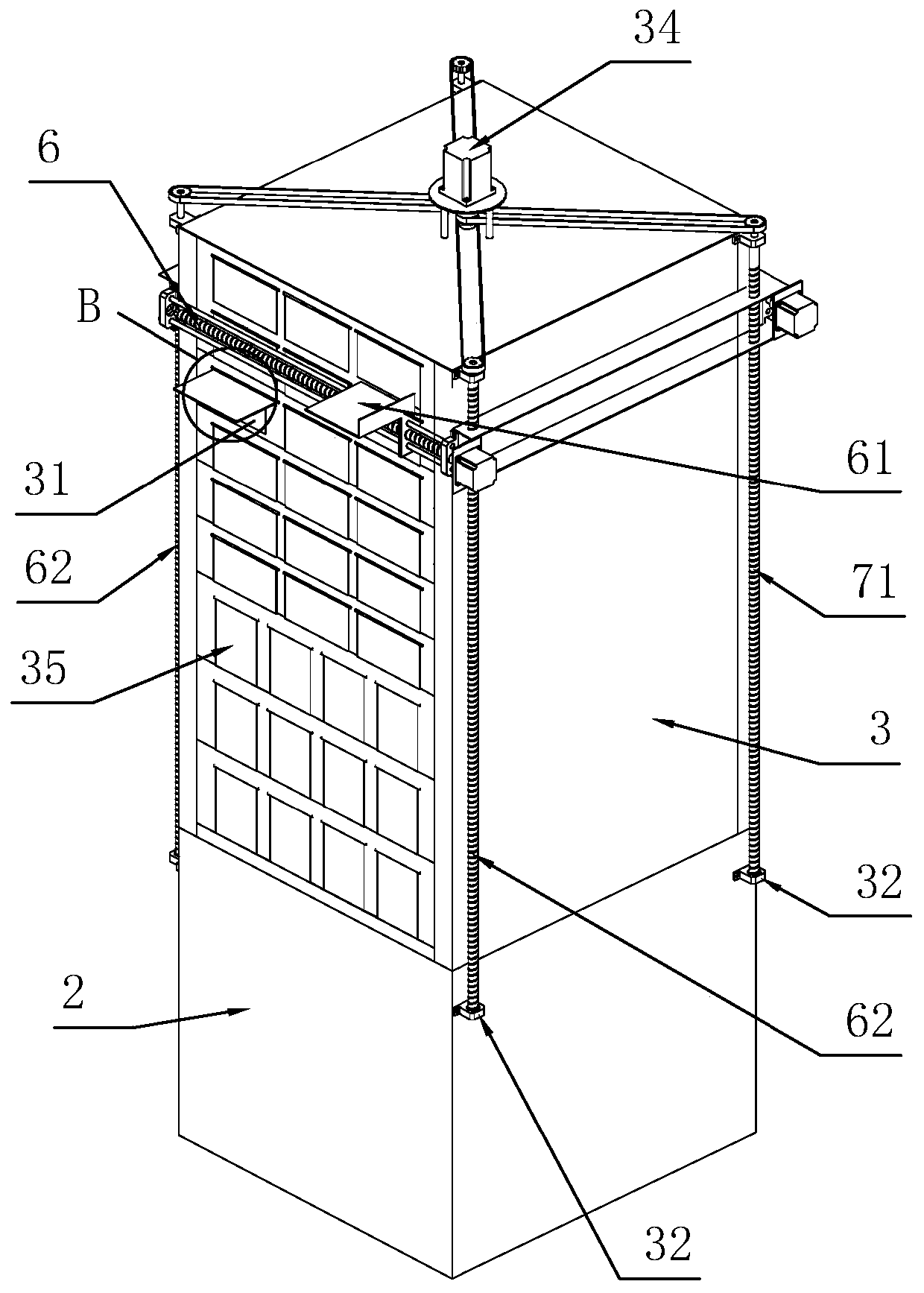

Vending machine having simple structure

PendingCN110211291AReduce the quantity requiredRealize automatic vending functionCoin-freed apparatus detailsApparatus for dispensing discrete articlesCouplingEngineering

The invention relates to a vending machine having a simple structure. The vending machine having the simple structure comprises a machine frame; a storage cavity and a pickup hole are arranged in themachine frame; several supply tracks for placing sold articles are arranged in the storage cavity; a delivery hole is formed on one end of the track direction of the supply track; a delivery mechanismfor transmitting the sold articles towards the delivery hole is arranged at the other end; the delivery mechanism comprises several push parts arranged on the various supply tracks, and a driving motor for driving the delivery part; the number of the driving motor is at least one; a first coupling part is arranged on the output shaft of the driving motor; each delivery part is separately providedwith a second coupling part; the first coupling part and the second coupling part can be in separable connection; and a switching mechanism for moving the first coupling part to any second coupling part is arranged on the machine frame. By adoption of the scheme, delivery for any supply track can be realized by adoption of the single driving motor; and thus, the vending machine having the simplestructure in the invention is low in equipment production cost, convenient to maintenance, and precise, simple and convenient to debug.

Owner:黄诚

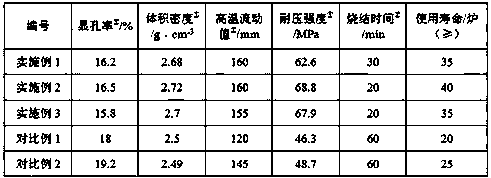

Environment-friendly silicon dry-type material and preparation method thereof

The invention discloses an environment-friendly silicon dry-type material and a preparation method thereof. The environment-friendly silicon dry-type material comprises the following components in percentage by mass: 13.6-14.4 wt% of quartz sand with the particle size of 3mm, 63.3-65.3 wt% of quartz sand with the particle size of 0.1-3mm, 15.5-16.5 wt% of quartz sand with the particle size of 0.088mm, 4.7-5.3 wt% of anhydrous glucose and 0.6-0.8 wt.% of sodium borate. When the silicon dry-type material is used for smelting plain steel, the utilization ratio can reach 90% or above, thereby greatly saving the consumption of mineral resources. Since the quartz sand is low in price, the cost is only one twentieth of the magnesium dry-type material, thereby greatly lowering the steelmaking cost in the aspect of raw materials. On the premise of lowering the cost, the environment-friendly silicon dry-type material can completely satisfy the smelting requirements for plain steel without lowering the product quality. The anhydrous glucose used as the additive is odorless, tastes sweet, and can not generate any toxic or harmful gas during baking heating, thereby protecting the environment and good health of workers.

Owner:赵仕建

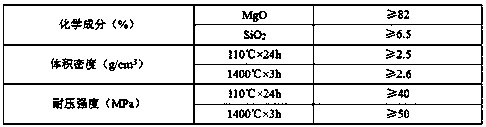

Environment-friendly water-base automatic-flowing fettling material and preparation method thereof

The invention discloses an environment-friendly water-base automatic-flowing fettling material and a preparation method of the fettling material. The fettling material comprises the following components: 5-50% of middle-grade magnesite clinker, 10-45% of 97 fused magnesite, 10-30% of 98 fused magnesite, 4-9% of silicon micropowder, 2-6% of white carbon black, 5-8% of metallic silicon, 5-8% of activated alumina micropowder, 6-15% of aluminum silica sol, 0.5-2% of SD80 and 1-3% of lignin, wherein the middle-grade magnesite clinker is graded by three particles: 10-40% of 5-3mm, 20-60% of 3-1mm and 30-60% of 1-0mm; the 97 fused magnesite is graded by three particles: 10-40% of 5-3mm, 15-50% of 3-1mm and 15-60% of 1-0mm; and the particle size of the 98 fused magnesite is 180-320 meshes. The fettling material is good in flowability, short in sintering time, good in erosion resistance and long in service life.

Owner:JIAOZUO JINXIN HENGTUO REFRACTORIES

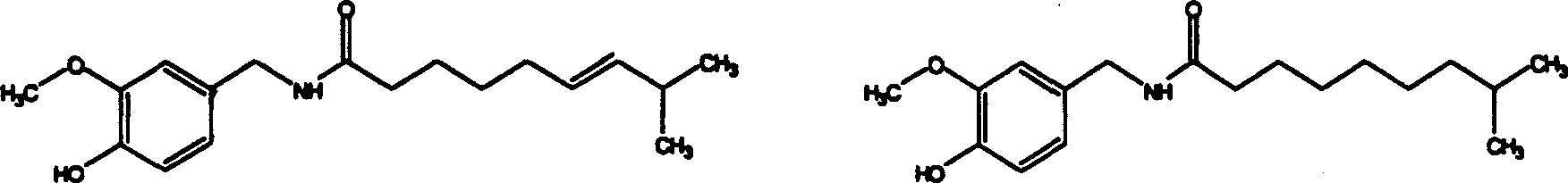

Molecular distilling process for enriching and purifying capsaicin

InactiveCN1176904CSave solventLow equipment requirementsCarboxylic acid amide separation/purificationChemistryRe crystallization

The present invention relates to the process of extracting capsaicin from chili fruit or peel and preparing natural capsaicin crystal. Extract containing capsaicin is obtained through organic solvent extraction of the spicy component from chili fruit or peel, depressing concentration and purification of the concentrated matter via molecular distillation and separation. Liquid chromatographic test shows that the extract has total content of capsaicin and dihydroapsaicin up to 50%. Through further macroporous resin adsorption and re-crystallization of the extract, may be obtained natural capsaicin crystal with capsaicin, dihydrocapsaicin and nordihydrocapsaicin in the total content up to 97%.

Owner:SUN YAT SEN UNIV

Inactive dried yeast crushing method capable of greatly improving yeast extract yield

The invention discloses a method for crushing inactive dried yeasts, which is suitable for producing yeast extracts by using the inactive dried yeasts. The method comprises the following steps of: dissolving the inactive dried yeasts into water in a ratio of 10-30% to prepare yeast suspension, and then placing the yeast suspension into a sand grinding mill; selecting sand grinding media with the particle diameter of 0.3 to 0.5 mm, wherein the medium materials are glass beads, zirconium silicate beads, compound zirconium beads, alumina beads or steel balls; and crushing the yeasts rapidly within 3 to 5 minutes at a rotating speed of 1,000 to 3,000 rpm, wherein the crushing rate is high. When used for the production of yeast extracts by an enzyme method, the inactive dried yeasts crushed bythe method disclosed by the invention can greatly increase the extract yield; besides, when matched with a continuously-operated sand grinding mill, the method can realize large-scale continuous crushing, and has a wide application prospect in the field of yeast extract industrial production.

Owner:GUANGDONG RECYCLEAN LOW CARBON TECH CO LTD

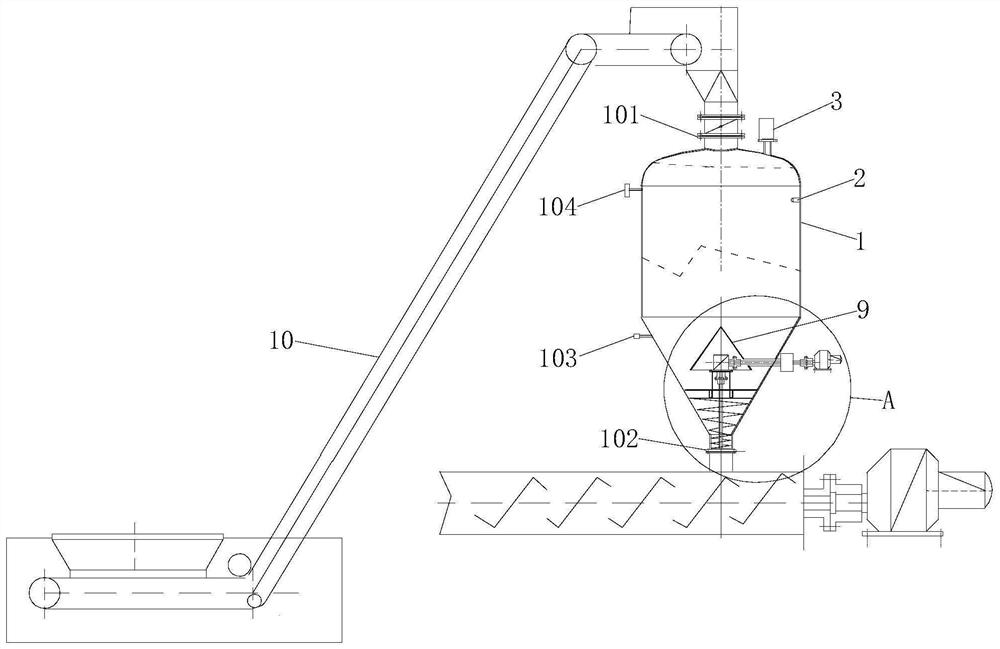

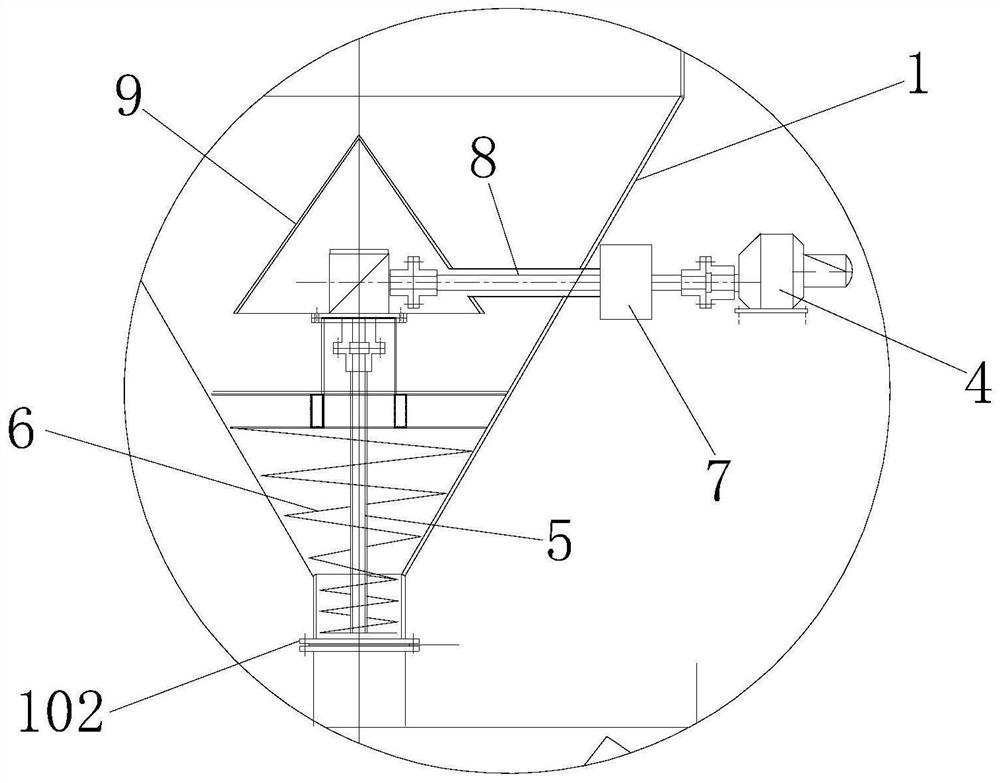

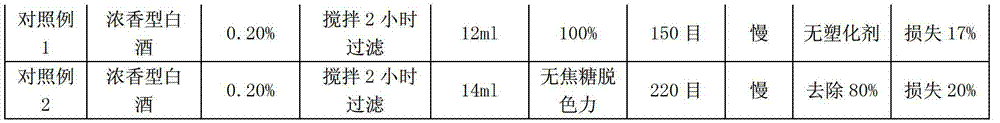

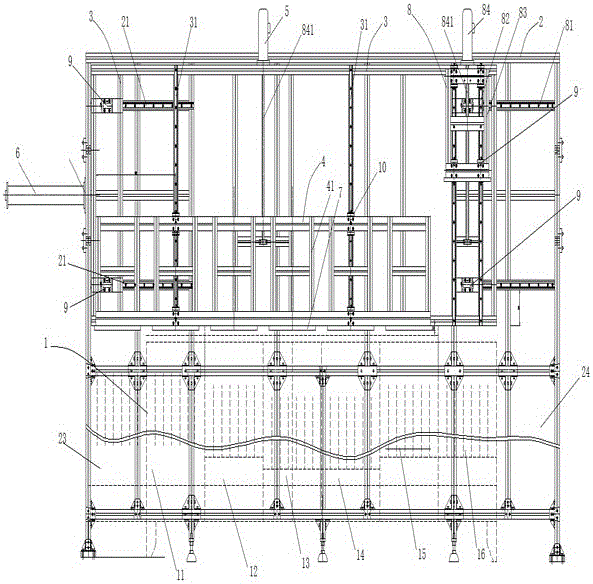

Anaerobic feeding system for pyrolyzing furnace

PendingCN112812795AMeet delivery needsGuaranteed to be inProductsReagentsToxic gasEnvironmental engineering

The invention belongs to the technical field of waste plastic treatment equipment, and particularly relates to an anaerobic feeding system for a pyrolyzing furnace, which comprises a feeding and conveying device, a stock bin and a discharging and guiding device, the upper end of the stock bin is provided with a feeding hole connected with the feeding and conveying device, and the lower end of the stock bin is provided with a discharging hole connected with the pyrolyzing furnace; the discharging and guiding device is used for guiding materials in the stock bin into the pyrolyzing furnace, a nitrogen inlet and an exhaust port are formed in the stock bin, an oxygen content detector is arranged in the stock bin, the nitrogen inlet is in an open or closed state based on a detection signal of the oxygen content detector, and when the oxygen content is larger than a set value, the nitrogen inlet is opened, nitrogen enters the stock bin from the nitrogen inlet to replace air in the stock bin, and the air is exhausted from the exhaust port, so that an oxygen-free environment in the stock bin is ensured, and toxic gas dioxin generated due to the fact that oxygen-containing air is brought in when a feeding system supplies materials to the pyrolyzing furnace is avoided; and meanwhile, the potential safety hazard of burning explosion possibly caused by contact of air and high-temperature oil gas in the pyrolyzing furnace is eliminated.

Owner:周一新 +1

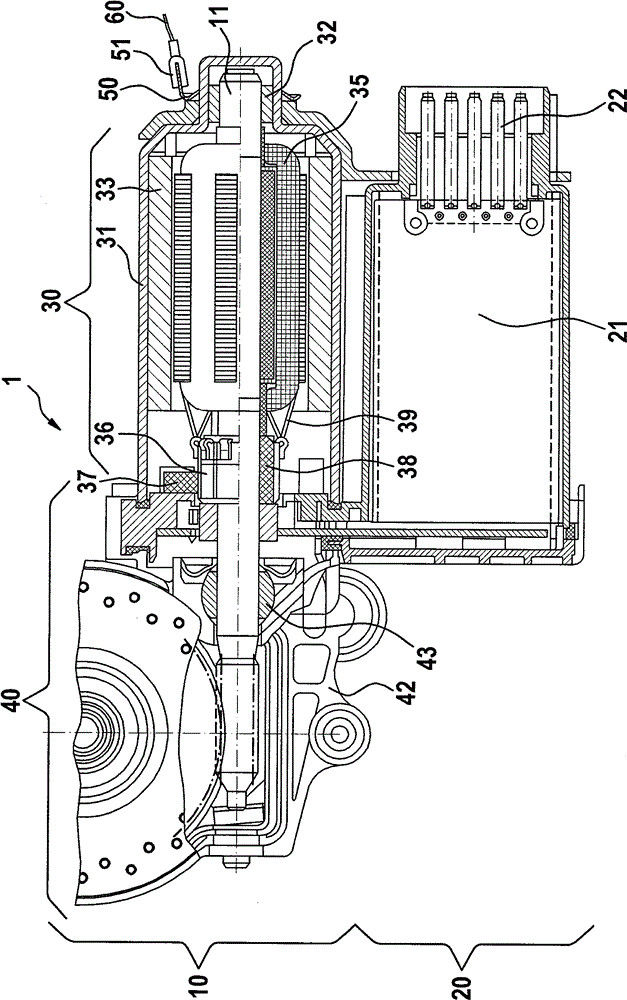

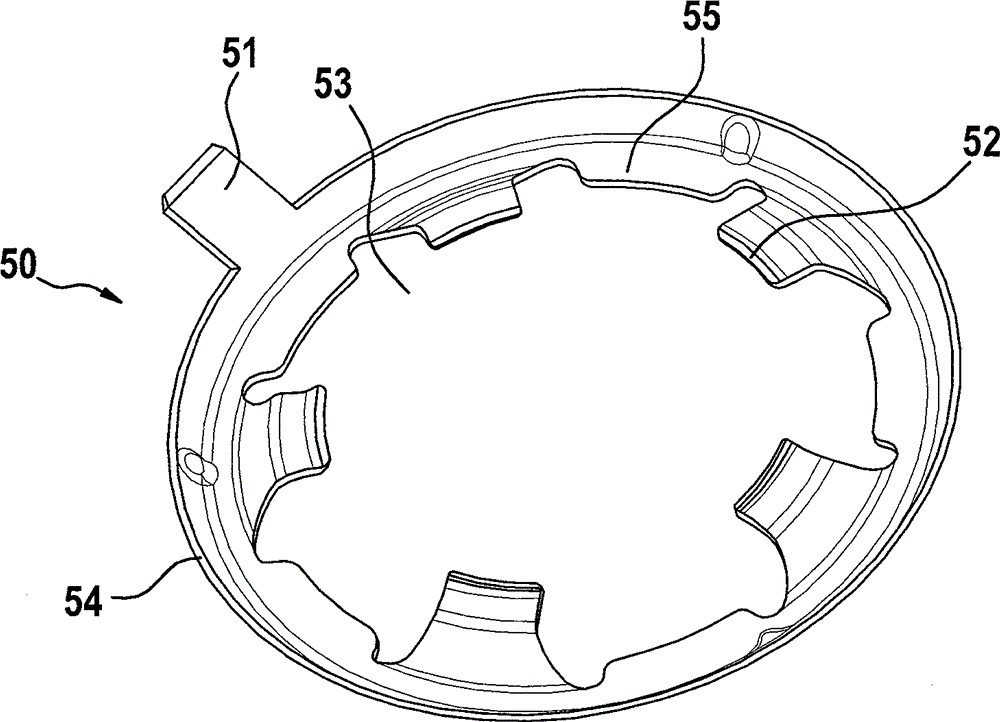

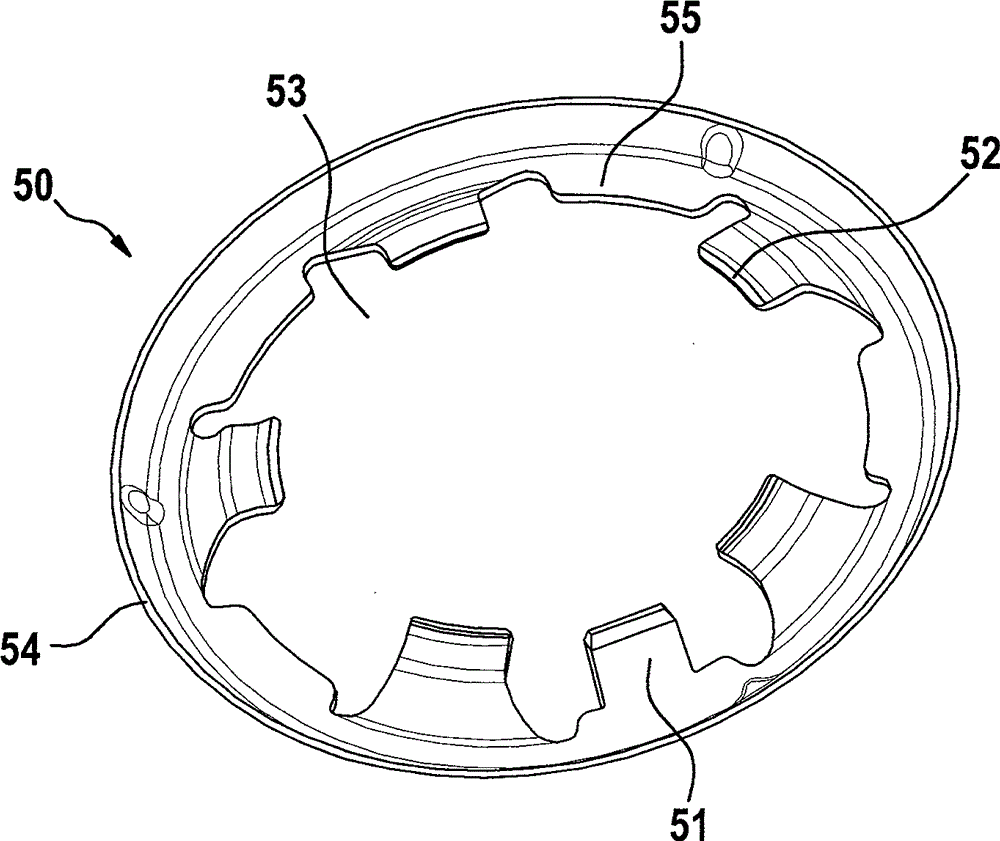

Electric driver for motor vehicle

ActiveCN104104192AImprove noise removalDesparking interference improvementAssociation with grounding devicesMechanical energy handlingEngineeringContact element

The invention relates to an electrical driver (1) for a motor vehicle, which comprises a driving module (10) with a motor module (30), and an electronic module (20). An interference device for the motor module (30) is arranged between the driving module (10) and the electronic module (20). The motor module (30) is provided with an electrode cover (31) used for accommodating a motor. The electrode cover (31) is connected with the motor module (30) through at least one fixing element (50). The fixing element (50) is provided with an additional contact element (51) used for connecting the electrode cover (31) with the bond strap of a vehicle.

Owner:ROBERT BOSCH GMBH

Process for producing liquid pectin

The invention belongs to the field of pectin extraction and manufacture and in particular relates to a process for producing liquid pectin. The process comprises the process steps: crushing the peel raw materials, digesting, performing primary filtering, extracting, performing secondary filtering, performing third-stage filtering, discoloring, desugaring, concentrating and filling. The process for producing liquid pectin is easy to operate and rapid in reaction, discoloring and desugaring are performed by utilizing an ion exchange column, the discoloring degree is high, impurities are prevented from being entrained, sieve concentration is repeatedly performed through molecules, the water, pigment, salt, sugar and small molecular substances can be completely removed, a high-purity pectin solution is obtained, the liquid pectin is filled in a vacuum mode, the outside pollution bacteria are isolated, and compared with the pectin powder, the liquid pectin is convenient to use and fast in absorption.

Owner:ANHUI YUNING PECTIN CO LTD

Special-purpose active carbon for removal of plasticizers in liquor and production method thereof

ActiveCN103394323BKeep the main flavorEfficient removalCarbon compoundsOther chemical processesActivated carbonPlasticizer

The invention provides special-purpose active carbon active carbon for removal of plasticizers in liquor, and the special-purpose active carbon active carbon is characterized in that: the methylene blue adsorption capacity of the activated carbon is 6-9 ml, and caramel decoloration rate is 30-60%. The invention also provides a production method and a use method of the active carbon. The special-purpose active carbon can effectively remove the plasticizers dissolved in the liquor, at the same time, main aroma types of various kinds of liquor can be maximumly retained, and the special-purpose active carbon is easy to remove without introduction of impurities.

Owner:CHONGQING BEYOND OCEAN CARBON MFR

High-efficiency, energy-saving and low-cost automatic cleaning machine

PendingCN106824925AHigh degree of automationGood control precisionHollow article cleaningCleaning using liquidsProgrammable logic controllerElectricity

The invention provides a high-efficiency, energy-saving and low-cost automatic cleaning machine. The high-efficiency, energy-saving and low-cost automatic cleaning machine comprises a plurality of cleaning tanks, a support, a cleaning rack, a cleaning bracket, a cleaning bracket driving part, a cleaning rack driving part, a plurality of cleaning plates and a PLC (programmable logic controller), wherein the cleaning tanks are arranged in the cleaning sequence; the support is erected above the cleaning tanks and is provided with a guide rail; the cleaning rack is arranged on the guide rail and is provided with a sliding rail; the cleaning bracket is arranged on the sliding rail and provided with a plurality of cleaning plate grabbing pieces; the cleaning bracket driving part is arranged on the cleaning rack and drives the cleaning bracket to move along the sliding rail of the cleaning rack; the cleaning rack driving part is arranged on the side wall of one end of the support; the cleaning plates are used for accommodating to-be-cleaned workpieces, the number of the cleaning plates corresponds to that of the cleaning tanks, and the cleaning plates are connected with the cleaning plate grabbing pieces of the cleaning bracket; the PLC is electrically connected with the cleaning rack driving part and the cleaning bracket driving part. The cleaning machine is high in automation degree, can realize continuous cleaning of pipes or bars, is high in cleaning efficiency, long in service life, reasonable in structural design and good in economic benefit, and is low in labor cost due to the fact that the whole cleaning machine can be operated by only one worker.

Owner:淮安展德光电科技有限公司

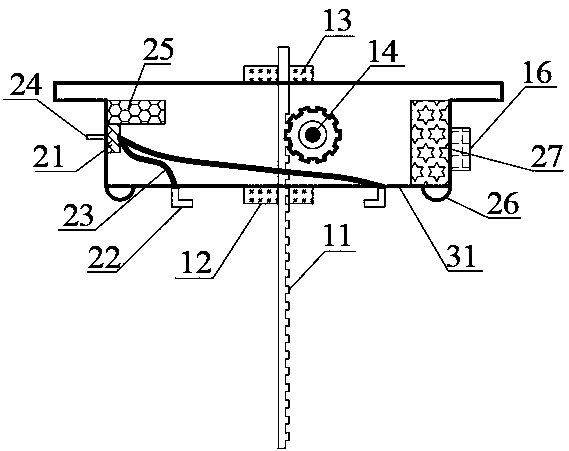

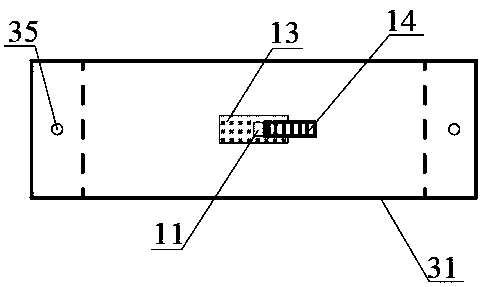

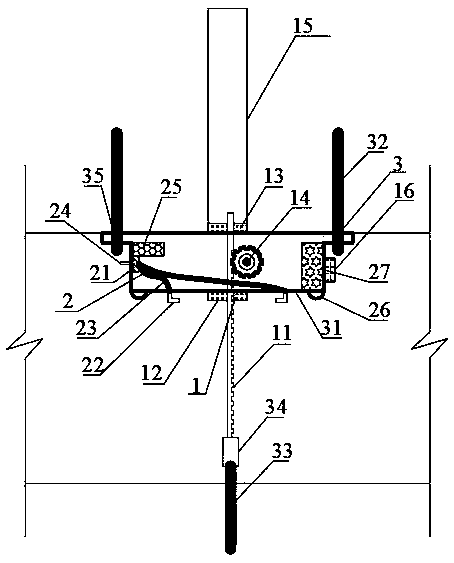

Wide-range roof-to-floor convergence tester and application method thereof

PendingCN110514093ALarge rangeTest accurateCleaning using liquidsMechanical measuring arrangementsComputer moduleComputer science

The invention discloses a wide-range roof-to-floor convergence tester and an application method thereof and aims to solve the problem in roof-to-floor convergence measurement of an existing coal minetunnel. The wide-range roof-to-floor convergence tester comprises a convergence test module, a water spraying and dust removal module and a fixed connection module, wherein the fixed connection moduleis used for integrating the convergence test module and the water spraying and dust removal module in a dustproof shell and fixing the whole instrument between roof and floor of the tunnel. The roof-to-floor convergence of the tunnel is recorded by relative moving of a tooth-shaped groove rod and a gear displacement meter, the tooth-shaped groove rod is deepen into a roof drilling protection pipeand is large in test range, the tooth-shaped groove rod is periodically cleaned by the special water spraying and dust removal model, a displacement test module is enabled not to be invaded with coaldust, and meanwhile, the wide-range roof-to-floor convergence tester is compatible with functions of convergence early warning and collision-prevention warning. The wide-range roof-to-floor convergence tester is suitable for long-term observation of roof-to-floor convergence of the coal mine tunnel and has the advantages of large range, test accuracy, high site applicability and the like, and thetest accuracy and instrument safety are ensured.

Owner:SHANDONG UNIV OF SCI & TECH

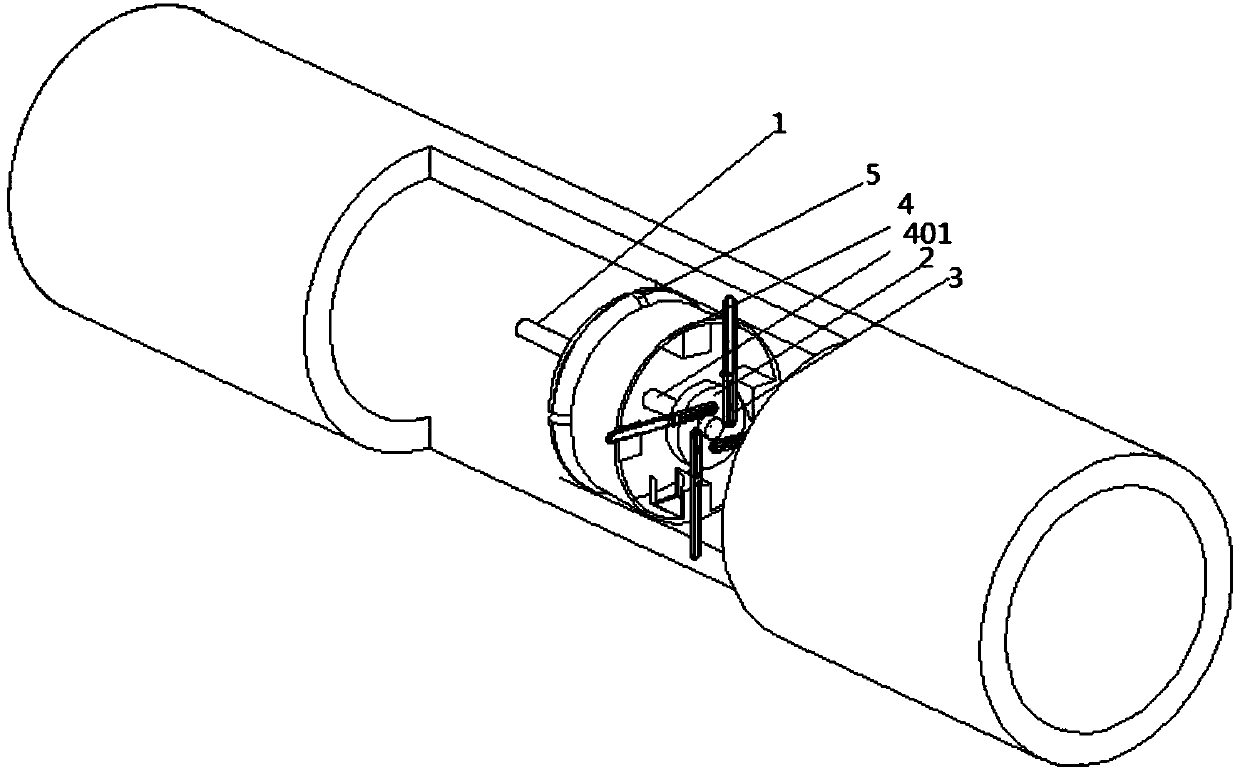

Cleaning head mechanism for cleaning inner wall of pipeline

InactiveCN107597754AConserve waterWill not bring inHollow article cleaningDirt cleaningWater qualityMechanical engineering

The invention provides a cleaning head mechanism for cleaning the inner wall of a pipeline. The cleaning head mechanism comprises a fixing shaft. A fixing disc is arranged on the fixing shaft. Four dirt removing blades are arranged on the fixing disc and are fixed to the fixing disc through fixing bolts. A dirt collecting box is arranged on the rear side of the fixing disc. The dirt collecting boxis cylindrical, and the front end of the dirt collecting box is of an opening structure. A hollow shaft is arranged in the middle of the dirt removing box. The fixing shaft is inserted into the hollow shaft to be fixed. Four dirt shoveling devices are arranged and are evenly distributed on the inner side face of the dirt collecting box. By means of the cleaning head mechanism for cleaning the inner wall of the pipeline, the dirt removing blades can rotate to shovel dirty marks adhering to the inner wall of the pipeline away, afterwards, blots which are shoveled away can be collected through the dirt collecting box and brought out of the pipeline along with running of the device, a rotary wiping device is additionally arranged so that the inner wall of the pipeline can be thoroughly wiped,the rest of few blots are brought out of the pipeline, water does not need to be used in the working process of the device, water can be used, and in addition, the blots in the pipeline cannot be brought into a river and pollute the water quality.

Owner:安徽大地环保科技有限公司

High-purity molten cast iron nitrogen increasing agent and nitrogen increasing method for blast furnace smelting

InactiveCN110283952ASimple ingredientsReduce contentBlast furnace detailsNitrogenBlast furnace smelting

The invention provides a high-purity molten cast iron nitrogen increasing agent for blast furnace smelting. The high-purity molten cast iron nitrogen increasing agent is prepared from, by weight, 25%-30% of N, 10%-15% of Mn and 35%-55% of Si. The invention further provides a high-purity molten cast iron nitrogen increasing method for blast furnace smelting. The method comprises the following steps that S1, the nitrogen increasing agent is crushed and sieved, and then the nitrogen increasing agent and blast-furnace normal injection pulverized coal are mixed to be uniform in proportion to obtain a mixed injection coal material; and S2, the mixed injection coal material containing the nitrogen increasing agent is put into a coal injecting tank of a blast-furnace coal injection system and conveyed to a blast-furnace tuyere through an injection pipeline, and then enters a blast furnace through a tuyere coal injection gun. According to the high-purity molten cast iron nitrogen increasing agent and nitrogen increasing method for blast furnace smelting, the nitrogen increasing agent is injected and enters molten iron, so that the influence of a slag layer is avoided, and the molten iron nitrogen increasing environment is improved. Combined with a normal coal injection process, the nitrogen increasing agent is uniformly injected, the segregation phenomenon of the nitrogen increasing agent and the pulverized coal is not generated, the content of N in the molten iron can be significantly increased, the blast-furnace production process and equipment procedures are not changed, and the industrial production adaptability is high.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com