Special-purpose active carbon for removal of plasticizers in liquor and production method thereof

A technology of activated carbon and plasticizer, which is applied in chemical instruments and methods, preparation of alcoholic beverages, inorganic chemistry, etc. It can solve problems such as chronic damage to the immune system and digestive system, increase the burden on the liver and kidney, and interfere with endocrine, etc. Clear and transparent, the effect of reducing the spicy feeling and reducing the stimulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

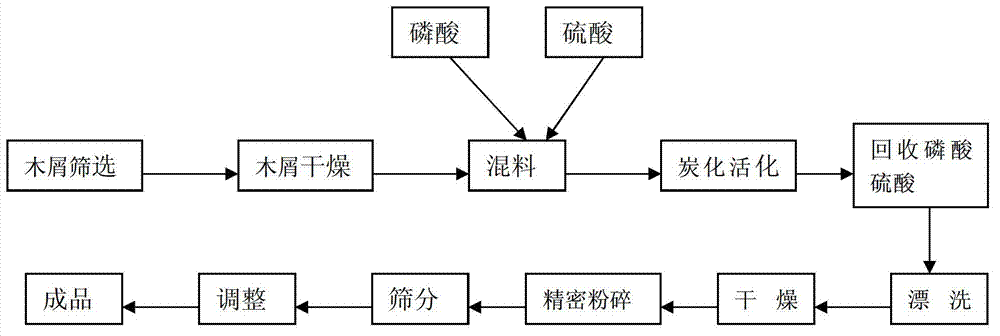

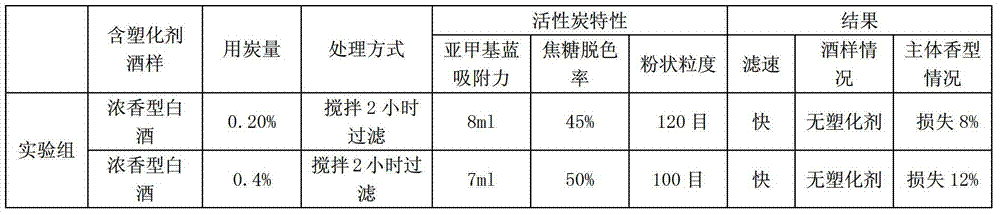

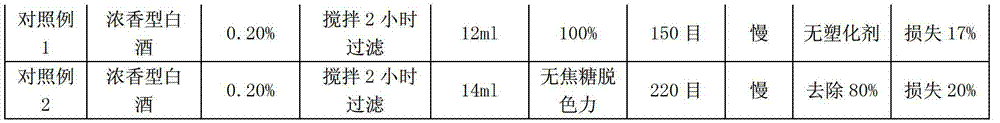

[0021] Experimental group: Sawdust is screened to remove wood blocks and silt, and then dried to remove part of the water and then mixed with activator phosphoric acid and auxiliary agent sulfuric acid. The ratio of anhydrous sawdust, phosphoric acid and sulfuric acid is 1.0:0.7:0.1. The mixture input The activation furnace is used for carbonization and activation, the activation temperature is 450-500°C (material temperature), and the activation time is 40-60 minutes. After recovering phosphoric acid and sulfuric acid from the activated material, the residual acid is further washed to make the pH value reach 3.5. Then dry it so that the moisture content is less than 10%, and then send it into precision crushing and sieving to control the particle size of the activated carbon powder to be 100-120 mesh. Finally, the product is adjusted so that the adsorption capacity of methylene blue is 7-8ml; the decolorization rate of caramel is 45-50%; the granularity of activated carbon po...

Embodiment 2

[0031] The special carbon of the present invention is prepared from the experimental group of Example 1. Table 2 shows the physical and chemical analysis and sensory evaluation results before and after using the special activated carbon to treat liquor.

[0032] Table 2

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com