Connection method of anti-inclusion pouring cup for large casting

A technology of large-scale castings and connection methods, applied in the direction of molds, cores, mold components, etc., can solve the problems of waste of metal materials, metal materials that cannot be recycled, and difficult to separate, so as to reduce production costs and ensure delivery progress , Improve the effect of metallurgical quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

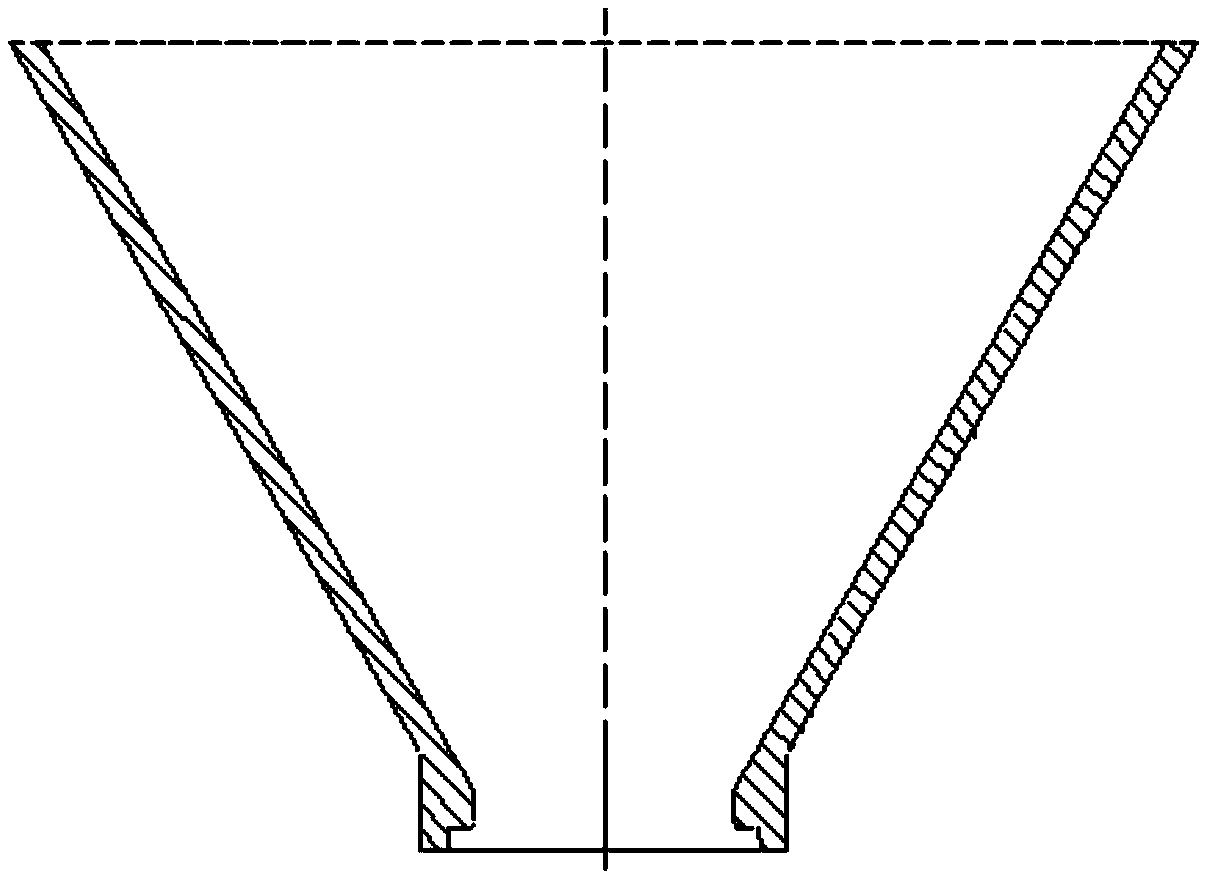

[0032] The implementation process of the connection method of the anti-inclusion sprue cup for large castings is: making the sprue cup mold and wax parts - making the sprue cup platform stage mold and wax parts - connecting the sprue cup and the sprue cup platform stage Wax parts—making sprue cup mating section molds and wax parts—sprue cup mating section wax parts are assembled and welded to the casting gate position—sprue cup assembly shell making—large casting shell making—sprue cup Combination of component shells with large casting shells - shell preheating, pouring.

[0033] The connection method process of the anti-inclusion sprue cup for the large casting is as follows:

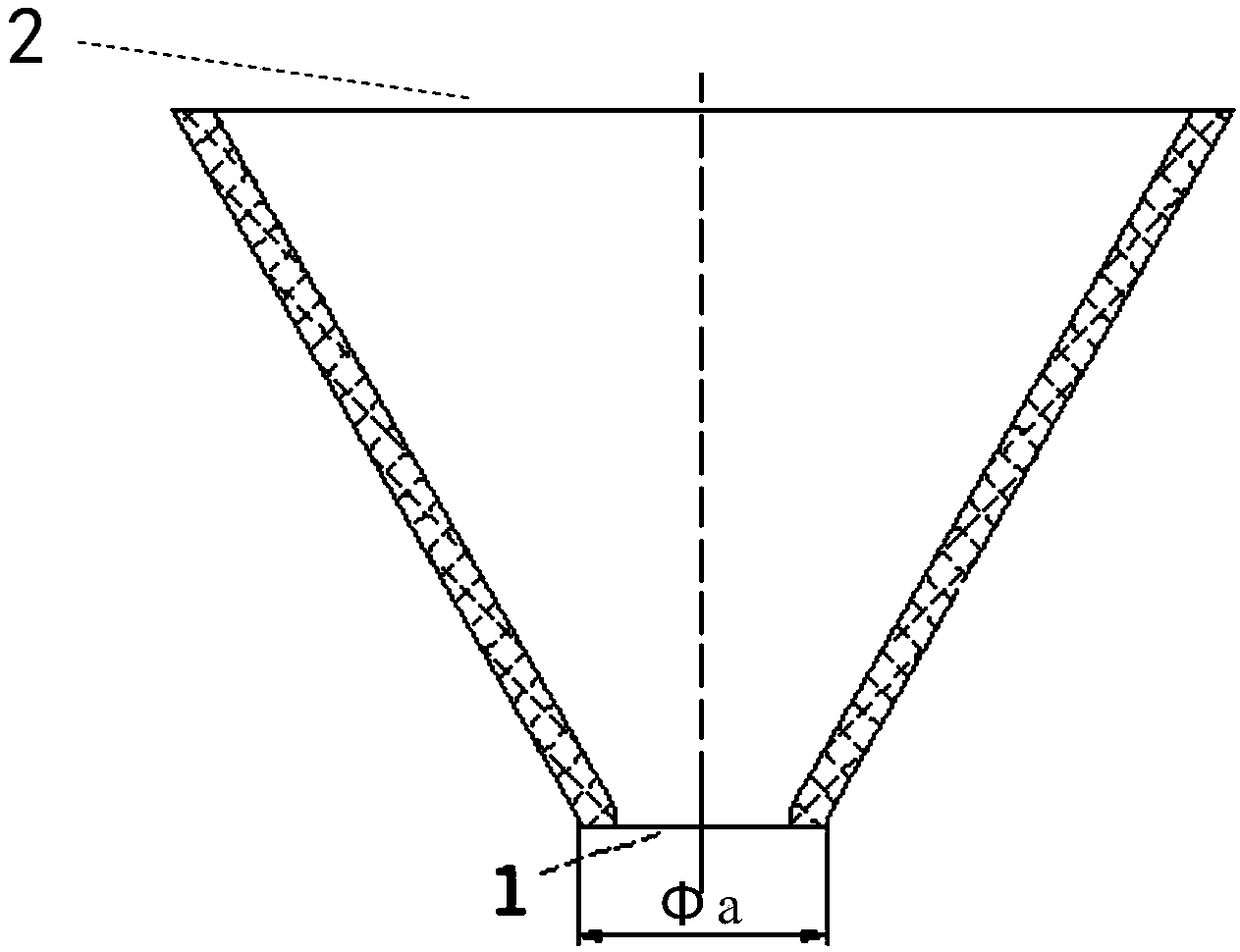

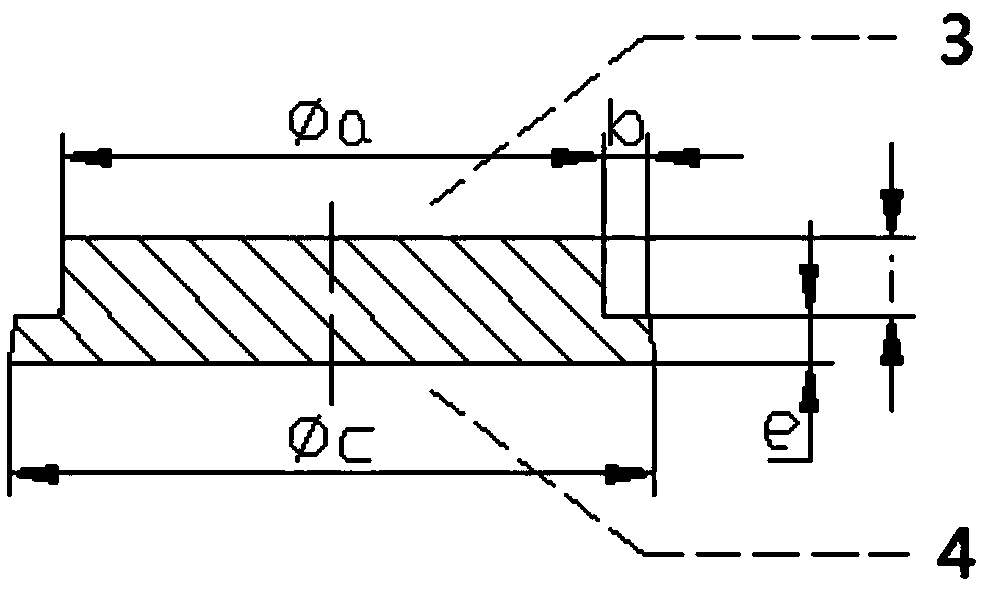

[0034] ① Make sprue cup and sprue cup platform stage molds, and press wax patterns; sprue cups can be funnel-shaped, see the attached figure 1 , to make the gate stage mold, see the attached figure 2, the mold of the gate cup platform stage is a ring-shaped wax piece, ensuring that the upper opening...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com